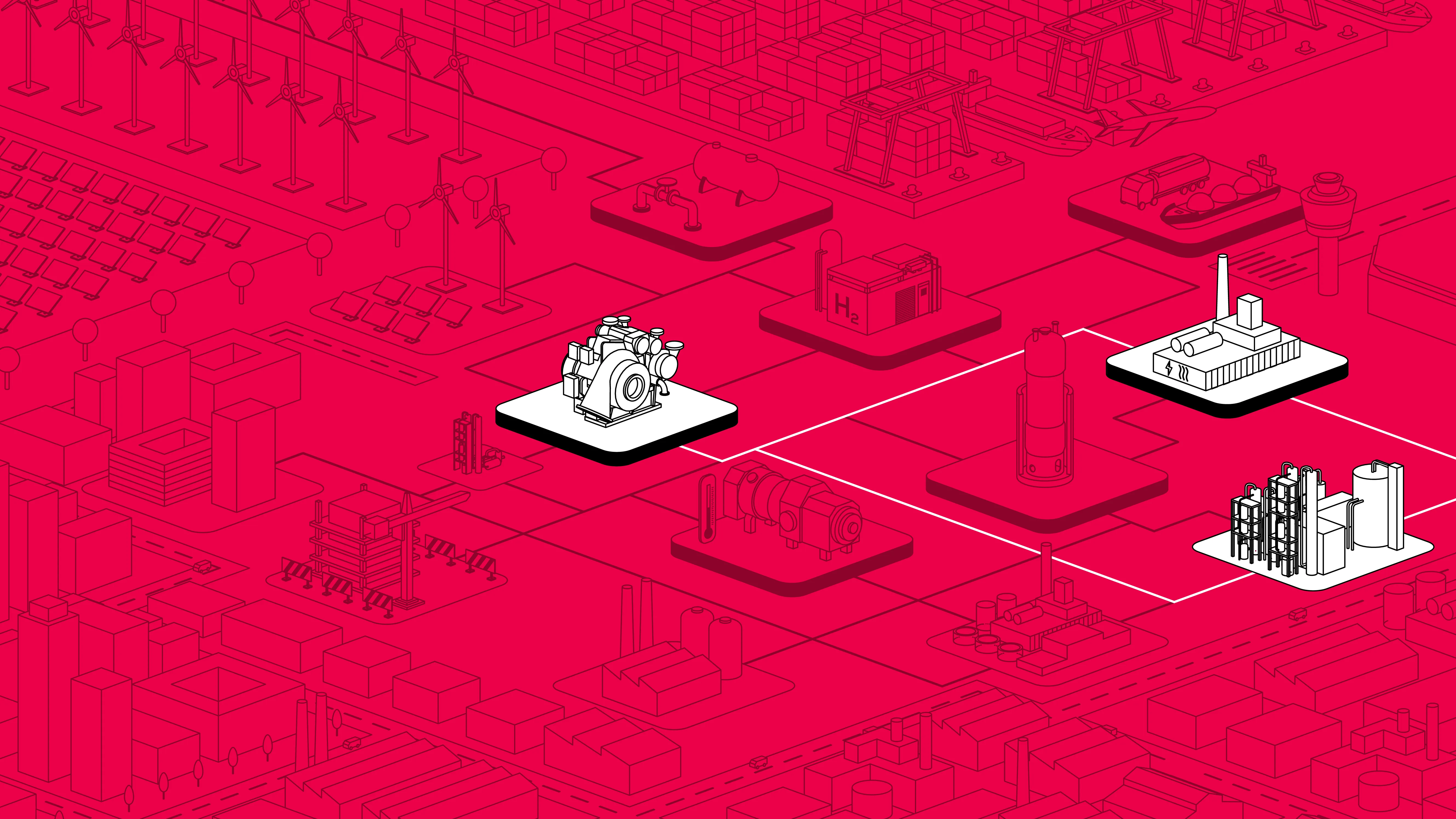

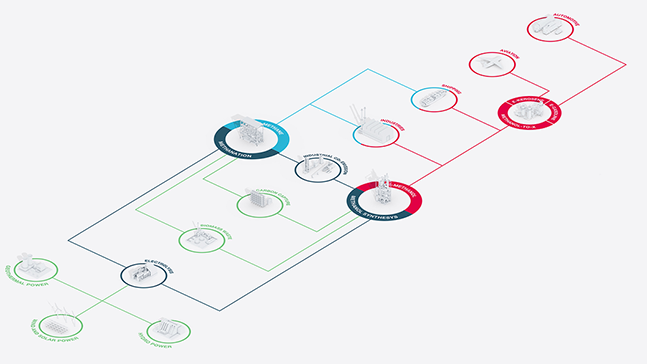

The Everllence Power-to-Liquid value chain

From renewable power to sustainable fuel — Everllence delivers all the core technologies required for efficient production of future fuels. Our systems are engineered for reliability, scalability, and maximum heat integration, enabling the production of e-methanol, e-gasoline (SAF), and other synthetic hydrocarbons at industrial scale.

Cornerstones of Power-to-Liquid

Learn about our world-renowned equipment

/ptl_main/evr_dropdown-meth_512x512_2025-10-22.png?sfvrsn=a21b5a49_3)

DWE® e-methanol synthesis modules convert renewable CO2 and green hydrogen into carbon-neutral e-methanol – a key product in Power-to-Liquid applications. The process makes use of captured or biogenic CO2 from renewable sources such as biogas, biomass, or industrial off-gases. E-methanol can be used directly as a clean marine fuel or as a feedstock for producing other e-fuels such as e-gasoline and e-kerosene, supporting scalable and sustainable fuel production.

Tailored Everllence solutions enable customers to expand production capacity while ensuring high process efficiency and consistent product quality.

/ptl_main/evr_dropdown-pbr_512x512_2025-10-22.png?sfvrsn=fd0330b9_2)

/ptl_main/evr_dropdown-rwgs_512x512_2025-10-22.png?sfvrsn=e70937ab_2)

The DWE® Reverse Water Gas Shift (RWGS) reactor system, developed in collaboration with Shell Catalysts & Technologies, forms the core of sustainable fuel production.

Operating as an endothermic molten-salt system, the reactor converts renewable CO2 and green hydrogen into syngas - the essential feedstock enabling the production of synthetic fuels such as e-kerosene.

The required process heat is supplied by renewable electricity. The RWGS design operates at temperatures more than 100–150 °C higher than conventional DWE® reactors and allows heat inputs of up to several tens of megawatts, resulting in high conversion efficiency, excellent temperature uniformity, and scalability for world-scale PtL plants.

/ptl_main/evr_dropdown-fischer-t_512x512_2025-10-30.png?sfvrsn=c6498c4e_2)

/ptl_main/evr_dropdown-cc_512x512_2025-10-30.png?sfvrsn=42af4a07_2)

/ptl_main/evr_dropdown-h2_512x512_2025-10-30.png?sfvrsn=e23b6a8a_3)

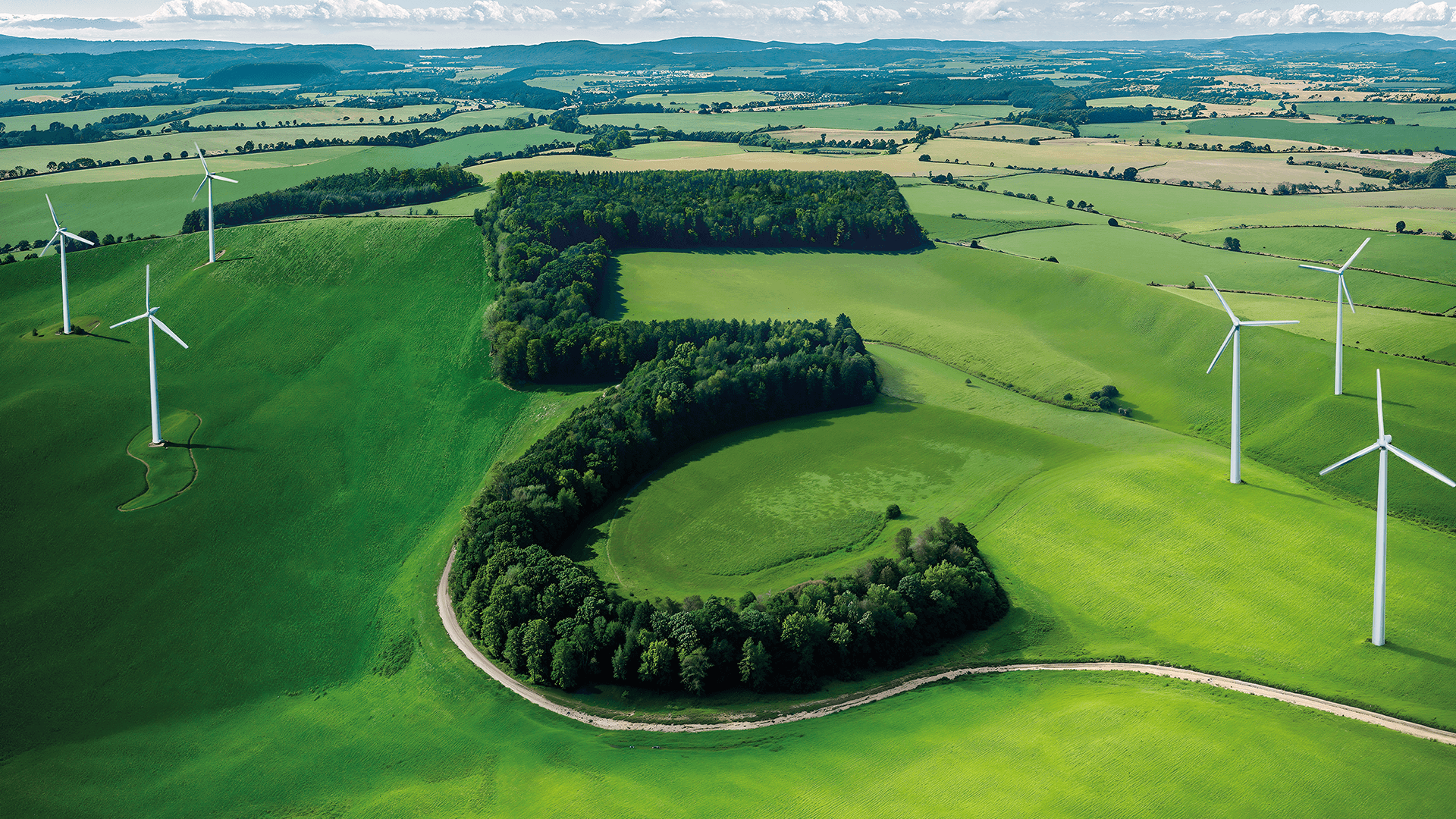

Scaling up e-SAF with Shell

Together with Shell, Everllence has demonstrated how PtL technologies can move from pilot project to full-scale production.

Our joint approach integrates Shell’s process knowhow with Everllence reactor expertise to produce e-SAF at industrial scale. This partnership highlights the transition from innovation to impact — accelerating aviation’s path to net zero.

/ptl_main/evr_shell_landingpage_header_1920x1080_2025-09-08.webp?sfvrsn=c090a99c_1)

We power decarbonization

Decarbonization requires more than ambition — it needs proven technology. Everllence combines more than 250 years of engineering heritage with a clear commitment to the energy transition.

Drawing on our experience in large-scale process engineering, we now focus on Power-to-Liquid

technologies — transforming renewable energy and captured CO₂ into sustainable fuels. These systems enable carbon-neutral operations in aviation, shipping, and industrial production, driving real impact in applications beyond the reach of electrification. We are rethinking how energy is produced, stored, and used. From advanced reactor systems and digital monitoring to full plant integration, Everllence provides the tools to decarbonize global value chains. Together with our customers, we build the technologies that define the next era of energy — efficient, circular, and sustainable by design.

Downloads

Continue reading

Contact our Everllence Industries support team

Lower your carbon footprint with Everllence

Reduce emissions, secure energy supply, and futureproof your business. Everllence provides end-to-end PtL technology solutions — from concept to commissioning.

Partner with us to build efficient and reliable Power-to-Liquid plants that drive real progress.

/ptl_main/evr_ptl_2025-10-23.webp?sfvrsn=3ecbe637_4)