By loading the video you agree to YouTube's privacy policy.

“Glatfelter Gernsbach has a long tradition,’ says Paul Stangenberg, Project Manager at Magnera, the mill’s parent company after Glatfelter’s 2024 merger with Berry Global’s HHNF business. “We’ve been making paper here for more than 140 years—Gernsbach is a papermaking town.” Some of the buildings here are still from a century ago, and over the decades the city has become a center of the paper industry—if you want to become a papermaker in Germany, you come here to study: tradition and innovation.

Inside the Gernsbach paper mill, specialty papers are produced—tea bags, coffee filters, paste papers, even technical papers for the automotive industry. Usually, on a day like today, machines hum, water from the nearby Murg River flows through the system, and demand for energy would remain high. But now with TURBAIR® vacuum systems integrated into the production line, the path toward sustainable operation is taking shape.

Tackling energy consumption in paper production

“We’ve long placed great importance on energy saving,” says Stangenberg, “and that’s only increased in recent years—especially with the coronavirus pandemic and the rising costs of electricity and gas.” The paper mill is the second biggest consumer of gas in the southwestern state of Baden-Württemberg, and its electricity usage, says Stangengberg, is comparable to that of a “large city”.

“We’re trying to minimize gas electricity, and resource consumption at every corner of the company.”

Paul Stangenberg, Project Manager, Magnera

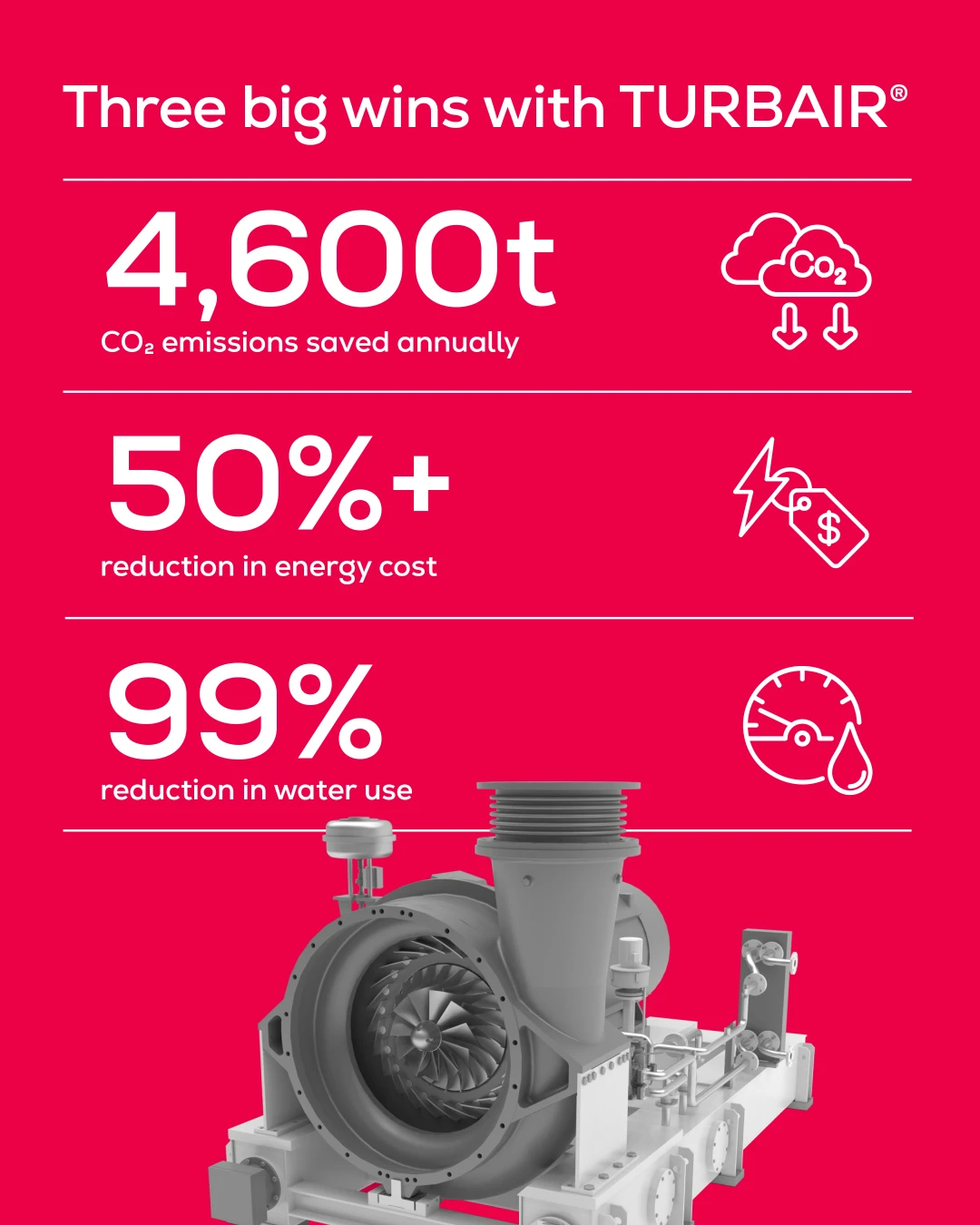

Cutting electricity use by 50% with TURBAIR®

In response, Magnera took action. Last year, two of the mill’s paper machines were retrofitted with next-generation type RT single-stage TURBAIR® vacuum blowers from Everllence—cutting electricity use in half and significantly reducing both gas and water consumption. And more installations are planned in the coming years.

Unlike the mill’s former water-ring pumps, which use water to form a rotating seal that generates suction, TURBAIR® systems have fewer moving parts and rely on air and high-speed impellers to create a low-pressure area—or vacuum—that draws water out of the paper web during dewatering.

Waste heat recovery in paper manufacturing

The upgrades, however, didn’t stop at the vacuum systems. On one machine, engineers installed a heat-to-heat air exchanger, capturing 130 °Celsius air coming out of the TURBAIR® blower to preheat the fresh air entering the combustion engine for drying. On the second machine, they’ installed an air-to-water heat exchanger to warm the process water used in paper production.

“Each machine saves some €440,000 per year in electricity consumption alone,” says Stangenberg. “Including gas and water, the total annual savings are between €500,000 and €600,000.”

“Each machine saves some €440,000 per year in electricity consumption alone.”

Paul Stangenberg, Project Manager, Magnera

Retrofitting and a new world record

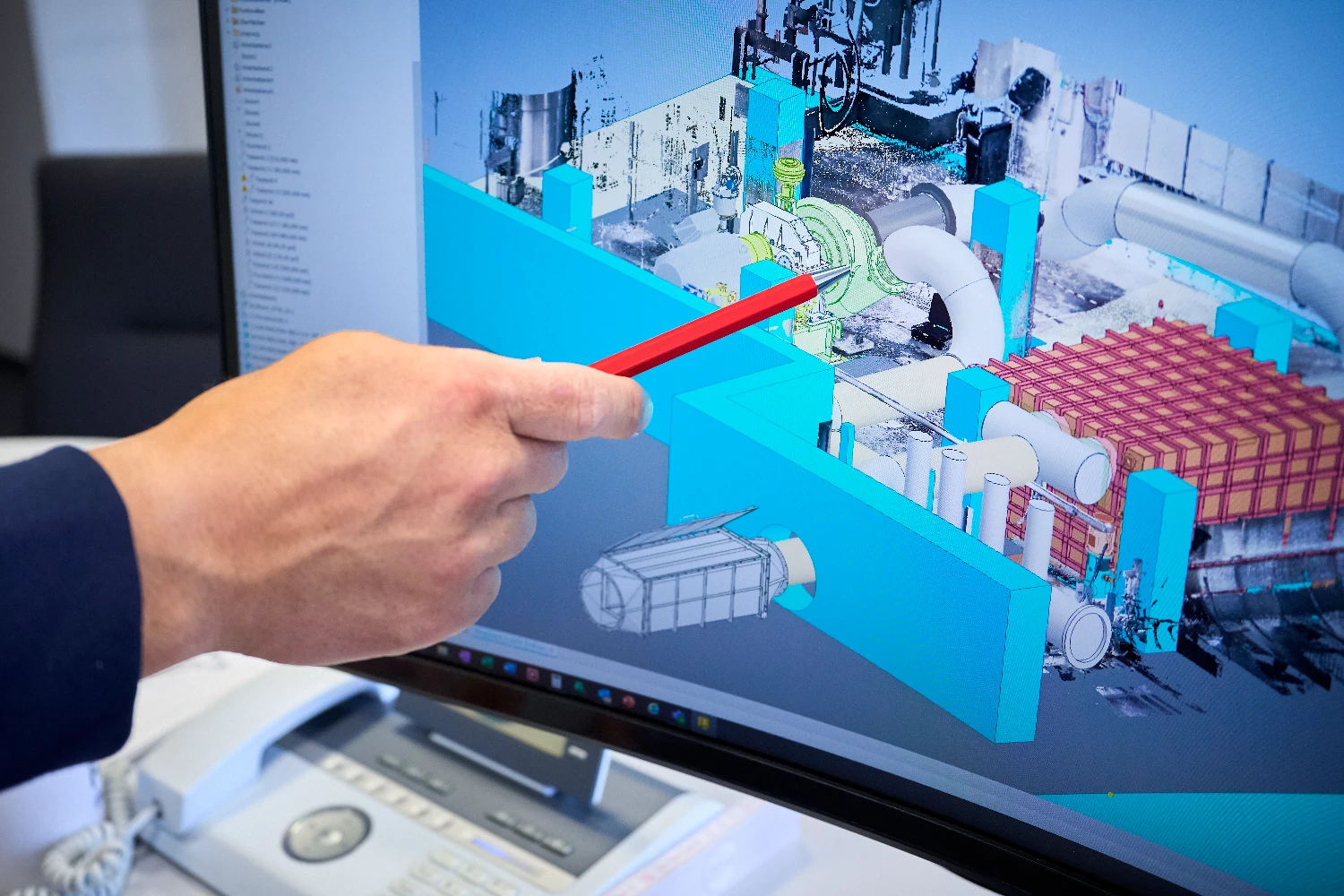

The decision to switch was made easier by experience. A TURBAIR® system had been running at the company’s Dresden site for over a decade—without technical failures and with minimal maintenance. Even so, installing the new systems came with challenges. The papermakers were wary that introducing new vacuum blowers would lead to disruptions in production. And space in the mill’s basement was limited; the machines had to be assembled in Zurich at Everllence’s productional hall, then taken apart and reassembled again inside the Gernsbach factory.

The switchover was fast—just one day for the first machine, 2.5 days for the second—bringing swift gains. “We were able to integrate a state-of-the-art system into a company with over 140 years of tradition,” says Rudi Ewert, Senior Sales Manager at Everllence, “without interrupting production.” And with the “exemplary start-up” of the system, any remaining doubts were gone. “The papermakers immediately understood how big the opportunities to save energy actually were,” says Ewert. “And the teams operating the two machines suddenly started competing to see who could use the least amount of energy.” Moreover, the operators also noticed that the dewatering effect had greatly improved—thanks to the stable vacuum conditions provided by TURBAIR®.

The following October, the paper mill set a new benchmark: one of its specialized inclined wire paper machines ran for more than 24 hours at a continuous production speed of 605 meters of paper per minute—without disruption. “This is a world record in our field of business and wouldn’t have been possible without the TURBAIR® system,” says Stangenberg.

Decarbonization in the paper industry: a turning point

Magnera is not alone. Around 1,000 TURBAIR® systems have been installed at paper mills worldwide. And recently, the technology was even used to dewater biodegradable dishware made from grass.

“If we can cut energy use at the vacuum system in half, that’s a major step forward.”

Manfred Dobler, Head of Paper Industry, Everllence

“We're definitely at a turning point,” says Manfred Dobler, Everllence’s Head of Paper Industry. “The paper industry is one of the biggest energy consumers alongside the cement. And vacuum systems account for up to a quarter of a paper machine’s total energy. Think of all the packaging paper, cardboard, tissues, diapers we use today—that demand is only going to increase as the population grows. So it’s more important than ever that we make a significant effort to decarbonize. If we can cut energy use at the vacuum system in half, that’s a major step forward.”

“Decarbonization is a big priority for us,” says Stangenberg. “We’re trying to minimize gas electricity, and resource consumption at every corner of the company.”

The TURBAIR® technology was designed with this exact purpose in mind, says Dobler. “Our company used to manufacture paper machines too. We’re the only supplier in the world that knows what a paper machine needs—and we’ve been able to develop a symbiosis with our own compressor technology so that we can meet the exact requirements for optimum dewatering on the paper machine.” The system is also highly flexible across different grammages and machine speeds, adds Dobler. “We’re the only supplier with the biggest operation areas for both single- and multi-stage blowers—that makes us unique.”

About the author

Berlin-based journalist Moritz Gathmann’s work has appeared in a number of media outlets, including Der Spiegel, the Frankfurter Allgemeine Sonntagszeitung and Zeit online.

Smarter vacuum. Cleaner results.