Our solutions

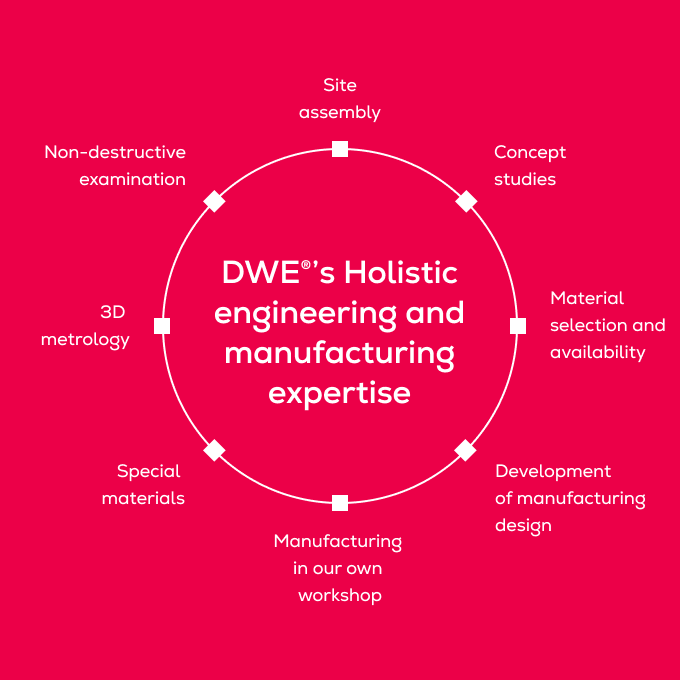

A holistic engineering approach

At Everllence, we combine decades of expertise with cutting-edge engineering to support the most demanding physics and fusion projects worldwide. Our holistic approach ensures end-to-end solutions:

- Concept studies & feasibility analysis – early-stage engineering insights

- Material selection & availability – ensuring durability and reliability

- Manufacturing design development – translating concepts into manufacturable solutions

- In-house manufacturing – precision production in our own workshops

- 3D Metrology – advanced dimensional control and laser measurement

- Non-destructive examination – ultrasonic, X-ray, pressure & vacuum testing (helium leak test)

- Site assembly & services – installation procedures, final assembly, and commissioning support

Step 1

Creative engineering in action

From concept studies to manufacturing design, Everllence transforms scientific visions into tangible solutions.We have participated in landmark fusion projects:

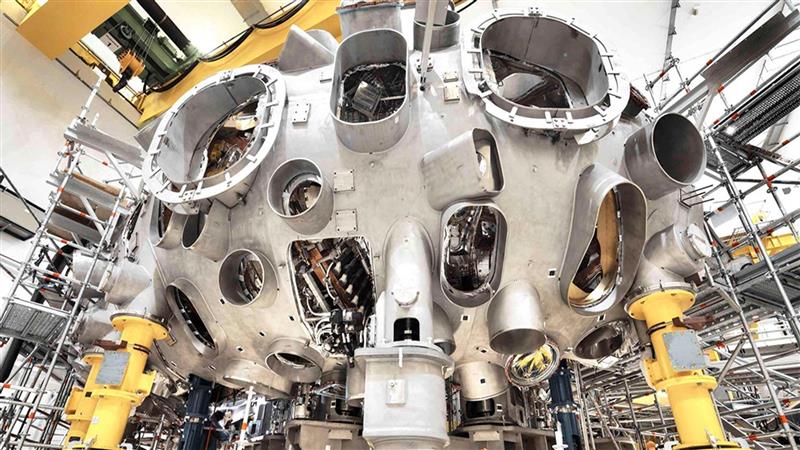

- Wendelstein 7-X (Germany): Supplied internal & external vacuum vessel plus machine foundation for the Max Planck Institute of plasma physics. First plasma achieved in 2016.

- ITER (France): Contributing to the world’s largest stainless-steel high-vacuum chamber (Cryostat, 30m high, 16,000 m³). ITER aims to generate 500 MW of thermal power.

Beyond fusion, Everllence has contributed to some of the most advanced scientific facilities:

- CERN particle accelerator (Switzerland)

- Munich II research reactor (Germany)

- ESO very large telescope (Chile)

Supporting aerospace and energy research with large-scale test stands, including:

- VINCI power plant test stand for Ariane 5 rocket engines

- High-altitude test stands for rocket and aircraft turbines

Step 2

Precision manufacturing

Our capabilities include:

- Plasma & fusion vessels for next-generation energy research

- Thermal insulation & support structures for largescale installations

- Vacuum chambers for scientific experiments and coating processes

- High-altitude test stands for aerospace applications

Step 3

Advanced quality assurance

- 3D laser metrology for complex geometries

- Non-destructive testing (ultrasonic, X-ray, pressure, vacuum helium leak tests)

Step 4

Site services & commissioning

- Development of installation and transport procedures

- Final assembly on site by Everllence experts

- Commissioning support for smooth project start-up

Everllence active in research

Visionary projects

Main spectrometer as ultrahigh vacuum vessel

- Length: 23,28 m

- Outer Diameter: 8884 mm

- Ultrahigh vacuum ≤10-11 mbar

- Design, calculation, fabrication and shipment of spectrometer

- Heating and cooling system (-20 / +350 °C)

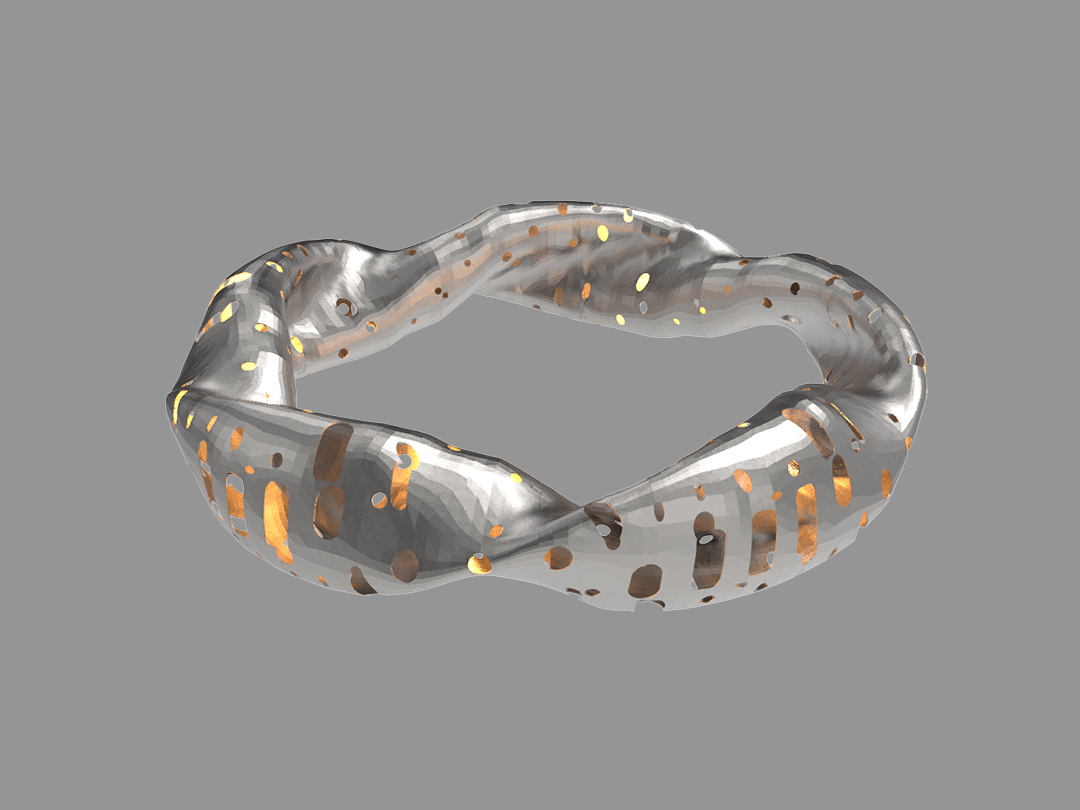

Basic modules for fusion experiments

- Mona Lisa of the art of welding

- Operating pressure: Ultra high vacuum <10-8 mbar

- CAD modelling, design, fabrication, trial assembly, measurement, leak test, shipment, field erection

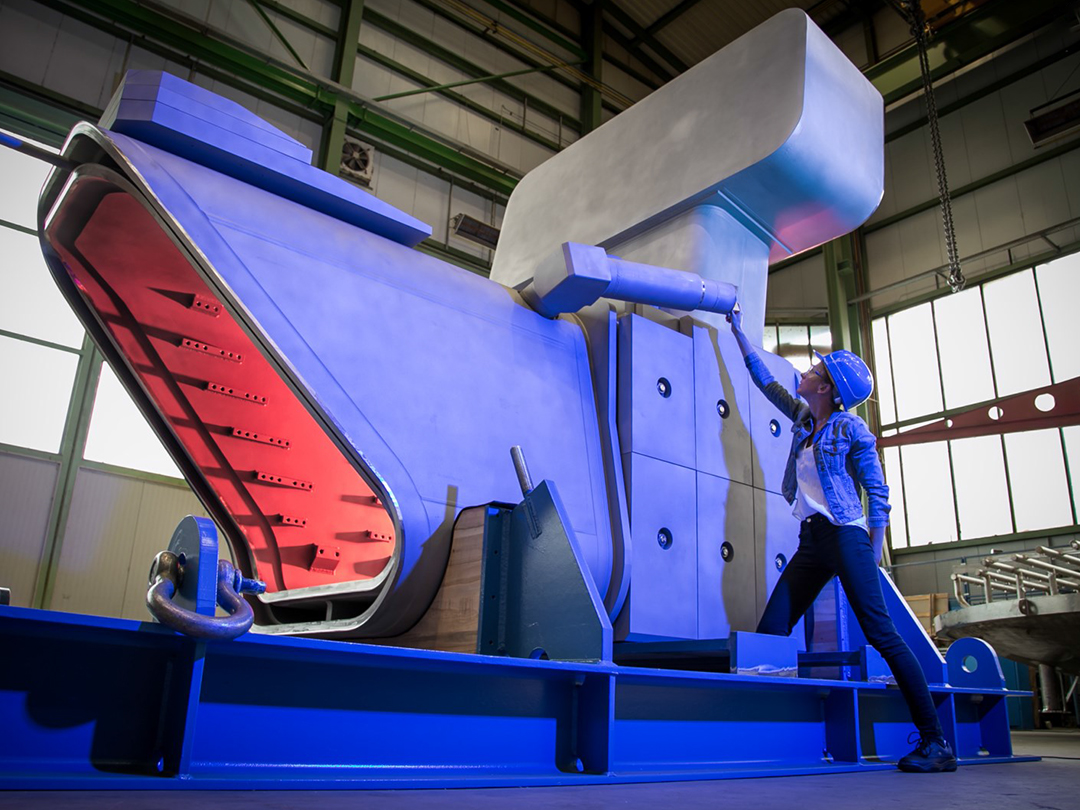

Diffuser and exhaust pipe for Ariane 5 VINCI rocket engine test bench

- Exhaust gas temperature: 3,500 K

- Thermal load on inner wall: 2-4 MW/m²

- Concept, thermodynamic and flow design, FEM analysis, engineering, design, manufacture, assembly, testing and adjustments

Condenser for Ariane 5 VINCI rocket engine test bench

- Weight: 345,000 kg

- Operating pressure: 30 mbar vacuum

- Calculations, engineering, design, manufacture, assembly, testing

Exhaust system for Ariane 6 engine test bench

- Max. thermal load on inner wall: 2 MW/m²

- Exhaust gas temperature: 3,500 K

- Engineering, calculations, manufacturing, design, fabrication, site-assembly

Contact

Ready to bring your research to life?

Partner with Everllence for your next fusion or physics project.