Work with an expert partner

from Everllence to both compress and cool the gas

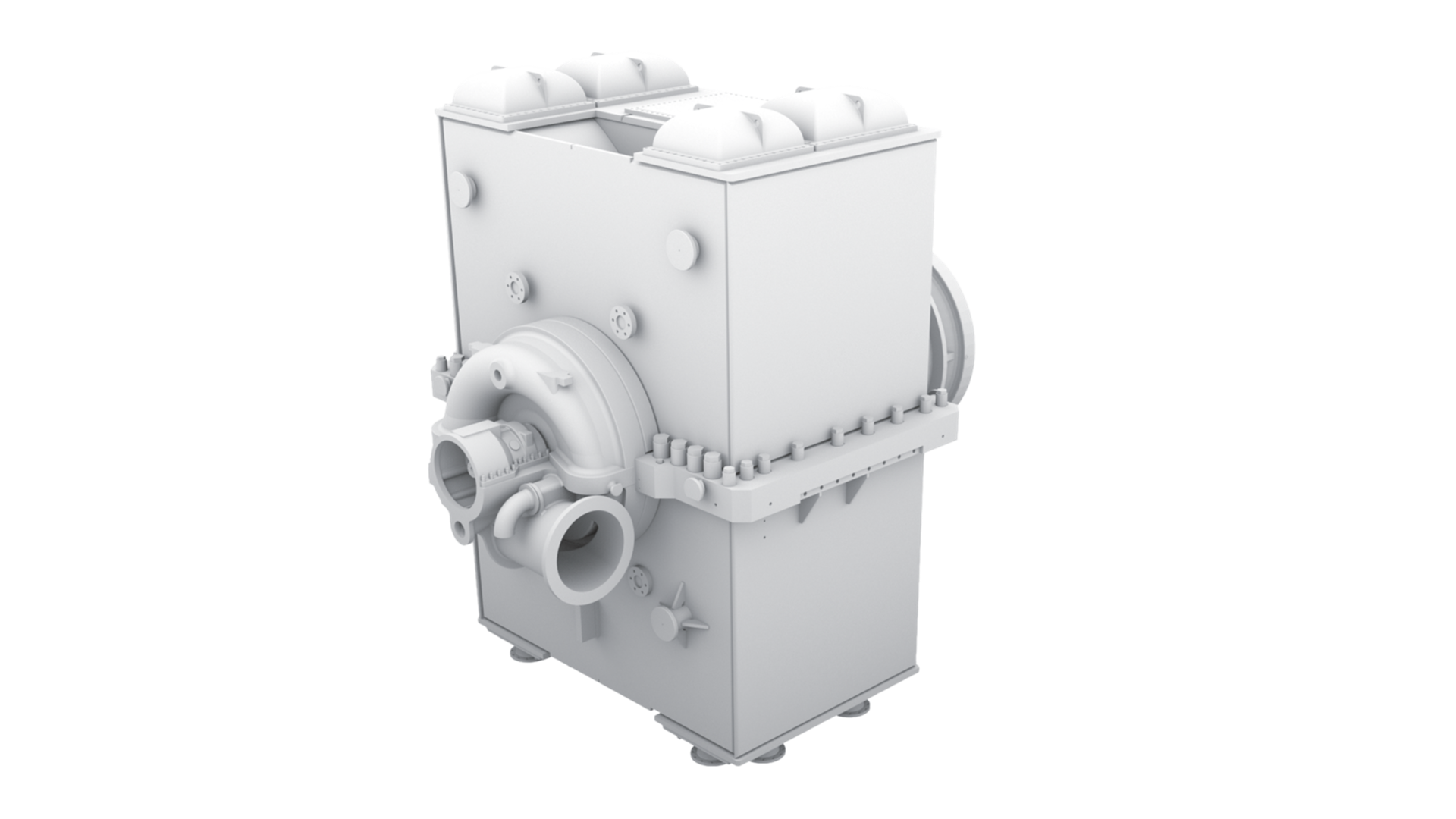

High-efficiency isothermal compressor for air separation and industrial applications

With decades of proven field performance, our isothermal compressor sets the benchmark for reliability and energy efficiency. Designed for air, nitrogen, or oxygen compression, it reduces energy consumption by minimizing driving power – ideal for demanding air separation and oxygen plant operations.

Offered in multiple frame sizes to suit diverse flow requirements, its compact and interface-friendly design enables easy integration into existing process plants. The RIKT model is optimized for compressing non-toxic, non-explosive fluids, making it a perfect fit for air separation units, compressed air energy storage systems, and other industrial applications requiring large air volumes.

Smart integration and compact power for seamless plant performance

Our isothermal compressor supports a wide range of compressor train configurations, combining different lines and drive types. With Everllence's full-train integration expertise, we ensure smooth, efficient plant implementation tailored to your needs.

Key Benefits:

- Maximum reliability and reduced energy usage

- Compact footprint with minimal space requirements

- Low noise emissions with advanced aerodynamic design

- Integrated coolers within the compressor casing

- Service- and installation-friendly configuration

From initial engineering to complete service solutions – Everllence is with you

From the very start of your project, we act as a trusted advisor, helping you optimize operations efficiently through engineering solutions and service models tailored to your needs.

With our versatile design approach, we provide customized isothermal compressor models, ensuring a perfect fit for your business requirements.

Find more insights

Downloads

Contact our Everllence industry team

Could your business benefit from one of our isothermal compressors?

You are constantly working to improve your operations. We are constantly working to improve our products. Why not get in touch to find out what we can achieve together?

Isothermal compressors FAQs

Everllence’ isothermal compressors achieve this through integrated cooling systems, ensuring reliable, energy-efficient performance. By preventing excessive heat, they optimize gas density, enhance isothermal compression efficiency, and reduce mechanical strain. These compressors are ideal for air separation units and industrial gas processing, where large-scale air, oxygen, or nitrogen compression is essential.

Isothermal compression for maximum energy efficiency

Isothermal compression technology for efficient energy storage