Future Fuels

Solutions for producing renewable fuels

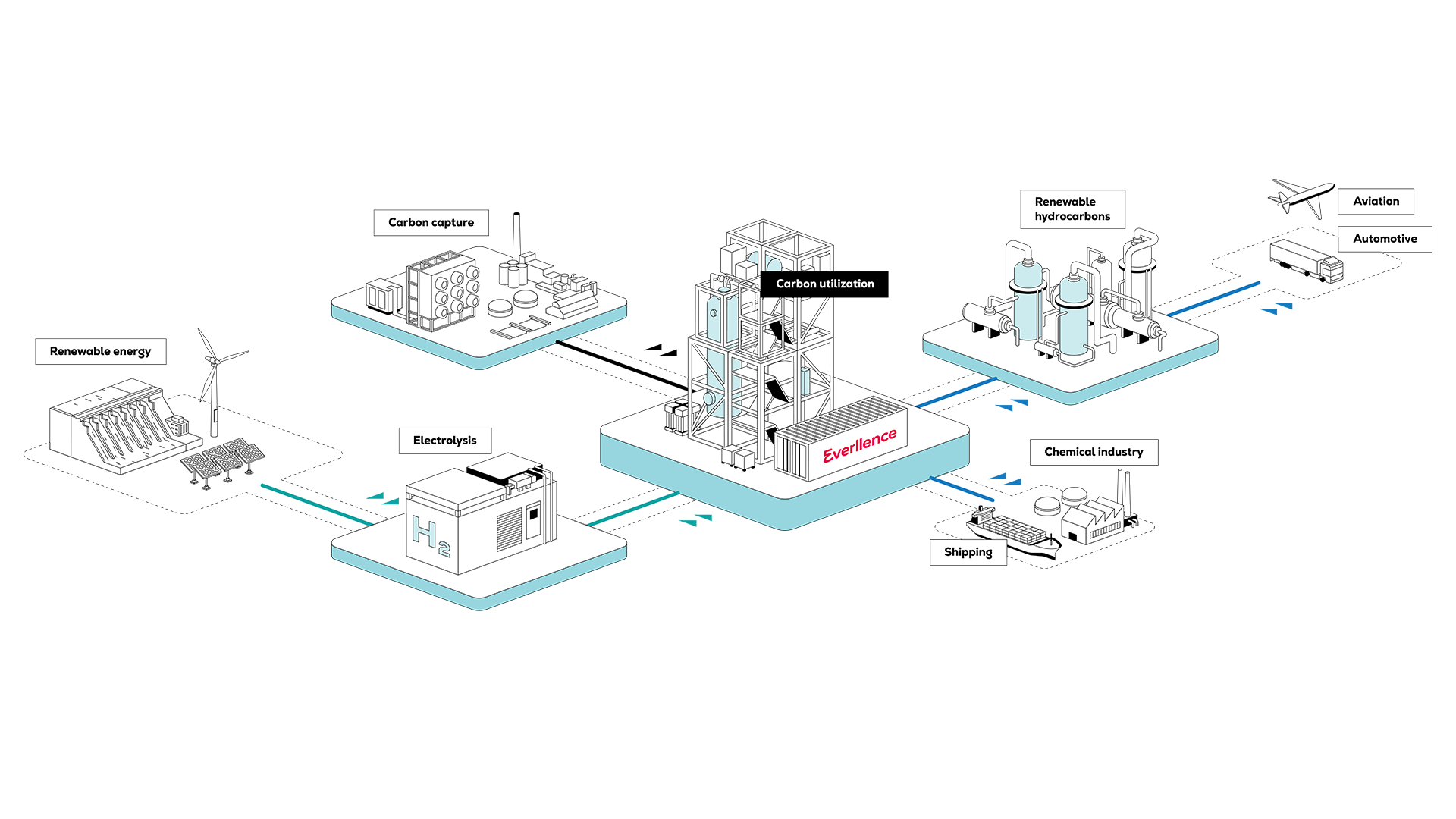

Renewable fuels such as e-methanol, e-methane (synthetic natural gas (SNG)), e-gasoline, and e-kerosene (sustainable aviation fuel (SAF)) are produced through synthetic processes. Unlike fossil fuels, they are climate-neutral and thus play a vital role in decarbonizing the maritime, aviation, industrial and mobility sectors. These fuels can defossilize sea, air and road transport, as well as power generation and certain industrial processes. Everllence offers the technology and equipment needed to produce and use these renewable fuels – from electrolyzers, CO2 compressors and synthesis reactors to dual-fuel engines for the shipping sector.

Facts

Good to know

year by 2050

aviation fuel (SAF) by 2030

(EU target)

“E-Fuels are not just an energy alternative-they’re the bridge to a sustainable and carbon-neutral future”

Dr Stefan Koch, Vice President & Head of Sales DWE®

How are e-fuels produced?

Electricity from renewable sources is used to split water into hydrogen and green oxygen. The hydrogen is then combined with carbon dioxide in various synthesis processes to produce a range of carbon-neutral fuels, including:

- e-methane (SNG)

- e-methanol

- e-kerosene (SAF)

- e-gasoline

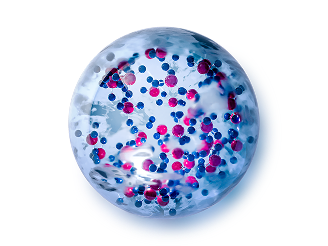

E-fuels produced with DWE® reactor modules

emerging as a leading alternative in sectors that are difficult to electrify.

E-methanol can be used in two-stroke and four-stroke marine engines, both for new builds and retrofits. In addition, e-methanol serves as a key feedstock in the production of other e-fuels, including e-gasoline and ekerosene.

E-gasoline is carbon neutral because the carbon dioxide released during combustion is the same carbon dioxide that was previously captured from the air. Together with our partner CAC Engineering, we provide commercial-scale olutions to convert renewable methanol to renewable

gasoline that meets the European fuel standard DIN EN 228 with no need for technical alterations to vehicles. It can be used in regular gasoline cars.

Where future fuels are needed most

Reference case: Chile

Haru Oni e-fuels plant

Located in southern Chile and commissioned in 2022, Haru Oni is a demonstration plant producing synthetic fuels including e-methanol and e-gasoline. It uses a 3.4 MW wind turbine and an electrolyzer to make hydrogen. An DWE® e-methanol reactor converts the hydrogen and carbon dioxide into methanol, which is then transformed into gasoline. The plant currently makes up to 600 metric tons of methanol per year, which are converted into some 35,000 gallons of synthetic gasoline. The operator, HIF, is planning a 325 MW wind farm to produce up to 140,000 metric tons of synthetic methanol per year.

Reference case-Qatar

Pearl Gas-to-Liquid plant

The Fischer-Tropsch process is key for making e-gasoline and e-kerosene from hydrogen and carbon dioxide. Everllence has also constructed several of the largest Fischer-Tropsch synthesis reactors in the world.

One example is the Shell Pearl Gas-to-Liquid (GtL) plant in Qatar, where Everllence delivered 12 large-scale Fischer-Tropsch reactors.

Reference case-Germany

Wertle Power-to-Gas plant

Built in 2013, in cooperation with Audi, the Wertle plant is Europe’s first Power-to-Gas (PtG) plant to provide vehicles with cleaner fuel. The plant is now operated by kiwi AG and is still the largest PtG plant in Europe with a 6 MW capacity. Everllence equipped the plant with a state-of-the-art methanation reactor that transforms hydrogen and carbon dioxide into climate-neutral methane. In 2021, the ElbBLUE container ship was the first ship in the world to run on climate-neutral SNG from Wertle.

Call our experts and start producing

Contact Everllence to discuss any aspect of setting up a future fuels production plant. We can advise on fuel infrastructure, reactor technologies, Energy Performance Certificate (EPC) services, legislation and regulatory compliance. Discover how your business can benefit from producing low-carbon fuels.

Downloads