What are the benefits of combined heat and power solutions?

Everllence CHP solutions are extremely versatile, capable of producing far more than just electrical power.

Combined heat and power technologies are proven, reliable and cost-effective systems, simultaneously generating electricity and heat from a single fuel source. CHP plants can easily adapt to changing electrical and thermal heat requirements throughout the year.

Highly efficient trigeneration solutions also generate cold in addition to electricity and heat. By including an exhaust gas or hot-water-driven absorption chiller, Everllence CHP plants can produce chilled water to run central air conditioning systems e.g. in data centers, in hospitals, hotels or office blocks.

Even in periods where there is no heat demand, the fast-starting gensets can be used as a peaking plant. These energy-saving approaches can be customized to serve a wide range of industries and applications. The CHP plants can also be combined with heat pumps for maximum thermal output.

How does a CHP plant work?

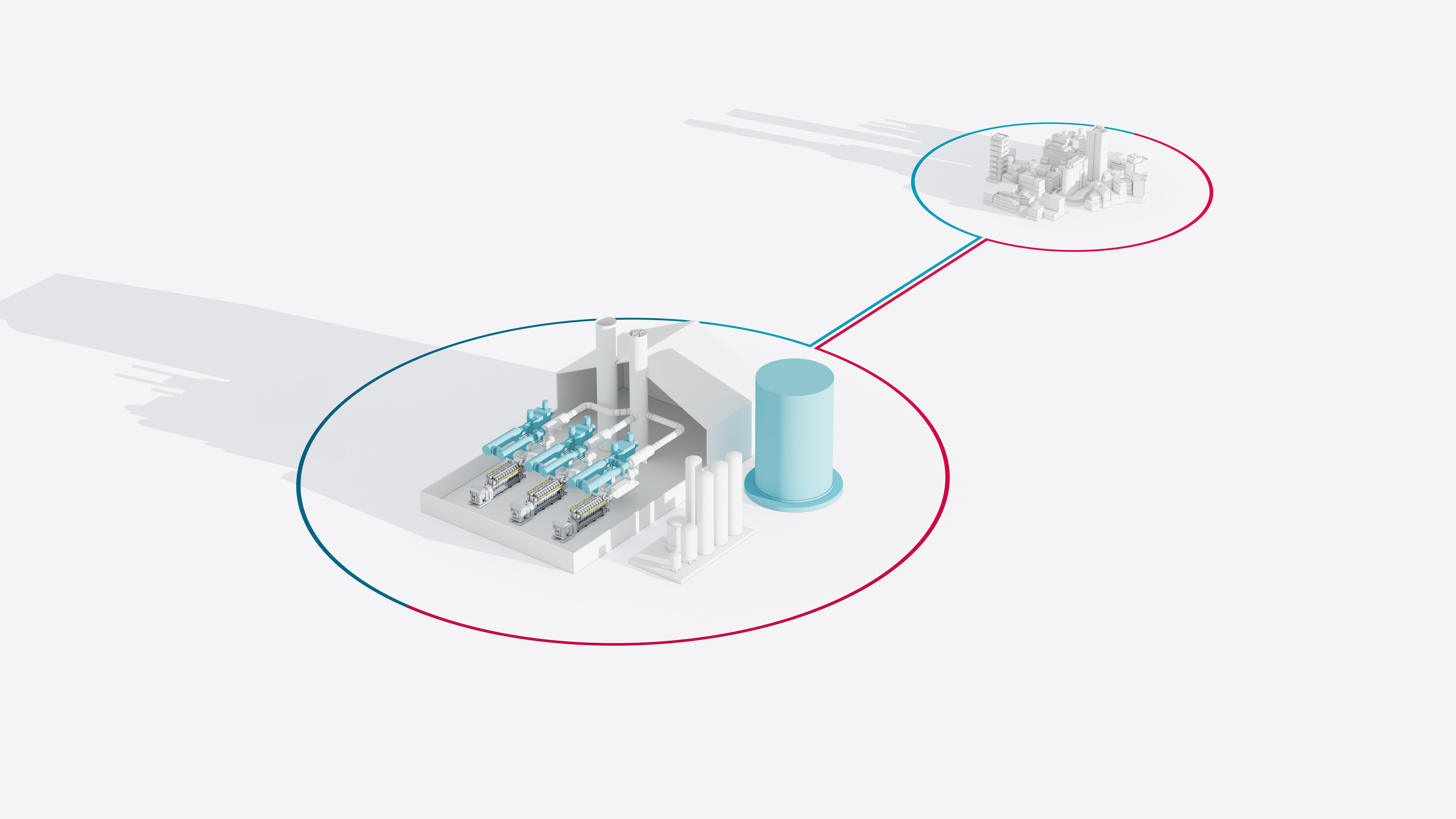

A CHP plant operates by simultaneously producing electricity and capturing usable heat that would otherwise be wasted during the generation process. This is also known as cogeneration and makes it an exceptionally efficient energy solution. Unlike conventional power plants, which lose a significant portion of energy as heat, a combined heat and power system repurposes that heat for practical applications such as industrial processes, district heating, or even cooling through absorption chillers.

The process begins with a primary energy source, such as natural gas, biogas, e-methane or other fuels, powering an engine to generate electricity. The heat produced during this generation is captured and utilized for thermal energy needs. This integrated approach not only reduces fuel consumption but also significantly lowers greenhouse gas emissions, making it a sustainable choice for industries, municipalities, and businesses.

By combining electricity generation and heat recovery, a CHP plant can achieve high efficiency levels, helping organizations save energy, cut costs, and contribute to a greener future.

Power smarter with flexible engine-based CHP plants

We design reliable engine-based CHP solutions with the flexibility to meet your changing load requirements. In addition to using practically all of the input energy to achieve efficiency levels of up to 95%, these systems also use the heat from the gas engine to produce heat or cold.

Everllence engine-based CHP solutions are the ideal choice if your business focuses on electrical power generation and hot water production, e.g. the power-to-heat ratio is higher than 0.8. We design CHP plants with engines that offer a great deal of flexibility in terms of the different electricity and thermal power demands that energy producers face throughout the year. Compact in design, these systems are quick to install and easy to maintain. The high-power density and fuel efficiency cut CO2 emissions and keep operating costs down.

How you benefit:

- Optimized fuel efficiency of around 95 %

- Excellent fast-start and dynamic as well as low-load capability

- Multi-fuel capability

Download

Get the complete picture

Contact our experts

Make the most of your energy – with combined heat and power

Discover the perfect CHP system tailored to your needs with Everllence. Get in touch today and let us help you boost your efficiency and take your operation to the next level!