Diesel to dual-fuel gas conversion

Our service engineers provide preventive maintenance, assist your troubleshooting, and get your facilities up and running in no time – wherever and whenever you need them.

One of the biggest retrofit options is to convert an existing diesel engine to a dual-fuel gas engine. This enables you to switch between diesel and gas as necessary, to both reduce operational costs and take advantage of optimal fuel prices as they arise.

In addition, using alternative fuels, such as LNG, ethane, LPG, or methanol, mean you can greatly

reduce SOx, NOx, CO2, and particulate matter, enabling you to comply with global environmental regulations, secure worldwide port access, and meet your own sustainability targets.

Important numbers

Facts about dual-fuel conversions

approximately

and more

and more

The project scope of a dual-fuel conversion

The scope includes changes to the main engine, installation of a Fuel Gas Supply System (FGSS), and the installation of bunker tank(s) or integration into an existing gas cargo system. In addition, Everllence can also provide turnkey solutions that include the FGSS. The following explanation is based on an LNG conversion.

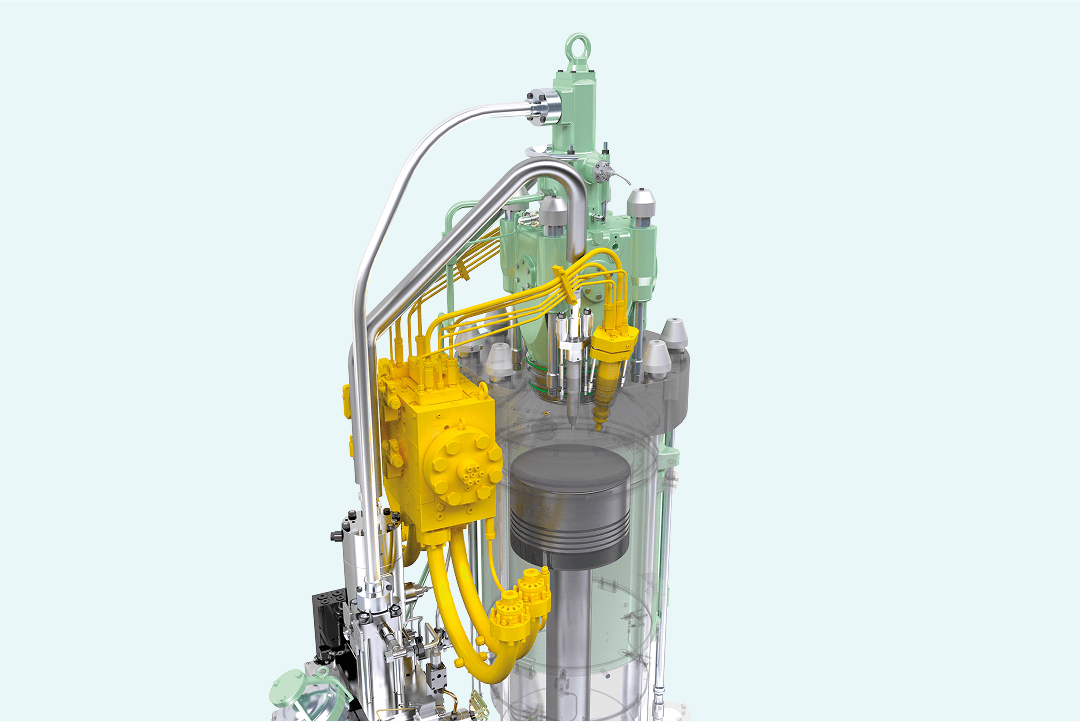

Engine conversion

The engine conversion mainly consists of rebuilding existing engine parts to enable the installation of a gas safety system and a fuel injection system.

This includes exchanging the existing cylinder cover and fuel oil pipes, and adding gas injection valves, gas control blocks, and gas chain pipes. Additional parts may also need changing, which is determined by a detailed study of your engine.

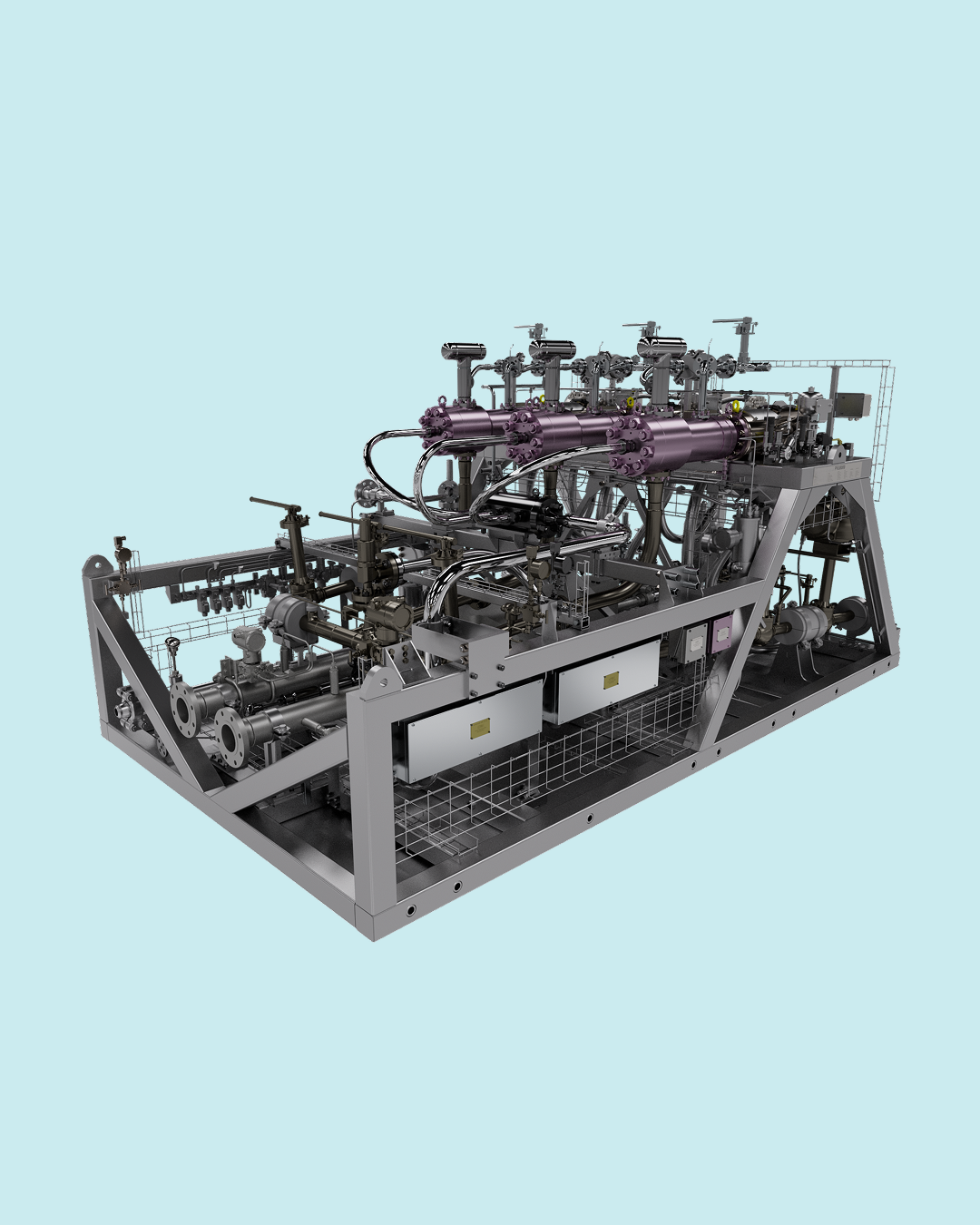

FGSS for LNG

As with any dual fuel engine, to deliver efficient gas injection the conversion requires a complete Fuel Gas Supply System (FGSS). The main function of this, together with a Gas Valve Train (GVT), is to pressurize and vaporize LNG from liquid to gas by increasing the pressure to 300 bar and 45°C, so that it can be injected into the engine.

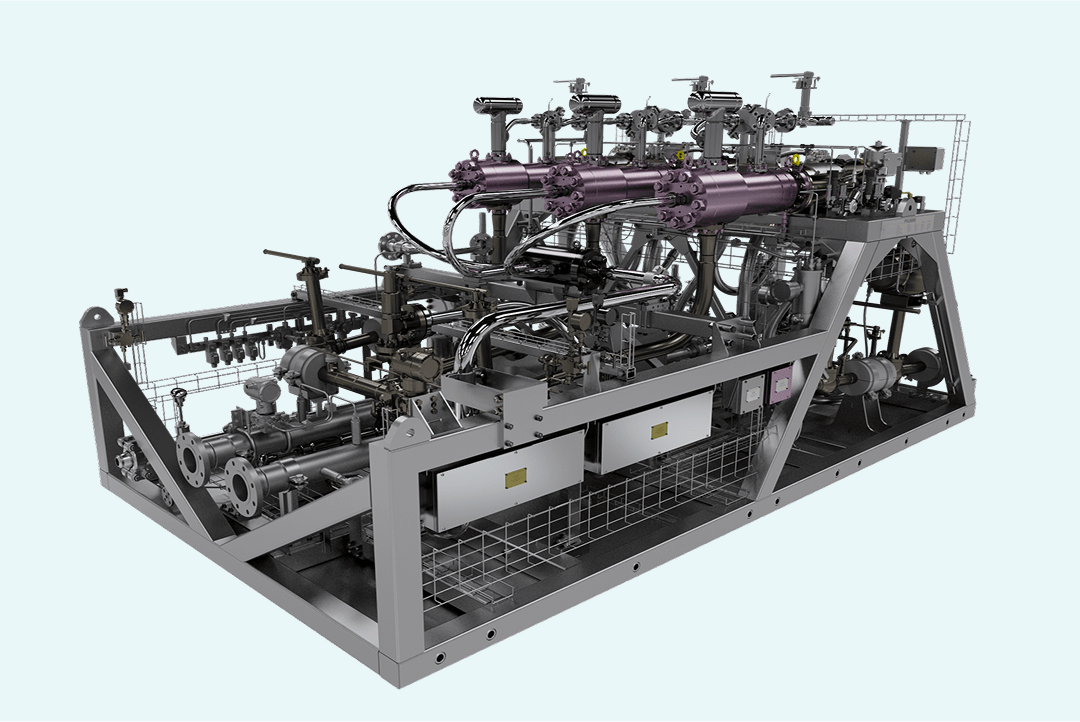

In recent years, Everllence has developed a Pump and Vaporizer Unit (PVU) that is interlinked with our main engine control system and forms a main part of the FGSS.

Bunker tanks or an integration

If the vessel does not already operate with gas as a cargo, bunker tanks for your chosen fuel will be required. This is an important decision and can be one of the project’s largest financial considerations.

Choosing the right bunker tank(s) depends on several factors, such as tank type, size, location, and price. If the vessel you are converting is a gas carrier, you can benefit from an integration to the existing cargo system.

“ A retrofitted vessel generates 35 times less CO2 emissions compared to a news build vessel. ”

Pontus Berg, Executive Vice President, BW LPG Ltd

By loading the video you agree to YouTube's privacy policy.

Contact our experts

Ready to start?

Everllence Are you looking to increase the efficiency, longevity, and profitability of your vessel with a dual-fuel retrofit conversion? Simply contact us and we’ll be in touch to start exploring your options.