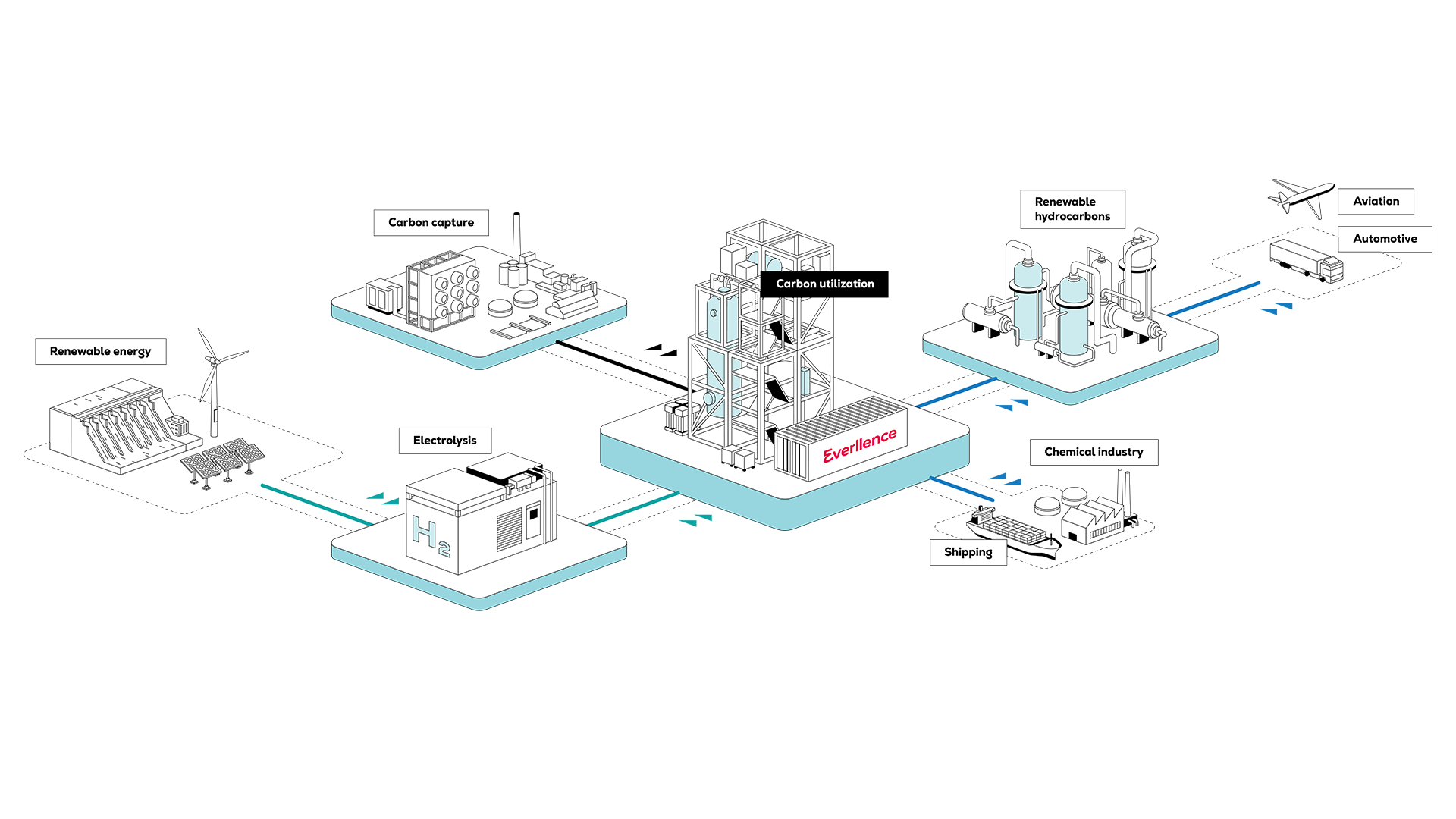

What is e-SAF?

e-SAF is a renewable fuel produced using Power-to-Liquids (PtL) technology that utilizes feedstocks, such as renewable (or nuclear) power, carbon dioxide (CO2), and water to create synthetic hydrocarbons. The solution proposed by Everllence and Shell is based on the Fischer–Tropsch (FT) pathway for making e-SAF.

The Shell X-to-Liquids (XTL) process leverages lessons learned from Shell’s integrated gas-to-liquids (GTL) technology, as applied at Pearl GTL in Qatar, the world’s largest integrated GTL facility. This extensive expertise allows the Shell XTL process to support large-scale e-SAF production, making it a viable option for meeting long-term decarbonization targets.

A productive partnership

Shell contributes catalyst formulations (for RWGS, FT synthesis and hydroprocessing steps of the integrated process), technologies for CO2 capture and optimized integrated design of both chemical process and utilities (including optimal use of steam, water, fuel gas, etc.) for making e-SAF, while Everllence provides the reactor equipment for FT and RWGS.

Everllence key equipment for e-SAF production

With decades of experience in chemical reactors, compressors and electrolyzer technology, Everllence can provide all the key equipment for e-SAF production. Our expertise spans salt-operated reactors, Fischer-Tropsch reactors (for Shell’s FT technology), high-performance gas compression, and green hydrogen production—delivering reliable, efficient, and industry-leading equipment for a sustainable future.

The Everllence subsidiary Quest One can provide the electrolysis equipment that turns renewable energy into green hydrogen. Quest One ensures cost-effective, efficient and large-scale production. CO2 can be captured and handled with our world-leading CCUS technologies.

/e-saf-page-(shell)/evr_dropdown-h2_1080x810_2025-10-22.webp?sfvrsn=1b0980bc_3)

/e-saf-page-(shell)/evr_dropdown-cc_1080x810_2025-10-30.webp?sfvrsn=2b246367_3)

The DWE® RWGS reactor is an endothermic, molten-salt-operated reactor system for the production of syngas from renewable carbon dioxide and hydrogen. The required process energy is provided as renewable electricity. Key innovations in comparison to standard Everllence molten-salt-operated reactors include:

- Operating temperature range elevated by more than 100-150°C

- Increased heat input of up to several 10 MWs

/e-saf-page-(shell)/evr_dropdown-rwgs_1080x810_2025-10-22.webp?sfvrsn=31ff332c_3)

The Fischer-Tropsch reactor converts the syngas produced by the RWGS reactor into Fischer-Tropsch wax. The wax made during Fischer-Tropsch synthesis is then passed to a hydroprocessing unit, based on another Shell proprietary technology, where final products are made, such as kerosene. Shell’s commercially mature Fischer-Tropsch technology is used in Shell’s GTL plants, for which Everllence has provided Fischer-Tropsch reactors.

/e-saf-page-(shell)/evr_dropdown-fischer-t_1080x810_2025-10-30.webp?sfvrsn=c8007a23_3)

RWGS pilot plant in Deggendorf achieves first 10,000 hours

Shell and Everllence initiated a close collaboration in 2021 for the development of the Reverse Water Gas Shift (RWGS) process. As part of this effort, a pilot plant was constructed at the Everllence’s research facilities in Deggendorf (see picture). This started operation in early 2023. Since commissioning of the plant, about 10.000 successful operating hours have been achieved.

/e-saf-page-(shell)/rwgs-pilot-plant.webp?sfvrsn=8b677934_3)

Downloads

Continue reading

Talk with our Everllence experts

Let’s decarbonize aviation!

Are you ready to help shape the sustainable future of aviation? Connect with our experts to explore everything from infrastructure and equipment to regulations and licensing. Let’s start the conversation today.

/e-saf-page-(shell)/page_header.webp?sfvrsn=83bf7721_3)

/e-saf-page-(shell)/evr_graphic_512x288_2025-11-06.png?sfvrsn=60d5326d_3)

/ptl_main/evr_ptl_2025-10-23.webp?sfvrsn=3ecbe637_4)