Facts

Good to know

Our retrofit solutions reduce GHG emissions by up to 20 percent

Potential in savings of CO2 emissions

Engines have a potential for a future fuel retrofit

Keep your engines, systems, and equipment compliant and competitive

Cargo ships and power plants are long-term investments. Retrofitted and modernized with high-value Everllence products, they become more sustainable, can continue to be used for decades, and are an attractive investment proposition.

Retrofits play an important role in the energy transition and are crucial for achieving a green fleet of ships or power plants that help to meet the targets of the Paris Agreement.

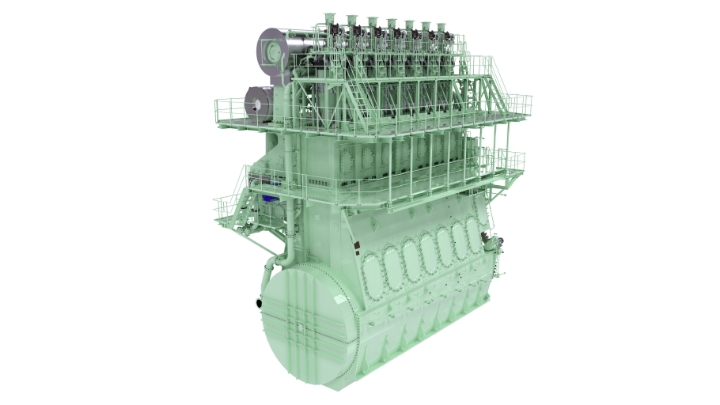

A recent study indicates that around 1,900 two-stroke and 1,800 four-stroke marine and power plant engines have the potential for a future fuels retrofit.

Maximize savings with future fuels through cutting-edge retrofit solutions

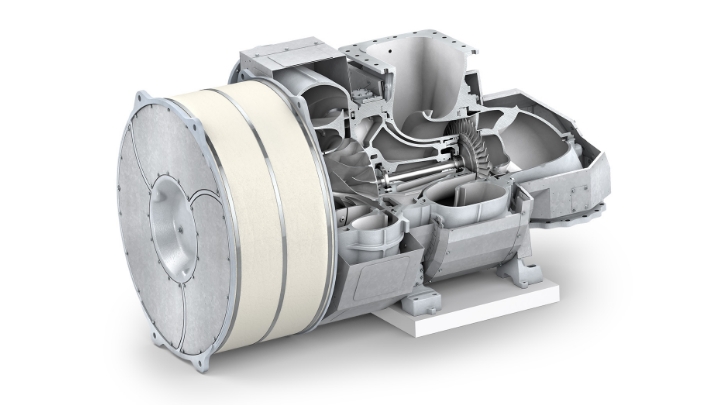

Switching between different fuels is made easy with Everllence dual-fuel engines, as they are highly versatile and capable of utilizing both liquid and gaseous fuels. This flexibility empowers you to transition between fuels at your convenience, whether driven by factors like fuel costs or regulatory requirements. What's more, these engines can seamlessly switch between fuels even while operating, all without compromising engine performance. Should you wish to convert single fuel engines to dual fuel, please note that such a transformation may necessitate adjustments to your fuel supply infrastructure. Our team of Everllence PrimeServ fuel experts is readily available to provide guidance and discuss the various possibilities.

Converting existing engines to dual-fuel operation is crucial to decarbonize shipping because it’s a powerful measure that can be implemented quickly. This is an essential first step, as all such dual-fuel engines can also be enabled to operate on a range of carbon-neutral synthetic fuels, including synthetic natural gas (SNG), green ammonia and methanol. And from an economic perspective, retrofitting is much more efficient than installing a new engine or building a new ship

Unlocking efficiency and cost savings

Our retrofit solutions, upgrades, and services optimize investment returns. They boost efficiency as well as performance, and reduce maintenance, fuel, and lube oil costs.

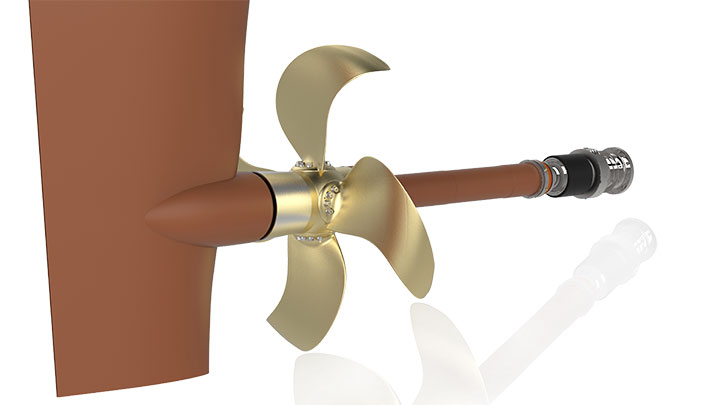

Retrofits and upgrades for marine applications

Keep your engines compliant and competitive

From retrofit products over engineering services to dual-fuel engine upgrades, we specialize in maximizing the value – and service life – of our assets.

Retrofits for power plants

For cleaner power plant operation

Embrace the future with cutting-edge retrofits that upgrade your energy assets to drive your business model today and tomorrow.

Experts in retrofitting and dual-fuel conversions

At Everllence, we have a long-standing experience in retrofitting engines with state-of-the-art technology. We have also pioneered the conversion of large container ships to LNG operation, for example for Hapag-Lloyd, and are currently converting engines on board of a Karadeniz Powership from heavy-fuel-oil to dual-fuel operation.

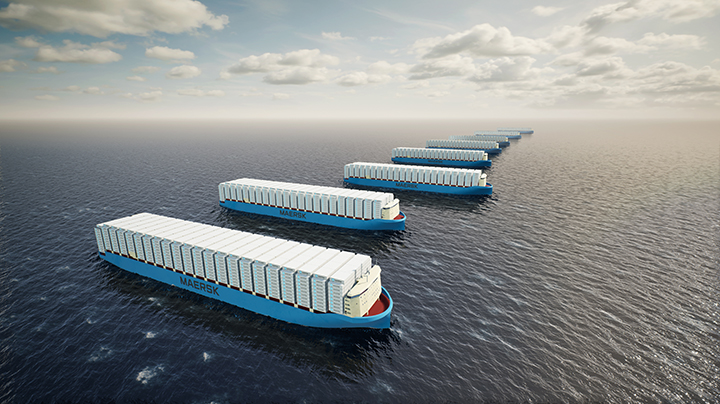

A.P. Moller – Maersk, the Danish integrated logistics company, has signed a contract with PrimeServ for the retrofit of the main engines aboard 11 container vessels equipped to dual-fuel Everllence B&W 8G95ME-LGIM10.5 types capable of operating on fuel-oil/methanol. The first vessel is set for a mid-2024 retrofit, facilitated by PrimeServ's comprehensive solutions package.

The Turkish company Karadeniz is known for providing floating power plants to areas in need of electricity worldwide. Everllence is helping Karadeniz to improve its environmental footprint by retrofitting heavy-fuel-oil engines to dual-fuel. Everllence PrimeServ is currently converting four powerships with a total of 32 engines to dual-fuel operation.

The ElbBLUE container ship represents a groundbreaking turning point in the decarbonization of the maritime industry. In 2021, it became the world’s first container ship to operate on climate-neutral synthetic natural gas (SNG). Retrofitted from an HFO to a Everllence dual-fuel propulsion engine, the ship is powered by a mix of climate-neutral synthetic and fossil liquid natural gas. In September 2021, the ElbBLUE bunkered 20 tons of synthetic natural gas and demonstrated a reduction in greenhouse gas emissions of almost one third during its first trip with the new fuel mix.

Finding the perfect fit

Beside methanole, other fuels can also be a solution for your marine application: LNG, bio fuels or ammonia. Find your perfect fit now.

Frequently asked questions

Retrofits benefit vessels of all ages, not just newer ones. It extends the operational life of vessels and ensures compliance with evolving industry as well as environmental standards. Retrofit options depend on the vessel's age, condition, and design, but older ships can benefit from retrofits as well.

Upgrading to cleaner technologies in marine applications provides numerous environmental and regulatory benefits. This includes significant reductions in emissions of air pollutants, compliance with international regulations, improved fuel efficiency, and noise reduction. Moreover, cleaner technologies enhance safety, contribute to long-term sustainability by reducing carbon emissions, and open access to environmentally conscious markets.

The expected downtime during a retrofit or upgrade project varies significantly based on factors like the project’s size, customization, location, regulatory requirements, and unforeseen issues. Downtime can range from a few weeks to several months. Efficient project planning can help reduce downtime, while unforeseen problems may extend it. The goal is to strike a balance between minimizing downtime and ensuring high-quality and safe work.

.jpg?sfvrsn=e0a42aea_3)