Decades of compression excellence

Centrifugal compressor designs driving efficiency and reliability

No matter what your industry, increasing the efficiency of your operations will be high on your list of priorities. Everllence centrifugal compressors handle large volume flows and require minimal downtime, increasing your ROI on a daily basis.

Many sectors that rely on compressors operate in high-risk environments, processing costly, hazardous, or highly flammable substances. At Everllence, we recognize that our machinery is central to these processes; therefore, we are committed to continuously improving and innovating our well-established centrifugal compressor designs.

_1920x1080.png?sfvrsn=e1673b9a_1)

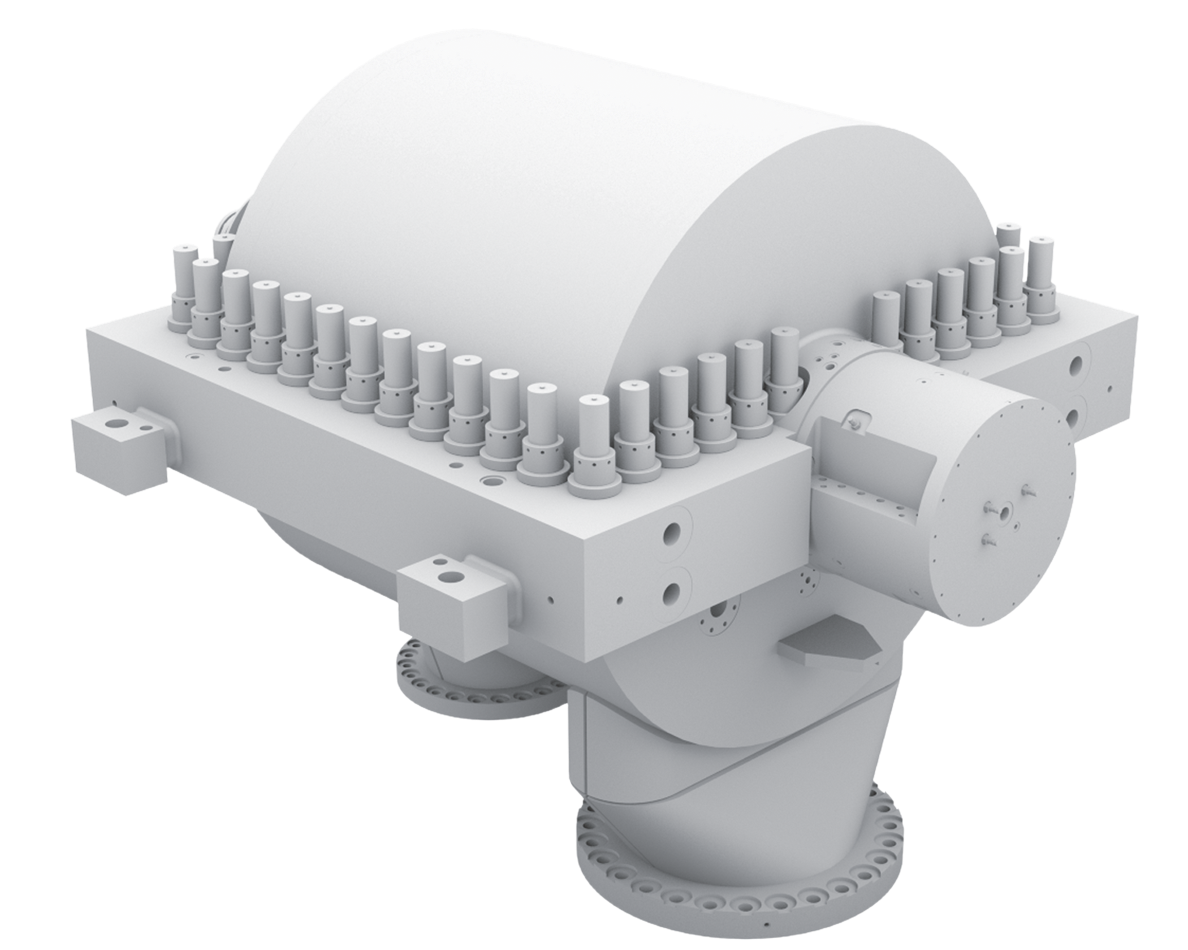

Barrel-type or horizontally split – finding the best centrifugal compressor for you

Whatever your application, we select the optimal flow path technology from our two proven centrifugal compressor designs: barrel-type (RB) or horizontally split (RH). Each one handles a broad spectrum of flow rates and extreme discharge pressures, ensuring compatibility with even the most demanding industry requirements.

Our modular configurations range from predesigned centrifugal compressor packages to fully customized units, offering flexibility to suit diverse operational needs. Our Configure-to-Order compressors achieve the fastest machine train delivery times while maintaining optimized CAPEX levels. And there is no compromise to our high equipment quality and reliability. With our Engineer-to-Order solutions, we accommodate all our customers’ needs – no matter how severe the process and how extreme the corrosion – leveraging our years of expertise as a tailor-made equipment specialist.

Find more insights

Downloads

Contact our Everllence industry team

Find the compressor that suits your needs.

Dry screw, axial, centrifugal, or a custom combination – whatever type of compressor design you require, we’ve got the solution. Call us today, and our experts will guide you through our robust, modular solutions engineered for efficiency and reliability.

Centrifugal compressors FAQs

Centrifugal compressors and axial compressors both increase gas pressure but operate differently. Centrifugal compressors accelerate gas outward using an impeller, converting kinetic energy into pressure within a diffuser. In contrast, axial compressors use multiple stages of rotating and stationary blades to gradually compress gas along a straight path. The key distinction lies in how the gas moves: centrifugal compressors rely on radial motion, whereas axial compressors maintain a linear flow.

As well as air, centrifugal compressors can handle a variety of gases depending on their design, material compatibility, and operational requirements. These include natural gas (for transmission and processing), hydrogen (for refining and chemical applications), carbon dioxide (for industrial processes), nitrogen (for purging systems), ammonia (for fertilizer production), and helium (for specialized applications).

Centrifugal compressors transform kinetic energy into pressure energy through a rotating impeller, which consists of a series of vanes or blades attached to a central cylinder. The process begins with gas (or air) entering through an inlet and reaching the centrifugal impeller. The impeller then spins at high speed, using centrifugal force to push the gas outwards. This action increases the velocity of the gas, which then moves into a diffuser where its kinetic energy is converted into pressure. A collector gathers the pressurized gas and releases it through an outlet.

Everllence centrifugal compressors for reliable refinery operations worldwide

Efficient compression solutions for transporting and storing natural gas

Robust centrifugal compressors for offshore exploration and production

.png?sfvrsn=ba22e528_1)