The Esbjerg Project at a Glance

By 2030, Esbjerg must phase out fossil-based heat generation. As part of this transition, the city decided to shut down its coal-fired power plant. The local utility company DIN Forsyning chose to implement several sustainable solutions to supply heat to the city.

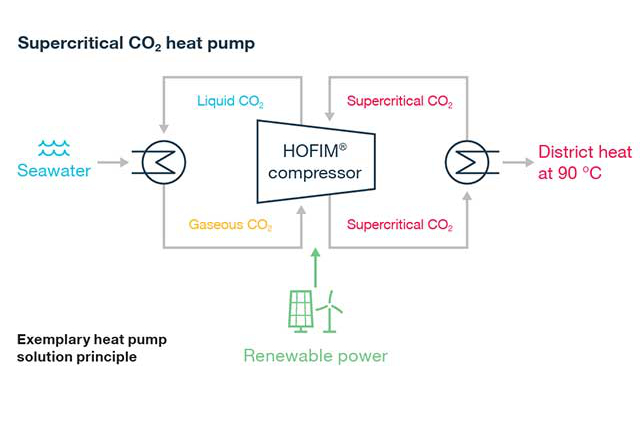

One of these solutions is a large-scale heat pump plant. Two heat pump units developed by Everllence, featuring HOFIM® compressors with integrated turbines, will ensure round-the-clock heat production for the district heating network.

The Esbjerg heat pump will be powered by renewable electricity from offshore wind farms. To generate heat for the district heating system, thermal energy is extracted from seawater in the harbor basin and used to heat the refrigerant CO₂. The gas is then vaporized and compressed until it reaches a temperature high enough to boil water. This heat is then transferred into the district heating network.

“It’s a solution that supports decarbonization efforts and can be used not only for district heating but also industrial processes worldwide”

Karl Böhle, Senior Project Manager, Everllence

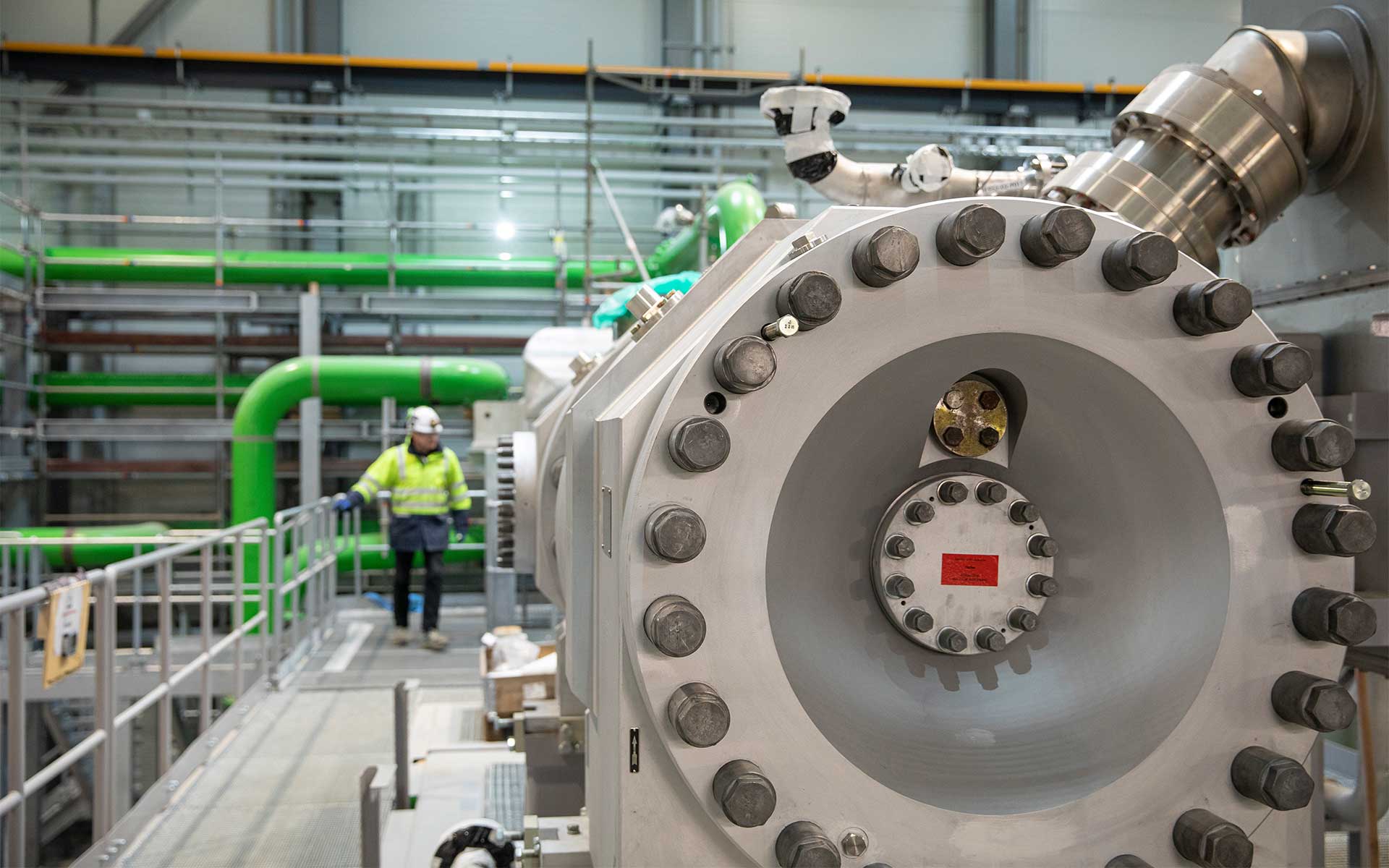

Inside the world's largest seawater heat pump plant

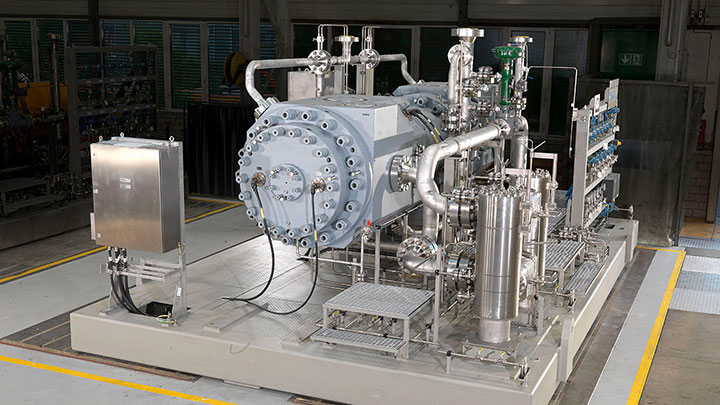

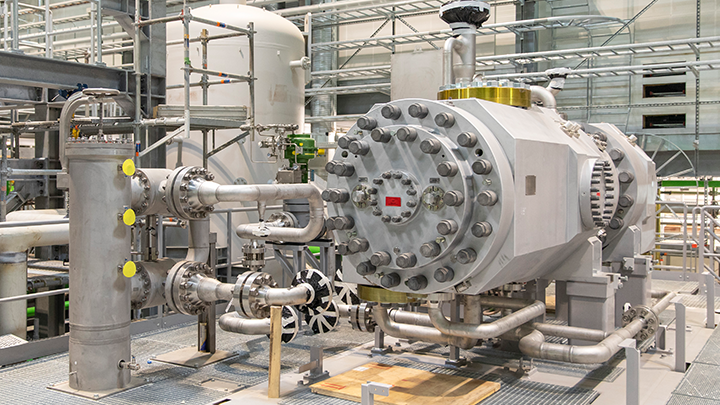

HOFIM® compressor

The high-speed oil-free integrated motor compressors are essential components of the heat pump plant in Esbjerg. The compressos run with very low noise levels and are designed for well stream gas. But they can also be used with LNG, hydrogen or CO₂, like in Esbjerg.

Benefits of the HOFIM® compressor:

- Emission-free

- Low weight

- Ideal for remote control and unmanned operation

Grid balancing

When using renewable energies grid balancing is an important factor as the production of wind and solar energy can change very fast. The heat pump system used in Esbjerg allows the change of electrical consumption. Thanks to the grid they can also add further renewable energy sources in the future.

Benefits of Grid balancing:

- Change of electrical consumption

- Storage of renewable energy

- Integration of further renewable energy sources possible

CO₂ as refrigerant

Esbjerg is located next to the sensitive ecosystem of the Wadden Sea, UNESCO World Heritage Site and National Park. DIN Forsyning therefore needed a non-toxic, non-flammable and safe to handle refrigerant for the heat pumps. All of these factors can be found in CO₂, which is why they chose CO₂ over ammonia or a synthetic option. Furthermore, CO₂ is a natural part of the environment and just goes into the carbon cycle of the sea if it leaks.

Benefits of CO₂ for the heat pump:

- Inexpensive compared to synthetic refrigerants

- Environmentally friendly

- Available in large quantities

Green district heating is the future

The coal power plant in Esbjerg was taken offline at the end of August 2024, marking the switch to seawater heat pumps that will provide nearly 100,000 people in the greater Esbjerg area with carbon-free heating.

However, the heat pump plant in Esbjerg is only the beginning. Another Danish company, Aalborg Forsyning, has commissioned an even larger turnkey heat system. It will feature four heat pumps from Everllence and is even bigger than the Esbjerg facility—showing that industrial-scale heat pumps are an important contributor on the way of moving big things to zero.

Get in touch

Contact our experts

You want to learn more about our heat pumps and the possibilities for your business? Contact our experts and take a step towards sustainability.