Digital Twins

We use digital twins to simulate very complex turbomachinery systems and their behavior and management, by means of artificial intelligence, allowing the equipment to be optimized even before it is installed. This lets us accelerate the design of complex control concepts in an early phase and allows for the development of special software functions. The execution of the virtual commissioning before live commissioning also reduces real-life setup time. Benefits of using digital twins include customized software solutions, improved software quality, increased efficiency through optimized process control, reduced commissioning time and simulation-based operator training.

Remote monitoring

Your turbomachinery generates valuable operational data every second. Our digitally enabled services use this data to keep you one step ahead—ensuring reliable performance, minimizing downtime, and optimizing operations based on real-time insights.

At the core is secure, high-speed connectivity to PrimeServ’s global Remote Operation Center. Our experts continuously monitor system parameters, detect irregularities, and provide timely support to keep your assets running at peak performance.

Our digital services and digital solutions are modular, scalable, and can be tailored precisely to your operational needs—from basic monitoring to full lifecycle support.

On-Premises solutions

Industrial automation requires control systems with powerful computational capacity. For this purpose, we have developed a versatile control system extension that runs locally on industrial personal computers (IPCs). An IPC is an expandable and customizable on-premises hardware solution that offers high performance with industry-standard safety and availability. This boost in performance allows you to enjoy the full benefit of our digital solutions. Connected directly to the control system via a secure and reliable communication channel, the IPC acts as the perfect platform for multiple AI-based apps such as the “virtual sensors app” or the “compressor/heat exchanger performance monitoring app”. As an independent extension, the system can easily be updated, and new intelligent automation solutions can be integrated to suit your changing needs.

Autonomous operations

Autonomous operation in turbomachinery is rapidly evolving, driven by digital innovations and cross-industry expertise. Everllence outlines a strategic roadmap toward fully unmanned, energy-efficient systems by 2028, supported by AI, digital twins, and remote services.

Our digital roadmap - our mission

We believe that digitalization is more than just a tool — it’s a mindset. At Everllence, our mission is to unlock the full potential of turbomachinery through intelligent technologies and strategic innovation. With our digital roadmap guides the journey, we are advancing toward predictive, unmanned, and ultimately autonomous operation. Every step takes us closer to more sustainable, efficient, and cost-effective plant performance.

Next-generation automation means increased efficiency. At Everllence, we see it as our mission to make turbomachinery operation more, smarter, and more sustainable — accelerating the energy transition. Higher levels of automation benefit the environment and improve the cost-effectiveness of industrial plants. Digitalization and AI will soon enable fully autonomous operation of turbomachinery trains.

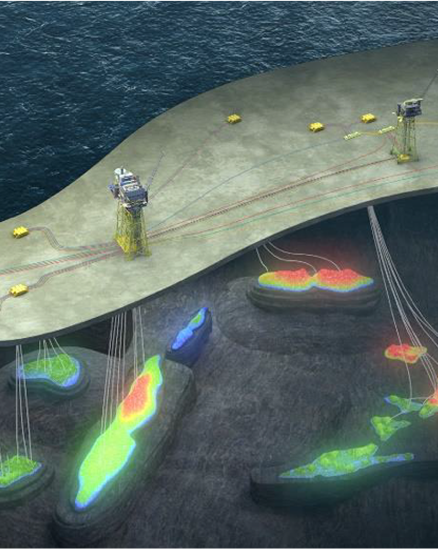

With the progress of digitalization and AI, fully autonomous turbomachinery trains are no longer a distant vision. Many upstream topside, subsea, and midstream applications are already fully automated — operated remotely and without on-site personnel.

The ultimate goal: energy-efficient, autonomous remote operation of entire process plants. Since 2021, Everllence (formerly MAN Energy Solutions) has supported customers with near-autonomous operation across all market segments. By 2028, we aim to deliver fully autonomous operation for all our turbomachinery systems — ensuring continuous, unmanned, safe, and energy-optimized performance.

Maintenance is evolving from routine-based tasks to insight-driven strategies. Everllence is driving the automation of key steps in the maintenance cycle, including condition assessment, diagnosis and prognosis. These developments lay the foundation for a gradual shift away from reactive interventions and fixed schedules toward predictive, data-informed maintenance approaches.

Our digital solutions continuously monitor turbomachinery performance and apply intelligent algorithms to detect anomalies, assess system behavior and anticipate potential issues before they escalate. These insights enable earlier, more targeted interventions that help minimize downtime, optimize resources and reduce the total cost of ownership.

The goal is maintenance that responds to actual machine needs in real time. With condition-based triggers and AI-supported diagnostics, service becomes proactive, precise and seamlessly integrated into operations, ensuring stable performance, greater reliability and maximum asset availability.

Clear value

Our digital solutions deliver measurable benefits across all dimensions of industrial turbomachinery operation:

- Safe – ensuring secure and protected operations

- Seamless integration – easy to implement into existing systems

- Unmanned – designed for autonomous operation

- Reliable – consistent performance under all conditions

- Energy efficient – optimized for reduced energy consumption

- Uninterrupted – continuous operation with minimal downtime

Discover more

Our digital innovations

Contact our Everllence digital expert team

Let’s talk digital transformation

From AI-powered control to secure automation and secure automation — our experts help you define the right digital strategy for your turbomachinery

Remote commissioning of a compressor train

In 2020, the Covid-19 pandemic interrupted the construction of a new nitric acid plant in Uzbekistan, forcing engineers from Everllence to embark on a historic step in mechanical engineering: the first fully -remote supervisioned commissioning of a compressor train using digital technology. Our mobility was restricted but we had completed the necessary preparation and had the required digital tools.

Unmanned operation of upstream topside compressors

Everllence is delivering highly digitalized compressors for the first unmanned gas production platform in the Yggdrasil field in the North Sea. Designed for fully remote operation without crew, the platform will be controlled entirely from an onshore operations center. Everllence’s digital solution enables automated operation of the two HOFIM® motor-compressor systems, improving safety, reducing operating costs and lowering the environmental impact of offshore production.

Download