Brusøyskjær

In October 2020, PrimeServ concluded a project involving the retrofitting of an SCR-LP (Selective Catalytic Reduction) system on a fishing trawler operated by a Norwegian shipping company, Ivan Ulsund Rederi. As a result, the Brusøyskjaer now enjoys the benefits of reduced NOx levels that surpass IMO Tier III standards, while its 6L27/38 main engine operates on a reduced fuel-oil consumption thanks to other modifications.

PrimeServ states that in this case up to 90% of the trawler’s NOx emissions can be reduced – starting at as low as only 15% engine load.

.jpg?sfvrsn=4c1ddf32_1)

Your solution in a world of strict regulations

As ships carry passengers and cargo throughout the world, they produce exhaust emissions that have a damaging impact on fragile ecosystems. Finding ways to reduce emissions and make ships greener is an important task for the future of the marine sector. IMO Tier III, ECA, and energy efficiency design indices (EEDI) regulations define the limits for all vessels sailing in international waters. This means reduction of NOx, SOx and carbon emissions. To ensure the future viability of their fleets, shipowners and operators need to comply with these regulations without sacrificing ship engine performance and propulsion efficiency.

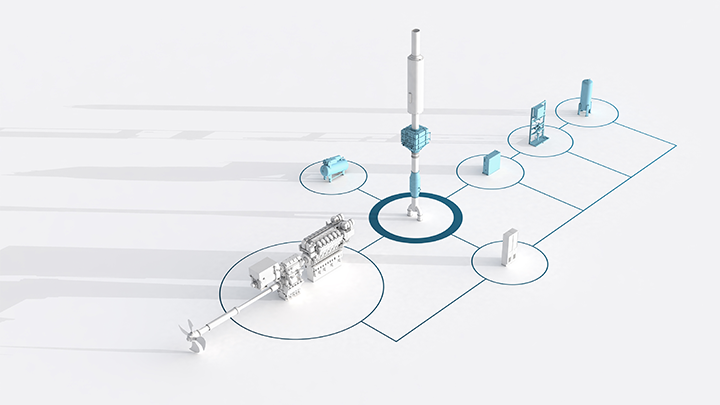

Everllence exhaust gas aftertreatment systems ensure vessels with conventional propulsion can meet the International Maritime Organization’s (IMO) strict regulations, even in emission control areas (ECA). Our system solutions are highly effective technologies to minimize harmful NOx and SOx emissions.

Expertise to meet your needs

Everllence brings together comprehensive technologies and competencies: Injection systems, turbochargers, control and aftertreatment systems. This enables us to design and implement highly efficient emission-reduction packages. The Everllence SCR (selective catalytic reduction) control system, for example, is integrated in the overall engine control system and adapted to the fuel injection system and turbocharger, enhancing the efficiency and reliability of the whole system. Up to 2.5 g/kWh of fuel oil consumption can be saved thanks to the integration of Everllence SCR and optimized control strategies compared to the use of an SCR system provided by a third-party supplier. How you benefit from Everllence exhaust gas aftertreatment systems:

- Reduce NOx emissions by up to 90%

- IMO Tier III compliance

- Increased efficiency (fuel and urea)

- One source, one point of contact

- Single source, single responsibility for IMO Tier III certification/compliance

Contact our experts

Meeting high standards with exhaust gas aftertreatment systems

Everllence is the right partner to innovate your business and head towards a greener future. Get in touch now to learn more about our exhaust gas aftertreatment system solutions!

PrimeServ protects your energy assets from day one

PrimeServ is our high-quality after-sales support. Whether you feed energy into the grid or satisfy a localized demand on land or at sea, our technicians provide what you need – where and when you need it, ensuring the availability, flexibility, and profitability of your plant.

- Fast, reliable and expert customer support

- Bespoke service agreements

- Global service – 24 hours a day, 365 days a year

- Fast, reliable and expert customer support

- Prompt delivery of OEM spare parts

- Bespoke O&M contracts

- Global service – 24 hours a day, 365 days a year

FAQ

Frequently asked questions about exhaust aftertreatment systems

Exhaust gas is the term for the gas that is emitted after the combustion of fuel, e.g. in ships. It consists of reaction products like dust, sulfur oxides, nitrogen oxides and carbon monoxide.

Exhaust gas aftertreatment systems are integrated into engines to reduce emissions. Gases like sulfur oxides and nitrogen oxides are converted into harmless gases like water vapor or nitrogen gas (N2). Therefore, exhaust aftertreatment systems are a solution to meet regulations like the IMO Tier III.

Downloads

Find even more information about exhaust aftertreatment systems