Benefits at a glance

Proven performance from a global market leader

trains currently in operation

maximum volume flow

years of continuous development

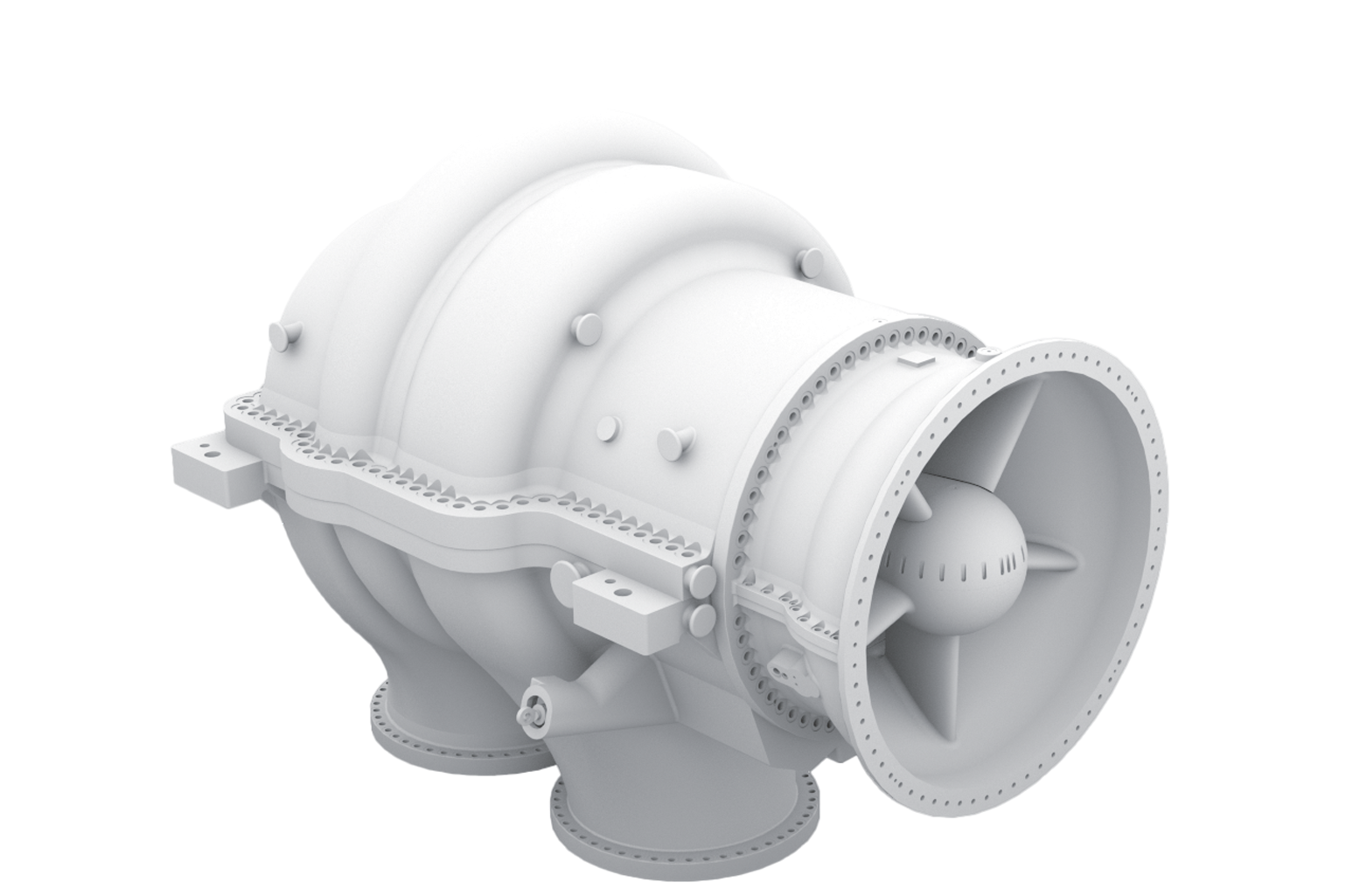

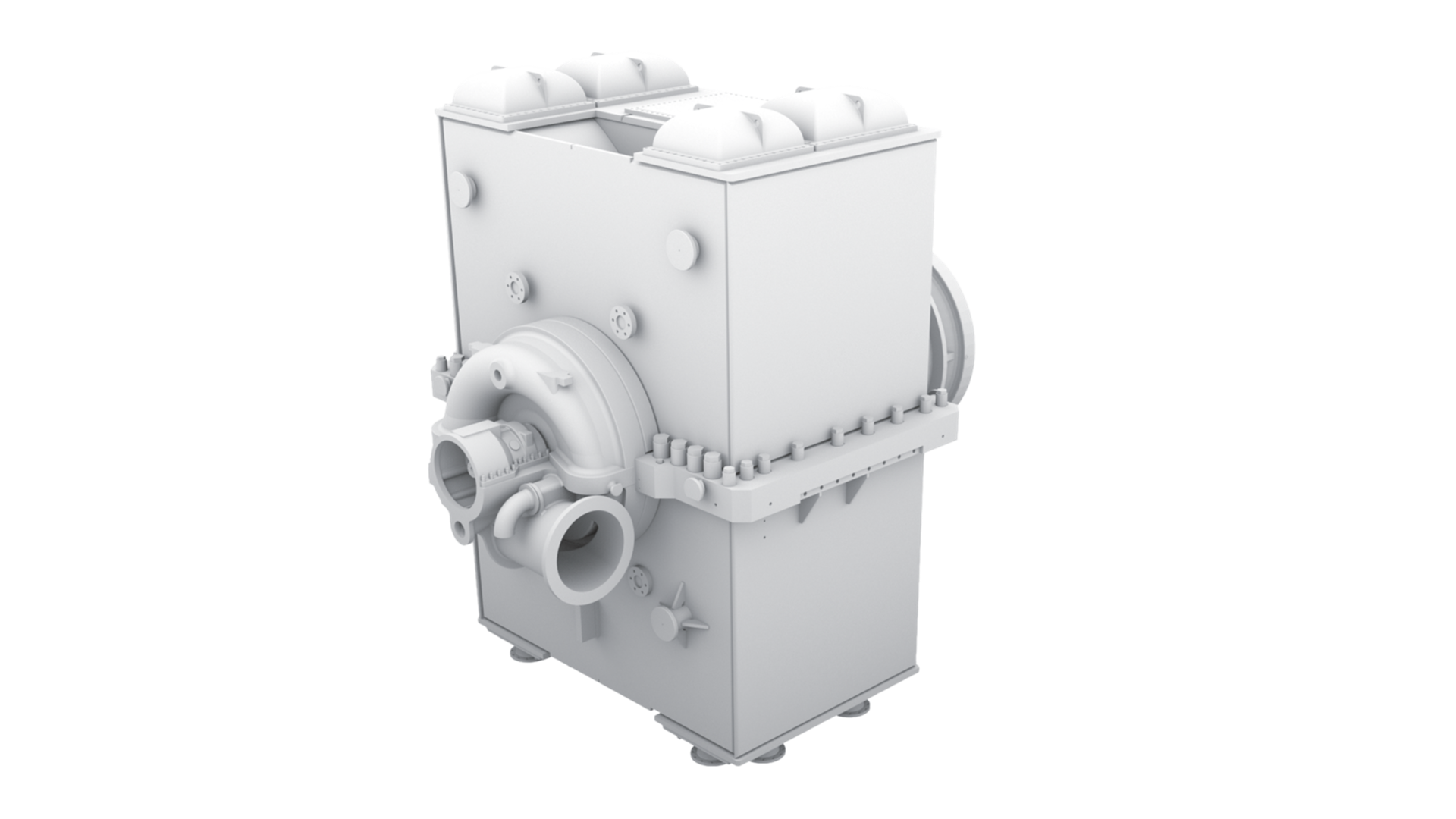

EM-driven compressors & AIRTRAINs

Air separation units (ASU) are used in many applications in industries ranging from iron and steel to food and medical gases as well as in the production of green ammonia and methanol. We have supplied over 80 AIRTRAINs and hundreds of electric motor(EM)-driven compressors to air separation plants worldwide. Everllence can supply either AIRTRAINs that consist of steam-turbine-driven main air compressor (MAC) and booster air compressor (BAC) or separate MACs, BACs and NICs (nitrogen compressor) with electric motor drive. Our comprehensive product range can be tailored to your needs, effectively addressing oxygen requirements ranging from 500 tpd to 5,000 tpd.

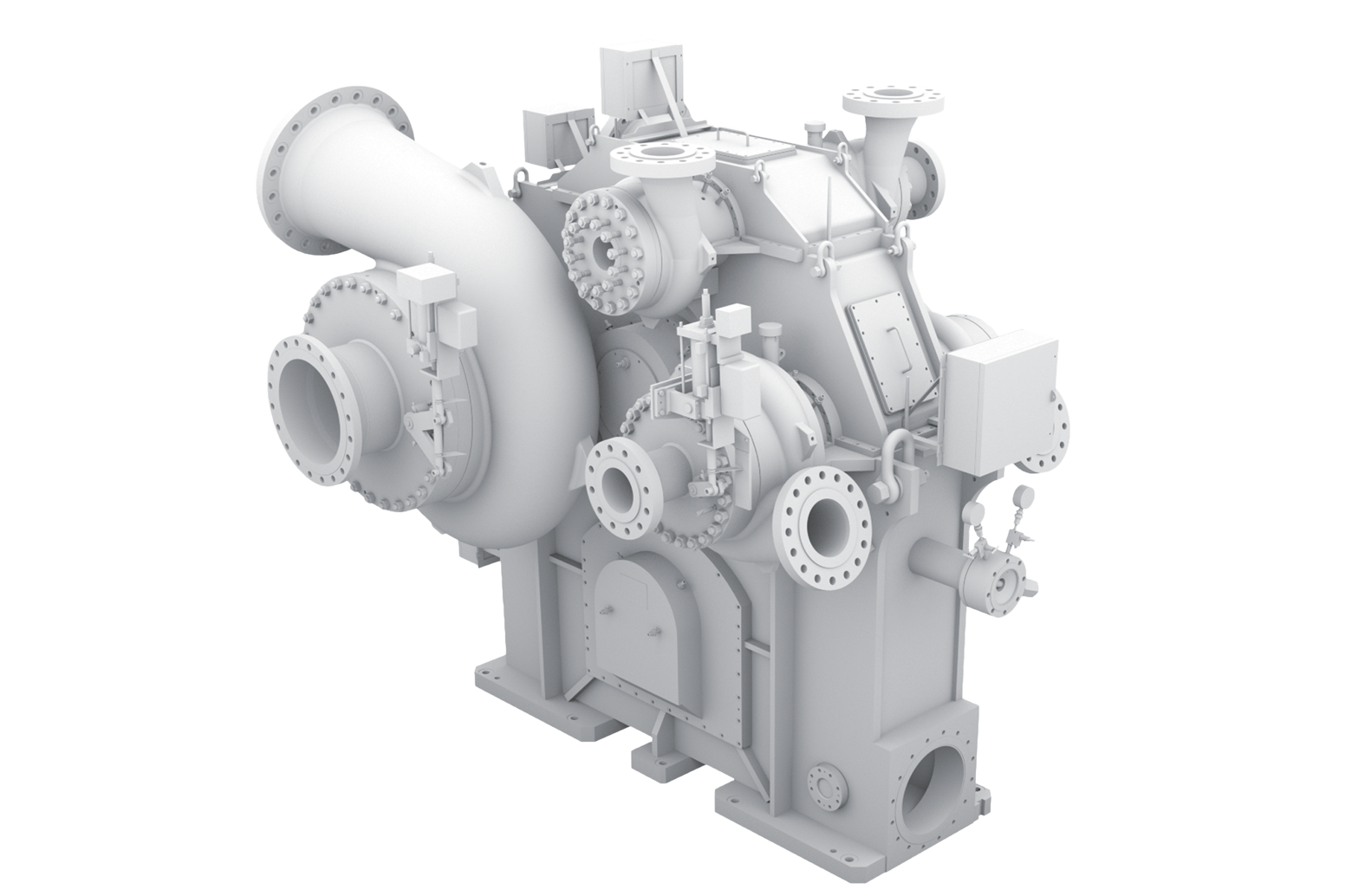

Ultra-large air separation units

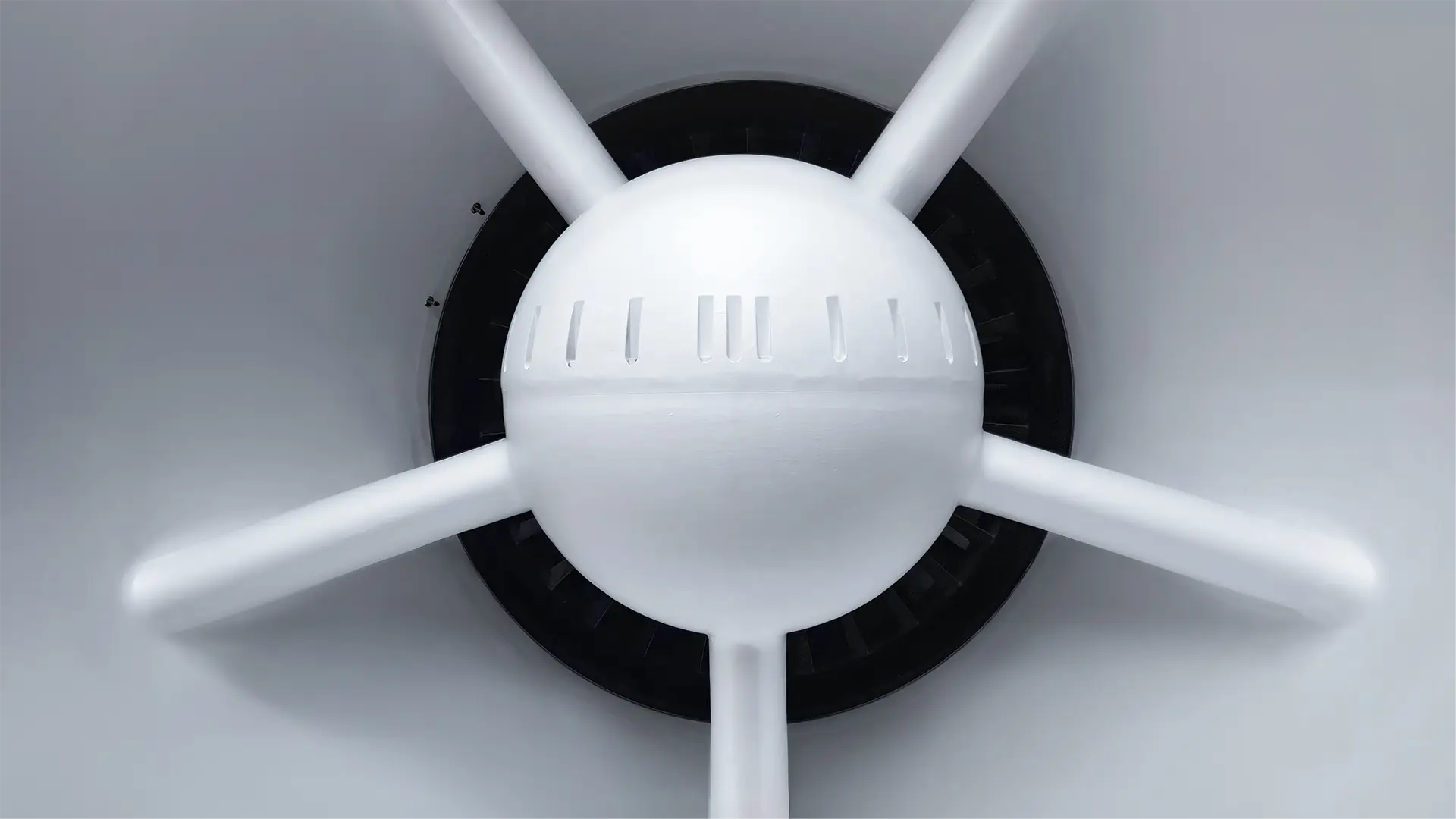

AR-MAX1, our standardized axial/radial main air compressor, really is a piece of equipment you can rely on. As one of the leading large air separation units (LASU) on the market, it delivers volume flows up to 1.5 million cubic meters per hour, easily handles pressures up to 25 bar, and exhibits optimum robustness. And when it comes to transportability, AIRMAX trains are very competitive due to their high speed and consequentially its compact design.

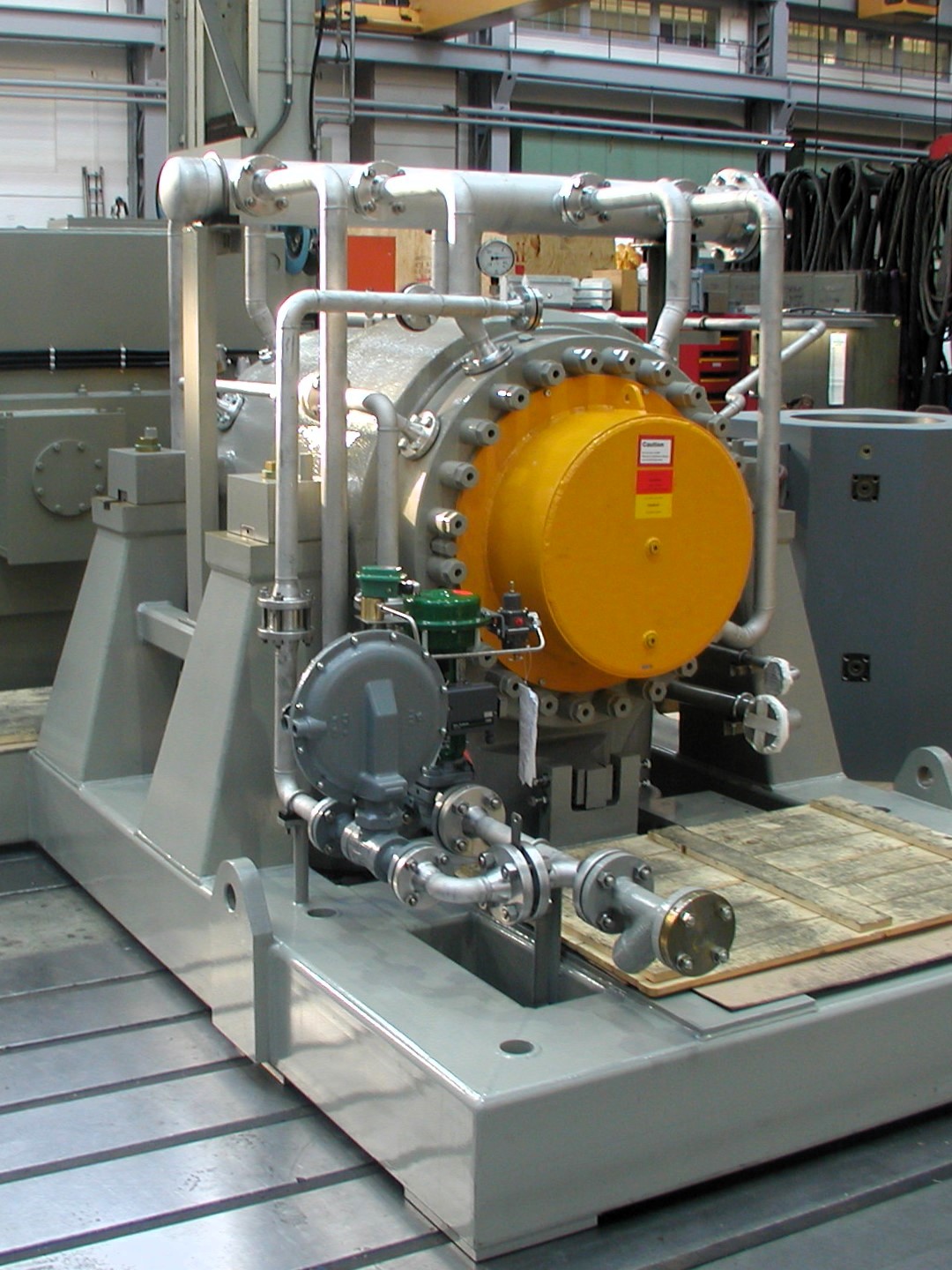

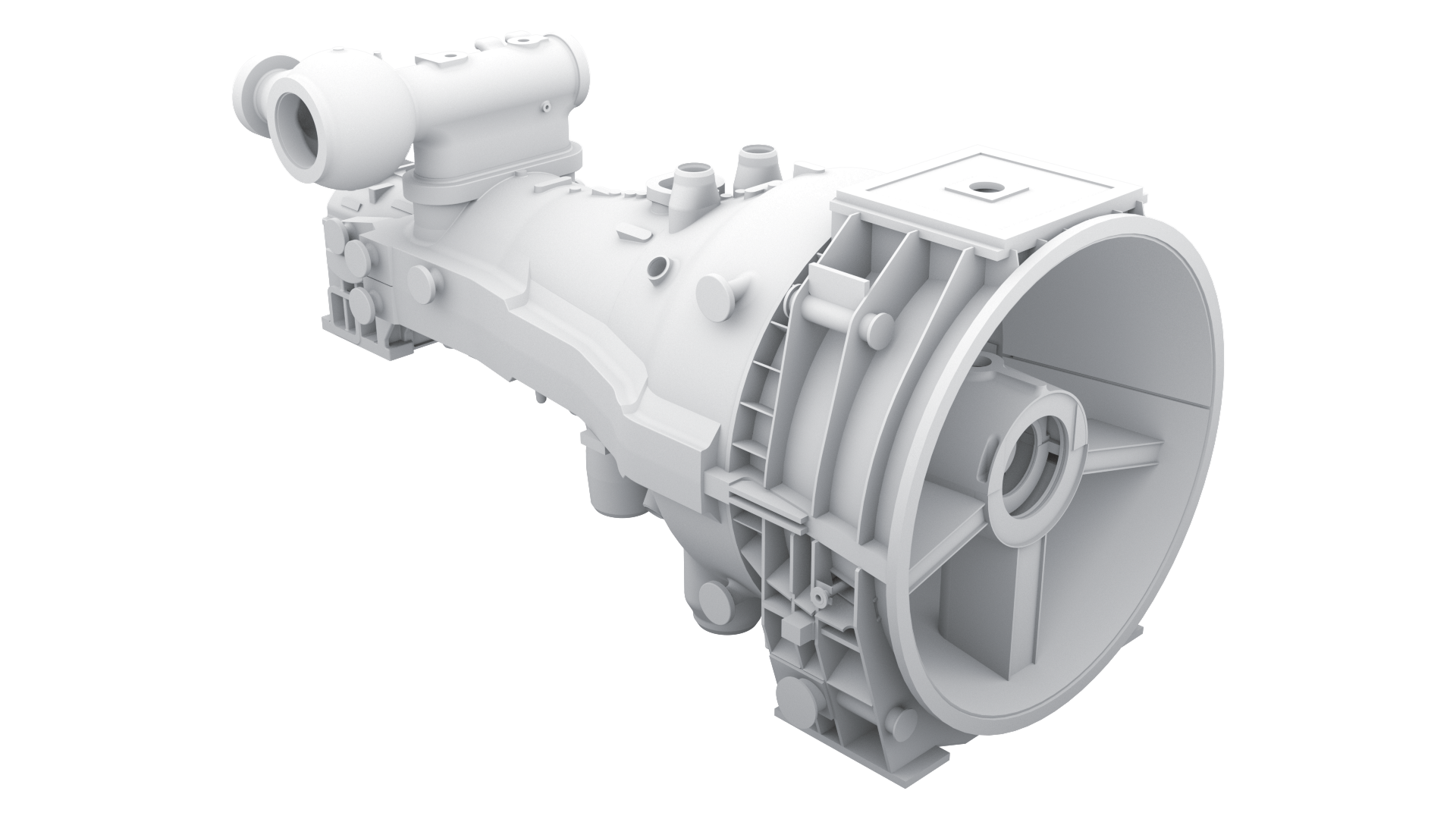

Oxygen compressors

We have over half a century of experience in designing oxygen turbo compressors and have supplied several hundred casings to the market. We exclusively use single-shaft compressors for this purpose, with impellers, diffusers, and labyrinth strips manufactured from non-sparking, ignition-resistant materials. Putting safety first also means eliminating dead spaces where particles could accumulate, and an emergency thrust bearing in each compressor casing.From individual components to complete compressor trains

State-of-the-art and customized air separation solutions

of oxygen with EM- and ST-driven compressors

discharge pressure achieved by proven inline, single-shaft oxygen compressors

Engineered to deliver

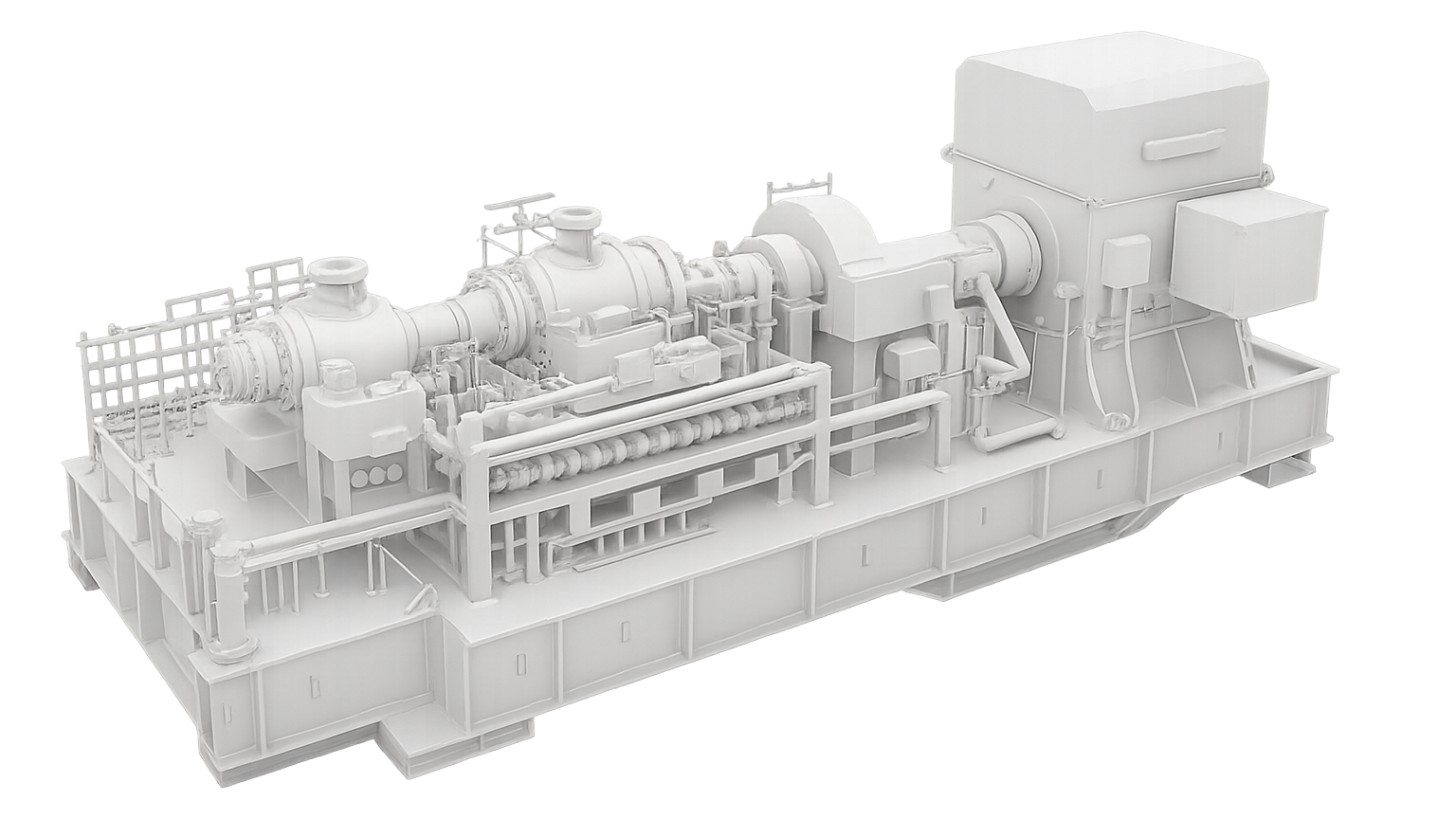

Our air separation technology at work

Everllence is delivering two air separation trains – including the largest motor-driven RIKT – to generate blue hydrogen. Together with nitrogen, blue hydrogen will be used to produce blue ammonia.

| Country | USA |

| Application | Blue ammonia |

| Project status | Ongoing |

| Customer benefits | Significant reduction of emissions through carbon capture for permanent sequestration / improvement of sustainability performance |

| Scope of work | 2x (RIKT 160-3 + RG 63-6 + RG 45-5) |

For the largest methanol plant in China, we supplied the entire train as the well-known and reliable solution from one hand. All rotating equipment and auxiliaries were provided by Everllence.

| Country | China |

| Application | Methanol production |

| Project status | Completed in 2019 |

| Customer benefits | Complete train from a single source for highly energy efficient production of methanol |

| Scope of work | 1x (RIKT 160-3 + MST 100 + RG 56-4) |

For an air separation plant in Saudi Arabia, Everllence is delivering a combi-RG machine (main air compressor & nitrogen compressor) to produce nitrogen, which is used in combination with green hydrogen to produce green ammonia.

| Country | Saudia Arabia |

| Application | Green hydrogen and nitrogen to green ammonia |

| Project status | Ongoing |

| Customer benefits | Cost-effective production of carbon-free hydrogen in the form of green ammonia for transportation and industrial sectors globally. |

| Scope of work | 1x RG 100-7 |

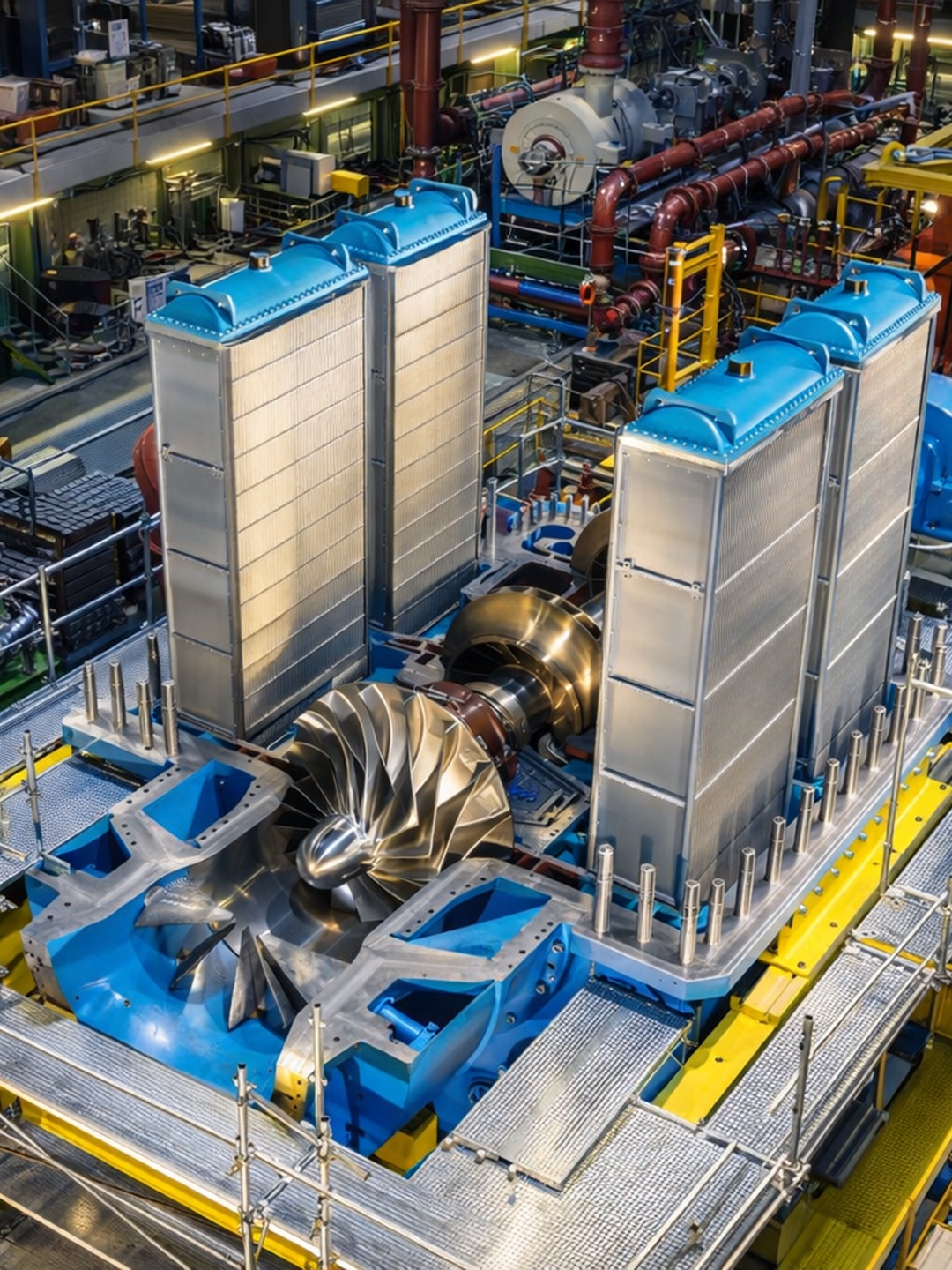

In South Africa, Everllence has supplied the largest axial flow compressor in an industrial application with an effective volume flow of over 1 million cubic meters of air per hour.

| Country | South Africa |

| Application | Coal-to-Liquid |

| Project status | Completed in 2017 |

| Customer benefits | Very economic in CAPEX and OPEX, superior surge robustness, excellent transport features. |

| Scope of work | 1x AR 140-06M |

Contact our Everllence industry support

Looking to optimize your operations?

Our compressors will contribute to the ecological and economic optimization of your industrial gas processes. With its compressor trains, Everllence has set a new benchmark for air separation units. We provide standard and tailor-made solutions for all processes in air separation and industrial gases industry.

Protect your assets and keep your turbomachinery running

With customized service agreements and global 24/7 response, Everllence PrimeServ offers an optimal support solution. Our service engineers conduct regular preventive maintenance to ensure that your trains and machinery operate at peak efficiency, in addition to providing troubleshooting assistance whenever and wherever it is needed.

Delivering precision, reliability, and efficiency

Designed with versatility in mind, Everllence air and gas compressors adapt seamlessly to diverse applications, ensuring optimal performance in everything from power generation to chemical processing.

MAX flow. Carbon capture.

Capturing CO2 from flue gases is an attractive proposition for high-emission industries, reducing carbon taxes and enhancing your contribution to environmental protection. The main challenge is separating the CO2 from the high-volume flows of post-combustion flue gases. The Everllence MAX1 axial compressor is the best solution on the market as it can handle flue gas volumes of up to 1.5 million m3/hour.