Tailor-made chemical reactors to meet your individual requirements

As a pioneer in chemical reactor technology, Everllence (formerly MAN Energy Solutions) is constantly working to push the boundaries of what is possible. We work closely with our customers in the chemical, refinery, and utility sectors to design and engineer industrial chemical reactors with cutting-edge features. We use high-grade steel and, if required, this is combined with special cladding to manufacture reactors capable of withstanding all sorts of chemicals.

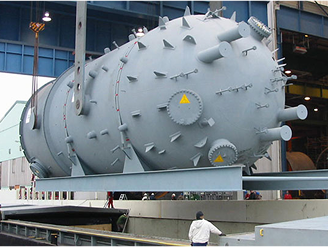

DWE®, a subsidiary of Everllence based in Deggendorf, manufactures tailor-made chemical reactors to meet your individual requirements. We offer salt-operated and water-, gas- or oil-operated reactors up to 12 meters in diameter and 1,800 metric tons in weight. We also manufacture customized special reactors.

By loading the video you agree to YouTube's privacy policy.

Premium chemical reactors

Everllence has a proven history in constructing reactors and pressure vessels with various wall thicknesses for the chemical industry, refineries, power plants, and similar industrial plants. We design in strict compliance with your requirements. And our years of experience in industrial chemical reactor construction give us the highest level of expertise.

The tubular reactors in operation all over the world have made Everllence a trusted partner. We pride ourselves on our strong customer relationships. Our careful handling of large numbers of tubes, tube-to-tube sheet welding, as well as our zero-tolerance quality control have proven to be a strong foundation for our business.

We believe innovation is a constant process and conduct technical research into manufacturing and heat treatment. We offer process development and testing in our pilot plants or in a pilot chemical reactor built for you. Our workmanship, particularly our welding, is outstanding. We can ship even very large reactors from our production facilities and can set up our systems at your site in next to no time

Features

Our chemical reactors can take on the extremes

maximum weight of a DWE® reactor

Industrial chemical reactors from Everllence

It’s your choice – a custom-made reactor for your business

All our top-quality reactors need minimal downtime and have guaranteed spare parts for their long lifetime, thereby reducing your OPEX. We can also conduct feasibility and safety studies, carry out revamps, or supply start-up services for our reactors’ systems.

Our salt-operated reactor design enables high-efficiency processing of both exothermic and endothermic processes at very high temperatures. Molten salt is used as a heat transfer medium to either remove or provide the process heat. Exothermic reactors are commonly used in the production of chemicals such as phthalic and maleic anhydride (PA / MA), methyl methacrylate (MMA), acrylic acid (AA), and acrolein (AC). Endothermic applications include, for example, the production of vinyl formamide.

These radial flow reactors are made from high-grade materials and can be combined with special cladding.

For particularly demanding applications, special alloys can be used to further enhance the longevity and safety of the reactors.

DWE® salt-operated reactors offer reduced downtimes, excellent availability and longevity. Precise process control and high selectivity guarantee a decrease in OPEX for your bottom line.

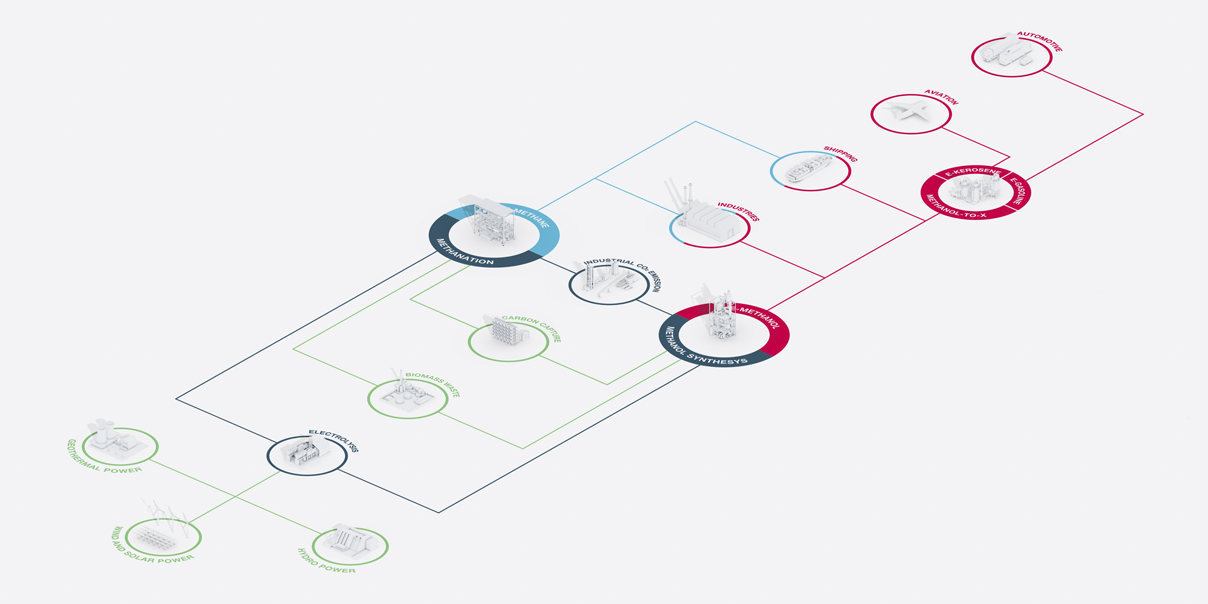

Building on the continuous development of our salt-bath technology, we have also engineered the endothermic Reverse Water Gas Shift (RWGS) reactor based on electrical heat input. It enables the production of renewable syngas from CO₂ and H₂—serving as a critical feedstock for the synthesis of sustainable fuels and chemicals. A key application is the generation of green kerosene for the aviation industry.

- Tubular reactors with up to 60,000 tubes

- Custom-made

- Multi-stage reactors, sector design, containment design

- Temperature 300-650°C

- Total heat removal rate of up to 80 MW

Our water-, gas- and oil-operated reactors for liquefaction processes or methanation are serving a growing market worldwide. They are used in the increasingly important production of liquid hydrocarbons from natural gas, biomass, or coal. Known as GTL, BTL, or CTL processes, they require robust and durable fixed-bed tubular reactors. These reactors are also used to produce methanol and ethylene oxide or for methanation.

Water-, gas- and oil-operated reactors from Everllence DWE® are made from high-grade materials such as carbon steel, nickel alloy, low- and high-alloy steel, and stainless steel. If required, special cladding materials—durch as zirconium—are available to meet particularly demanding application needs.

- Multi-stage reactors

- Radial and axial flow

- Fixed-bed

- Batch and continuous operation

There are several reasons why you might need a custommade reactor for your business. The production of some chemicals calls for special materials and conditions in the reactor. You might need a pilot reactor which we design and deliver exclusively to your specifications. For health and

safety reasons, you might require specially secured reactors with a containment design. Or you might need a sector design as the entire reactor is simply too heavy or large to be transported to the intended site in one piece. Whatever you need by way of special reactors, Everllence has the

solution.

- Multi-stage special reactors

- Sector design for large reactor systems

- Containment design for extra safety

- Reactors made from high-grade materials

- Pilot plants

Reference cases

A reliable partner for clients across the globe

- Country: Singapore

- Completion Date: 2023

- Scope of Work: Engineering, design and manufacturing

- Dimensions: Length: 33m, Diameter: 3.8 m, Weight: up to 115to

- Technical Highlights: Zirconium cladded, 16 bar operating pressure

- Country: Qatar

- Completion Date: 2010

- Scope of Work: 12 reactors 30.000 tubes each

- Dimensions: Length: 12.9m, Diameter: 7m, Wall thickness: 142mm, Weight: 1200to

- Technical Highlights: Design PD 5500, Shell material: 19Mn5 20MnMo-Ni45

- Country: Saudi Arabia

- Completion Date: 2014

- Scope of Work: 3x methyl methacrylate (MMA) reactors with bolted heads

- Dimensions: First stage reactor: Diameter: 9.5m, Weight: 455to, Second stage reactors: Diameter: 10.5 m, Weight: 470to per reactor

- Technical Highlights: First stage reactor with 37.650 tubes with intercooler, Second stage reactors with 43.823 tubes

- Country: China

- Completion Date: 2023

- Scope of work: 3 salt-powered reactor systems

- Dimensions: Height: 7m, Diameter: 12m (excluding heads)

- Technical Highlights bzw. Key Features: Operating Temperature up to 450°C,

38.500 reactor tubes

- Country: China

- Completion Date: 2025

- Scope of work: 1 Containment design reactor system including quench zone

- Dimensions: Height: 5m, Diameter: 8m (excluding heads)

- Technical Highlights bzw. Key Features: Operating Temerature up to 400°C

27.000 reactor tubes, top head flange thickness >550mm

Contact our chemical reactor experts

Reactor solutions tailored to your process

Everllence has delivered over 750 individual reactors to the chemical and petrochemical industries worldwide. Find out what we can do for your business.

DWE® reactor services

We want you to get the most out of your investment: Service-lifeextending revamps and conversions are available for all assets in the DWE® reactors portfolio. As a service customer, you benefit from the experience and innovation of designers, engineers, and technicians who know your reactor – down to the last gasket. From design studies to aftersales service, as a reliable and competent partner, we accompany your reactor through all phases of its service life.

Downloads

Comprehensive solutions and detailed information from Everllence

Your future, your fuel