Marine

Advancing ammonia engine innovation

The Everellence B&W ammonia two-stroke engine builds on the proven ME-LGI concept and the development is currently well underway at our Research Centre Copenhagen. Designed as a newbuild engine, which will become available as retrofit solution for electronically controlled ME-C engines, this ammonia-fuelled marine engine is engineered to enable low-emission operation for tomorrow’s fleet.

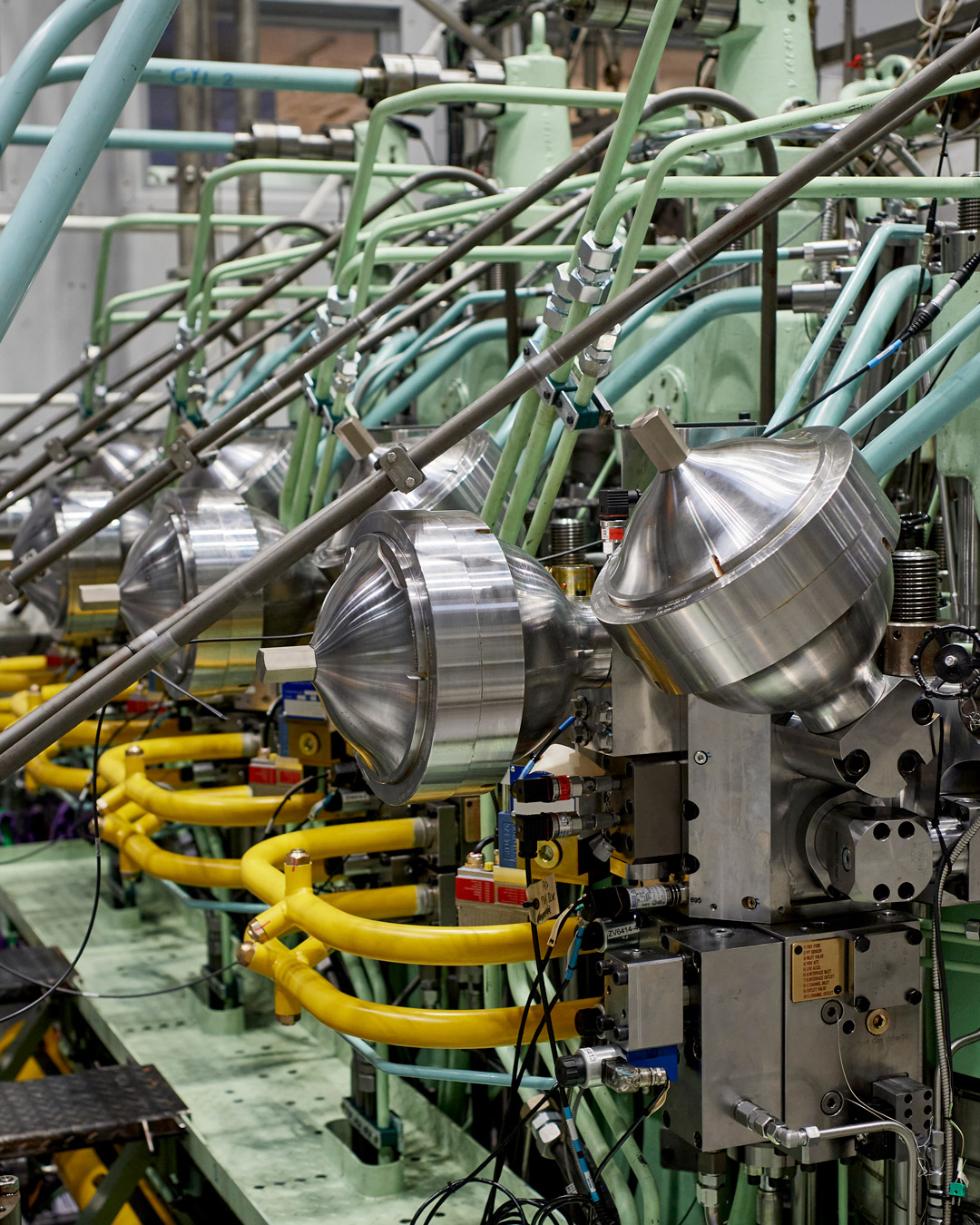

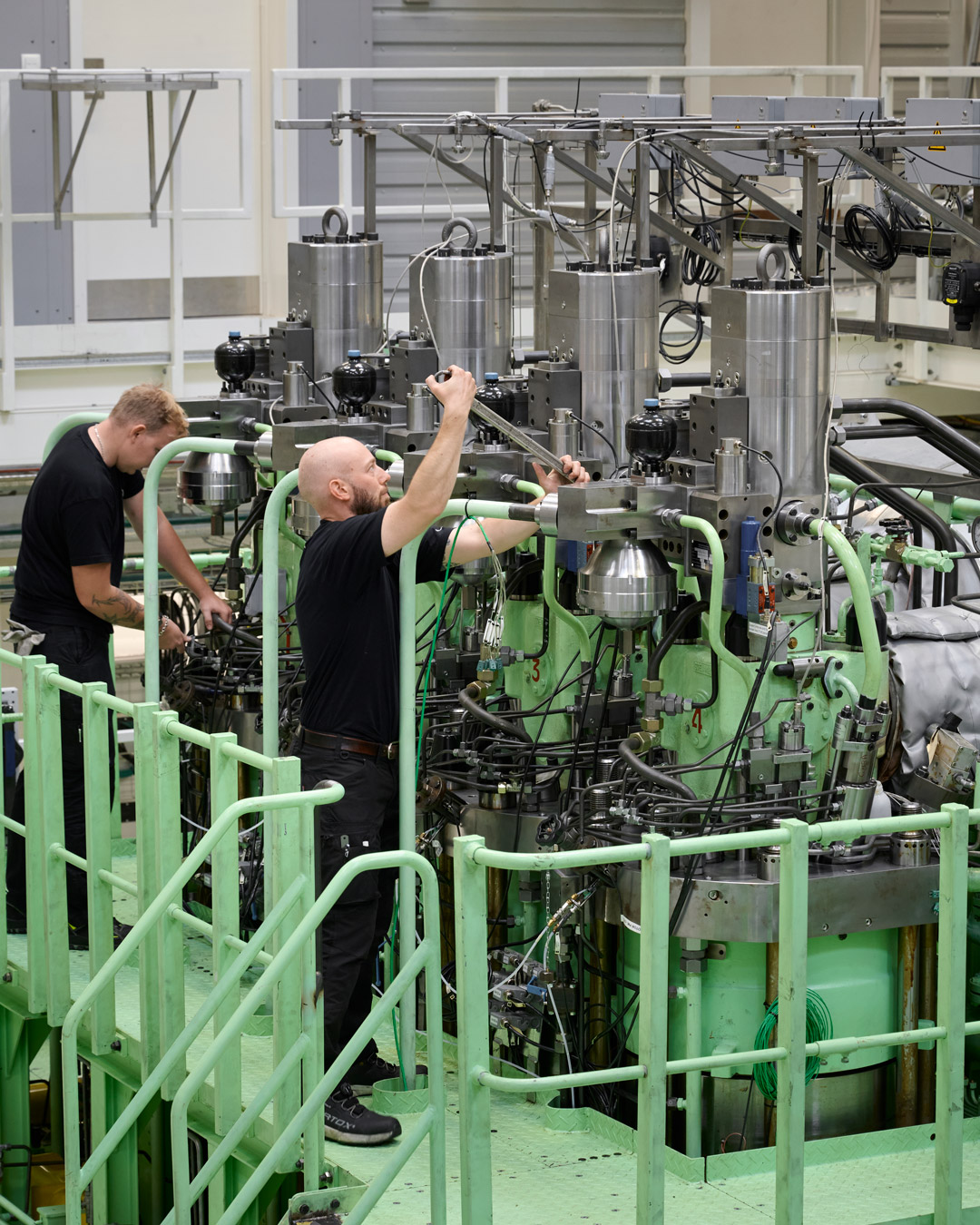

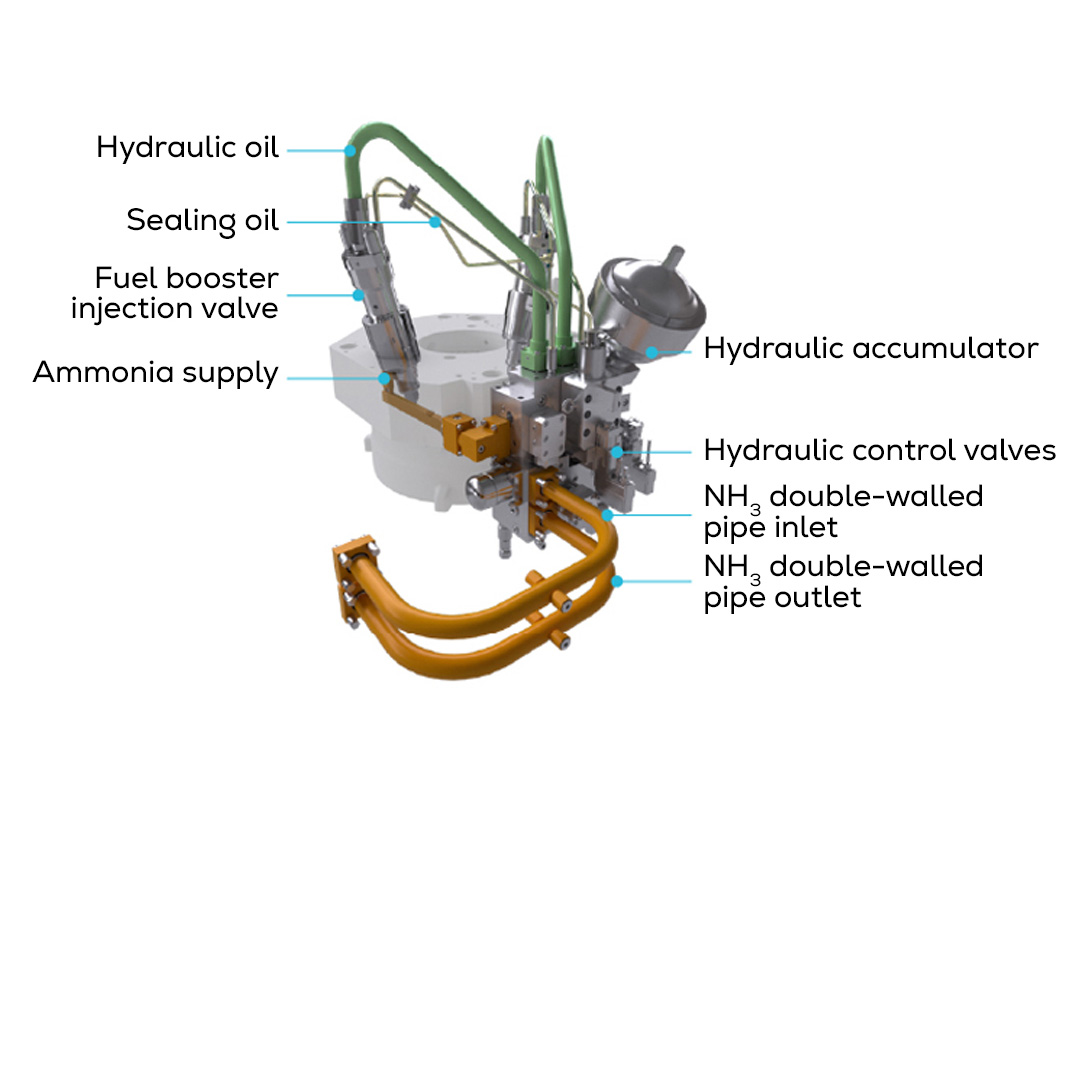

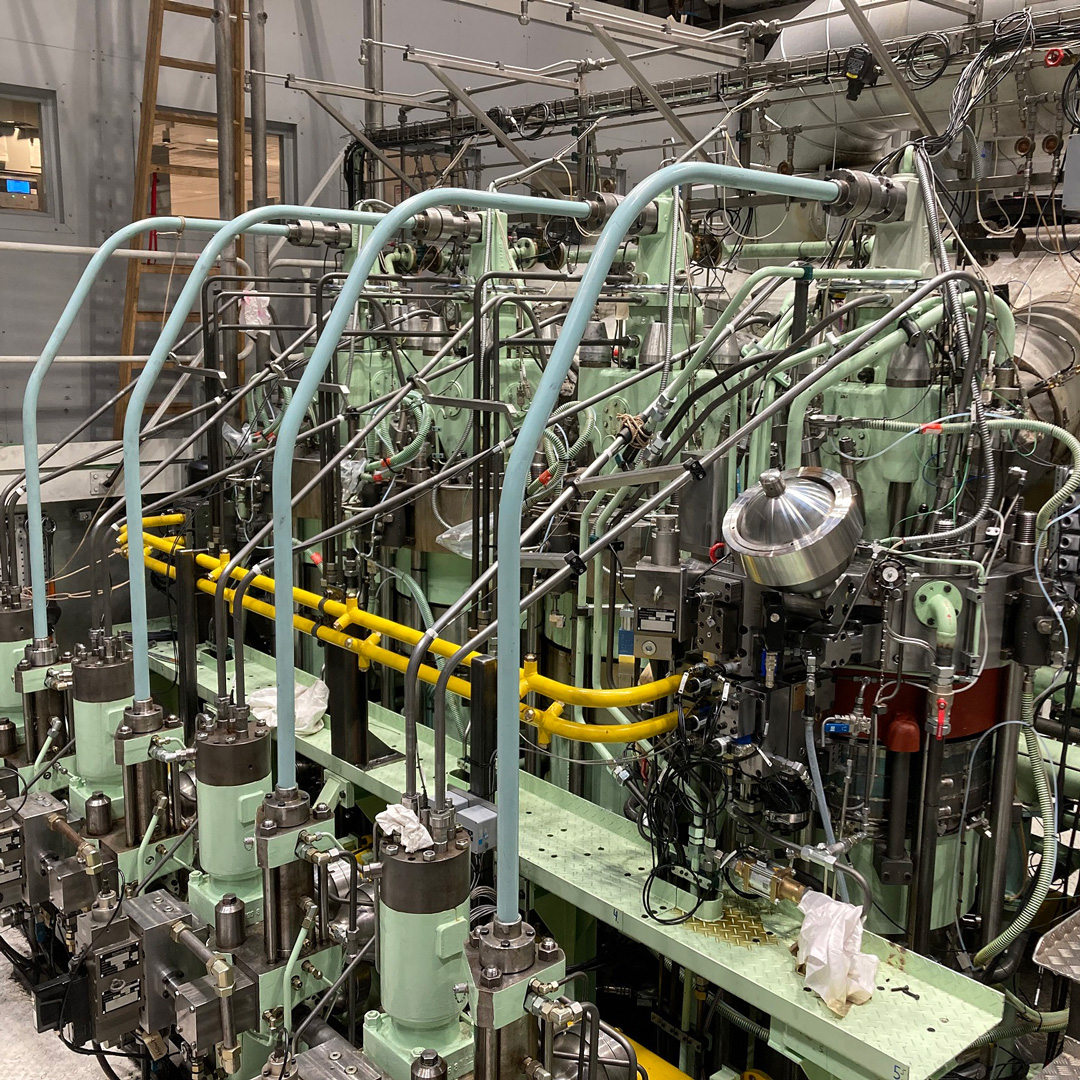

Our engineering teams are incorporating essential safety features such as ammonia containment systems, sensors, system ventilation and double-walled piping. In July 2023, the first ammonia combustion was successfully achieved on our research engine, with highly stable performance data.

Full-scale engine testing began in November 2024 and focuses on combustion behavior, emissions, engine tuning, atomizer validation and control system verification. The testing phase is scheduled to continue through mid-2025.

Powering the future with zero-carbon fuel

Everllence B&W ME-LGIA development

By loading the video you agree to YouTube's privacy policy.

Key benefits of ammonia engines

Ammonia-powered engines offer a compelling combination of efficiency, sustainability, and flexibility – making them a future-proof choice for clean marine propulsion.

- High energy efficiency with low emissions

Ammonia can be used as an energy carrier of sustainable hydrogen and is carbon free. The two-stroke ammonia engine is designed to run with as little as 5% pilot oil at 100% load (L1 rating*), with the remaining 95% of energy coming from ammonia. This results in high power output, excellent engine efficiency, and extremely low emissions - making it a future-proof solution for clean propulsion.

* Performance values indicated refer to energy fraction for L1 rated engines operating at 100% load point in Tier II mode. Actual values may vary depending on engine rating and load conditions. - Carbon- and sulphur-free combustion

Ammonia produces no carbon or sulphur emissions, enabling clean and sustainable combustion. Green ammonia is especially promising as a marine fuel due to its potential for lower production costs compared to other e-fuels such as e-methanol and synthetic natural gas. This positions the ammonia-fuelled engine as a strong candidate for large-scale decarbonization in shipping. - Flexible retrofit options

Ammonia-fuelled engines can be adapted to customer needs – either as newbuilds or as modular, dual-fuel retrofit solutions for existing electronically controlled engines. Whether you operate a modern fleet or look to decarbonize existing vessels, our experts can help you implement the most suitable ammonia engine configuration for your operation.

Contact our Everllence energy support experts

Let our expertise work for your business

Everllence provides the advice and solutions you need to make your business ready for the future. Get in touch today - and we'll set you up for a successful tomorrow.

The Everllence B&W ammonia engine design philosophy

Ammonia mode

The target of 5% specific pilot oil consumption at 100% load for L1-rated engines has been reached*.

There is potential for further reductions, but additional four-cylinder testing will showcase the full potential. The initial ME-LGIA engines will have 5% SPOC*.

We aim for the same heat rate as “fuel oil mode”. The ammonia engine concept will be based on the Liquid Gas Injection engine concept, which is well known from the existing methanol and LPG-fuelled Everllence B&W two-stroke dual-fuel engines.

*Performance values indicated refer to energy fraction for L1 rated engines operating at 100% load point in Tier II mode. Actual values may vary depending on engine rating and load conditions.

Fuel oil mode

In fuel oil mode, we target identical performance as a conventionally fuelled diesel engine

Safety and environmental compliance

Everllence combines proven emissions control systems with dedicated safety measures for ammonia-fuelled engines – ensuring reliable operation and full compliance with global marine regulations.

Engineered safety:

ammonia auxiliary system

The auxiliary systems have been optimized for the Everllence B&W ammonia engine and ensure safe and efficient operation. The ammonia catch system and the addition of absorbers make sure that no ammonia above 5 ppm will be vented to the atmosphere at our Research Centre Copenhagen. These engineered safety measures are critical for enabling ammonia as engine fuel at scale – while maintaining strict environmental protection standards.

Selective catalytic reduction technology

To reduce nitrogen oxide (NOₓ) emissions and to meet IMO Tier III emission regulations, ship engines from Everllence have been equipped with selective catalytic reduction (SCR) technology for many years. This after-treatment process removes NOₓ from the exhaust gas through catalytic reduction, and also eliminates ammonia slip from the exhaust.

SCR systems using urea were already introduced in the 1990s aboard four bulk carriers. Pending the outcome of full-scale ammonia engine testing, the SCR system volume and ammonia consumption may be adjusted to ensure Tier III compliance.

Upcoming ExpertTalks

Marine

Everllence B&W ME-LGIA (morning session)

Download

Everllence Introduces Two-Stroke Ammonia Engine to Global Maritime Industry

Mitsui E&S begins full-scale testing of ammonia engine in Japan

Two-stroke ammonia engine achieves full-load operation at 100% power

Successful ammonia engine tests pave the way for zero-carbon propulsion