Taking performance to the max

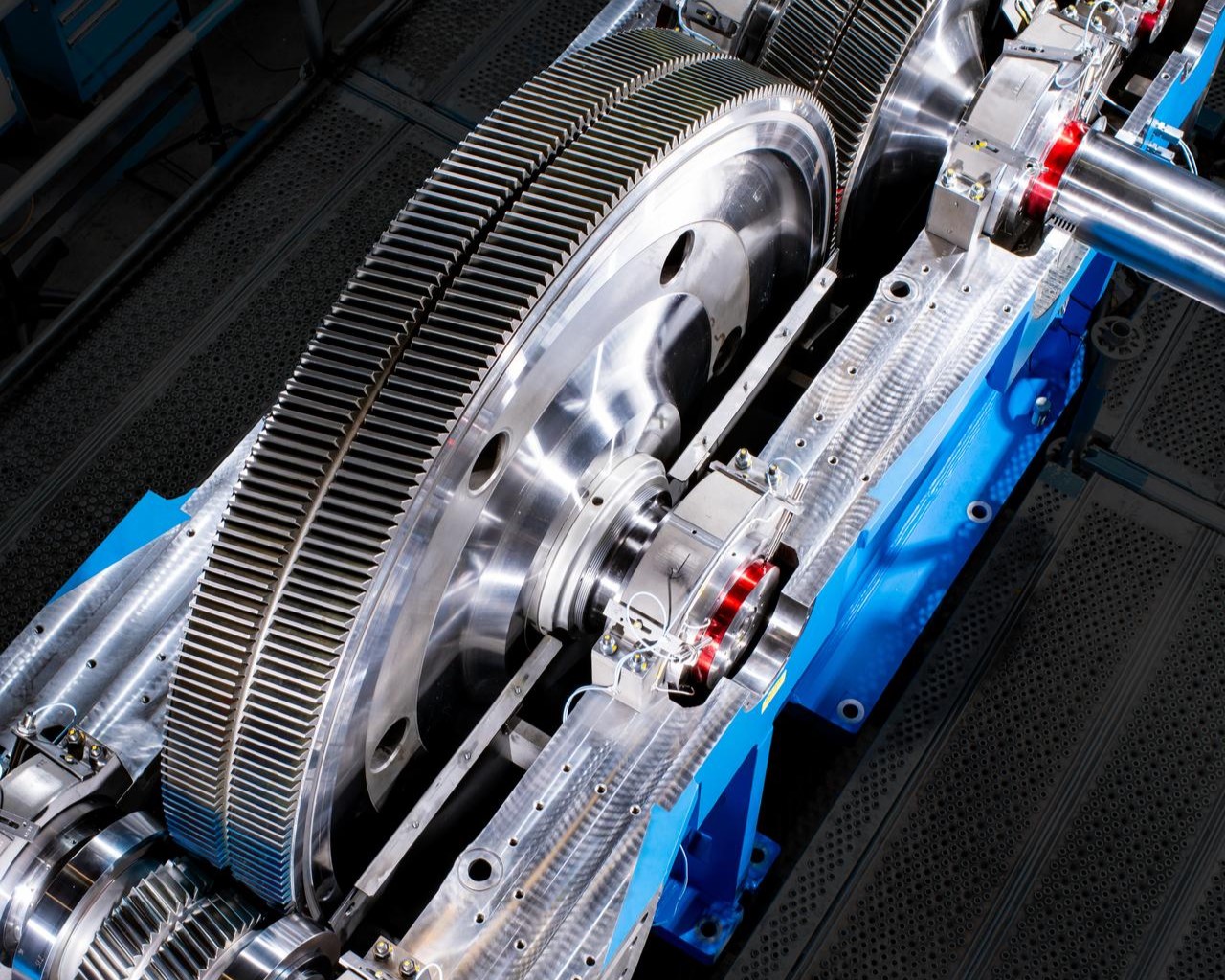

maximum number of impellers

High efficiency for a wide range of applications

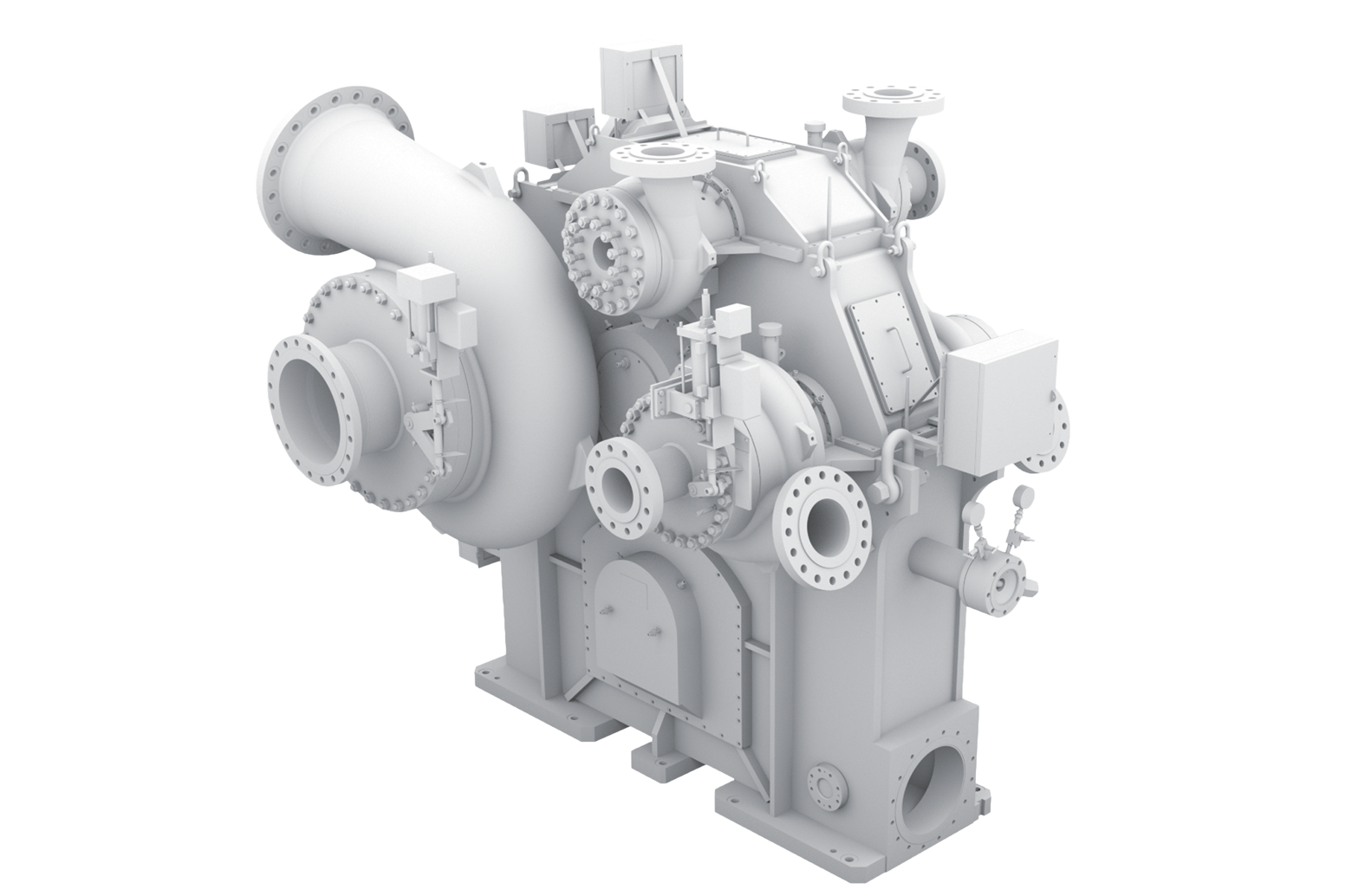

Everllence integrally geared compressors deliver high efficiency and a speedy return on investment. Regardless of which application you are running, our integrally geared compressors are the ideal choice for your business. They are fully flexible and can be adapted exactly to your requirements.

How you benefit:

- Individually adjustable impeller speed for optimum flow and costs

- Quasi-isothermal compression

- Different compression sections within one casing

- Up to three combined applications within one casing

The integrally geared range: From a modular design to custom-made

Built with modularity in mind, our integrally geared compressors adapt seamlessly to your specific application while maintaining their robust durability. Customize your multi-shaft compressor to meet your needs – from thermodynamic and mechanical design to precision-engineered components, assembly and, of course, rigorous testing. Or choose from our modularized range of integrally geared compressors for air, fuel gas, CO2 and other applications.

Applications:

- Industrial gases

- Carbon capture, utilization, and storage (CCUS)

- Heat pumps

- Energy storage and power generation

- Hydrogen (H2)

- High-temperature compression

- Oil & gas and iron & steel

- Chemicals, petrochemicals, and refineries

- Fertilizer industry

Contact our Everllence industry team

Fully flexible, efficient and reliable

From industrial gases to oil and gas or purified terephthalic acid to nitric acid, whatever industrial process you are involved in, you can choose a perfectly tailor-made or modularized compressor from our RG integrally geared compressor range. Talk to us to find out more.

Find more insights

Downloads

Integrally geared compressors FAQs

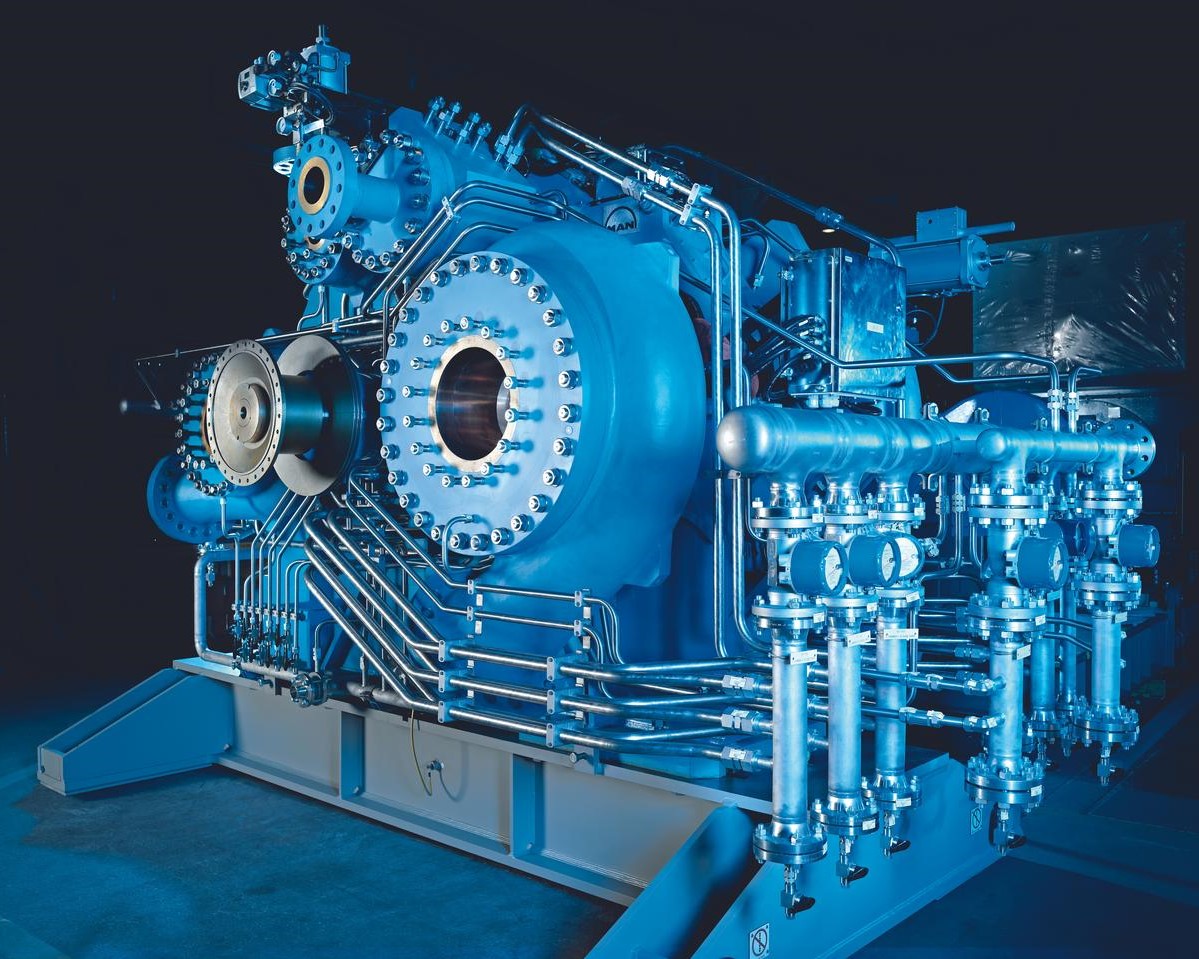

An integrally geared compressor operates using a central bull gear – a large gear that drives smaller pinions and distributes torque. The bull gear serves as the main drive, powering several smaller pinions (gears mounted on separate shafts that rotate at different speeds) to maximize efficiency. Unlike conventional single-shaft compressors, a multi-shaft integrally geared compressor allows each impeller to rotate at its most effective speed, improving performance and reducing energy consumption across different compression stages. Additionally, the entire system is housed within a single casing, which minimizes footprint, simplifies maintenance, and enhances reliability.

Integrally geared compressors fall under API 617, which establishes comprehensive standards for centrifugal compressors, including integrally geared designs. Additionally, API 672 specifically governs packaged integrally geared centrifugal air compressors used across the petroleum, chemical, and gas industries. Everllence integrally geared compressors are engineered for maximum efficiency and reliability, ensuring full compliance with industry regulations, including the relevant API standards.

Powerful compression for demanding basic materials production

Precision performance for efficient air separation

Reliable compression solutions for complex refinery processes