Simplifying complexity with solutions tailored to your needs

Why choose PrimeServ Omnicare?

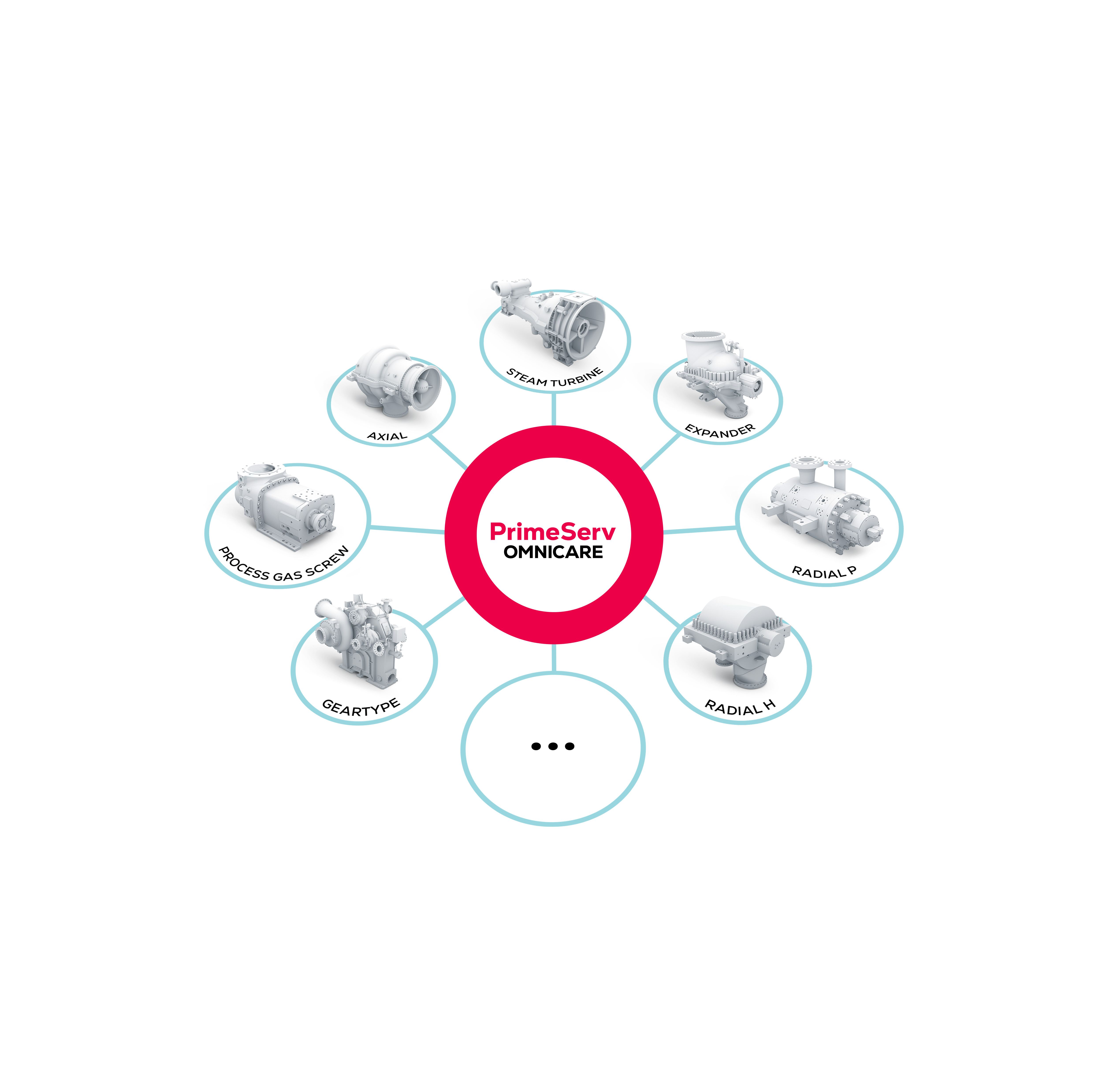

- All rotating equipment. One expert partner.

We cover turbines, compressors, expanders – across all major brands and configurations. - Complete lifecycle coverage.

We deliver comprehensive turbomachinery service solutions, including field service, repairs, revamps, replacements, and digital agreements – all from one source. - Global network. Local execution.

We deliver fast response through regional Omnicare Centers, backed by 250+ years of engineering experience. - OEM-grade quality for every brand.

We stand for certified processes and precision standards – even for third-party equipment. - Proven performance and efficiency gains.

You benefit from extended service life of your turbomachinery, improved efficiency, lower emissions, and reduced operating costs.

Our services for all rotating equipment

Rapid response, expert cause analysis, and quality service to protect your business

Boosting lifetime efficiency and business value

Smarter operations and cost control through predictive maintenance and tailored digital service agreements

Driving efficiency and accountability with full management of scheduled maintenance

Benefit from greater flexibility, faster turnarounds, and services available anytime, anywhere

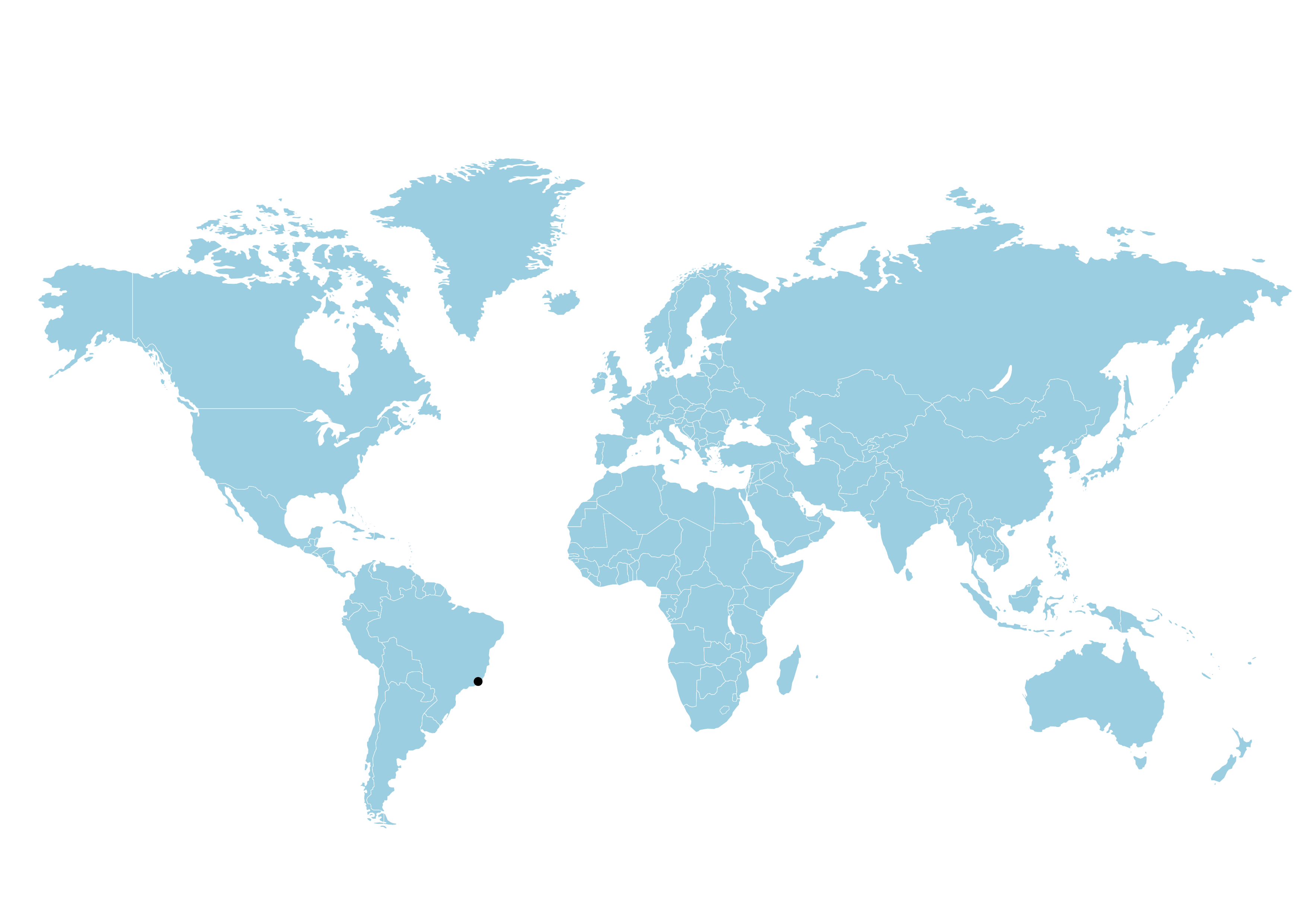

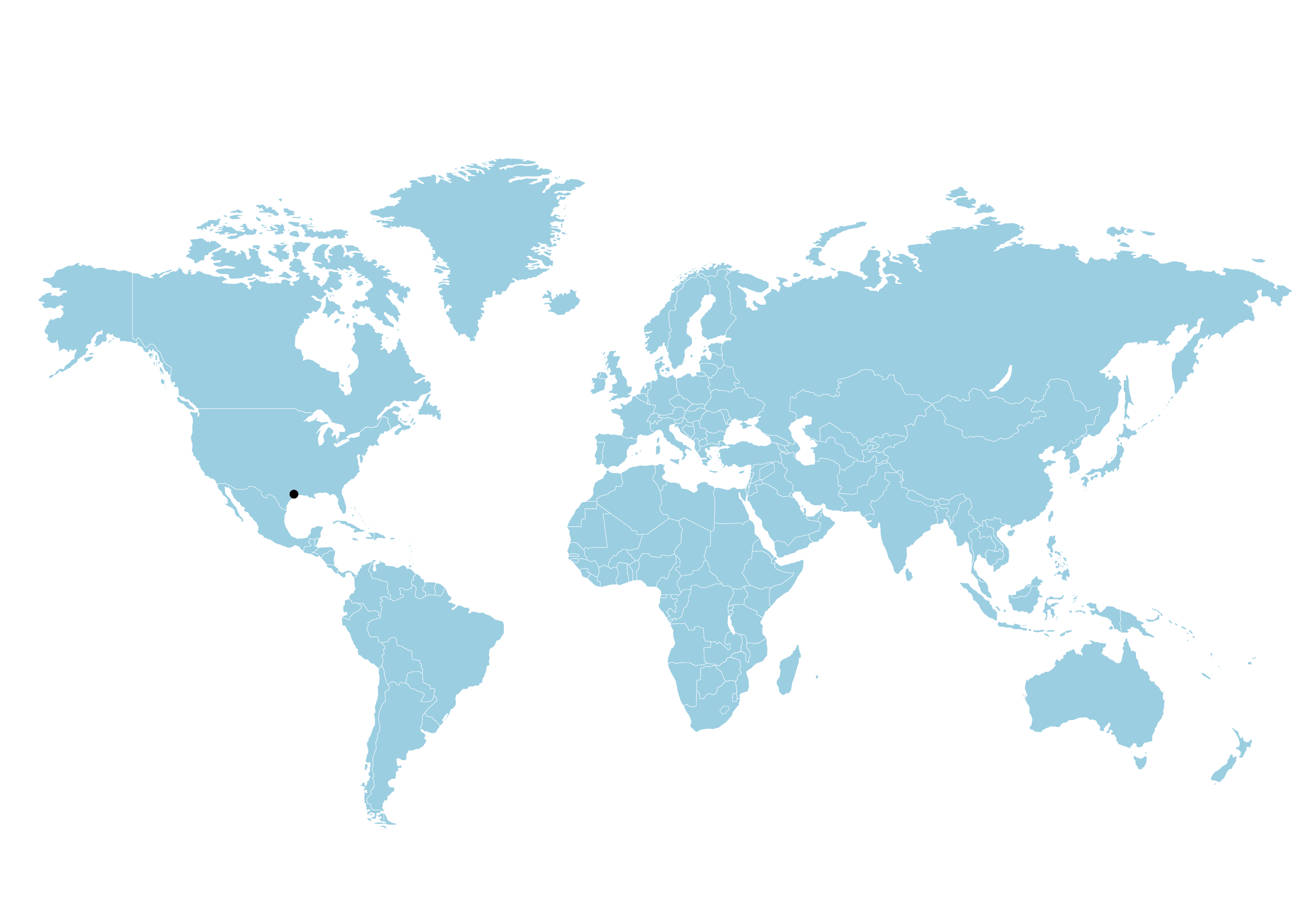

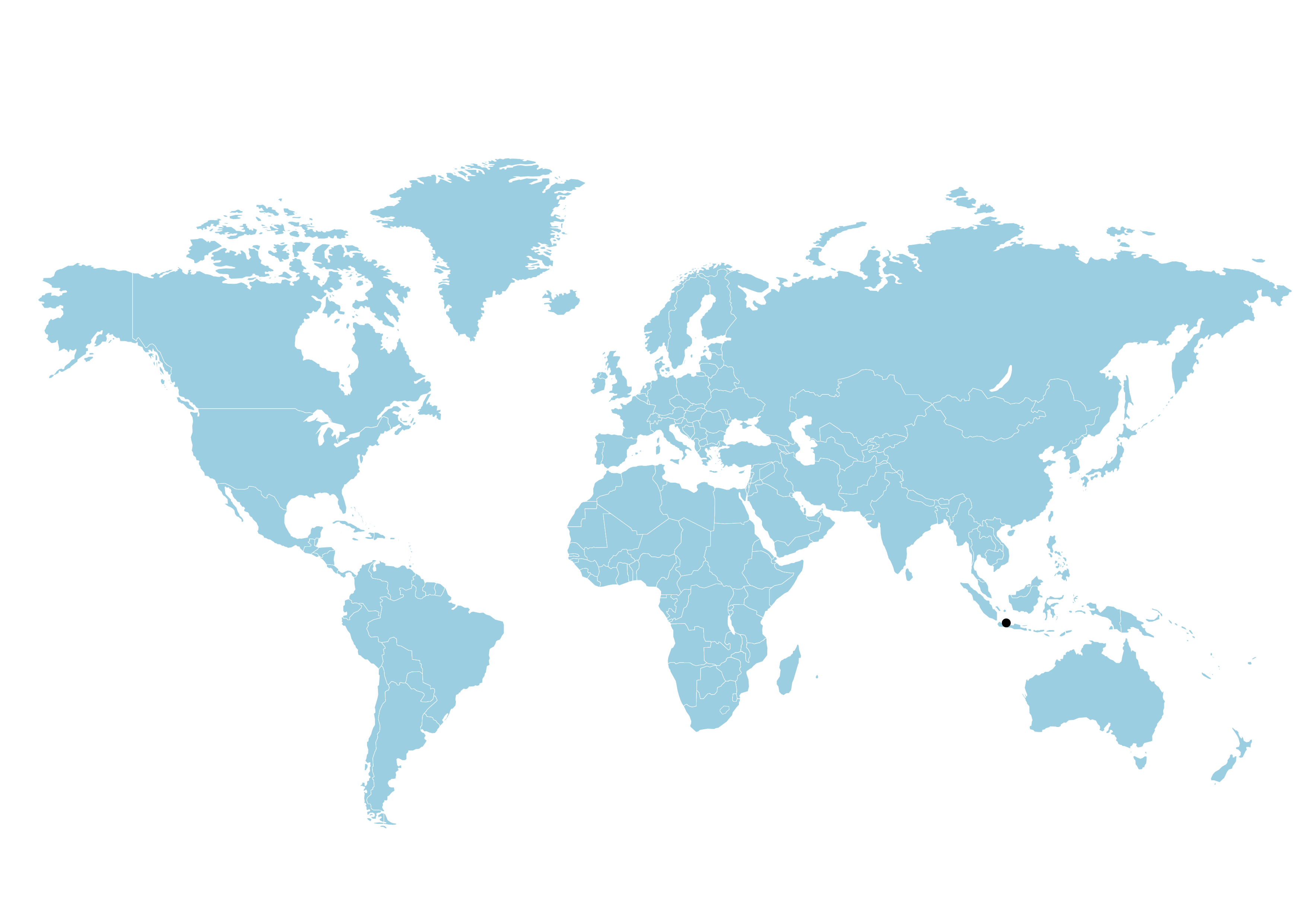

We are where you need us – our global Omnicare Centers

Our network brings expert service close to your operations – with local execution, fast response, and full-scope support across all major turbomachinery brands.

Capabilities:

- Local field service, repairs, and component overhauls

- Reverse engineering, spare part manufacturing, and footprint solutions

- Turnaround execution, revamps, and digital service support

- Support for industrial facilities and offshore operations

Facility highlights:

- 5,000 m² workshop with 40-ton crane.

- 50+ machines for precision part manufacturing.

- Solar-powered facility with rainwater reuse system.

Capabilities:

- Local field service, repairs, and component overhauls

- Reverse engineering, spare part manufacturing, and footprint solutions.

- Turnaround execution, revamps, and digital service support.

- Support for industrial facilities and compressor applications.

Facility highlights:

- 9,600 m² climate-controlled workshop with 45-ton crane.

- Large-scale machining: up to 105” swing (lathe), 84” swing (VTL).

- Laser welding cell for journals, coupling ends, and compressor casings.

Capabilities:

- Local field service, repairs, and component overhauls.

- Reverse engineering, spare part manufacturing, and footprint solutions.

- Turnaround execution, revamps, and long-term service agreements (LTSA).

- Support for regional industrial facilities and offshore operations

Facility highlights:

- 550 m² workshop with 2-ton and 3.2-ton jib cranes.

- Low-speed balancing machine (1.5-ton capacity).

- Dedicated sandblasting, welding, and assembly areas.

Capabilities:

- Local field service, repairs, and component overhauls.

- Reverse engineering, spare part manufacturing, and footprint solutions.

- Turnaround execution, revamps, and digital service agreements.

- Long-term service support (LTSA) for heavy-duty equipment.

Facility highlights:

- 1,400 m² workshop with cranes up to 50 tons (hook height up to 10 m).

- Access to machinery for repairs up to 320 t and 7.2 m outer diameter.

- Rotor repair capability up to 90 t and 3.7 m diameter.

Capabilities:

- Local field service, repairs, and component overhauls.

- Reverse engineering, blade and spare part manufacturing, and rotor storage.

- Turnaround execution, revamps, and footprint solutions.

- Long-term service agreements (LTSA) for industrial and power applications.

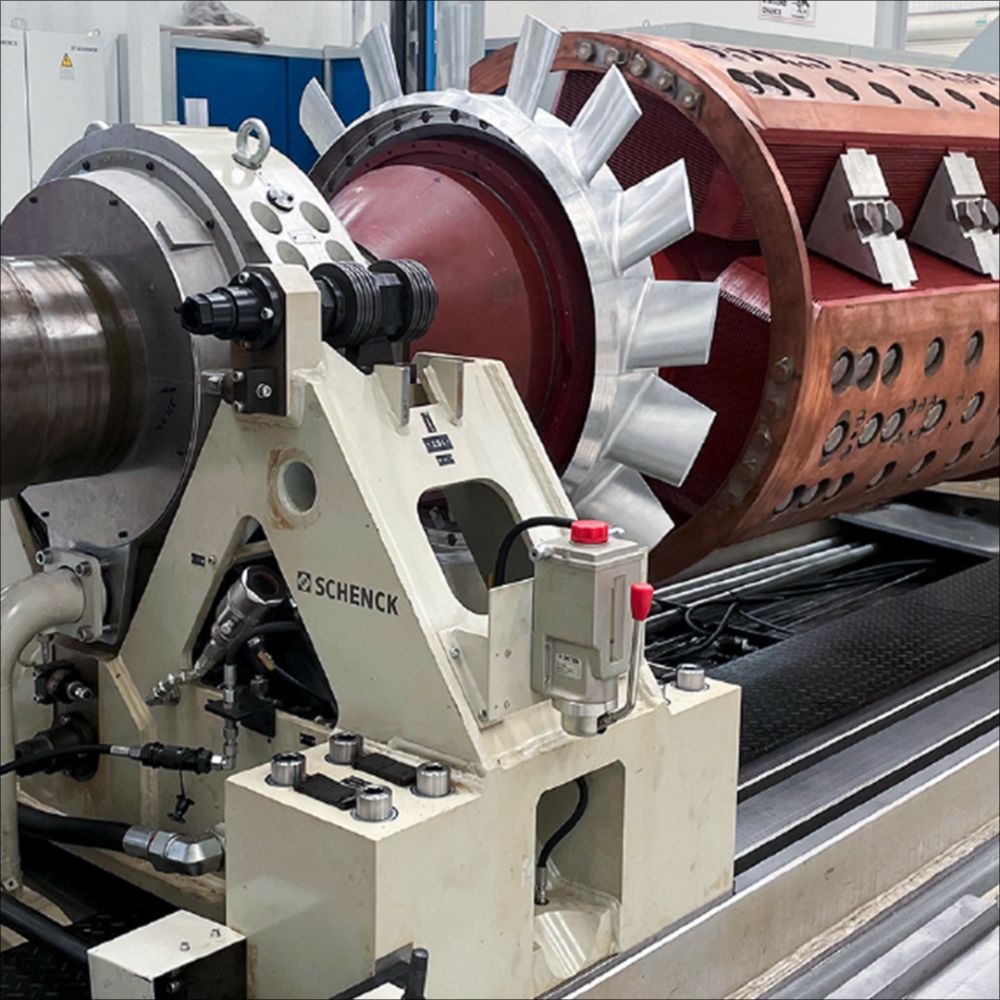

Facility highlights:

- 16,000 m² workshop with crane capacity up to 50 tons.

- 3D CMM (fixed and portable) for precision measurements.

- Laser welding and in-house blade manufacturing.

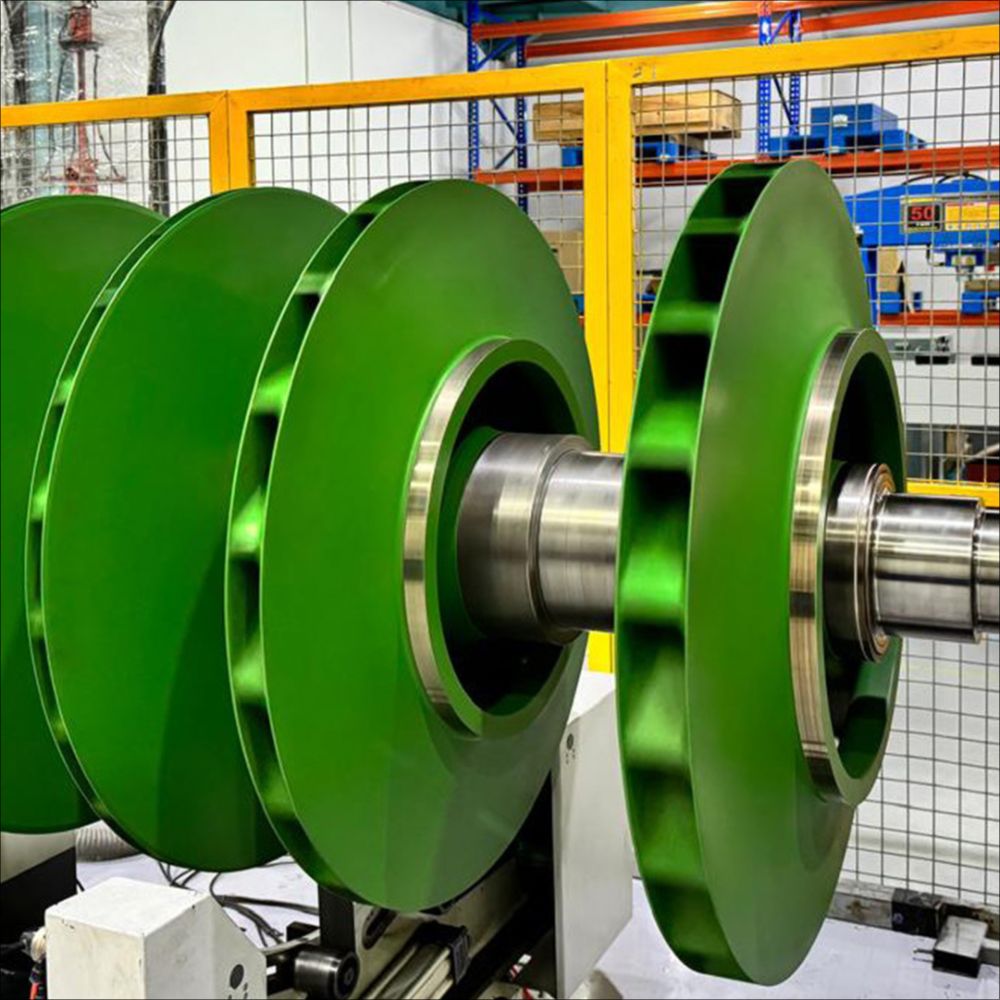

Unlock the power: Rebundling your barrel compressors

.webp?sfvrsn=1ea1c9fe_1)

Success stories from across the globe

Challenge: Rotor damage uncovered during shaft replacement

Solution: Reverse-engineered missing components and fully restored the rotor

Result: Reduced lead time and ensured OEM-grade quality

Challenge: Cracked impellers and no available documentation

Solution: Rebuilt all key compressor parts locally to OEM standards

Result: Full functionality restored with minimal delay

Challenge: Severe casing cracks and corrosion in a compressor

Solution: Used laser welding and precision machining to restore the barrel bore

Result: Downtime minimized; repair costs reduced by up to 80%

Challenge: Standard replacement turbine was too large for the existing setup and required major structural changes

Solution: Delivered compact, custom-fit unit that matched original footprint and avoided disruption

Result: Structural modifications eliminated; long-term performance secured

Challenge: Rotating equipment across five refineries required overhauls during scheduled turnarounds

Solution: Executed complete multi-OEM scope with local teams and full on-site delivery

Result: Reliable, consistent results achieved with 100% local execution

Downloads

Continue reading

Contact our PrimeServ Omnicare experts

Need service for a mixed fleet? Let’s talk.

Whether you operate compressors, turbines, or expanders from multiple OEMs, we’re here to support you. From turnarounds and overhauls to reverse engineering and digital monitoring, Omnicare provides one trusted partner for your entire rotating equipment train.