Production site Berlin

World-class compression technology developed in Berlin. At Everllence Berlin, 380 employees from 18 countries are responsible for the development, engineering, production, sales and testing of high-tech integrally geared radial compression systems. Our Berlin compression solutions are integral part to transform towards a sustainable industrial future and are used in Carbon Capture Utilization and Storage, Hydrogen as well as Heat pump applications. We strives to transform energy into sustainable progress and prosperity for a climate-neutral future. #movingbigthingstozero.

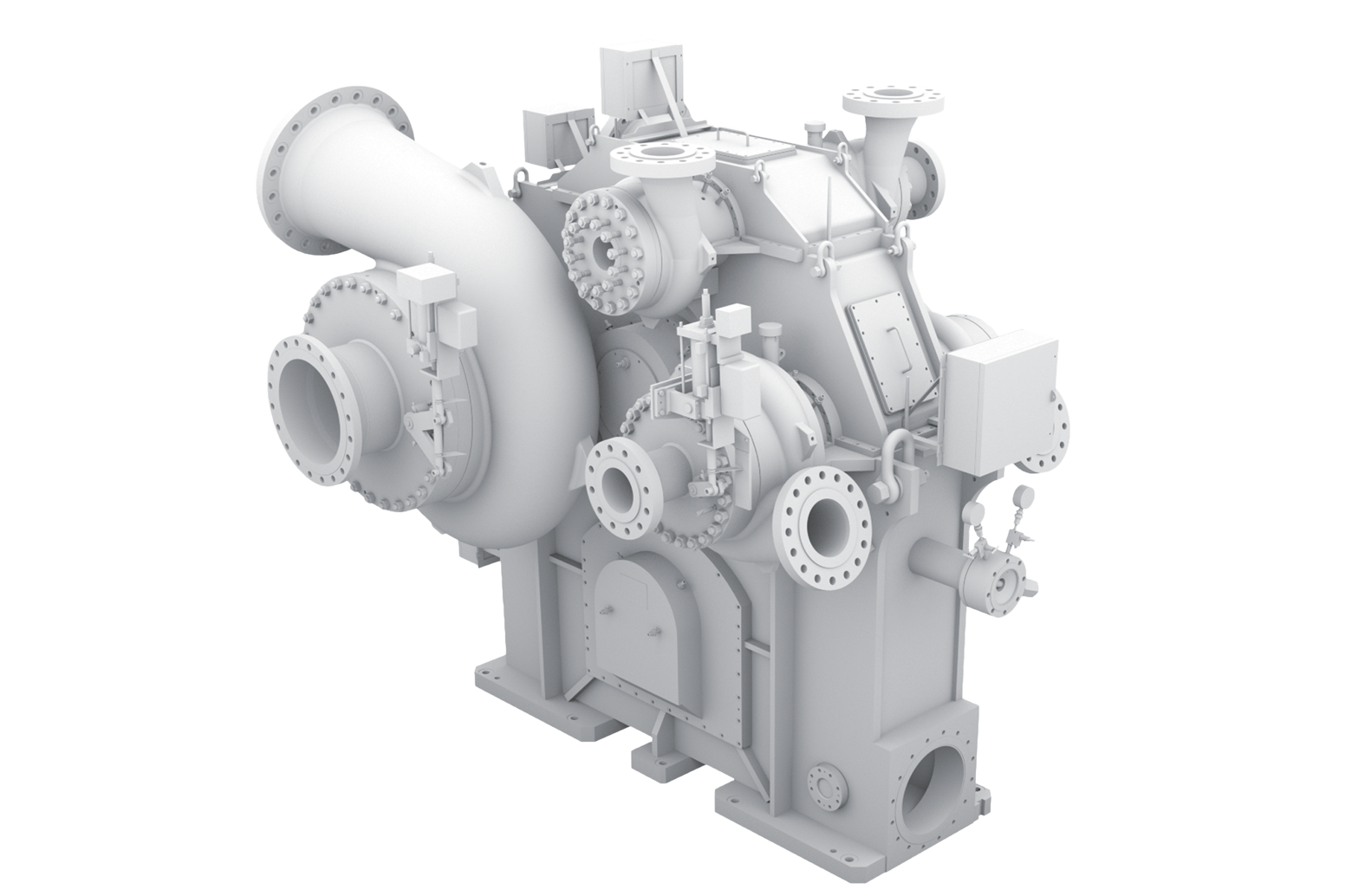

Gears and integrally geared compressors

Berlin is the center of excellence for integrally geared compressors.

The Product center combines the competencies for the engineering and the production of integrally geared compressors including the manufacturing of impellers and gear sets as well as the assembling and testing of gear boxes serving both the new equipment and PrimeServ business.

Technology innovation

CCUS

The rise of renewables is good for the planet. Converting renewable electricity into storable fuels spreads the benefit of carbon-neutral energy across sectors. The power-to-X process allows for just that. It is a transformation technology that converts electricity into carbon-neutral synthetic fuels, which can then be used in other sectors or be stored until needed.

Heat pumps

Hydrogen

Hydrogen is a key element in the energy transition. It has the potential to decarbonize a vast variety of sectors, from shipping, heating and cooling to industrial applications. We at Everllence acknowledge the power of H2 and with our solutions and services, we are already covering all parts of the hydrogen economy today.

unit weights with tolerances <8µm

different nationalities just as diverse as Berlin

Technologies and business activities in Berlin

Fully adaptable to your needs, our integrally geared compressors typically stand for high efficiency and a speedy return on investment in a wide range of applications. This multi-shaft centrifugal compressor allows for up to five pinions, depending on your individual requirements.

- Individually selectable impeller speed for optimal flow and costs

- Up to three combined applications within one casing

- Sealing and intercooling opportunities

Career and training offers

Address

Everllence SE

Egellsstraße 21

13507 Berlin

t +49 30 440402 0

Everllence Berlin

Egellsstr. 21

13507 Berlin

Everllence Berlin

Egellsstr. 21

13507 Berlin

Everllence Berlin

Egellsstr. 21

13507 Berlin

Everllence Berlin

Egellsstr. 21

13507 Berlin

History

1857 – First BORSIG Compressor in Berlin

1977 – First BORISG Multi-Shaft Compressor designed in Berlin

1996 – Establishment of GHH BORSIG

1997 – World first 10stage CO2 integrally geared compressor supplied to customer

2010 – MAN Diesel and MAN Turbo merge to become MAN Diesel & Turbo

2018 – MAN Diesel & Turbo becomes MAN Energy Solutions SE

2025 - MAN Energy Solutions becomes Everllence