Benefits at a glance

What defines pulp and paper today

Energy-efficient vacuum technology for perfect paper

With TURBAIR®, Everllence offers vacuum systems developed specifically for the paper industry. Our systems dewater the paper sheet and press felts. The vacuum blowers also shift paper between sections of the paper machine and help recover water for reuse. Our TURBAIR® vacuum technology completes these tasks in a sustainable, energy-efficient, and flexible manner. TURBAIR® systems require up to 60% less energy. Additionally, it is possible to reuse the hot exhaust-air in the energy cycle using a heat exchanger, leading to a further reduction in overall energy consumption of up to 80%. Connected to a heat pump, even more savings are possible for the whole plant.

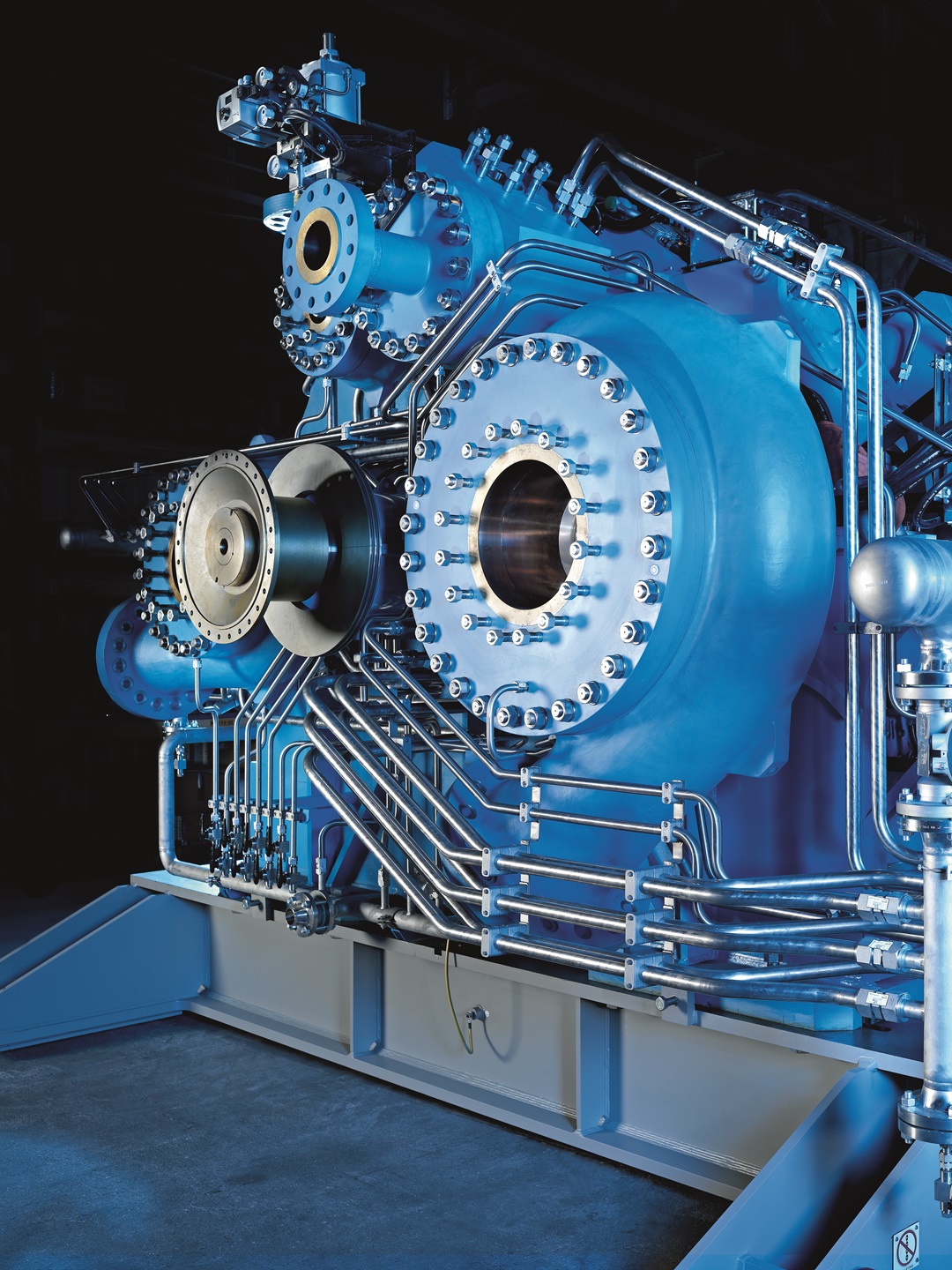

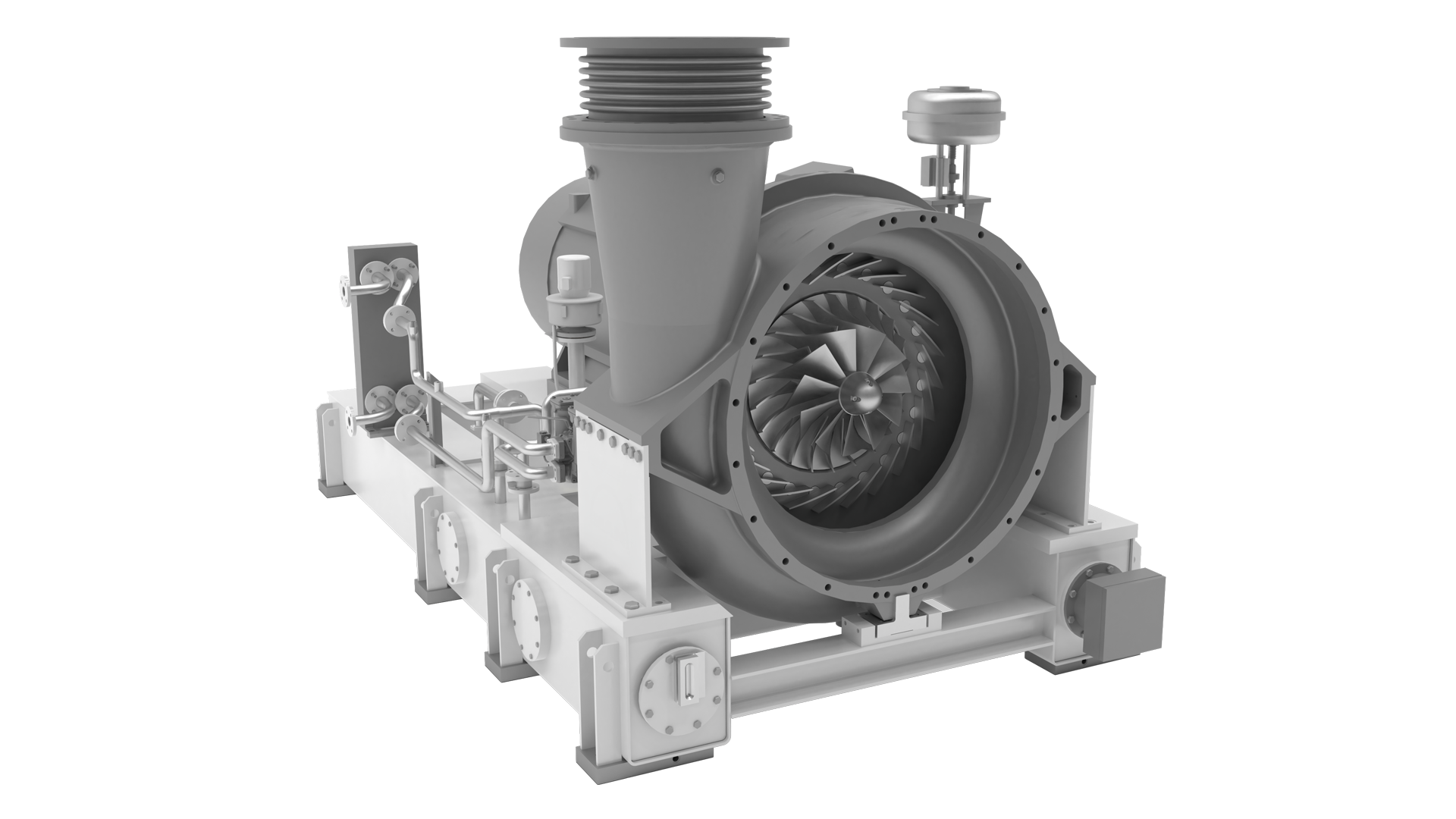

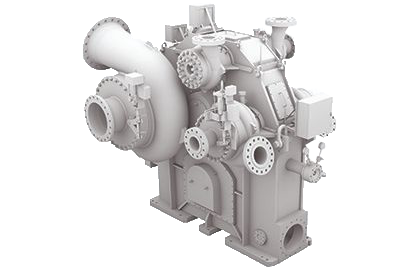

TURBAIR® vacuum blowers

A step ahead for our paper industry customers

TURBAIR® vacuum technology has been specifically engineered for efficient paper sheet dewatering. It is applied in board, tissue, and graphic paper machines, delivering the following key advantages:

- Widest operating range among all vacuum technologies

- Energy savings up to 60%, plus up to 70% additional savings through heat recovery

- Variable speed drive for flexible and efficient operation

- Market-leading water separation with TURBAIR® separators

- No sealing water, no water consumption, no wearing parts

- Suction flow rates up to 200,000 m³/h with adjustable vacuum levels up to 80 kPa

- Fully automatic control system for all paper machine operating modes

- Robust, low-maintenance design for continuous operation

Heat pumps for industries

Heat pumps that decarbonize pulp and paper

Heat pumps help the pulp and paper industry reduce heating costs and CO₂ emissions by recovering waste heat to generate process steam at 80 to 200 °C, addressing the roughly 70% share of energy demand driven by drying processes:

- Decarbonization of thermal energy supply for pulp and paper production

- Significant reduction of heating and overall plant energy costs

- Utilization of waste heat from drying and process streams

- Steam generation for drying processes at temperatures from 80 to 200 °C

- High system efficiency through advanced heat pump technology

- Seamless integration into existing paper and pulp plants

- Reduced dependency on fossil fuels and boilers

- Robust, industrial-grade design for continuous operation

Efficiency that powers the pulp and paper industry

TURBAIR® vacuum blowers and industrial heat pumps engineered for pulp and paper

Engineered to deliver

Our vacuum blower technology at work

At Glatfelter Gernsbach, Everllence cut energy use where it matters most. By retrofitting two paper machines with TURBAIR® vacuum blowers, we halved electricity consumption in the dewatering process, reduced water and gas use, and turned waste heat into usable energy. The result: lower operating costs and a clear step toward decarbonized paper production.

| Country | Germany |

| Application | Paper mill – vacuum system retrofit for energy, water and emissions reduction |

| Project status | Completed / Operational (retrofit already implemented with further installations planned) |

| Customer benefits | Significant energy savings (electricity reduced by ~50%) with concomitant cuts in gas and water use; substantial annual cost savings (~€500,000–€600,000 per machine); enhanced sustainability and reduced CO₂ emissions through elimination of water-ring pumps and improved vacuum process efficiency; waste heat reuse for process pre-heating. |

| Scope of work | Retrofit of two next-generation TURBAIR® single-stage RT vacuum blowers on two paper machines, including integration with heat-to-heat and air-to-water heat exchangers for waste heat recovery. |

Contact our Everllence experts

Update your technology to give your business the edge

Could our TURBAIR® vacuum system sit at the heart of your production process, cutting costs and improving your environmental performance? Talk to us to find out more.

Smarter vacuum. Cleaner results.

Rapid and dependable support for your turbomachinery

Everllence PrimeServ delivers tailored service agreements and global 24/7 support, ensuring optimal uptime. Our engineers perform regular preventive maintenance to maintain peak efficiency and are ready to troubleshoot any issue, wherever and whenever it arises.