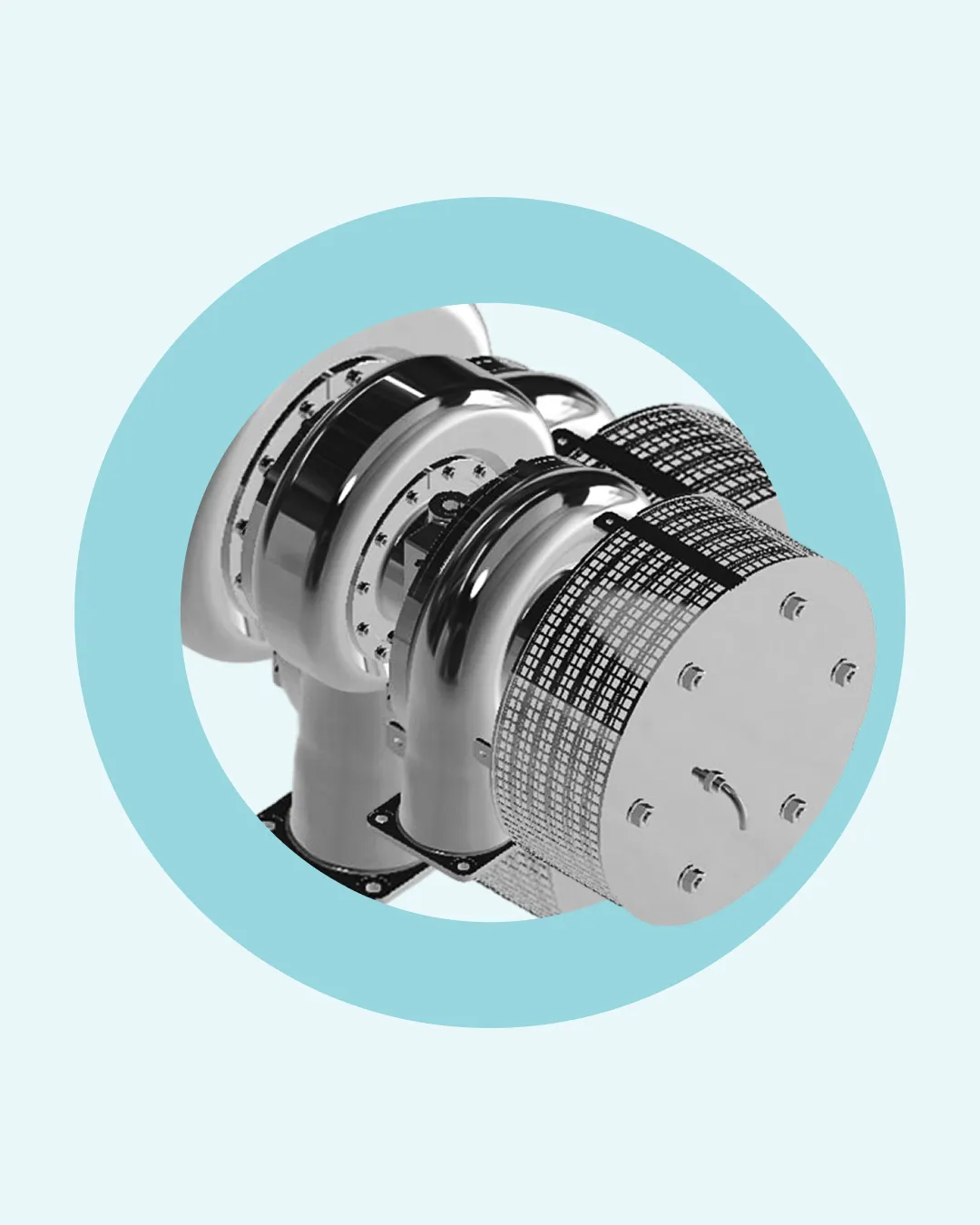

Are you looking for a trouble-free turbocharger operation without compromising on quality?

Engines designed by Everllence (former MAN Energy Solutions) have been equipped with MET turbochargers for more than four decades. As an original equipment manufacturer (OEM) for our own produced turbochargers, we know how important it is to maintain the highest quality standards in order to deliver the best overall lifetime performance. With this core value in mind, Everllence PrimeServ maintains the same standard for the Mitsubishi turbocharger series. All spare parts installed in your turbocharger are from the OEM, and service is performed by our experienced certified service engineers.

Everllence PrimeServ has over 15 years of experience in providing service, maintenance, repair, and original spare parts by being an authorized repair agent for MET Turbochargers. Our network currently consists of eight authorized service centers, with additional locations expecting to open in the near future.

Our services

- Maintenance and repair of all MET axial and radial turbochargers

- Pre-dry dock inspections of MET axial turbochargers

- Global supply of original spare part kits and replacement parts with short delivery times

- Exchange-based service solutions

- Integration of MET services into existing Everllence service agreements

- Management of consignment stock

Your benefits

- Global one-stop shop service and spare part supply for your Everllence and MET turbochargers

- OEM-level service supplier with centuries of experience in turbocharger service and repairs

- Seven MET-authorized workshops and certified service engineers

- 24/7 flexible service and support

- Six month Everllence PrimeServ warranty

Download the latest MET service letter

According to the manufacturer's experience, aged deterioration of wear parts that have been exposed to exhaust gases (also called hot-parts) is frequently observed after around 10 years in operation. In the service letter below, we offer in-depth information regarding the inspection of turbocharger hot-parts.

Avoid dry dock delays and unbudgeted costs with our MET pre-inspection service

MET axial turbochargers are usually operated so that major overhaul services are carried out during the vessel’s dry docking period. Unfortunately, unexpected damages on wear parts exposed to exhaust gases (e.g., turbine blades, nozzle, gas outlet guide) are often discovered during the overhaul.

As these spare parts are not included in the major overhaul kit (C1 and C2), this may lead to unbudgeted costs as well as delays in dry-dock. To avoid such unexpected findings and possible delays, we recommend a pre-inspection of the turbocharger turbine side three to four months ahead of the scheduled dry docking or major overhaul.

Trust Everllence for authorized MET pre-dry dock inspections

As an authorized repair agent for MET turbochargers, Everllence PrimeServ offers pre-dry dock inspections of your MET turbocharger. As an alternative, we also provide our customers with an inspection report, which can be completed by the crew. Free of charge and without obligation, Everllence PrimeServ will evaluate the returned report and confirm the condition accordingly.

Important numbers

Fact about

MET-authorized

Contact our experts

Contact your nearest MET-authorized repair agent

As an OEM with decades of experience in turbocharger service and repairs on our own Everllence turbochargers, the majority of our global service locations can provide maintenance and repairs for your MET equipment. To find the nearest Everllence PrimeServ service center, please visit the location finder.

Resources hub

Find even more information about MET turbochargers

Downloads

Contact our Everllence PrimeServ experts

Omnicare services