Boost productivity, elevate efficiency.

Discover how Everllence TURBAIR® vacuum systems set new standards in energy efficiency and sustainability. With cutting-edge technology, up to 80% energy savings, and a maintenance-free design, TURBAIR® transforms de-watering into a future-ready process.

Why choose a TURBAIR® vacuum system?

TURBAIR® industrial vacuum blowers – turning the page on efficiency

By cutting consumption of energy and process water in the paper production flow, TURBAIR® supports your efforts to reduce tremendous OPEX and exceed environmental regulations. Make your business competitive by employing our innovative technologies to your advantage.

Depending on the type of paper you manufacture, the amount of vacuum and volume required for production will vary. The TURBAIR® vacuum system adapts dynamically to changing conditions to provide the exact volume and vacuum needed for a perfect result.

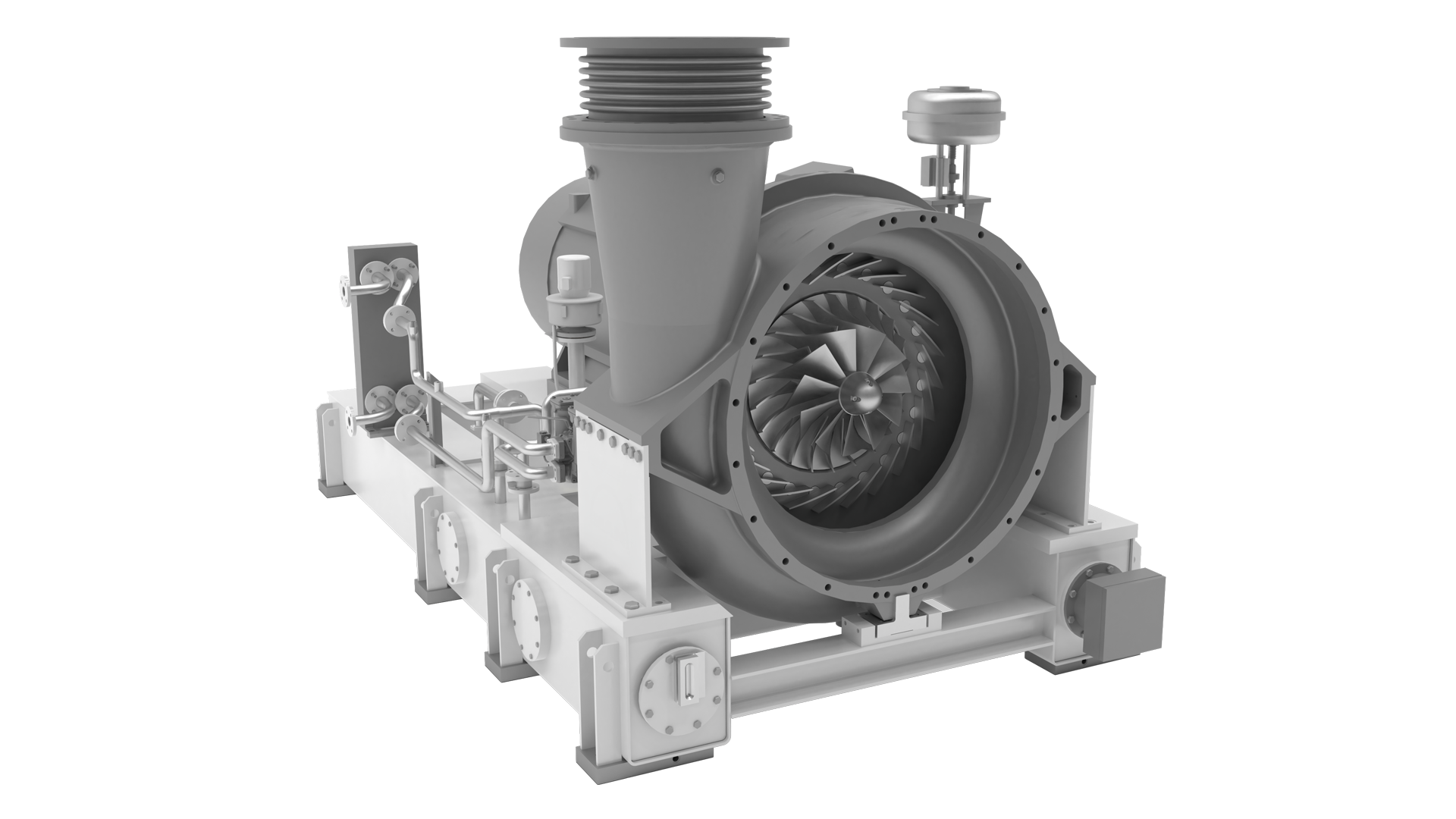

Single- and multi-stage blowers for reliable, maintenance-free operation

Everllence TURBAIR® vacuum systems are available in two versions: As a compact single-stage radial blower with a vacuum level of up to 65 kPa, or as a multi-stage radial blower with up to four vacuum levels with a maximum of 75 kPa. Both types are available with fixed or variable speed.How you benefit:

- Heat recuperation equivalent of up to 75% of absorbed blower power

- Adjustable vacuum levels at varying flow rates

- No wearing parts

- No water consumption

- Long service life

Practical applications: where technology meets practice

Everllence TURBAIR® vacuum system in use across the globe

At Glatfelter Gernsbach, Everllence cut energy use where it matters most. By retrofitting two paper machines with TURBAIR® vacuum blowers, we halved electricity consumption in the dewatering process, reduced water and gas use, and turned waste heat into usable energy. The result: lower operating costs and a clear step toward decarbonized paper production.

| Country | Germany |

| Application | Paper mill – vacuum system retrofit for energy, water and emissions reduction |

| Project status | Completed / Operational (retrofit already implemented with further installations planned) |

| Customer benefits | Significant energy savings (electricity reduced by ~50%) with concomitant cuts in gas and water use; substantial annual cost savings (~€500,000–€600,000 per machine); enhanced sustainability and reduced CO₂ emissions through elimination of water-ring pumps and improved vacuum process efficiency; waste heat reuse for process pre-heating. |

| Scope of work | Retrofit of two next-generation TURBAIR® single-stage RT vacuum blowers on two paper machines, including integration with heat-to-heat and air-to-water heat exchangers for waste heat recovery. |

Our solutions for the forest fiber and paper industry are designed to save water and energy and keep noise emissions low – helping our customers stay competitive while improving their overall environmental impact. In this project, our oil-free screw compressors ensure reliable, efficient gas compression with minimal maintenance, tailored to the customer’s specific process needs.

| Customer | Process industry |

|---|---|

| Customer type | Paper mill |

| Application | Combined heat & power for own consumption and grid |

| Location of installation | Germany |

| Commercial operations | 2020 |

| Blower type | One multi-stage blower type RC 80-4 and one single-stage blower type RT 56-1 |

| Energy and heat savings | 44% and 70%, respectively |

| Water savings | 10.4 MWe and 9.1 MWtherm |

| Commercial operation | 10 m3 |

| Scope of work | Replacement of existing vacuum system |

Contact our Everllence industry team

A vacuum blower system to keep your paper producing business competitive: TURBAIR®

If you’re looking to cut your energy costs and to reduce your environmental footprint, you should consider Everllence’s TURBAIR® vacuum blower system. Talk to us to find out how we support the pulp and paper sector worldwide.

Find more insights

Downloads

Industrial vacuum blowers FAQs

A radial blower is designed to generate a high-pressure airflow by pushing air outward away from a central, rotating impeller. Air enters the blower through the impeller and is accelerated outward as the impeller spins. Pressure builds up as the air is forced through the casing of the radial blower, exiting at high velocity. This makes radial blowers the ideal choice for applications requiring a strong airflow, such as dewatering processes in the paper and pulp industries.

Solutions for a competitive pulp and paper business

Vacuum blower technology supporting industrial heat pump applications