Important numbers

Facts about our digital service agreements

Our service packages

Find the right service package

Every business has its own challenges. That’s why we offer flexible and scalable monitoring services designed to meet your specific needs. Explore the maintenance cycle below to see how each of our service packages aligns with your operational goals and drives efficiency at every stage.

Operational and process data from your core equipment and auxiliary systems are collected, encrypted, and transmitted via a read-only interface to the Everllence CEON (former MAN CEON) cloud platform.

How you benefit: Everllence CEON makes your equipment data actionable and supports all levels of maintenance. We collect data from machines and auxiliary systems such as oil systems, motors, generators, gearboxes, and seals, and can also collect data from third-party equipment. Secure storage is ensured by AWS in Germany, with end-to-end encryption protecting data during transmission. The read-only interface prevents tampering, maintaining data integrity and security.

This step is part of the following service packages:

- PrimeServ Digital Service Agreements

- PrimeServ Assist

- PrimeServ Connect

Our algorithms check whether your equipment is operating within optimal performance parameters and correlate all monitored data to generate a “health score”.

How you benefit: Condition assessment enables early and proactive detection of developing machine wear or anomalies. The Everllence CEON dashboards display key operational data, allowing you to monitor different aspects of your asset’s performance. Automated alerts help you react quickly to anomalies and avoid unplanned downtime.

This step is part of the following service packages:

- PrimeServ Digital Service Agreements

- PrimeServ Assist

- PrimeServ Connect

We use machine learning algorithms and AI to align detected events with known failure modes. Our service engineers leverage all available resources and expertise to conduct a thorough root cause analysis.

How you benefit: Our dedicated service engineers have in-depth knowledge of your equipment’s setup, condition, and history, enabling them to perform precise diagnostics. By continuously expanding our failure database, we enhance our diagnostic capabilities and improve long-term reliability for our customers. Advanced algorithms identify and categorize different operational modes and behaviors, ensuring a more accurate analysis.

This step is part of the following service packages:

- PrimeServ Digital Service Agreements

- PrimeServ Assist

We assess failure modes and ongoing degradation to predict how much longer your machine can operate and determine the optimal timing for maintenance activities.

How you benefit: By leveraging data, AI, and over 100 years of OEM expertise, we provide a data-driven answer to the critical question of how long operations can continue. This reduces the risk of unexpected or unplanned shutdowns, ensuring greater reliability for your equipment.

This step is part of the following service packages:

- PrimeServ Digital Service Agreements

- PrimeServ Assist

Existing maintenance schedules may need adjustments depending on the condition of your machinery. Our adaptive maintenance strategy takes the entire plant’s production requirements and resources into account, integrating predictive, preventive, and condition-based maintenance concepts.

How you benefit: The optimal maintenance strategy considers all surrounding operations to minimize the impact of maintenance work. You gain access to the best turnaround and repair slots, along with cost-efficient and reliable maintenance options. We can also integrate spare-part recommendations, supply, and management to streamline planning.

This step is part of the following service packages:

- PrimeServ Digital Service Agreements

A dedicated project manager oversees the planning and execution of all maintenance projects, coordinating a full team that includes a dedicated field service coordinator.

How you benefit: Maintenance projects are handled by specialized personnel familiar with your equipment. You receive priority treatment for quotations, delivery, and response times. Ordering processes are streamlined, and field service call-out agreements ensure fast response in emergencies.

This step is part of the following service packages:

- PrimeServ Digital Service Agreements

PrimeServ Connect

Streamline your operations with our connectivity-only package, providing uninterrupted data management, secure handling, and reliable storage via the Everllence CEON platform. This solution ensures seamless access to machine data at all times. With our pool of service engineers, remote technical assistance is available 24/7.

PrimeServ Assist

Optimize your equipment’s performance and availability with PrimeServ Assist. This comprehensive package integrates machine data, advanced analytics, and human expertise. Through remote monitoring, our dedicated service engineers proactively oversee your equipment and deliver tailored technical recommendations, ensuring reliable and efficient operations.

PrimeServ Digital Service Agreements

Maximize efficiency and reliability with Digital Service Agreements tailored to your operational needs. Each agreement includes a dedicated key account team, integration with PrimeServ Assist, priority service access, customized maintenance strategies, and expert spare parts management. You benefit from improved machine operations and higher productivity through reduced unplanned outages and optimized maintenance intervals.

Our digital services in action

Streams of data might seem abstract, but the benefits of AI-enabled machine monitoring can have immediate impacts: improving equipment performance, extending machine lifecycles, and lowering maintenance costs. Here are some examples of how our digital remote monitoring has delivered tangible results.

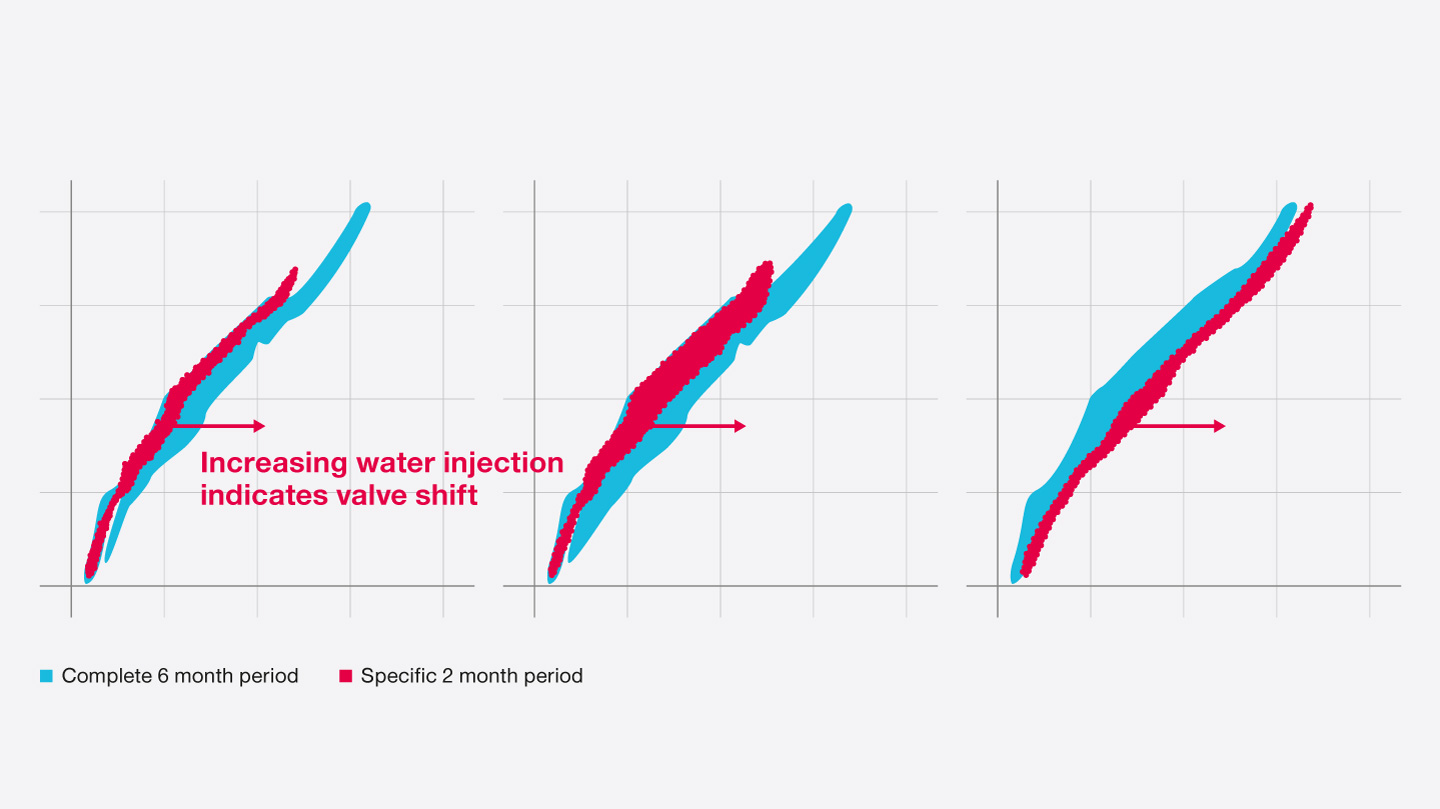

From anomaly detection to optimized performance

A MST100/400 steam turbine exhibited increasing water injection levels at one valve, signaling inefficiencies in atomization and evaporation. Leveraging insights from our AI-powered monitoring system, our experts scheduled targeted repairs during planned maintenance and installed optimized nozzles. This approach prevented unplanned downtime, reduced operational costs, and improved equipment reliability.

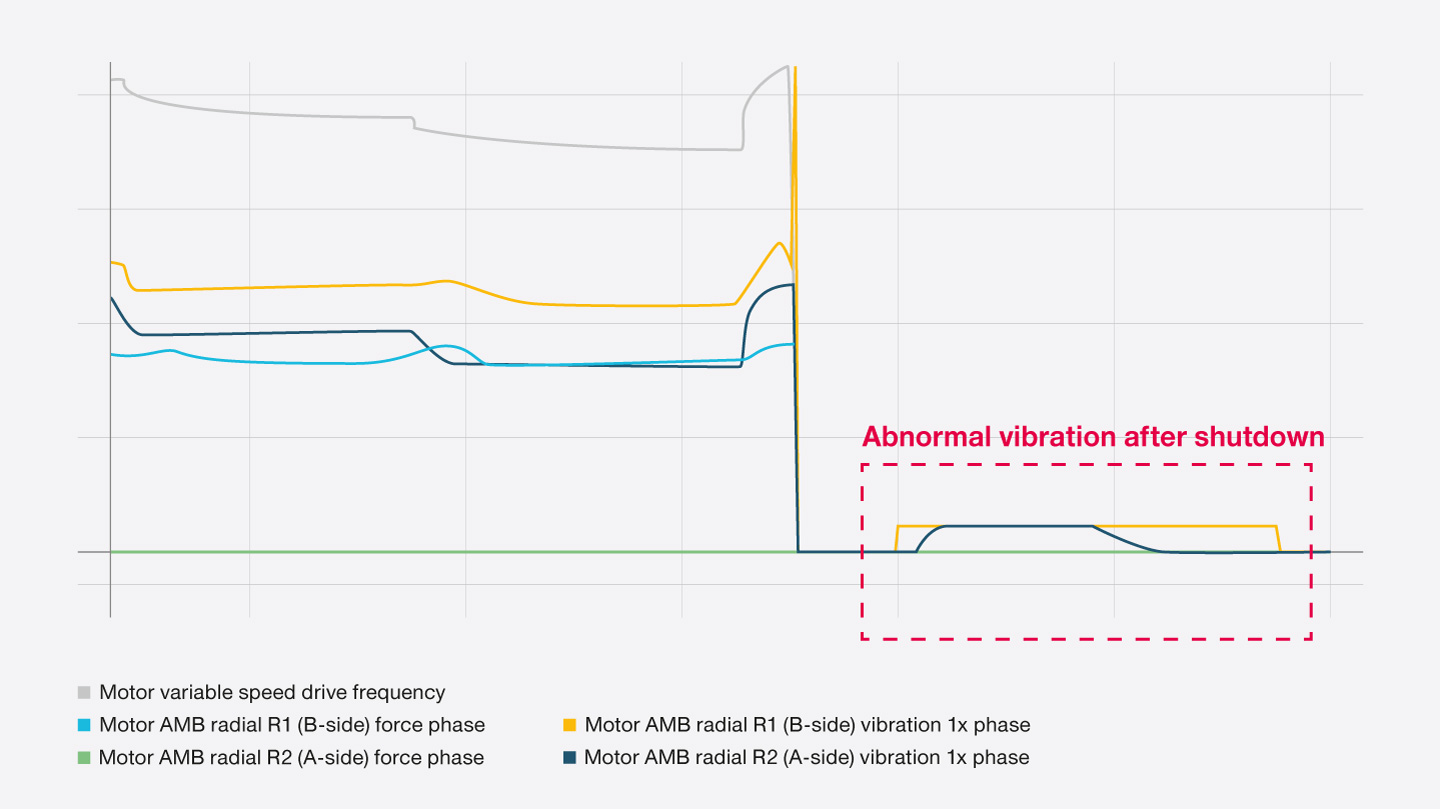

Rapid remote assistance with Everllence CEON

The Everllence CEON system detected unusual vibration spikes on a compressor train's active magnetic bearings (AMB). Our experts at the Remote Operation Center (ROC) in Zurich analyzed the data and adjusted damping forces remotely to address the issue. This swift action minimized downtime, avoided additional field service costs, and ensured optimal equipment performance.

Maintaining operations with advanced monitoring

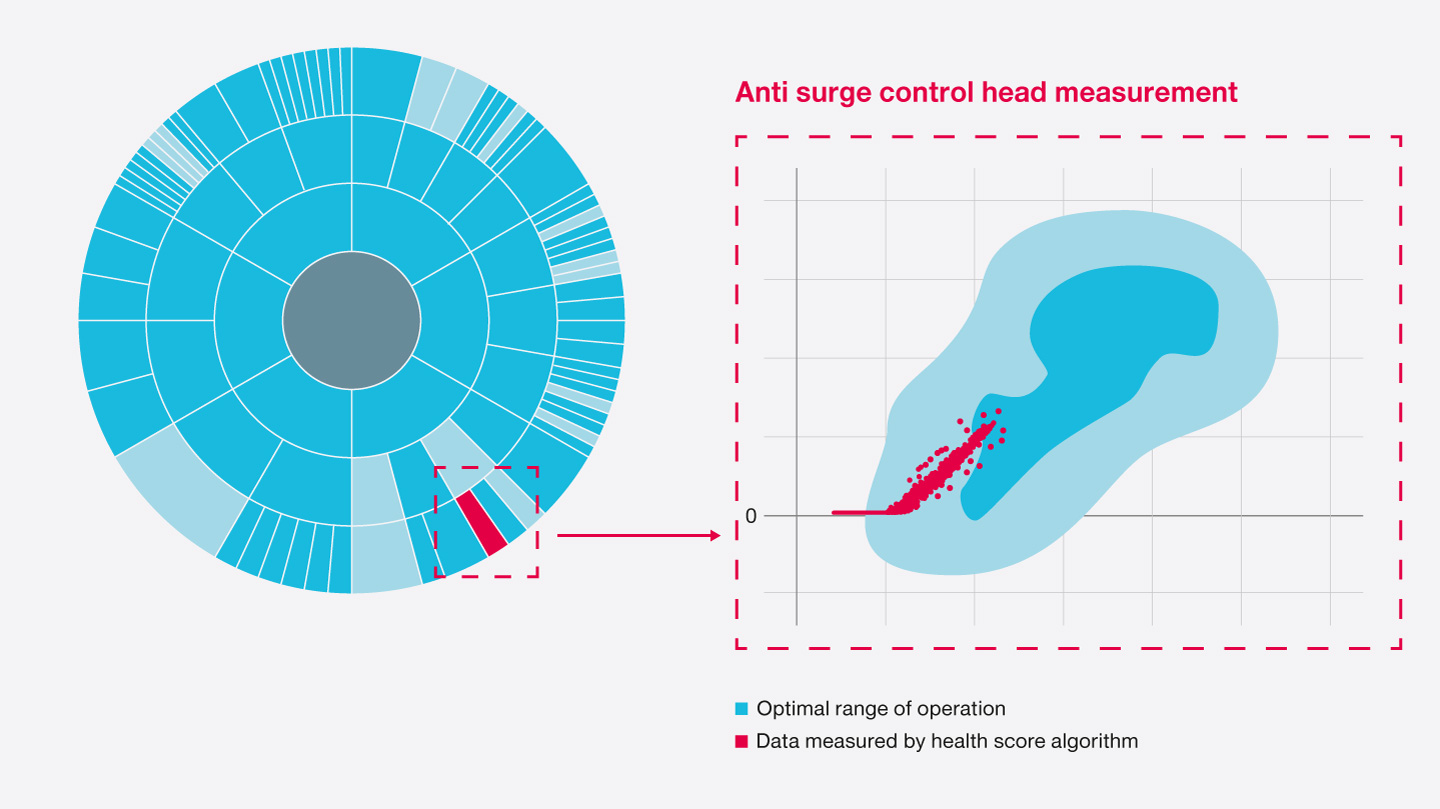

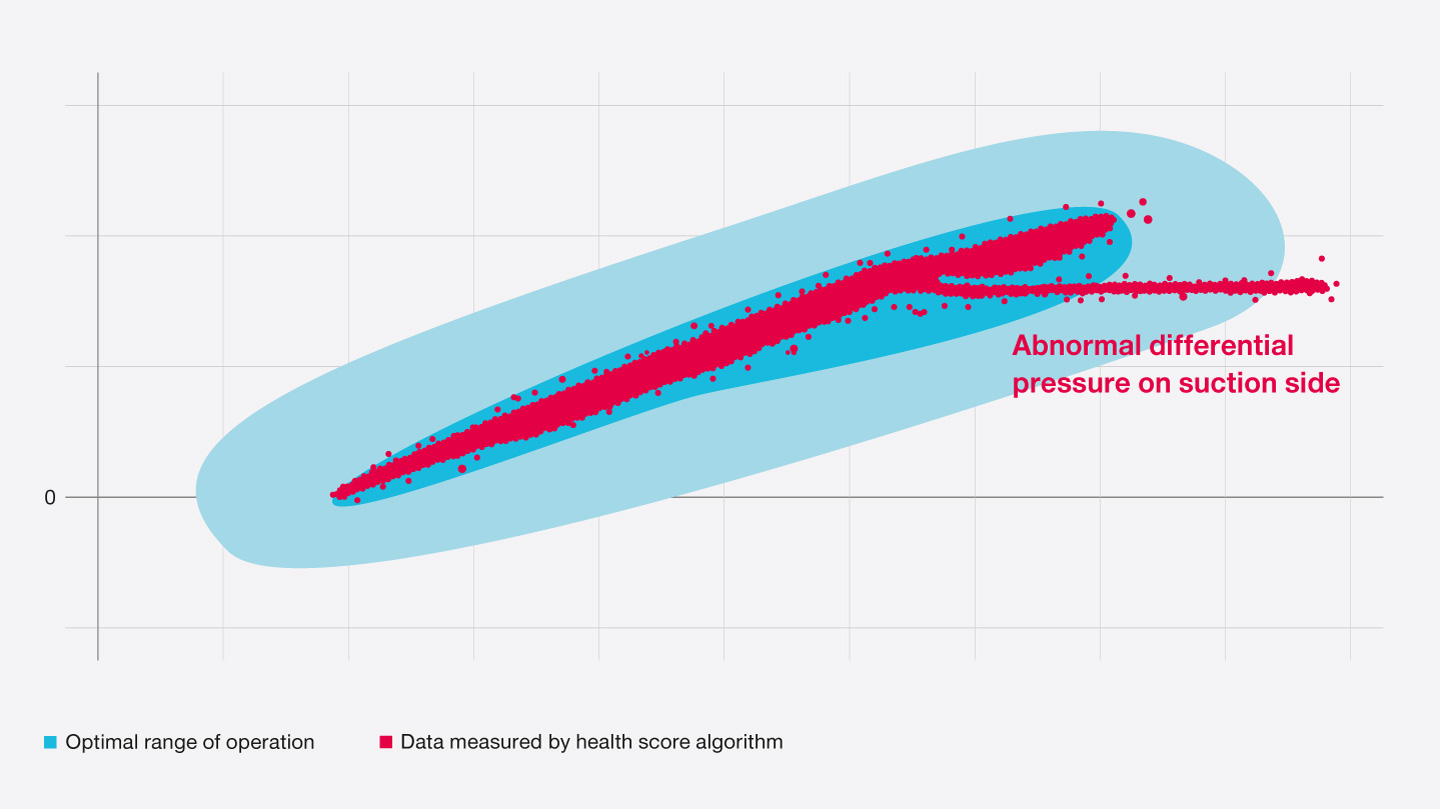

During remote monitoring of a compressor train in a nitric acid production plant, a low anti-surge control score was detected. Our ROC engineer identified a drop in head value to 0.0 J/kg, indicating a malfunctioning anti-surge control system. By advising temporary adjustments to the anti-surge valve, we enabled continued operation without disruptions until repairs were conducted. This proactive approach ensured process stability and minimized downtime.

Preventing failure with remote detection and solutions

A HOFIM® compressor at a gas storage plant experienced freezing issues, indicated by anomalies in its health score and cooling gas temperature trends. Using insights from our advanced monitoring system, our ROC engineers identified the root cause to be hydrate formation caused by low ambient temperatures. To mitigate the issue, we implemented temporary alarms and developed a hydrate detection algorithm, enabling operators to act quickly and prevent blockages. This proactive solution ensured reliable performance, maintained stable operations, and safeguarded system integrity.

Contact our Everllence experts

Let's unlock your equipment's potential

Consult our experts to optimize the maintenance of your equipment with our digital monitoring solutions. By leveraging the powerful Everllence CEON platform and our OEM expertise, we can help you increase efficiency, minimize downtime, and ensure long-term reliability.

Downloads