PrimeServ

The world’s most efficient two-stroke engine for methane as a fuel

Perfect for newbuilds or retrofits, the ME-GI engine minimizes operating costs by delivering industry-leading thermal efficiency – no matter which fuel is used. This makes the ME-GI dual-fuel engine particularly advantageous for container vessels operating in markets with fluctuating fuel prices.

The ME-GI engine is compatible with both bio-methane and synthetic natural gas (SNG), offering a clear pathway to reduce greenhouse gas emissions. With this flexibility and performance, ME-GI engines are paving the way for more sustainable propulsion systems across global fleets.

Methane-fuelled two-stroke engine

Meet the world’s most efficient two-stroke engine for methane

By loading the video you agree to YouTube's privacy policy.

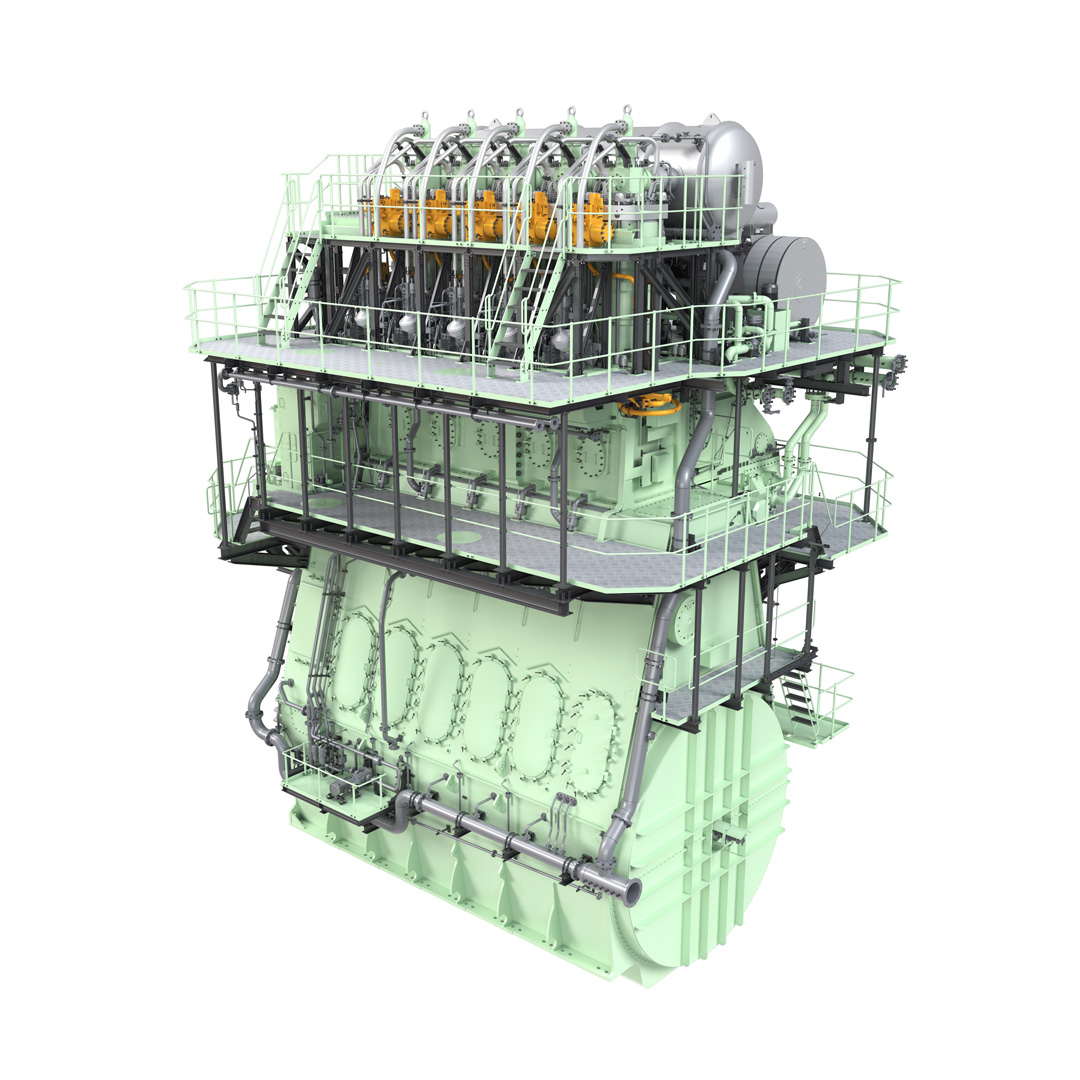

The ME-GI engine

Next-generation performance and efficiency

The Everllence B&W ME-GI engine is designed to meet the demands of next-generation shipping by combining outstanding fuel flexibility, low emissions, and a host of engineering upgrades for reliable, long-term performance. With its proven dual-fuel concept, the ME-GI engine sets new benchmarks in efficiency and environmental compliance – making it a future-ready solution for LNG and methane-powered vessels.

Key benefits of the ME-GI dual-fuel engine

The ME-GI dual-fuel engine, based on trusted two-stroke technology, offers a wide range of operational advantages:

- Proven two-stroke Everllence B&W engine technology

- Minimal environmental impact thanks to negligible methane slip and reduced CO₂ emissions

- No need to compensate with liquid oil fuels in low methane number conditions or high ambient temperatures

- Flexible operation on fuel oil or LNG / methane

- No knocking issues

- Supports waste heat recovery (WHR)

- Easier retrofit compared to Otto cycle engine

These key features make ME-GI engines a preferred choice for shipowners or operators seeking performance, flexibility, and long-term regulatory compliance.

Contact our Everllence energy support experts

Let our expertise work for your business

Everllence provides the advice and solutions you need to make your business ready for the future. Get in touch today - and we'll set you up for a successful tomorrow.

Lower OPEX through fuel flexibility and optimized systems

The ME-GI engine is engineered for lower operating costs across all fuel scenarios. It delivers the same industry-leading thermal efficiency regardless of fuel type – a major advantage in volatile energy markets where LNG bunkering becomes increasingly standardized.

Auxiliary equipment costs have been reduced, and installation has been simplified. In addition, multiple system improvements contribute to a more environmentally friendly operation. These benefits reinforce the ME-GI dual-fuel engine as a smart investment for modern fleets.

Upgraded components for maximum efficiency

The latest generation of the ME-GI engine includes a comprehensive set of component upgrades that improve reliability, boost efficiency, and lower OPEX, helping you to stay competitive in a challenging market.

- Lowest gas consumption of any marine two-stroke engine

- Simplified piping system enables a more compact installation with fewer components and lower maintenance costs

- New gas block with enhanced window valve enables cut-out of cylinder operating on gas, while allowing continued operation on fuel oil

- Updated pilot oil injection system enables reduction of pilot oil energy fraction to as low as 1.5% at 100% load (L1 rating) for specific bore sizes*

- Optional compact Pump Vaporiser Unit (PVU) features embedded redundancy and integrates directly with the ME-GI engine control system

*Performance values indicated refer to energy fraction for L1 rated engines operating at 100% load point in Tier II mode. Actual values may vary depending on engine rating and load conditions.

What else is there to know about the ME-GI engine?

Core questions on performance, fuel, and emissions answered.

The low methane slip on ME-GI engines is achieved through several design and combustion-related factors:

- Use of the diesel cycle, which ensures complete combustion due to very high temperatures and a rich fuel mixture

- A high compression ratio

- An optimal design of combustion chamber and components

These features make ME-GI dual-fuel engines stand out for both performance and environmental compliance.

Discover related products

B&W ammonia engine development

Everllence is aiming to deliver the first ammonia engine, the Everllence B&W ME-LGIA, to a shipyard in 2025. It will be available as newbuild or retrofit.

B&W ME-C

Our ME-C engines with electronic controls serve up a host of advantages. You can look forward to superior performance parameters, compactness, fully integrated electronic control as well as the necessary fuel injection pressure and rate shaping at any load. Plus, the ME-C engine can be retrofitted for alternative fuels such as methanol, LPG, methane or ethane as well as ammonia estimated for 2026.

- Engine speed: rpm to 56 – 167

- Output: 4,350 – 82,440 kW at L1

The technology of the ME-GIE is based on our successful ME-GI engine. This engine can be operated with liquefied ethane gas (LEG) as well as fuel oil – which makes it the standard choice for ethane carriers. This engine offers very competitive fuel oil and gas consumption, plus operational stability and efficiency due to the diesel principle.

- Engine speed: 72 – 100 rpm

- Output: 8,600 – 21,440 kW at L1

Our ME-LGIM is a dual-fuel engine characterized by its high efficiency and capability of operating on methanol. With a proven record of more than 600,000 operating hours on methanol alone, the engine concept provides a high degree of reliability. When fuelled by green methanol, our ME-LGIM engine can offer truly carbon-neutral propulsion, while reducing sulfur and particle matter emissions significantly at the same time.

- Engine speed: 56 – 125 rpm

- Output: 6,950 – 82,440 kW at L1

B&W ME-LGIP

Our ME-LGIP is the only two-stroke dual-fuel engine on the market which can be fuelled with LPG. The low operational costs as well as the simple retrofit solution are particularly convincing.

- Engine speed: 72 –103 rpm

- Output: 8,600 – 22,720 kW at L1

Hapag-Lloyd’s new LNG container vessel

Hapag-Lloyd takes a major steps in the direction of decarbonization. The company ordered a methane-powered container vessel with a dual-fuel engine that can also run on synthetic methane.

The world’s largest and cleanest car carrier

Höegh Autoliners is introducing the world’s largest and most environmentally friendly car carrier, the Höegh Aurora. This vessel is able to run on both traditional fuels and methane as part of their groundbreaking fleet renewal program.

Alternative fuels for your two-stroke powered vessel: Ammonia, methanol and methane in focus

Watch the recording of our Everllence ExpertTalk on alternative fuels for large merchant marine vessels. Get insights into the most promising marine fuels of the expected future fuel mix for two-stroke vessels, namely ammonia, methanol and methane.

ME-GI Engine Orders Pick Up Momentum in LNG Carrier Segment

Surge in ME-GI engine orders confirms market leadership in LNG carriers

Downloads

Get more insights on our ME-GI engines

Events

Two-stroke Everllence ExpertTalks