Everllence compressors

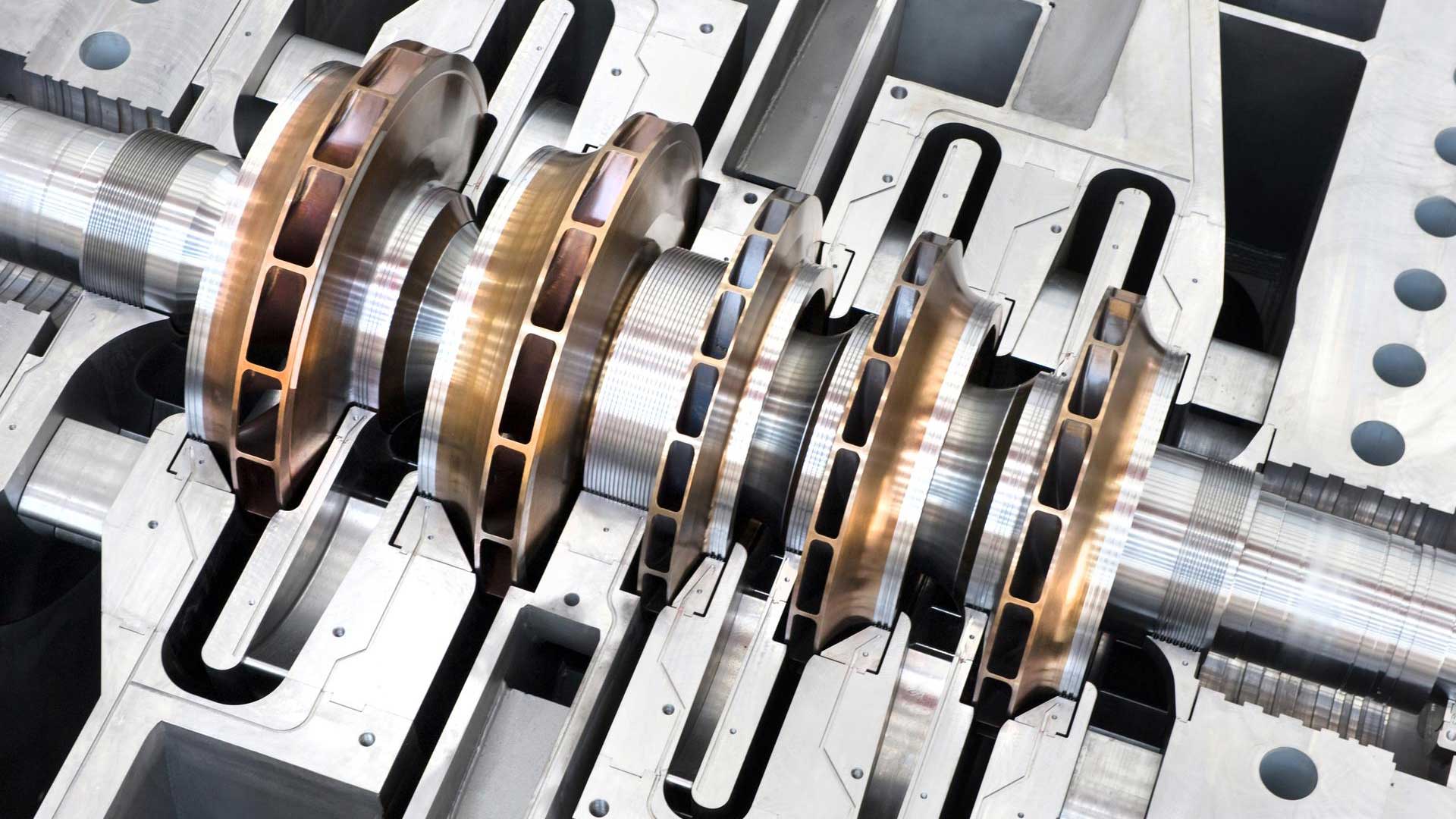

Air and gas compressors you can count on

trouble-free continuous operation in refinery and other areas of application.

Introducing the Everllence compressor range for industry

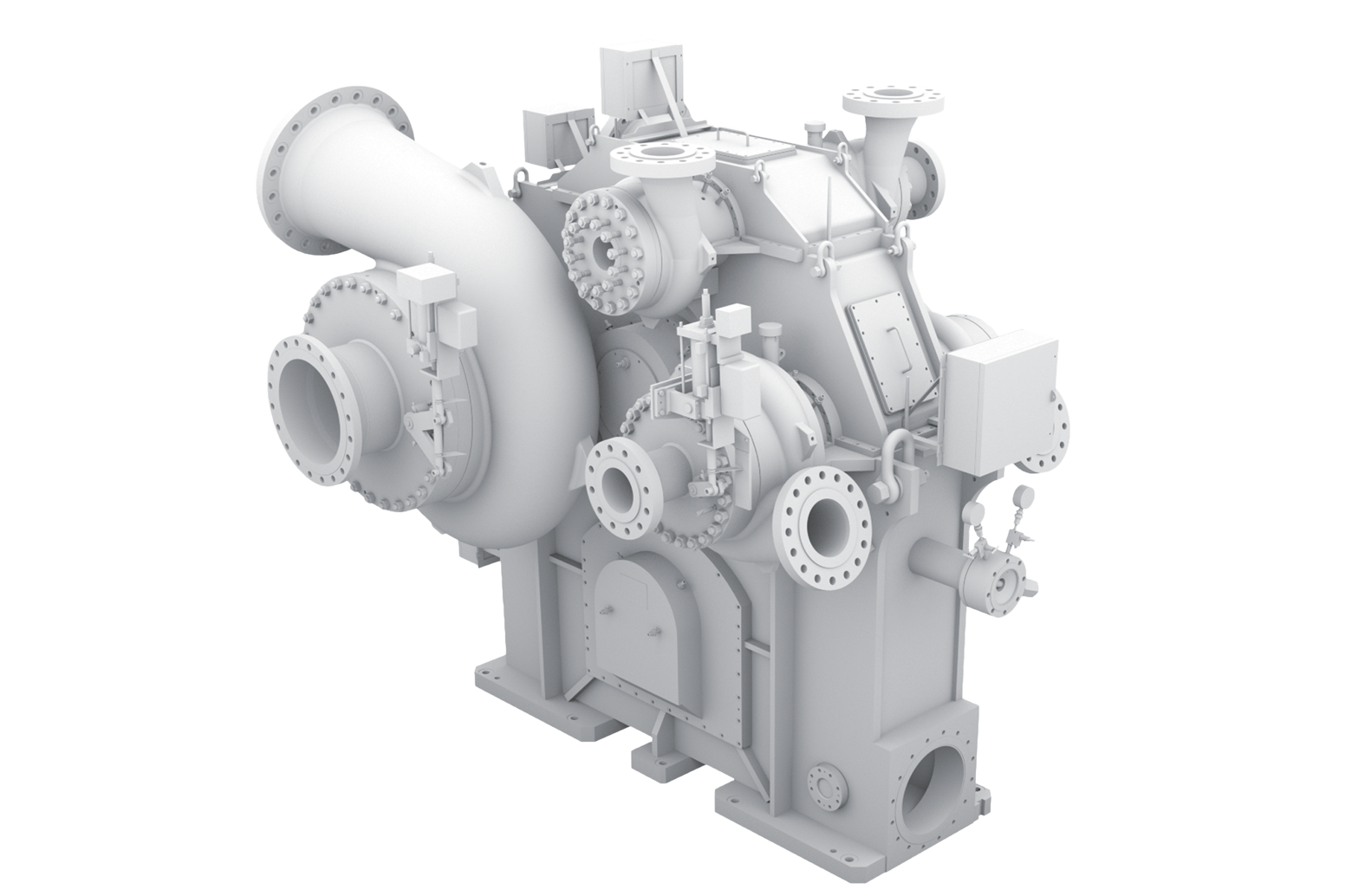

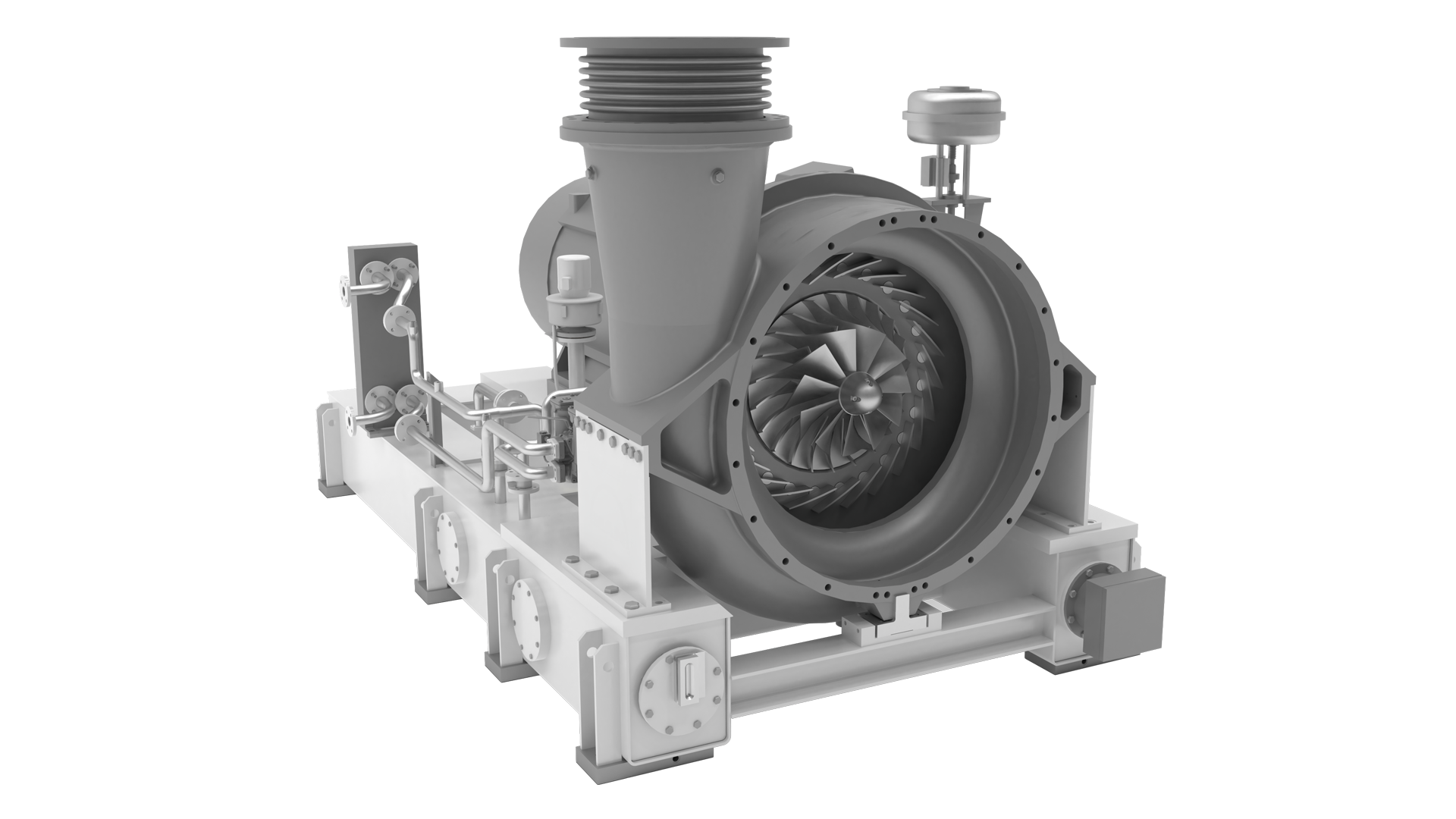

These compressors sit at the center of several high-volume flow industrial applications such as in blast furnace blowers, propane dehydrogenation, air separation, fluid catalytic cracking and others.

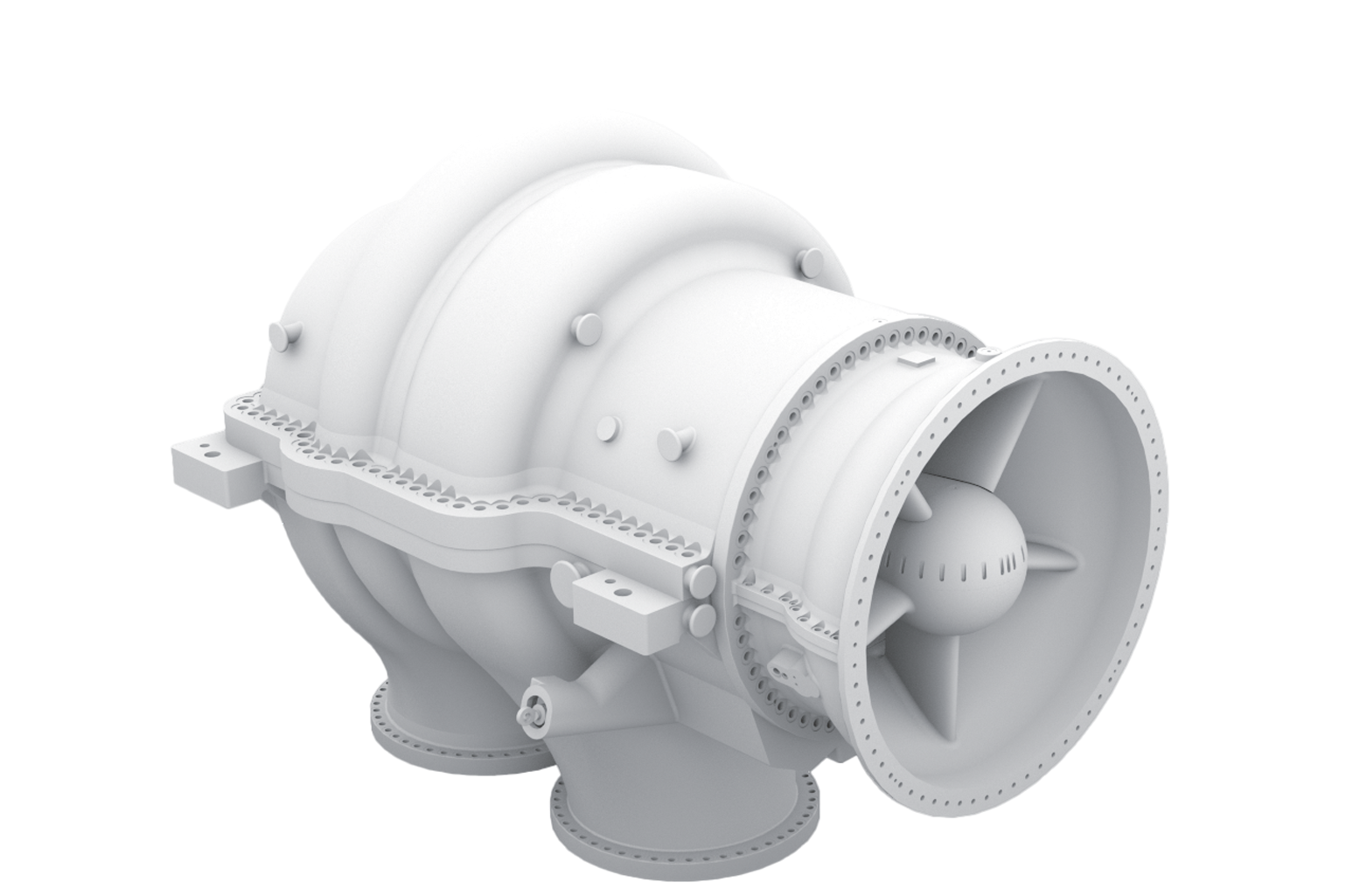

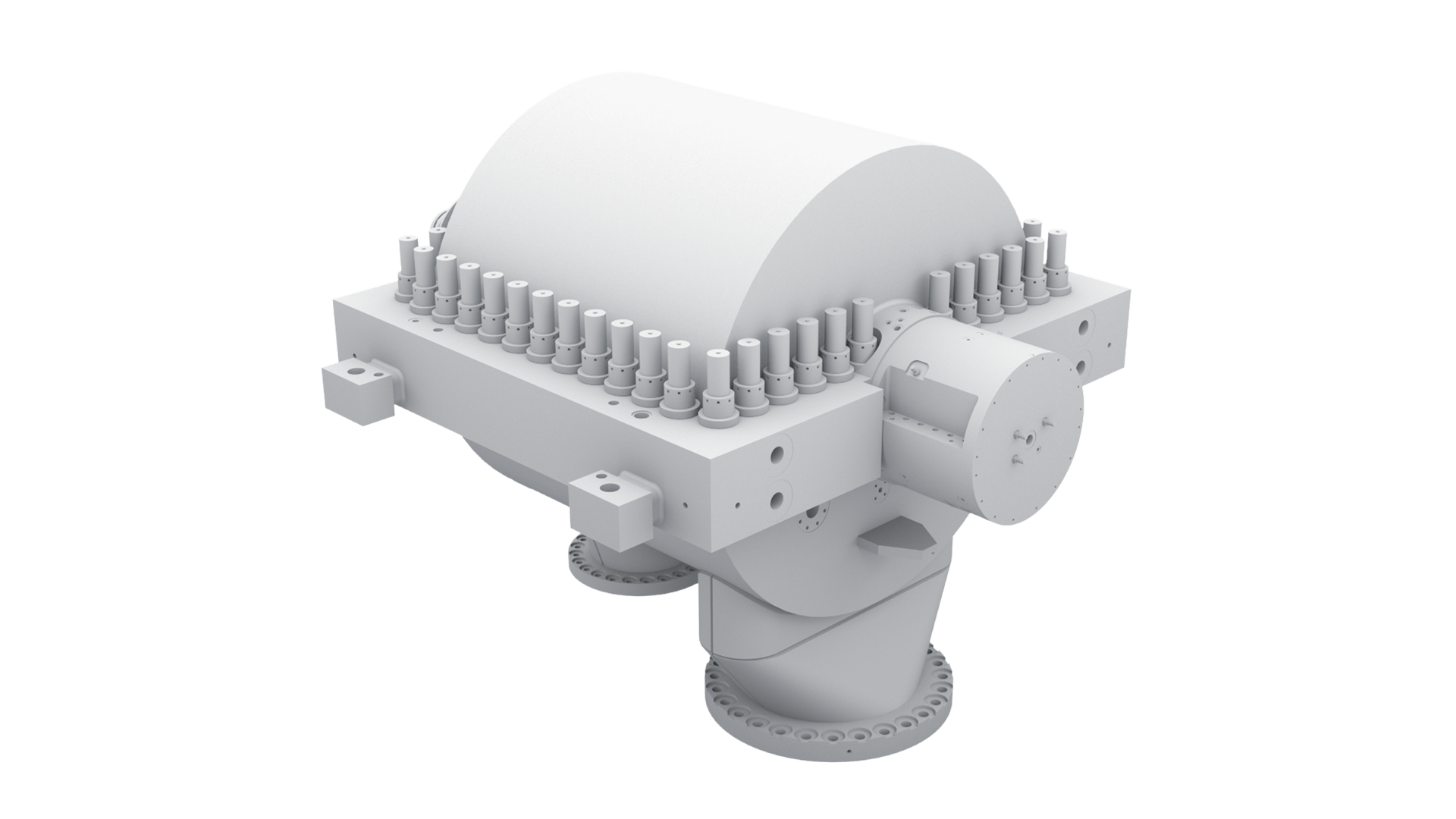

These multi-shaft centrifugal compressors allow for up to five pinions, depending on your individual requirements. These compressors are popular due to their high efficiency and low investment outlay.

These unique integrated coolers allow for extremely high efficiency and operational robustness. Their core application is in air separation plants.

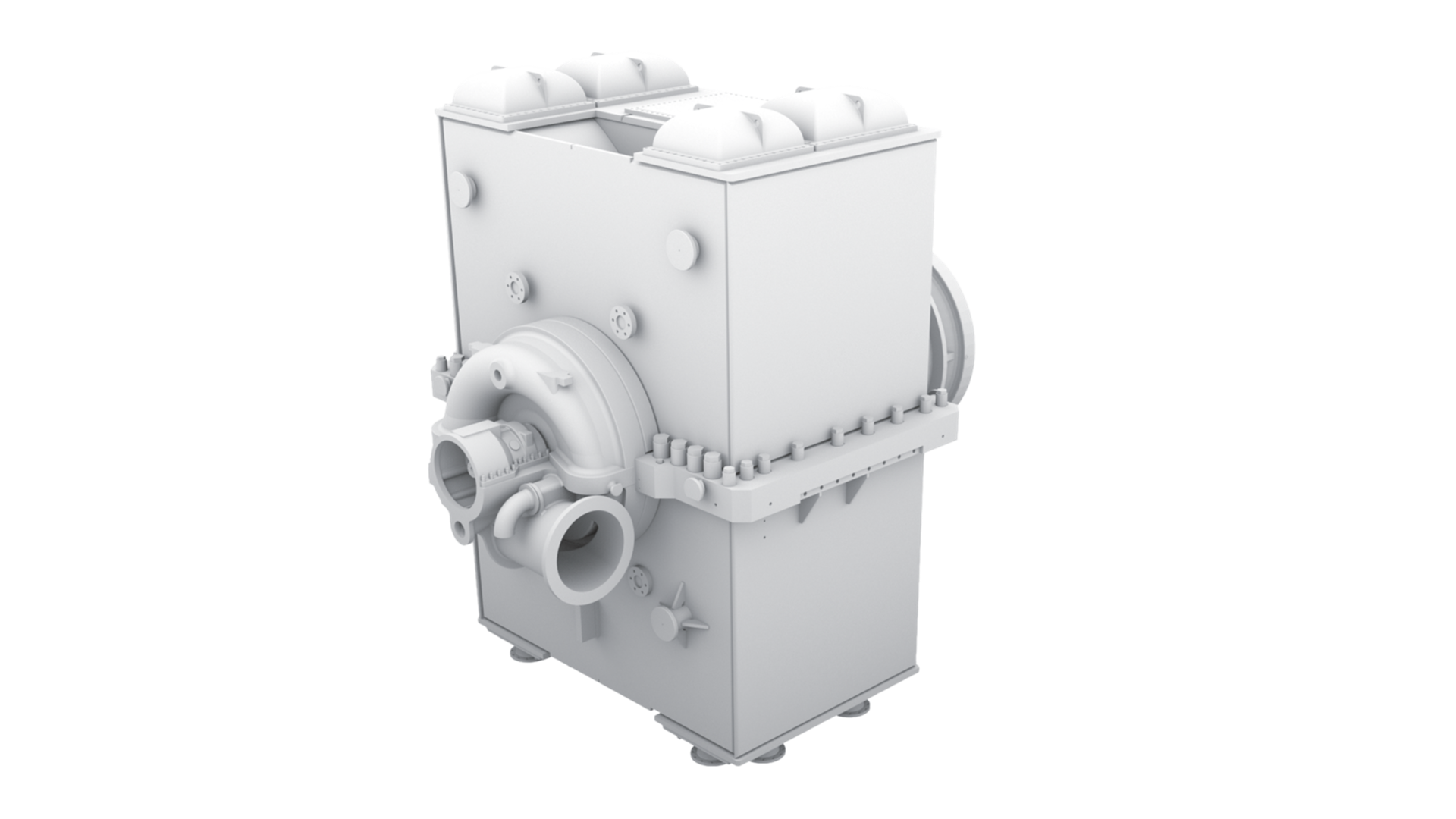

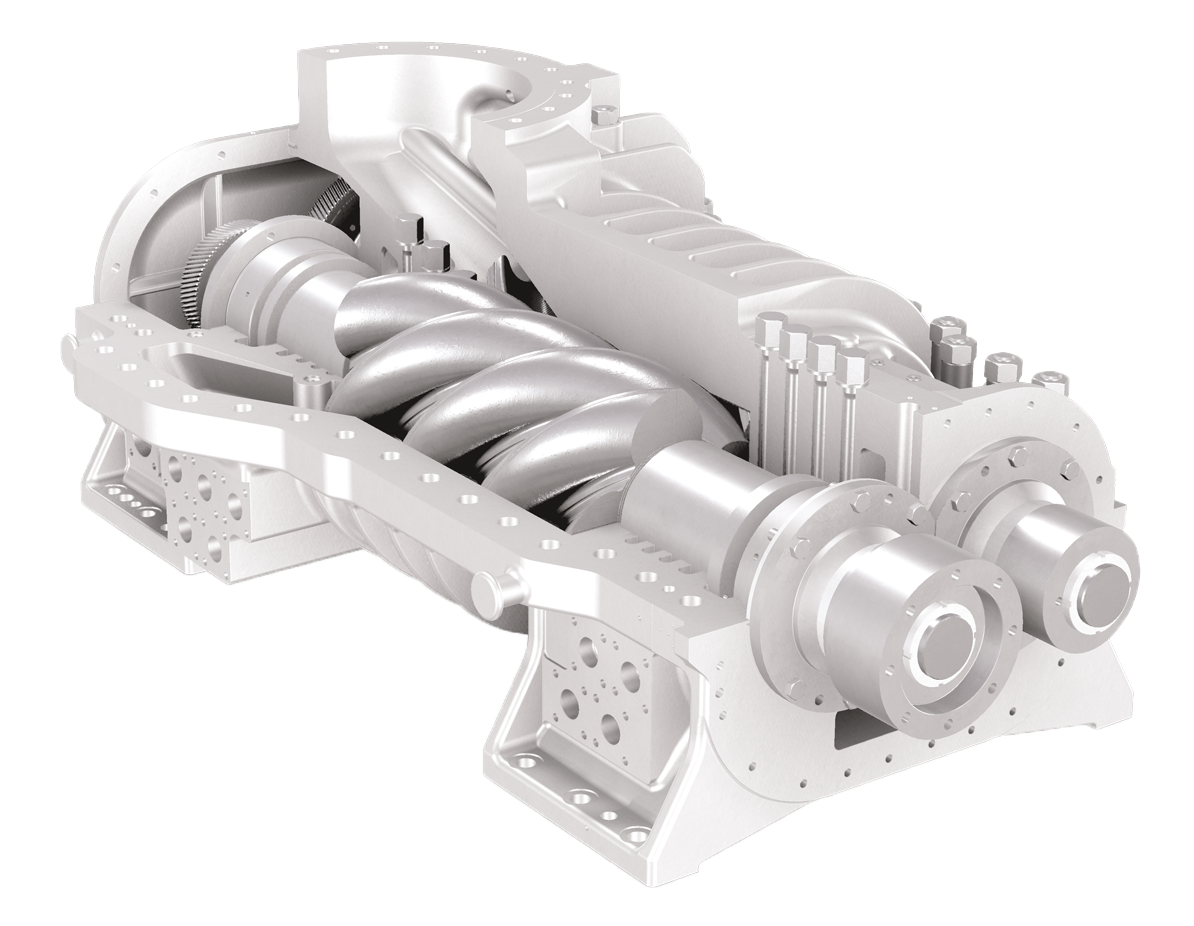

These oil-free compressors feature in a wide range of processes in exploration and production, LNG, fuel gas, industrial gases – including hydrogen, and other industries. They are suitable for onshore and offshore conditions and capable of compressing all gases except pure oxygen.

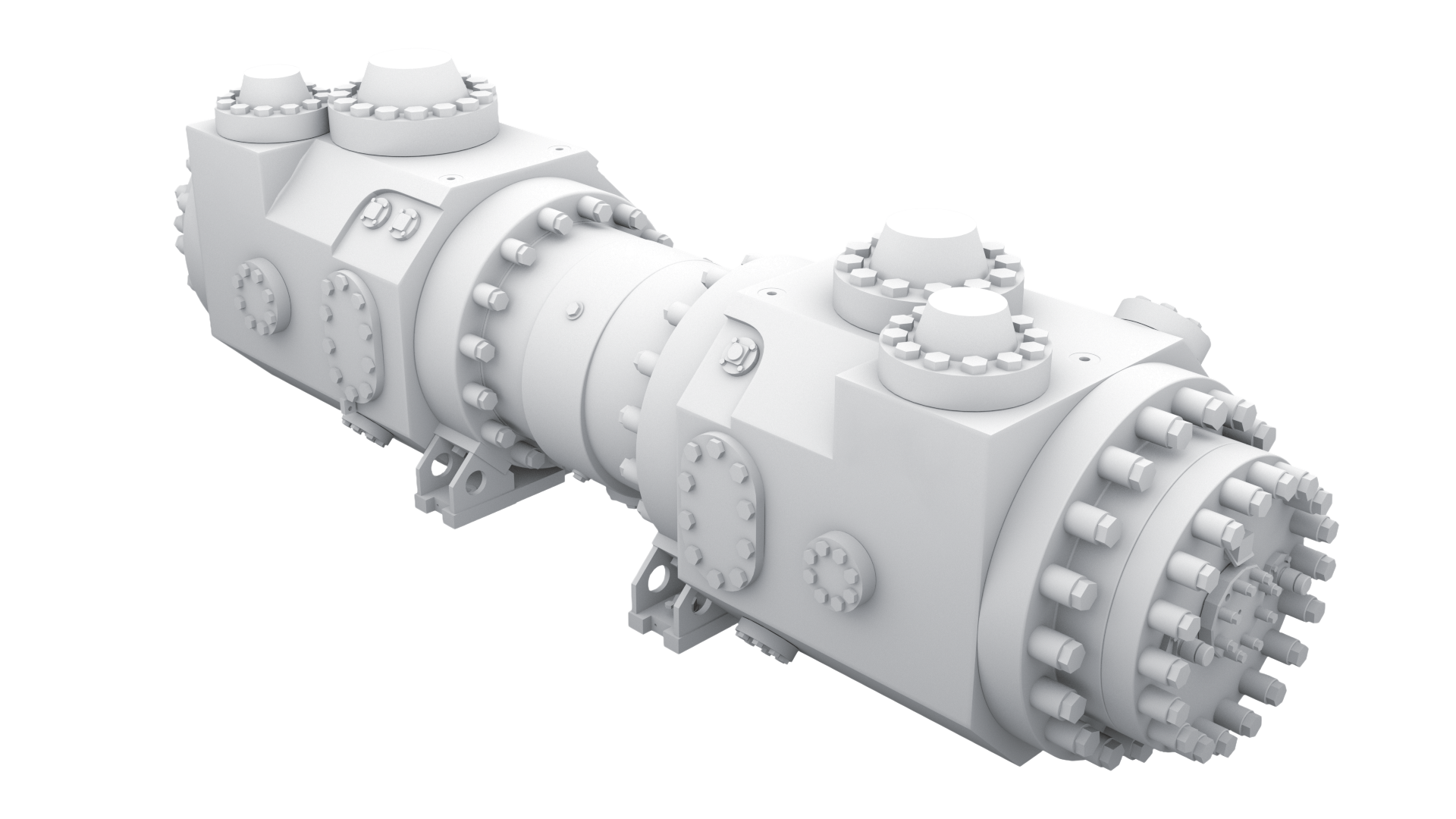

Available in horizontally split (RH) or barrel-type (RB) designs, these compressors are well-proven and are used in many industries, from chemicals to exploration and production, industrial gases and others.

Our hermetically sealed compressor solutions – including the proven HOFIM® and MOPICO® designs – are built for demanding and hazardous applications. Their closed, leak-tight construction ensures maximum safety and reliability in gas compression.

We developed these compressors for the pulp and paper industry in particular. TURBAIR® is available as a single blower with vacuum level up to 65 Kpa, or as a multi-stage blower with a maximum of four different vacuum levels up to 75 Kpa.

Contact our experts

Everllence compressors unite proven technology with innovative solutions

All our compressors comply with current design standards and have been thoroughly tested. Highly reliable, they need little maintenance and ensure minimal downtime. Learn how our products can assist in enhancing your processes.

Compressor FAQs

Yes. Regular maintenance is crucial for compressors to ensure optimal performance, reliability, and longevity. Scheduled maintenance helps identify wear and tear before it leads to unexpected failures. And of course, proper servicing keeps the compressor running at peak efficiency. With Everllence PrimeServ (former MAN PrimeServ), our service engineers provide preventive maintenance, assist your troubleshooting, and help keep your facilities up and running. They are on hand wherever and whenever you need them. How you benefit:

- Fast, reliable and expert customer support

- Bespoke service agreements

- Global service – 24 hours a day, 365 days a year

Go to Everllence PrimeServ