High performance built on decades of experience

A fully sealed compressor which pushes the boundaries

Our HOFIM® improves oil and gas recovery while reducing emissions. Its high-speed motor with magnetic bearings enables low-maintenance, quiet operation with no warm-up and unlimited starts. Suitable for pipeline, subsea, LNG, hydrogen and CO₂ applications.

Typical performance data:

- Compression power up to 18,000 kW (24,000 HP)

- Discharge pressure up to 303 bar (4,395 psi)

- Emission-free, environmentally friendly system

- Small footprint and low weight

- Extended operating range and flexible operation

- Ideal for remote control and unmanned operation

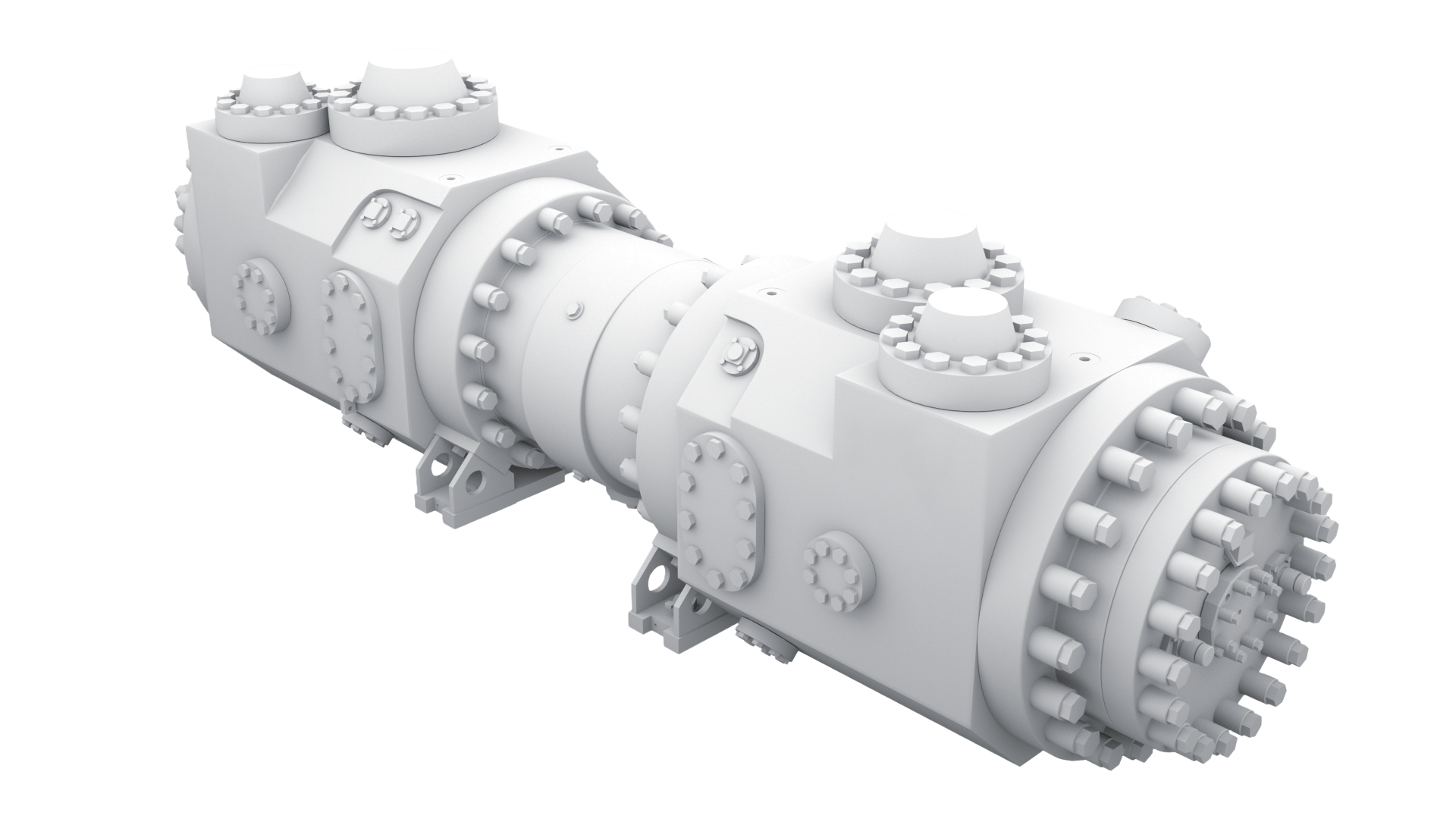

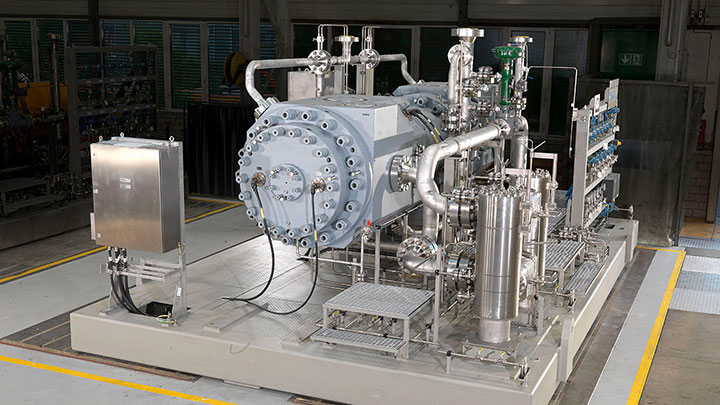

MOPICO® – say hello to cutting-edge pipeline compression

The hermetically sealed MOPICO® motor-driven compressor ensures reliable, low-maintenance operation for continuous gas transport. Its simple design with a single rotating element and magnetic bearings eliminates couplings, gearboxes, lube oil and shaft seals, resulting in low lifecycle costs. MOPICO® operates quietly and supports unlimited starts.

Typical performance data:

- Compression power up to 18,000 kW (24,000 HP)

- Discharge pressure up to 150 bar (2200 psi)

- Inlet flow up to 30,000 m3/h (17,650 cfm)

How you benefit:

- Emission-free, environmentally friendly system

- Small footprint and low weight

- Extended operating range and flexible operation

- Ideal for remote control and unmanned operation

Find more insights

Downloads

Contact our Everllence industry team

Seal the deal with Everllence

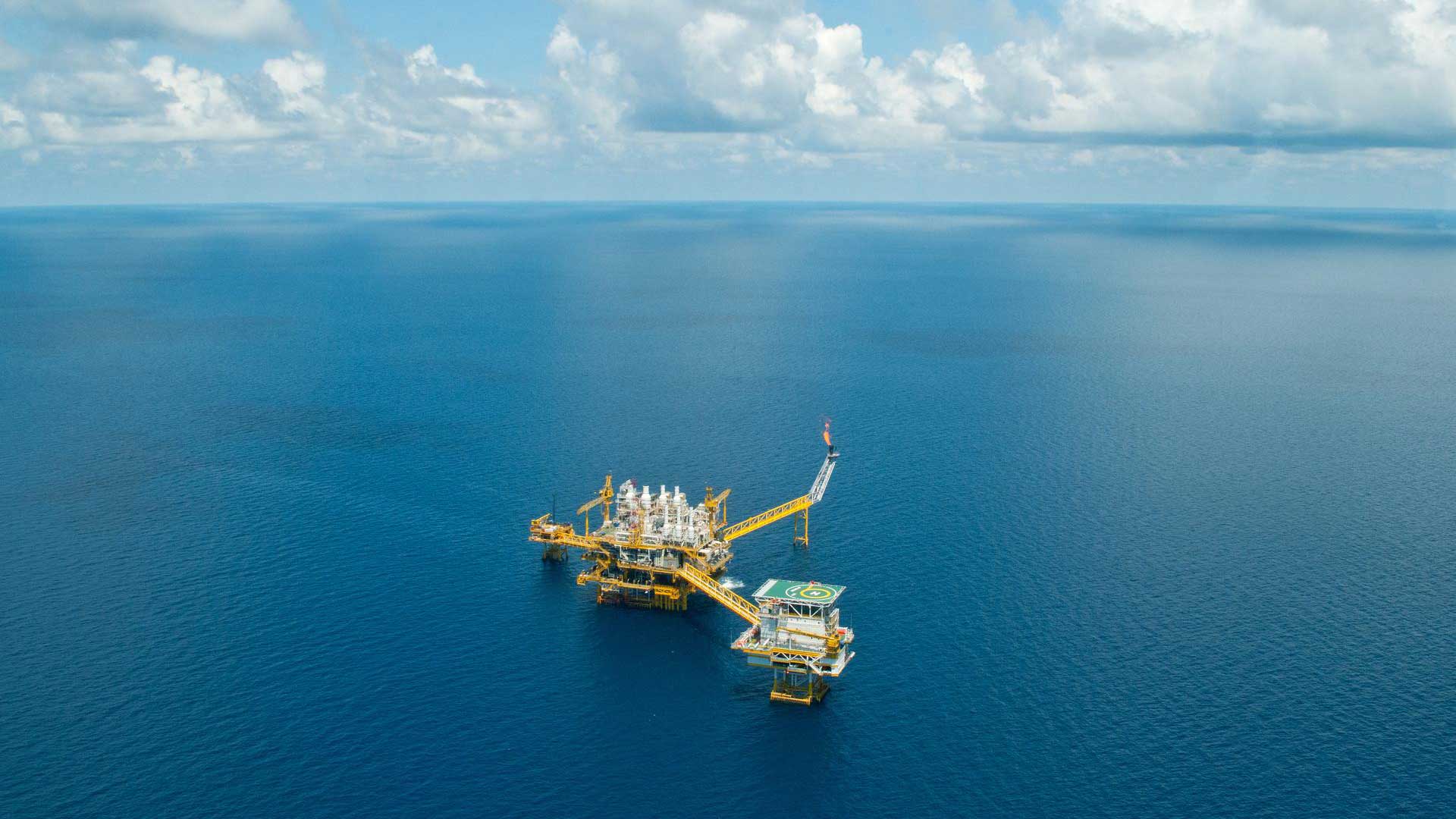

Interested in highly efficient, clean offshore drilling solutions? Transporting natural gas across vast distances? Reliable and robust, our HOFIM® and MOPICO® compressors are a huge advance in offshore drilling and pipeline compression machinery. See how your business could benefit from our latest developments in fully sealed compressor technology.

Hermetically sealed compressors FAQs

A hermetically sealed compressor integrates the motor and compression unit within a single airtight casing, eliminating the need for external seals, couplings, and lubrication systems. As a self-contained unit, the motor directly drives the compressor, simplifying operation and reducing maintenance.

It works by drawing in gas via a suction line. The gas then enters the compressor shell, where it circulates around the motor for cooling before reaching the compression chamber. As pressure increases, the gas is discharged for transport or further processing.

Hermetically sealed compression for safe gas handling

Hermetically sealed compressors for demanding oil and gas production

Hermetic compressor technology enabling subsea compression systems