Our compression technology for carbon capture

Everllence plays a key role in carbon capture: We provide the compression technology necessary for the various CO2 gas streams within the capture process (amine, cryo, PSA, membrane), thereby integrating compression duties for CO2 liquefaction or delivery to pipeline for transportation.

Furthermore, we provide extended process components and turbomachinery solutions such as closed water-cooling loops and process solutions with heat and power recovery.

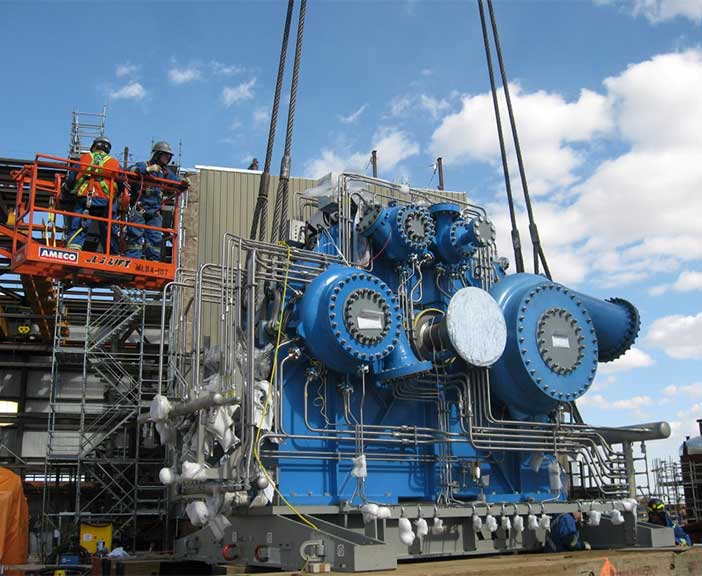

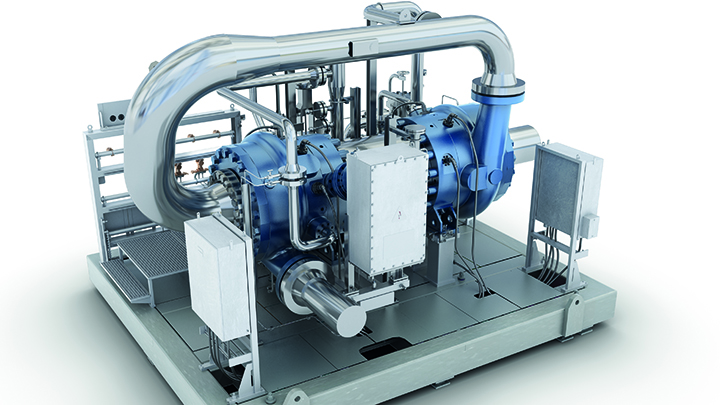

The Everllence RG compressor can contain up to ten impeller stages. This enables a very compact design, compression of a wide range of gases, and a high-pressure ratio. Our complete package option consists of a compressor core unit, driver, process gas coolers, lube oil system, process piping, and auxiliaries. This ensures the shortest possible on-site installation times

Facts

Good to know

Everllence' systems will avoid CO2 emissions in the gigaton range in the future

Geological storage must be at depths greater than 800 meters to maintain the CO2 in a dense liquid state. This requires injection pressures between 130 and 250 bar.

of CO2 per annum will have to be stored globally to keep climate change within the limits set forth in the Paris Climate Agreement (according to IEA 2020)

Find the right carbon capture and storage technology for your plant

Everllence is your expert for Carbon Capture Use and Storage (CCUS) technologies: We supply the technology for the compression of CO2/super-critical CO2, for the liquefaction of CO2 and for heat recovery and heat integration for process plants. We focus on modularization and standardization of our CCUS solutions to decrease complexity and workload on site for our customers,

Carbon capture, utilization, and storage (CCUS) provides a proven and practical way of reducing emissions for large industrial plants. Everllence technology plays a key part in CCUS.

.jpg?sfvrsn=839615c3_3)

Integrally geared compressors are used in industrial gases, oil and gas, CO2, urea, purified terephthalic acid or nitric acid processes. They can also be used as fuel gas boosters for large-scale gas turbines.

Compressors manufactured by Everllence is at the heart of many processes in various process industries. They are renowned worldwide for their quality as well as their high efficiency.

Greener cement industry with CCUS

Together with strong partners, Everllence offers carbon capture as a solution to its customers in the industry sector. As one of them, Heidelberg Materials Norcem will realize the world's first carbon capture facility for large-scale cement production

Carbon capturing

Emission capturing at Heidelberg Materials

As one of the biggest producers and distributors of building materials in the world, Heidelberg Materials aims to make its entire product portfolio climate-neutral by 2050.

Soon, Norcem will have the world’s first cement facility to realize a carbon capture plant in Norway. In 2024, the subsidiary of Heidelberg Materials will commission a system in Brevik developed by Everllence and Aker Carbon Capture. The goal of the two partners is to develop even more efficient capture processes – one key to this is heat recovery. “Carbon Capture Heat Recovery” (CCHR®) uses heat pump technology based on the Everllence CO2 compressor, thus reducing the capture plant’s energy consumption by 30 %.

Also using carbon capture, the cement facility will capture, compress, and liquefy 400,000 tons of CO2 per year – around half of its total carbon dioxide emissions – and transport it by ships to an underground storage facility.

Get in touch with our experts

Would you like to learn more about carbon capture and storage and which technologies best meet your needs?

Our global network of dedicated engineers is happy to point out the perfect solution for you and your business. Start your change process toward carbon neutrality now and reach out to us today.

Frequently asked questions

Carbon capture and storage (CCS) is the process of capturing CO2, typically from an industrial source, either before it is released into the atmosphere or after release, via direct air capture (DAC). The captured CO2 is compressed into liquid or solid form, which can then be transported to storage locations deep underground such as depleted oil fields, saline aquifers, or other porous geological formations. This process is known as sequestration.

The CO2 can be captured after combustion using methods such as amine treatment, cryogenic capture or pressure swing adsorption. Most-commonly it is captured by amine absorption. The CO2 is removed by a chemical absorption process that involves exposing a flue gas stream to an aqueous amine solution. CO2 reacts with the amines to form a soluble carbonate salt. This reaction is reversible and the CO2 can be released by heating the solution with the carbonate salt in a separate stripping column. The pure CO2 is then compressed and transported to a storage site.

In many cases, the captured CO2 can serve a new purpose in other industries. For example, CO2 is needed at industrial sites making fertilizers, plastics and rubber; and it has numerous applications throughout the food and beverage industry, and in the medical industry. The purified CO2 can be transported to those facilities that utilize CO2 as feedstock.

CO2 can also be used to enrich greenhouse air to increase plant yields. Installations that traditionally emit large amounts of carbon dioxide are candidates for CCS technology, either retrofitted or as part of new plant construction. There are currently 27 large-scale CCS projects operating around the world, with many more expected.

Carbon sequestration is the process of removing CO2 from the atmosphere and storing it.

Carbon dioxide must be compressed to be fit for transport. Everllence uses a gas compressor to reach the desired pressure.

Capture your unavoidable emissions

Everllence offers carbon capture and utilization technologies that support the extraction and compression of CO2. Once captured, CO2 can be stored and reused to form the backbone of a circular carbon economy.