High performance built on decades of experience

Real innovation for your industry

Everllence offers various types of axial flow compressors to meet your specific applications in the air separation sector, the iron and steel industry and fertilizer business. We also serve downstream fluid catalytic cracking (FCC) and propane dehydrogenation (PDH) processes in further markets. Depending on your requirements, you can choose from Everllence non-intercooled AG or AR axial flow compressors.

We continuously advance our axial compressor portfolio and are proud to be the world’s leading supplier, with more than 1,000 units in operation. Typical applications include air separation plants and liquefied natural gas (LNG) facilities, propane dehydrogenation and low-BTU fuel gas services, as well as CO₂ compression and compressed air energy storage (CAES). Axial compressors are also used in wind tunnel installations and flue gas compression for industrial processes.

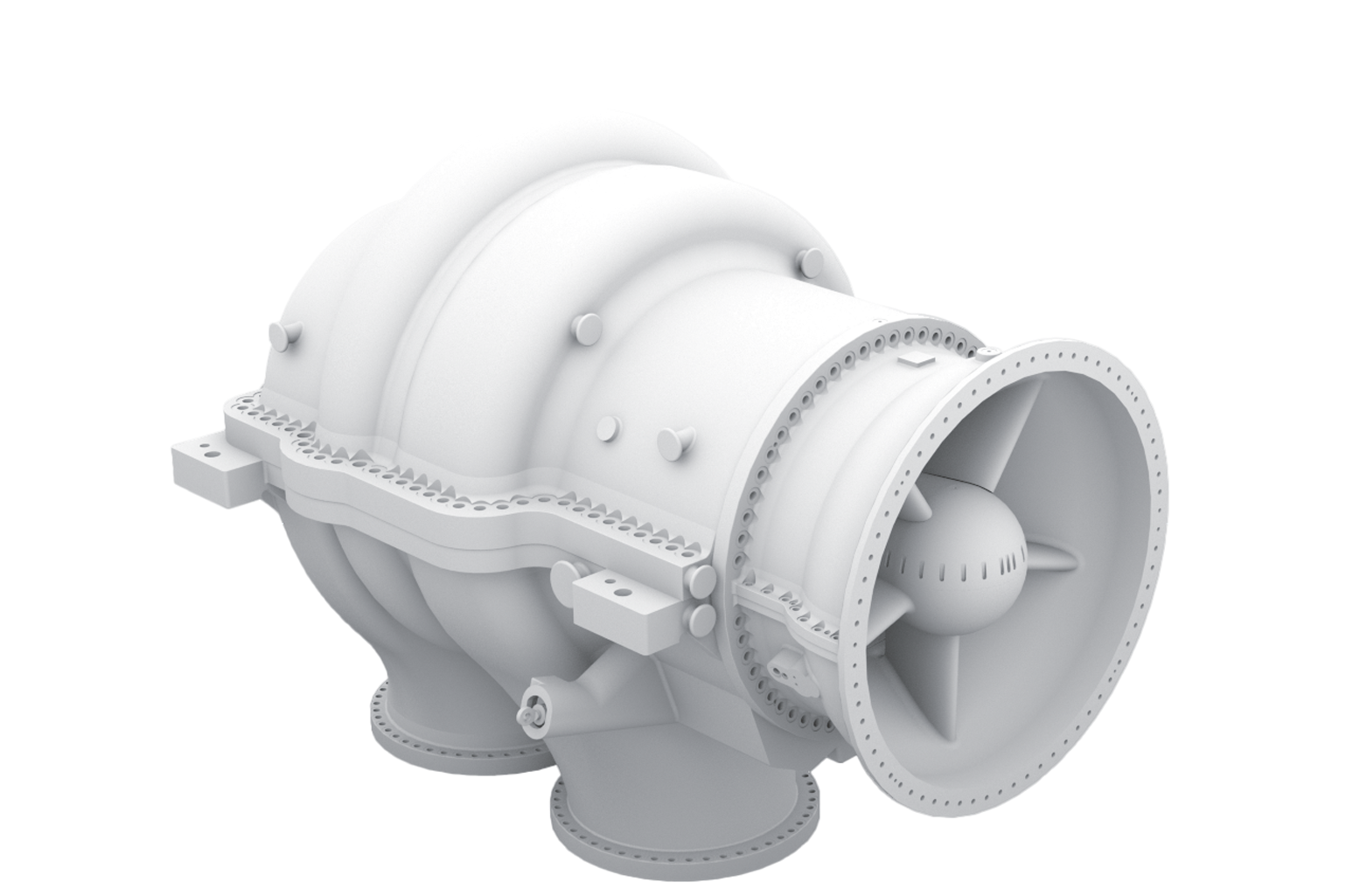

The next generation of axial compressor: The MAX1

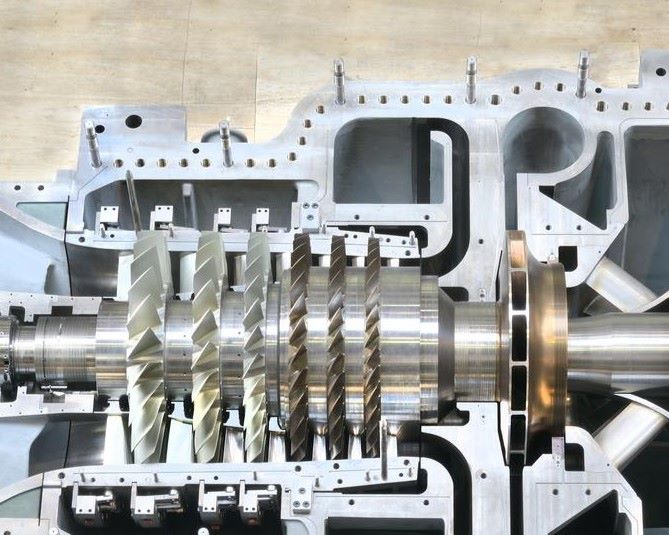

A revolutionary product borne out of decades of experience, the MAX1 standardized axial/radial main air compressor is equipped with advanced MAX1 blade technology.

Our axial compressor is designed to deliver volume flows up to 1.5 million cubic meters per hour, pressures up to 25 bar and is uniquely compact, robust and efficient. Its wide chord blading allows for greatly increased resistance to mechanical blade loads. It is a fully API compliant, standardized modular system with a simple layout and reduced number of parts.

With its potential ranging from higher pressures for HP-ASU, to very large air compressor trains (7,000 t/d O2 and larger), the MAX1 axial compressor is the smallest and lightest solution in the market. It is simple to transport, easy to maintain, operates with optimized efficiency and is highly robust.

Find more insights

Downloads

Contact our Everllence industry team

Let our expertise work for your business

Everllence provides the advice and solutions you need to make your business ready for the future. Get in touch today - and we'll set you up for a successful tomorrow.

Axial compressors FAQs

Compressors and machinery trains for basic materials production

Liquefaction enables safer and more efficient gas transport and storag

Reliable compression solutions for industrial gas production