The facts speak for themselves

Everllence delivers its first process gas turbine

Move towards carbon neutrality and economic efficiency

In many industrial processes, lots of valuable energy and residual gases can simply go to waste. With the general drive towards carbon neutrality and demands for ever greater economic efficiency, it has become important for industrial machinery to operate with optimal efficiency while maximizing resource utilization.

Everllence expanders are particularly designed for energy recovery. Turboexpanders utilize excess power or heat to drive separate power generation units or turbomachinery in power recovery trains, thereby achieving maximum efficiency.

Powerful, carbon-free energy systems by Everllence

We are constantly developing new processes and solutions for a carbon-free future. Our energy storage and heat pump solutions are designed as closed cycles containing compression and expansion of diverse refrigerants and air. Let Everllence be your partner to improve and optimize your processes – ensuring reliable power is delivered when it is needed.

Depending on your requirements, Everllence expanders come in single and multistage designs and in axial or radial blade/impeller configurations. Our turboexpanders are either connected to a power generator or directly integrated into a compression train.

Range covered:

- Power output up to 45 MW

- Inlet temperature up to 760°C (1,400°F)

- Inlet pressure up to 25 bar

Choose the Everllence expander that is right for you

In addition to the expander solutions highlighted here, steam turbine derivatives are also part of our offering. While not the primary focus of this overview, they are readily available and supported. If you're interested in these solutions, our expert team will be happy to advise you.

The integrally geared expanders are applicable in a wide range of processes such as terephthalic acid and nitric acid.

- High and low pressure ratios

- Single and multi-stage

- As a separate machine or as an integrated part of an integrally geared compressor

- Wide range of volume flows

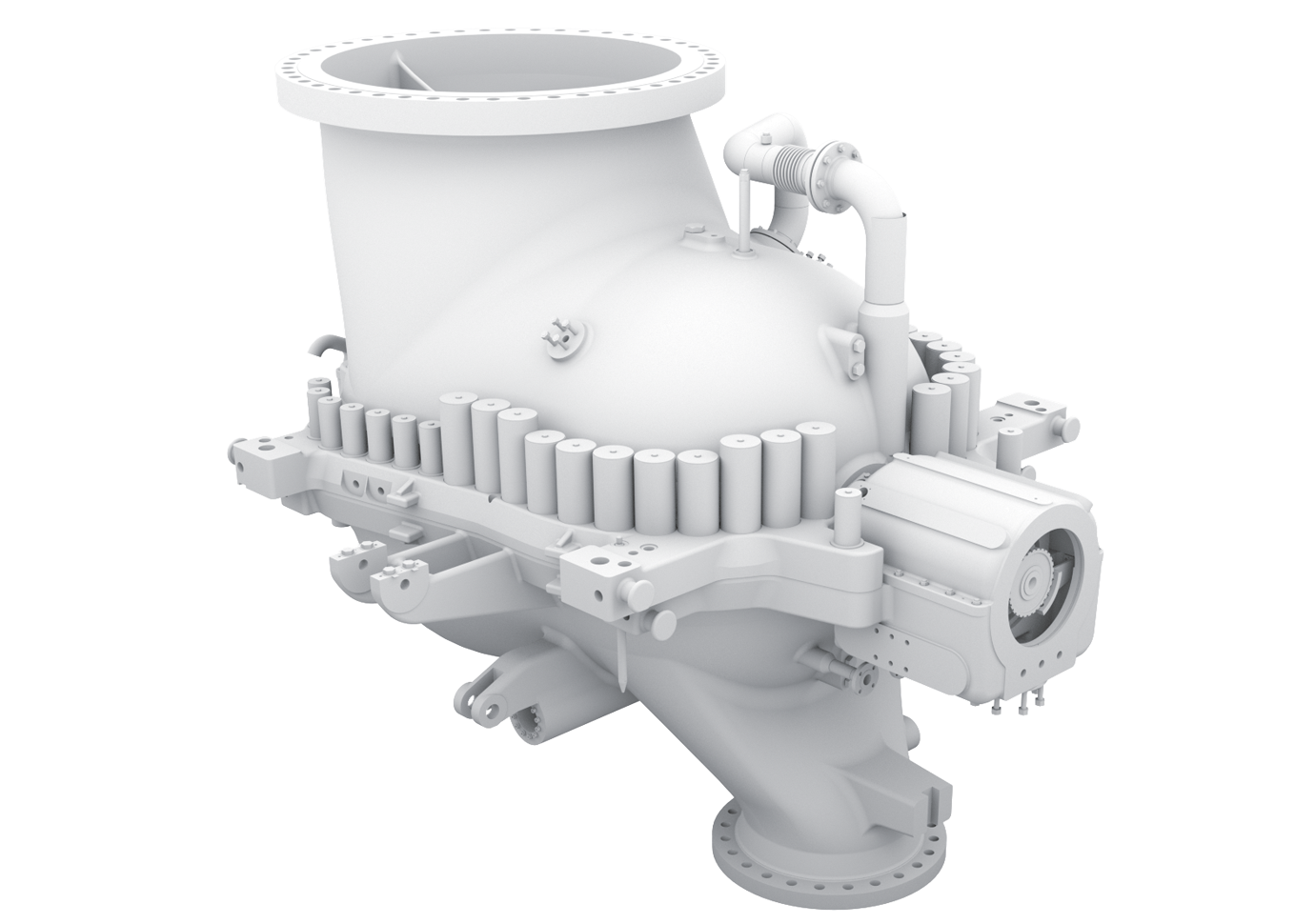

This expander is a standardized multi stage axial flow expansion turbine mostly used in nitric acid and blast furnace top gas recovery applications.

- High efficiency

- Stand alone or integrated in a complex train

- Available also in a single stage design with radial inlet and axial outlet

Everllence hot gas expander is operating at temperatures up to 760°C and therefore used in applications such as FCC.

- Available in single stage design with axial inlet and radial outlet

- Multistage design with radial inlet and outlet available

- Stand alone or integrated in a complex train

Find more insights

Downloads

Contact our Everllence industry team

Are you looking to optimize your energy recovery?

Everllence expanders could be just what you need. Our expanders improve the efficiency of your processes by recovering energy. Let us create a tailor-made machine for your business.

High-performance expanders FAQs

Energy recovery solutions for PTA and fertilizer production

Our expanders increase efficiency in refinery and chemical processes