Restoring uptime where it matters most

At Everllence PrimeServ Wind, we address the urgent need for fast, high-quality up tower repairs by combining rapid mobilization with onsite execution. This minimizes downtime and eliminates the delays and costs of transporting large components. With deep technical expertise and specialized tooling, built on decades of experience from wind and other industrial sectors, we resolve complex failures directly at height. Repairs are carried out safely and efficiently, even when no one has solved them before. This enables operators to restore turbine performance faster, reduce operational risk, and maintain energy output when it matters most.

As part of Everllence’s broader ambition to move big things to zero, our services also help reduce environmental impact by extending asset life and avoiding unnecessary resource use, contributing to more sustainable wind operations.

Our services

At PrimeServ Wind, we understand the specific needs of the wind sector and act as a one-stop solution for complex uptower recoveries. Our services address the most crucial and vulnerable parts of the turbine, going beyond routine maintenance. By performing specialized repairs onsite, we cut downtime, avoid costly logistics, and extend the lifespan of your assets.

Welding repair is a key service for restoring damaged or worn structural components in wind turbines. It enables recovery without full replacement, reducing downtime and preserving the integrity of critical systems.

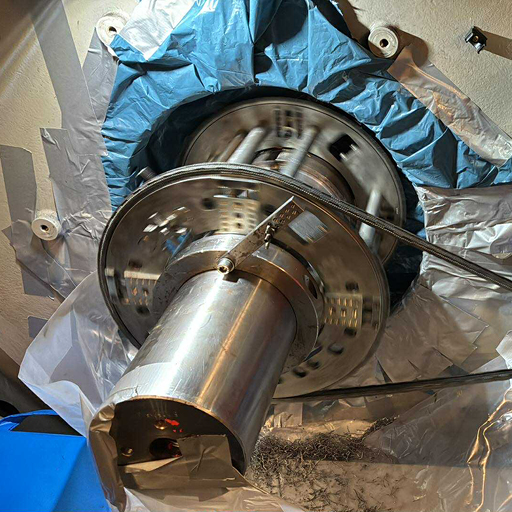

Wind turbines face extreme mechanical loads, where even small damage can affect performance. Machining restores precision and extends component life.

We offer on-site and up-tower machining that avoids crane use and full disassembly, reducing time and costs while improving turbine reliability.

Wind turbines are high-value assets exposed to constant stress and harsh conditions. Without proactive maintenance, minor issues can quickly escalate, causing costly downtime. Our services help maintain structural integrity, ensure safety, and keep operations reliable.

We provide specialized uptower repair services that solve complex challenges directly on the turbine, avoiding component removal and reducing downtime. Our in-house engineering team designs custom tools, fixtures, and procedures for unique tasks. From precision machining to structural welding and mechanical repairs, we deliver safe, efficient, and site-specific solutions.

Not all repairs can be done up-tower. For complex or heavy components, workshop repair delivers the highest safety, quality, and performance. Our global service stations offer full repair, refurbishment, and assembly, including gearbox overhauls and generator rewinds.

Seasonal maintenance peaks often create urgent demand for qualified engineers, made harder by a global skills shortage. Our Wind Engineers Outstaffing Service gives you fast access to pre-vetted experts ready to deploy on short notice.

Why choose us

At PrimeServ Wind, we combine rapid response to breakdowns with forward-thinking predictive maintenance to keep turbines running at peak performance. Whether it’s an unexpected failure or a planned intervention, our approach is built to deliver.

With a dedicated department focused solely on the wind industry, we bring specialized expertise, tailored solutions, and a deep understanding of turbine operations. Our mission is simple: minimize downtime, maximize reliability, and support your assets throughout their lifecycle.

Uptower recovery

Repairs are performed directly on the turbine by our expert engineers, who bring their workshop to the nacelle. From machining and welding to non-standard, tailor-made solutions, they restore components to manufacturer standards in days rather than weeks. By eliminating the need for cranes, we minimize downtime and revenue loss, ensuring operators maximize returns on their investments.

OEM-approved

Our procedures follow the same standards as the manufacturers who design the turbines. Every repair is performed by engineers using OEM-approved methods and documented compliance, ensuring the equipment is restored to manufacturer specifications. This guarantees OEM-level quality, consistent performance, and the highest repair standards across every site.

HSEQ compliance

Every PrimeServ Wind engineer works under strict Health, Safety, Environment, and Quality (HSEQ) standards. During repair and maintenance, safety is always our highest priority, making sure that operations continue, and recovery is delivered with uncompromising integrity and care.

Global standards. Local presence.

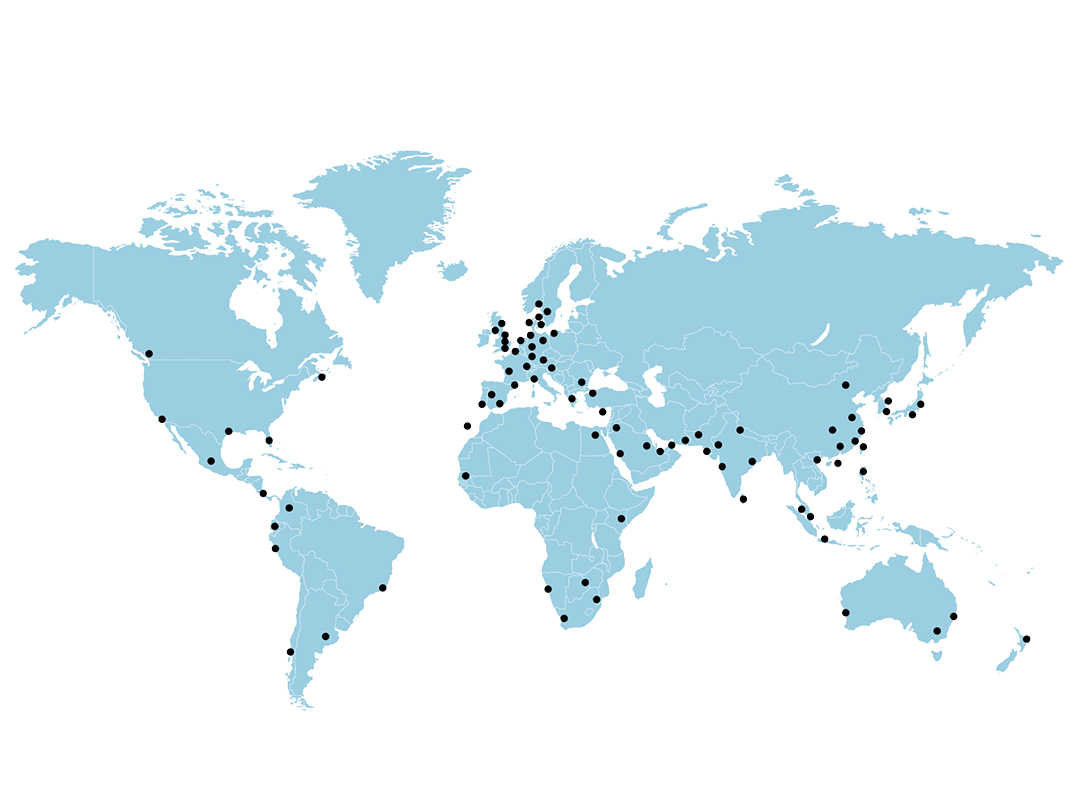

With 140 service stations worldwide, PrimeServ Wind combines international know-how with local expertise. Our local engineers are trained to meet global quality standards while following local regulations and speaking your language. This ensures fast mobilization, minimal mobilization costs, and reliable repairs delivered to the highest standards.

PrimeServ Wind worldwide

Our global network is built for speed and flexibility

A legacy of excellence, from the seas to the skies

For more than 250 years, Everllence has powered progress, from keeping global trade moving at sea to enabling the energy transition on land. Today, that heritage of engineering excellence lives on in PrimeServ, your strategic service partner.

PrimeServ Wind builds on this legacy with dedicated expertise for the wind sector, combining innovation, reliability, and uptime delivery.

Contact PrimeServ Wind experts

Find the right solution for your wind turbine operations. Whether it’s urgent support or a long term service agreement, our experts are ready to restore uptime quickly, safely, and to OEM standards.