Proven subsea performance at scale

Subsea compression in numbers

of uninterrupted operation by HOFIM® compressors in the Åsgard field (as of May 2025)

barrels of oil equivalent added to the Åsgard field recovery

power output per HOFIM® compressor on the seabed

Smaller investment, bigger gains, less CO2

Pressure in gas fields decreases over time. Our remote-controlled HOFIM® (High-Speed, Oil-Free Integrated Motor) subsea compressors ensure the constant flow of gas for processing in underwater facilities. This subsea compression technology greatly increases the total recovery of a gas field, allowing for maximum efficiency. And underwater operations also mean less CO2 is released into the atmosphere compared to traditional platform exploration.

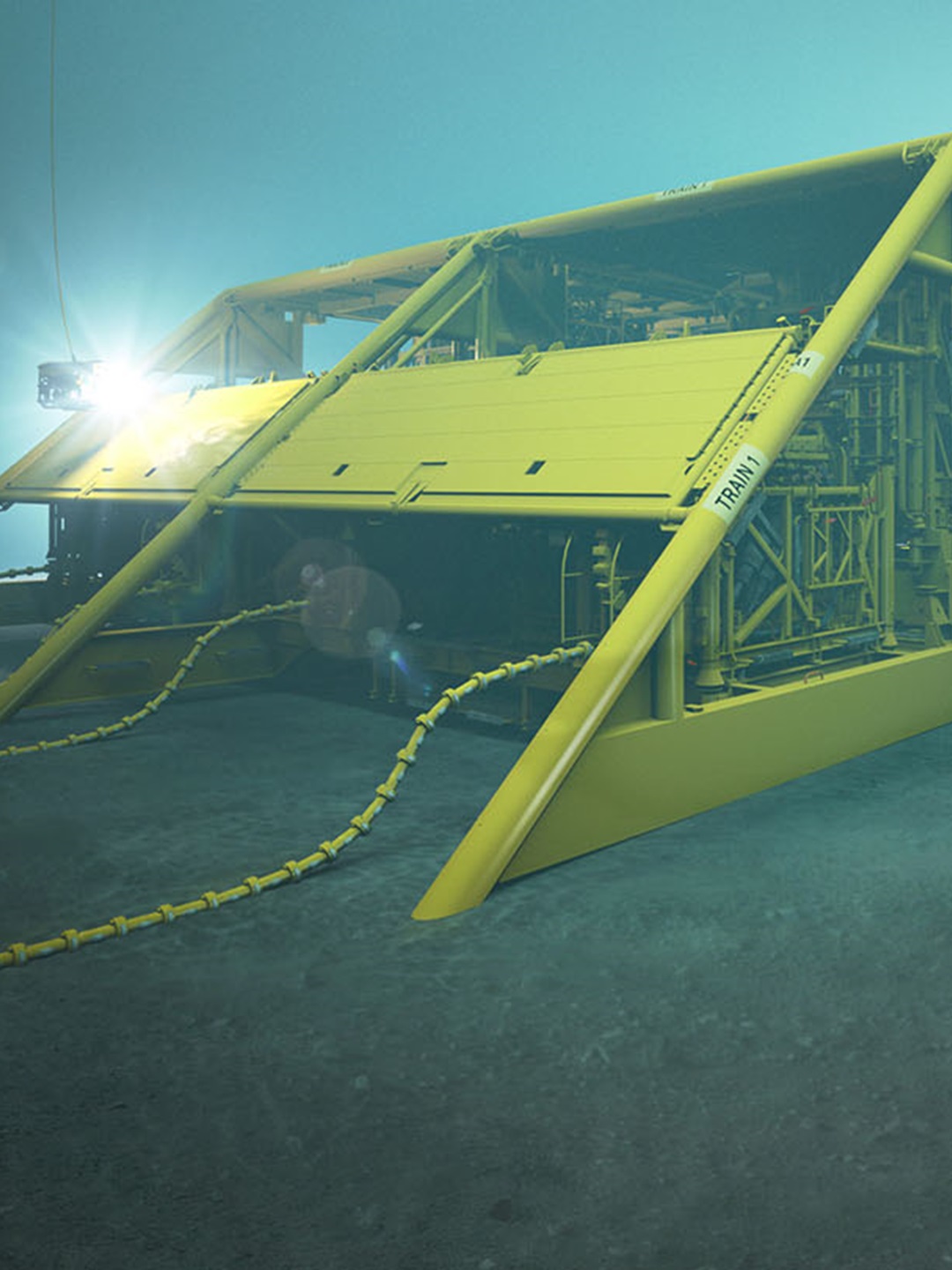

As a world first, Norwegian company Equinor operates an exploration facility at 300m below sea level, featuring two HOFIM® compressors. Everllence partnered with OneSubsea (former Aker Solutions) for this pioneering subsea compression project. The equipment functions efficiently without the intricate interaction of lubrication systems, dry gas seal mechanisms, gearboxes, and couplings. This makes it less prone to break downs. Encapsulation makes the subsea compressors leak-proof, and maintenance is reduced to a minimum as they run with almost no mechanical friction. Based on this success, we are developing further groundbreaking subsea technology together with OneSubsea.

Proven subsea compression under extreme conditions

Originally developed for demanding onshore applications such as gas storage, the HOFIM® compressor was specifically engineered and adapted for permanent underwater operation. Its hermetically sealed, motor-integrated design eliminates dynamic seals and prevents seawater ingress, while robust material selection and a fully enclosed process ensure maximum protection against internal corrosion. Designed for long service intervals and maintenance-free operation on the seabed, the compressor enables reliable pressure boosting directly at the reservoir.

At Equinor’s Åsgard field, the HOFIM® subsea compressors have proven their performance in real-world conditions, achieving more than 150,000 hours of uninterrupted operation (as of May 2025). The installation has significantly increased recovery rates, stabilized production, and reduced the need for topside infrastructure – demonstrating the viability of subsea compression as a key technology for efficient, low-impact offshore gas production.

Everllence solutions for subsea compression

Engineered for reliable offshore performance

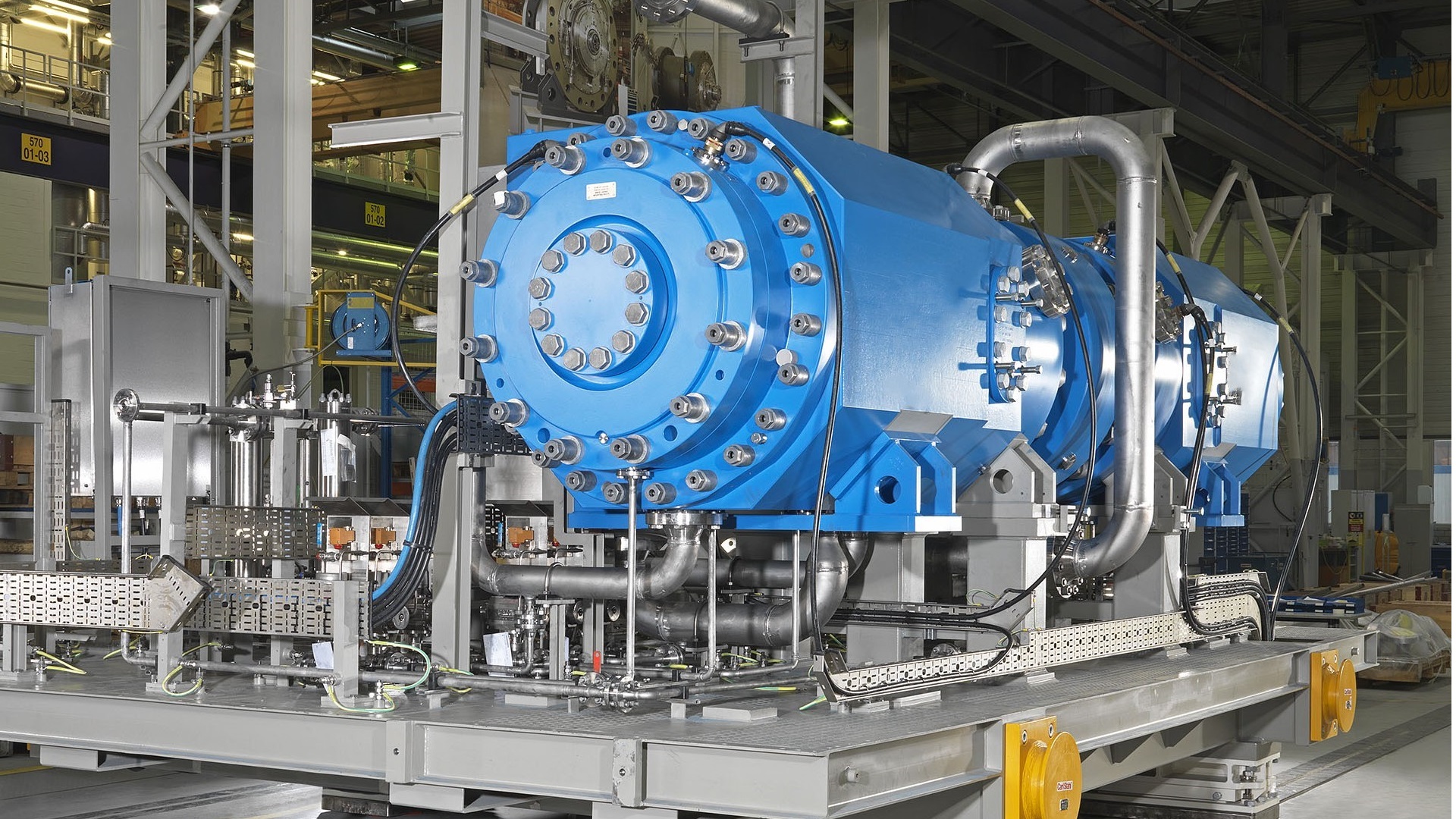

A pioneer in integrated turbo compressor systems, Everllence has elevated the technology to meet harsh underwater conditions.

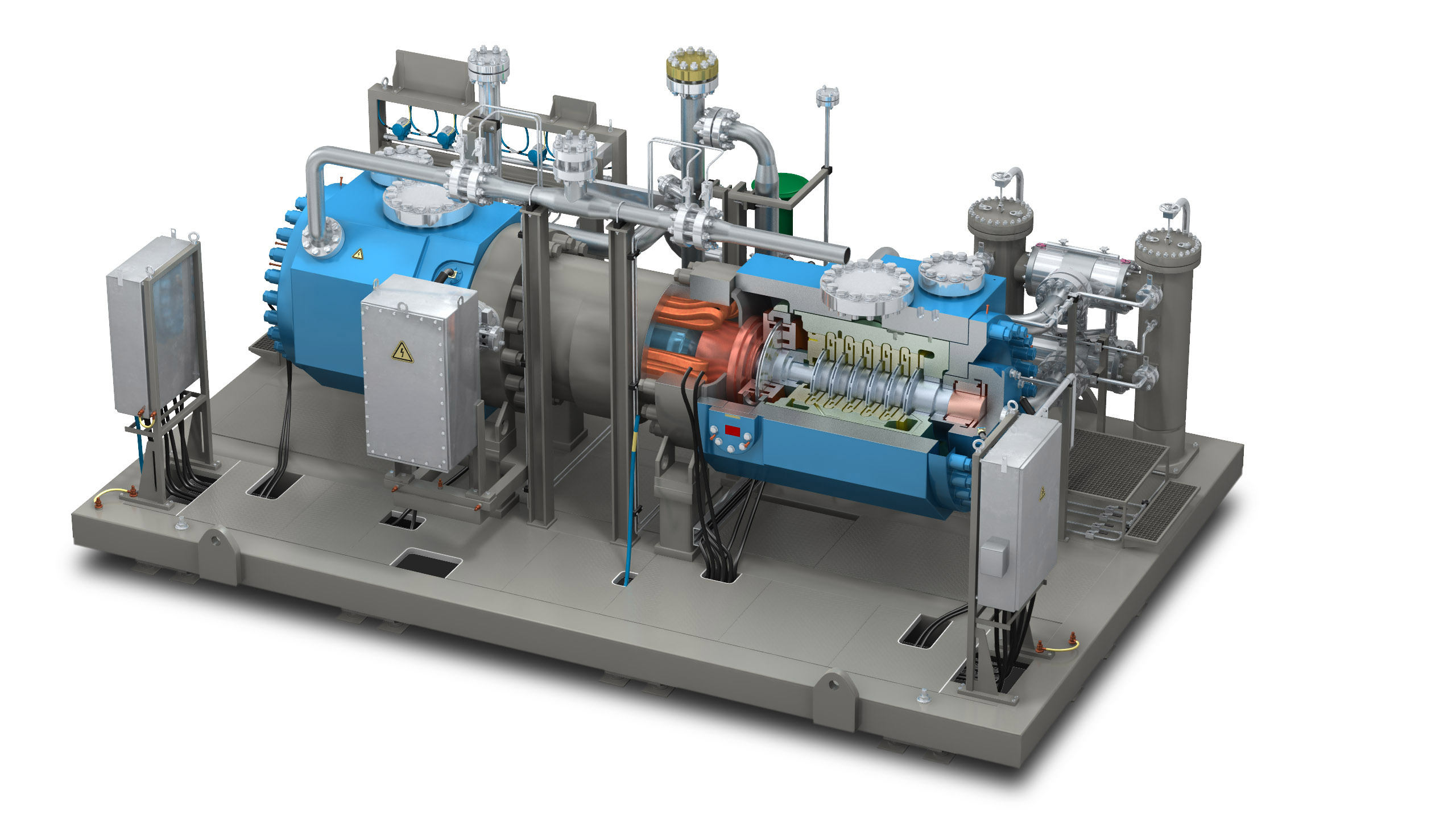

In 2015, Everllence delivered two HOFIM® subsea compressors to Equinor (formerly Statoil) of Norway. Featuring a compression power of 11.5 MW (15,000 HP) each, and design pressure of 220 bar (3190 psi), they are powerful pieces of extremely reliant machinery. Saving CO2 emissions and lending stability to the extraction process over the years, our sealed compressors have started a new chapter in offshore drilling.

Operating without lubricants, HOFIM® compressors are designed for the most demanding environments and leverage active magnetic bearing (AMB) technology. Their hermetically sealed design makes them ideal for subsea extraction, unmanned offshore operations, and gas storage. With unlimited start/stop capability, excellent part-load efficiency, and no lubricant contact with the process gas, HOFIM® compressors deliver high reliability, minimal downtime, and lower operating costs.

Drilling for oil or gas from remote offshore platforms is an expensive and extremely sensitive undertaking. Every hour of downtime is prohibitively expensive, as is each man-hour needed out there. Helicopter time, insurance, expertise – you name it. Everllence provides the compressors and digital solutions which allow for operations with a minimum of human intervention and downtime.

Contact our Everllence support team

Choose our technology to expand the boundaries of your operations

Everllence’s pioneering subsea compressor technology takes you further. Our highly reliable sealed compressors have already been successfully deployed on the seabed. Contact us and see how we can support your subsea compression project.

Downloads

Detailed information about our products and expertise

HOFIM® – engineered for subsea reliability

The HOFIM® compressor is a hermetically sealed, oil-free solution specifically designed for the most demanding subsea and offshore applications. Its motor-integrated design with active magnetic bearing technology eliminates dynamic seals, prevents leakage, and enables continuous, maintenance-free operation on the seabed. With high efficiency, excellent part-load performance, and unlimited start/stop capability, HOFIM® supports unmanned installations, enhances field recovery, and contributes to safer, lower-emission subsea operations.

Unlocking the future of turbomachinery

Everllence’s digital innovations enhance availability, operational efficiency, and safety, while supporting predictive maintenance, unmanned operations, and the move toward full autonomy. Our solutions meet our clients’ increasing requirements for energy efficiency and decarbonization.

Protect your assets and keep your turbomachinery running

With customized service agreements and global 24/7 response, Everllence PrimeServ offers an optimal support solution. Our service engineers conduct regular preventive maintenance to ensure that your trains and machinery operate at peak efficiency, in addition to providing troubleshooting assistance whenever and wherever it is needed.