Meet our experts

Watch the videos to learn more

By loading the video you agree to YouTube's privacy policy.

In this video, Senior Vice President of PrimeServ Hamburg, Olaf Gunia, introduces Hamburg as our flagship service location.

At this site, we offer comprehensive services for two-stroke and four-stroke engines, turbochargers, and turbomachinery equipment. Our workshop features a lifting capacity of up to 160 tons and a certified material testing laboratory—making Hamburg a standout within the PrimeServ network. Customers benefit from close collaboration and reliable, on-time spare parts supply.

By loading the video you agree to YouTube's privacy policy.

Our expert, Dan Zander, highlights the benefits of our reconditioning services.

Reconditioning means restoring used spare parts to meet original manufacturing tolerances—making them as good as new. Customers receive fully refurbished components, complete with warranty and overhaul intervals, while saving both time and budget. It’s the highest quality level we offer for used parts.

Overview

Our services

.jpg?sfvrsn=d92b15a5_1)

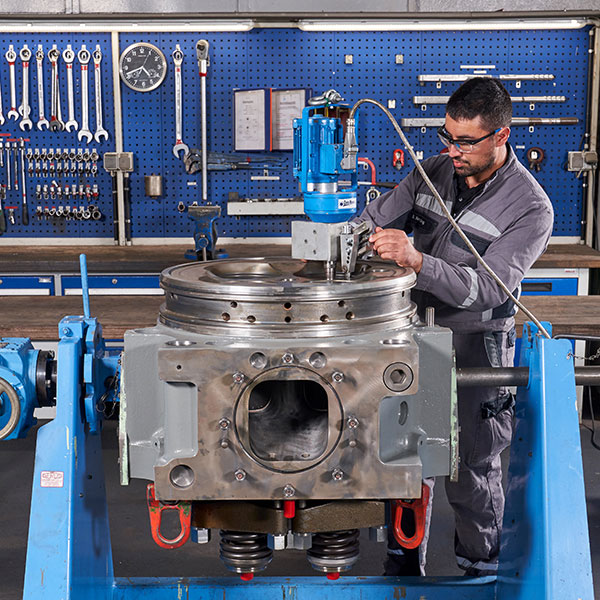

Workshop capabilities

We carry out repairs and industrial assembly services for two-stroke engines, four-stroke engines and turbomachinery.

- Machining small and large components up to 160 tons

- Welding procedures

- Piping and constructional steelwork

- Technical cleaning and packing

- Injection, pumps and valves

- Industrial assembly services

- Materials testing laboratory DIN EN ISO/IEC 17025

- ISO 9001, ISO 14001, ISO45001

Reconditioning: Components are restored to new building tolerances with advanced and extensive overhaul work. The warranty covers the work carried out.

Repair: Components are restored to a functional state. The warranty covers the work performed.

Exchange: Components are directly replaced with new stock parts for very fast delivery times or delivery in advance with used repairable parts returned – full new part warranty.

.jpg?sfvrsn=2c831c80_1)

The right support for your needs

As the original equipment manufacturer, we know your engine better than anyone else and can provide quality as well as reliability in order to reduce downtime and costs. All work is carried out by qualified professionals using specialized machinery and state-of-the-art procedures. We ensure compliance with SOLAS regulations and class rules throughout the life cycle of the component, e.g. with regard to updating the technical files (IMO compliance).

| Reconditioning | Repair | Exchange | |

| Property of | Customer | Customer | Everllence |

| Function in granted | Yes | Yes | Yes |

| New building tolerances | Yes | No | Yes |

| Return delivery required | No | No | Yes |

| Warranty | On work performed | On work performed | Same as for a new spare part |

| Fixes sales prices | Yes | No* | Yes / No* |

*depends on the inspection result

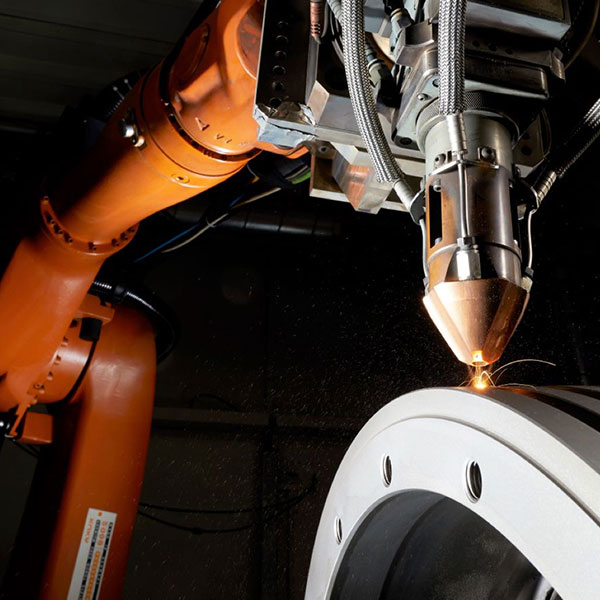

Our reconditioning services

| Reconditioning | Engine type |

| CR pumps | Four-stroke |

| Cross head pin | Two-stroke |

| Cylinder cover | Two-stroke |

| Cylinder head | Four-stroke |

| FIVA valves | Two-stroke |

| Injection nozzles | Four-stroke |

| ME HPS | Two-stroke |

| Piston crown | Two-stroke and four-stroke |

| Piston rod | Two-stroke |

| Plunger b./fuel pumps | Two-stroke and four-stroke |

| Support rings | Four-stroke |

| TC blades | Two-stroke and four-stroke |

| TC rotor shaft | Two-stroke and four-stroke |

.jpg?sfvrsn=a4440935_1)

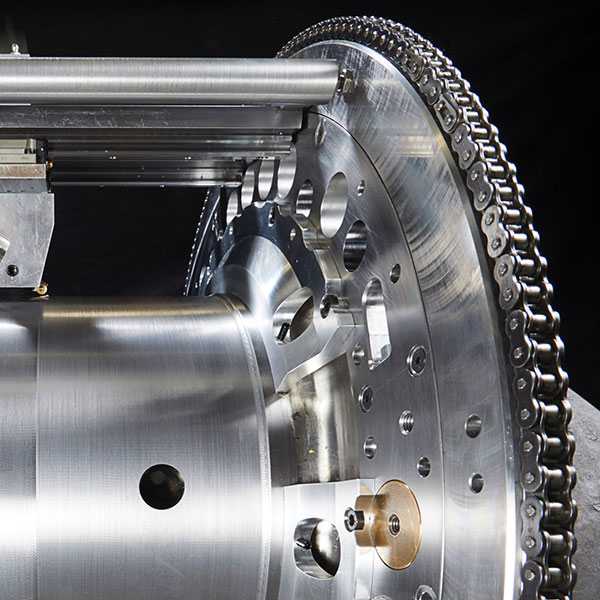

Our repair services

| Repair | Engine type |

| Alpha lubricator | Two-stroke |

| Charge air coolers | Two-stroke and four-stroke |

| Connecting rods | Two-stroke and four-stroke |

| Cylinder liners | Two-stroke and four-stroke |

| Governor | Four-stroke |

| Piston skirts | Two-stroke and four-stroke |

| TC overhauls | Two-stroke and four-stroke |

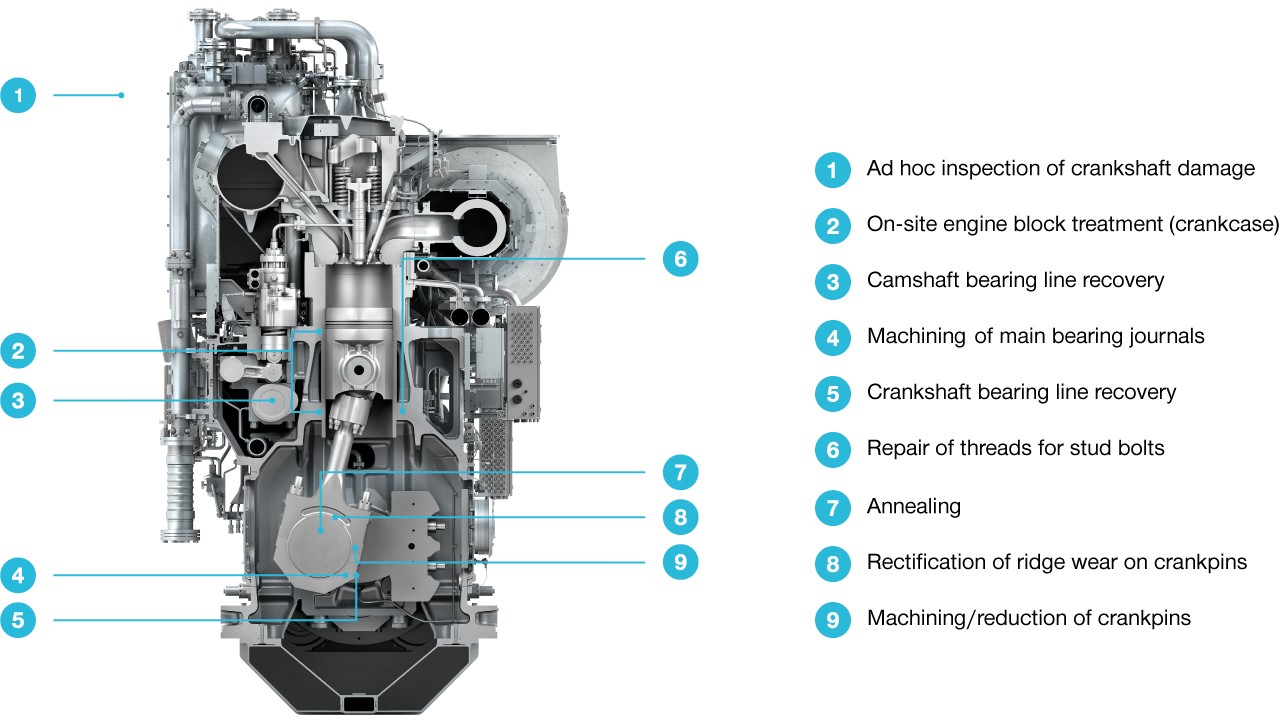

On-site recovery and major repairs

We are equipped with specialized tools (e.g. for crankshaft repairs) and have the experts to perform major repairs on four-stroke engines. We also offer crankshaft inspection after hot-running damage and other major repairs on four-stroke engines

Contact our experts

Our Everllence experts in Hamburg

Contact your local service partner at PrimeServ Hamburg.

Emergency no. +49 (0) 40 7409-409