Performance that pays off

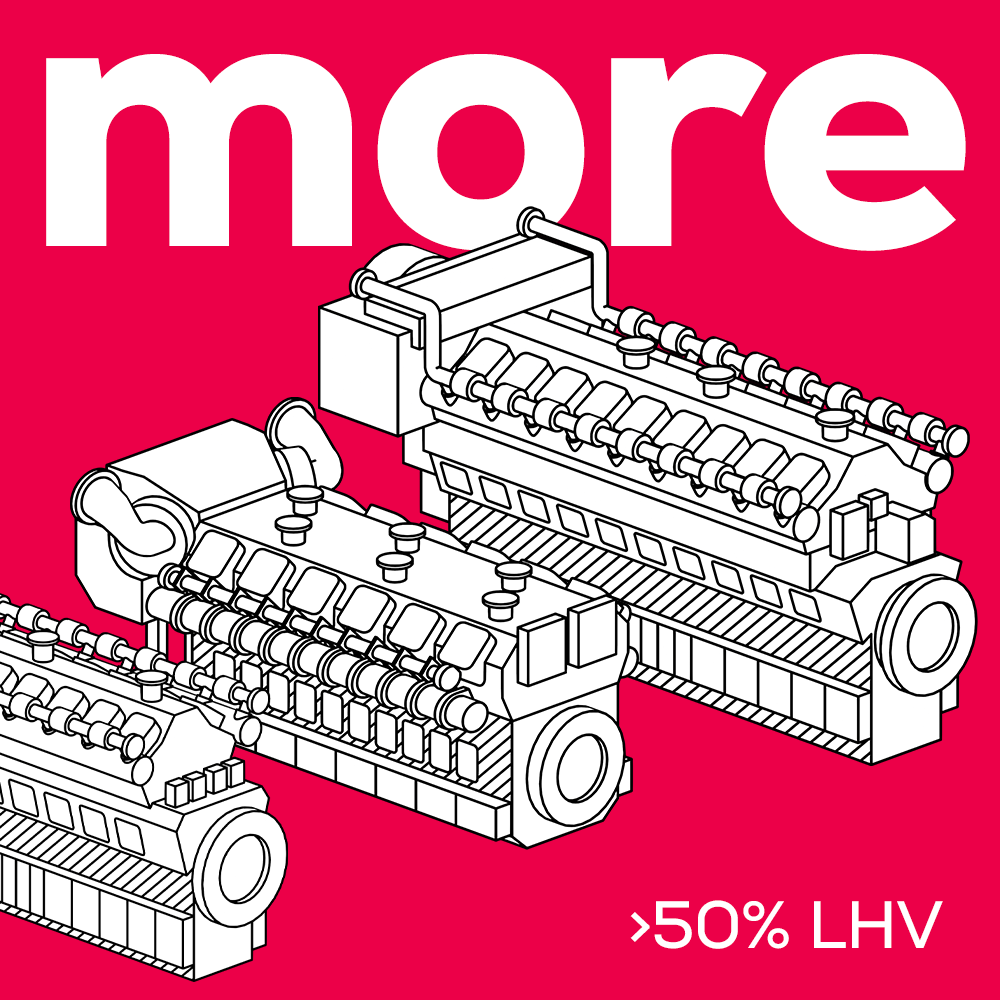

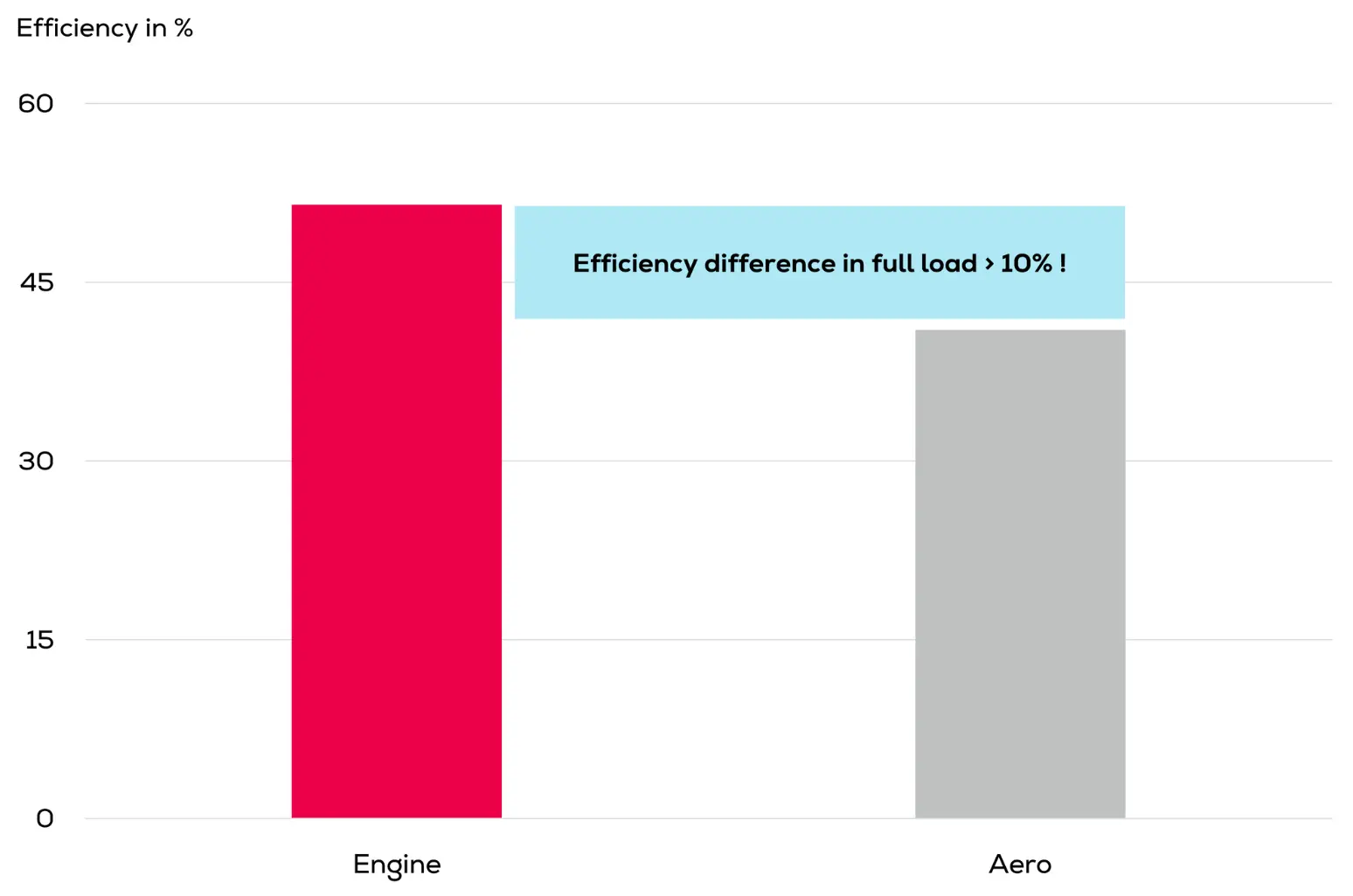

Efficiency

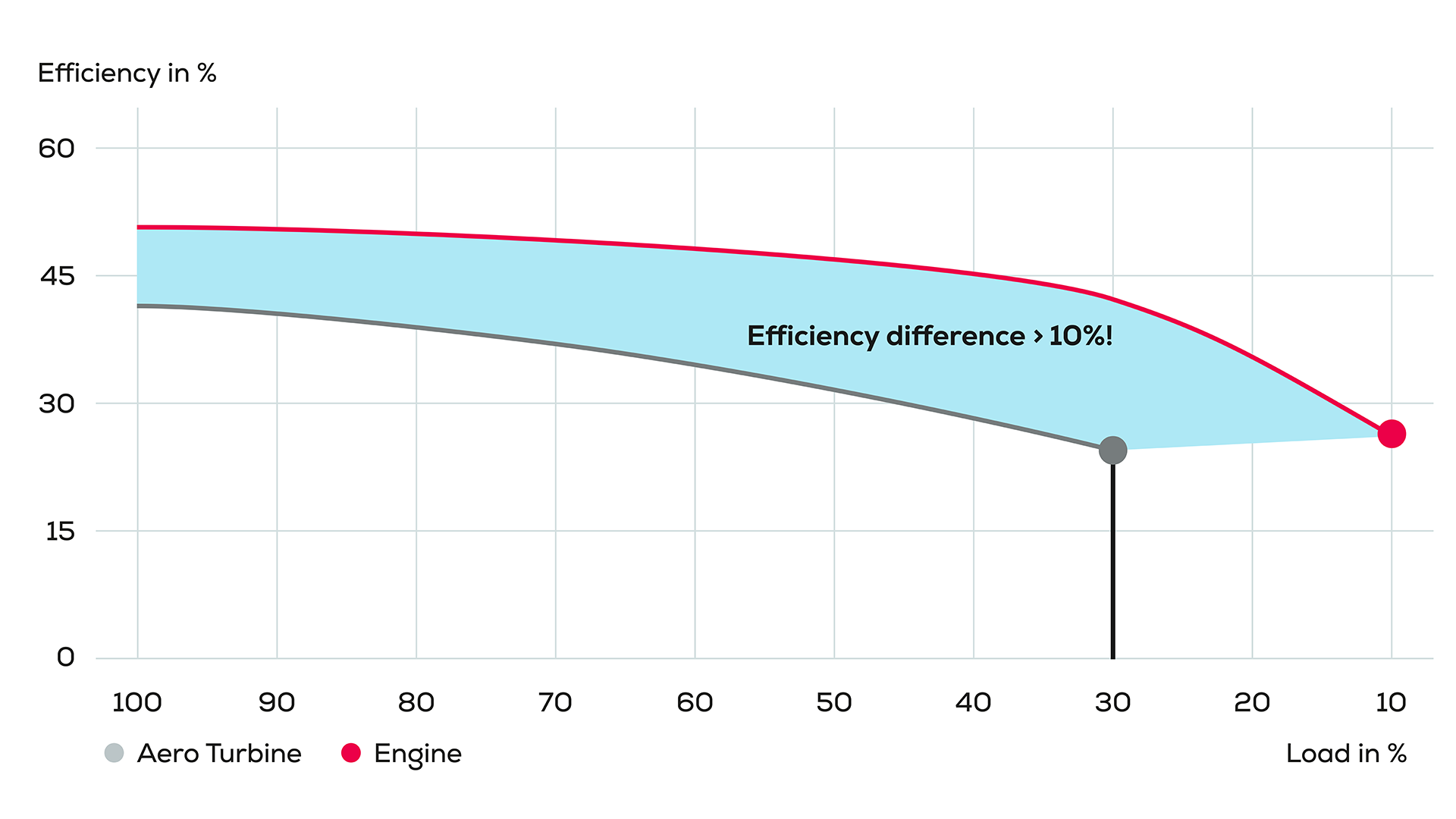

Aeroderivative turbines quickly lose efficiency once they leave full load. Their performance curve drops steeply with every step down in load and below ~30% load they can no longer operate reliably. Engines face efficiency losses too, but these are much less pronounced: performance remains steady even in partial-load operation and engines can be run continuously down to 10% load. Together with the resilience of engines at high temperatures, altitude, and under frequent cycling, this translates into real flexibility and efficiency for today’s grids.

- Engines support flexible starts and stops

- Reliable operation down to 10% load

- No derating for engines at 500 m altitude or 35 °C

The efficiency of Everllence engines remains comparatively stable under varying load conditions, whereas aeroderivative turbines show a marked drop in efficiency once operating below full load.

Why settle for an aeroderivative turbine when there’s a smarter way to balance the grid! Real projects already show what’s possible when flexibility meets efficiency. One example: a utility that significantly improved its performance. With every start, our technology proves that better efficiency isn’t just nice to have – it’s the difference that pays off.

Power plant in Schwäbisch Hall, Germany

To cut generation costs and expand district heating, two old engine units were replaced by a 7.5 MW gas engine. With over 94% total CHP efficiency, the plant now ensures grid services, optimized heat supply and long-term flexibility, all within the existing building.

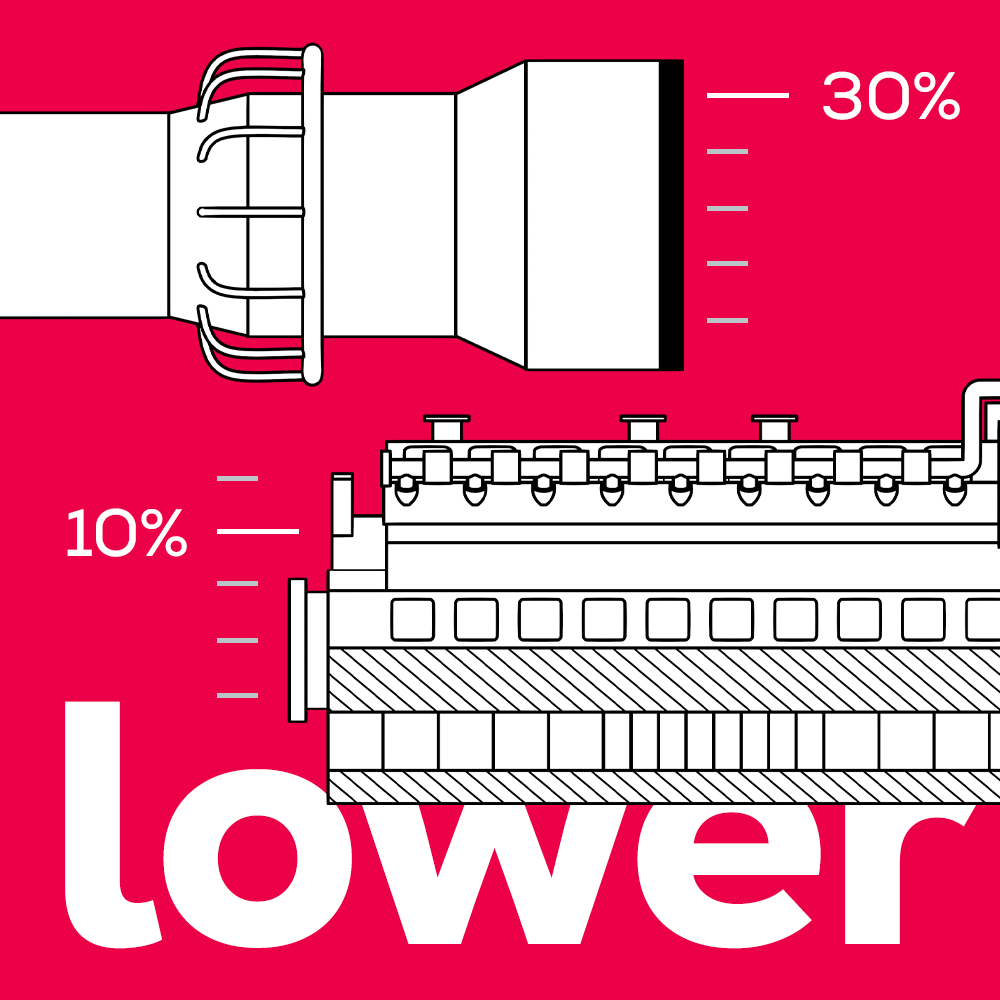

Built for every load

Minimum load

Balancing doesn’t always mean running at full power. In fact, part-load operation — especially in island applications — is often the rule rather than not the exception. Aeroderivative turbines start losing efficiency as soon as they leave full load and can't operate reliably below ~30%. Engines, by contrast, continue to deliver stable output and strong efficiency down to 10% load. That makes a critical difference in grids with frequent fluctuations, where availability alone isn’t enough. True flexibility means staying online, even when demand is low.

- Aeros don't operate below ~30% load

- Engines operate from 10% to full loads

- High performance at low demand

- Ideal for dynamic grid support

Everllence engines remain efficient and fully operable down to 10% load, while aeroderivative turbines can no longer run once they fall below ~30% load.

Why choose an aeroderivative turbine that drops off below 30% when there’s a proven technology that keeps balancing stable, even at low demand. In real projects, operators rely on engines that stay online, no matter the load. One example is Karpowership’s powership fleet, designed to provide flexible electricity wherever it’s needed. If balancing is the goal, part-load capability should never be the compromise.

Floating power plants by Karpowership

Ready again in no time

Start/stop operation

Frequent starts and stops are part of everyday balancing – but not every technology is made for it. Aeroderivative turbines suffer from increased wear and shorter maintenance intervals when cycled often. Everllence engines are designed differently: they start faster, tolerate frequent cycling without penalty, and maintain stable output from the first second of operation. Real-life projects already prove how engine-based solutions deliver exactly those qualities.

- Fast start from warm & standby

- Daily cycling without impacting the maintenance schedule

Peaking plant in Middlesbrough, UK

Fast to the grid

Starting times

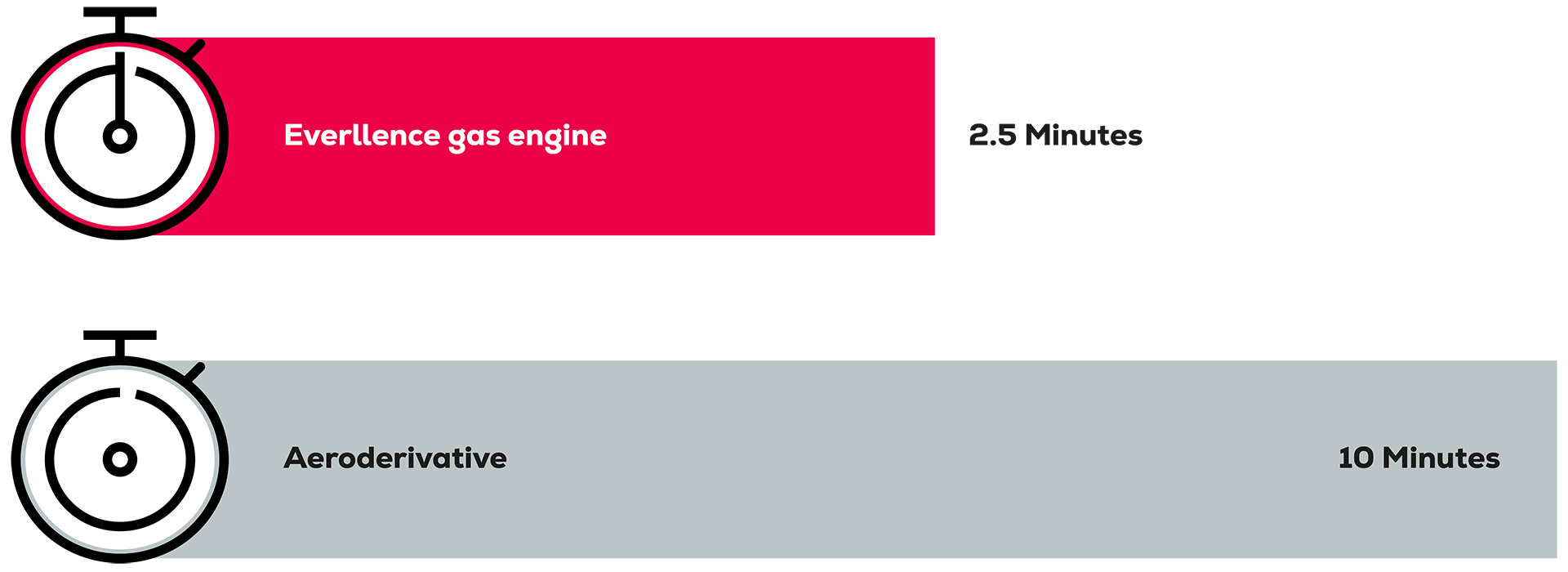

In balancing, time is critical. While aeroderivative turbines often need 10 minutes or more to reach full output, Everllence engines deliver power in less than 2.5 minutes from warm and standby. With minimal auxiliary loads and without the prolonged preheating cycles required by turbines, availability becomes a real-time asset. When supply and demand shift in seconds, being ready in a couple of minutes makes all the difference.

- <2.5 minutes from warm & standby to full power

- Significantly faster than aeroderivative turbines

Start-up times under comparable standby conditions. Everllence gas engine reaches full output in under 2.5 minutes, aeroderivative turbine requires 10 minutes.

When flexibility is key, waiting is not an option. In real balancing scenarios, every minute counts and the technology that responds first often wins. While traditional systems are still ramping up slowly, our engines are already delivering power in record time. That’s why more operators are turning to engine-based plants for fast availability.

Balancing power plant in Lakeland, USA

Consistent power in every environment

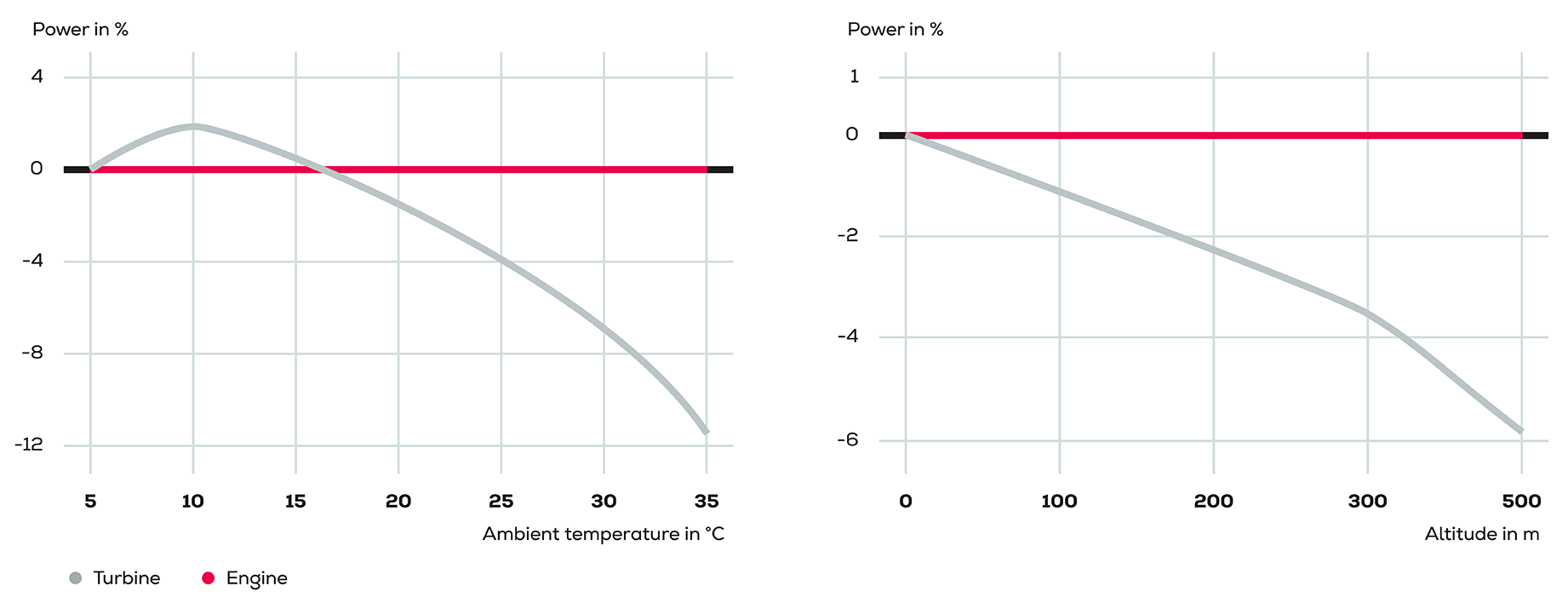

Ambient temperature

When temperatures rise above 15 °C, the efficiency and power output of aeroderivative turbines drop significantly (by up to 12% at 35 °C). By contrast, engine performance remains stable with minimal variation, even under high-temperature conditions.

Ambient pressure

At 500 meters altitude, aeroderivative turbines lose around 6% of their output due to reduced air pressure. Engine performance remains unaffected. Since most power plants are located between 0 and 400 meters above sea level, this pressure-related loss can significantly impact overall performance.

Left: Power output of aeroderivative turbines decline sharply as ambient temperature rises, while engine performance remains stable. Right: At higher altitudes, reduced air pressure significantly lowers turbine output, whereas engine output is unaffected.

Balancing doesn’t happen in ideal conditions. It happens in heatwaves, at elevation, in places where summer demand meets real-world constraints. So why rely on a system that falters when the environment shifts? Smart utilities have already started to choose engines that keep delivering.

Balancing plant in Texas, USA

Let's talk Balancing

Get power without compromise

Whether you’re planning a new plant or rethinking your current setup, we’re here to support you with proven engine technology and the right answers for your grid. Get in touch with our experts and start balancing smarter.