Tailor-made chemical reactors to meet your individual requirements

As a pioneer in chemical reactor technology, Everllence (formerly MAN Energy Solutions) is constantly working to push the boundaries of what is possible. We work closely with our customers in the chemical, refinery, and utility sectors to design and engineer industrial chemical reactors with cutting-edge features. We use high-grade steel and, if required, this is combined with special cladding to manufacture reactors capable of withstanding all sorts of chemicals.

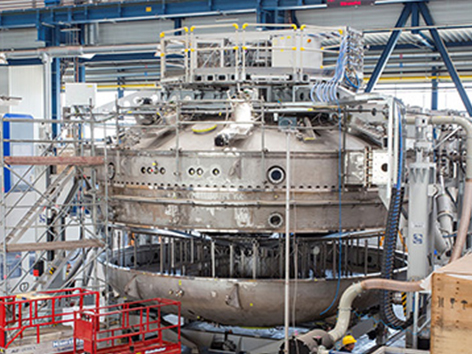

DWE®, a subsidiary of Everllence based in Deggendorf, manufactures tailor-made chemical reactors to meet your individual requirements. We offer salt-operated and water-, gas- or oil-operated reactors up to 12 meters in diameter and 1,800 metric tons in weight. We also manufacture customized special reactors.

Comprehensive solutions - from planning to execution

Our “Done in One” approach combines engineering, manufacturing, logistics, and execution in a single integrated offering. This ensures faster project delivery, minimized interfaces, and maximum reliability across the lifecycle of your FCC and refinery assets.

.gif?sfvrsn=a71b5cb2_3)

We offer

- Engineering & feasability studies

- Shutdown planning & project management

- Shop fabrication of heavy equipment

- Specialized Logistics & heavy-lift transport

- On-site assembly & installation

- Execution of revamps and turnarounds

- Support during commissioning

High-Performance FCC & Refinery Equipment

Critical equipment for refinery processes

- Up to 10 m in diameter, 70 m in length, 1,800 mt in weight

- Fully equipped (catalyst separation system), ready for operation

- Optimized for assembly

- Refractory lining

- Internals made from stainless steel

We supply:

- Regenerator/reactor heads

- Strippers

- Risers

- Y-pieces, etc.

We supply:

- Air grids

- Combustor risers

- Internal risers

We supply:

- Vapour lines

- Flue gas lines

We supply:

- Third and fourth stage separators

- Orifice chambers

Proven Success in Global Refineries

Key facts

- Project name: FCC TAR Q2 2021 MiRO, Karlsruhe

- Customer: Mineral-oil-raffinery Oberrhein (MiRO)

- Shutdown: 38 days

- Reactor size: 9 m diameter, 15 m length

- Reactor weight: 240 metric tons

- Scope of supply: manufacturing, delivery, and installation of reactor upper section

Further petrochemical equipment

Technical data outlines:

- Up to 70 m in length, 1,800 mt in unit weight

- Optimized for assembly

- High temperature chromium steel (e.g. 2 . Cr1Mo, 2 . Cr1Mo . V)

- Stainless steel cladding (weld overlay)

- PWHT in one piece

Vessels made of special materials.

- Made from materials such as zirconium or titanium

- Desulphurization reactors

- Duplex steel

- HDPE reactors

- High-pressure vacuum chambers for low-temperature natural gas liquefaction

- Up to 70 m in length, 1,800 mt in unit weight

Contact our DWE® FCC and refinery support team