Everllence machinery trains and components

Proven technology from a single source

of worldwide PTA machinery trains are supplied by Everllence

in a single turbo train, delivered in four shipments

Everllence machinery trains supplied worldwide

Mastering machinery trains for industrial applications

Industrial operations across basic industries, refineries and petrochemical plants, as well as the industrial gases sector, rely on highly engineered machinery trains to ensure efficient and reliable production. These integrated systems combine compressors, electric motors, steam or gas turbine drives, and expanders into precisely coordinated assemblies tailored to specific process requirements. Designing such machinery trains requires in-depth understanding of system interactions and operating conditions. By carefully matching all components, optimized performance, high availability, and efficient energy utilization can be achieved.

Mastering machinery trains through modular expertise

Building on decades of turbomachinery expertise, Everllence has translated this complexity into a portfolio of modular construction kits. Each kit is designed around proven technologies and standardized building blocks, while remaining flexible enough to accommodate application-specific demands. This modular approach enables turnkey delivery, compact layouts, and reliable performance – whether for offshore installations, large-scale industrial plants, or emerging energy applications. The result: machinery trains that are faster to deploy, easier to integrate, and engineered to perform over their entire lifecycle.

Everllence at its best

Our modular construction kits

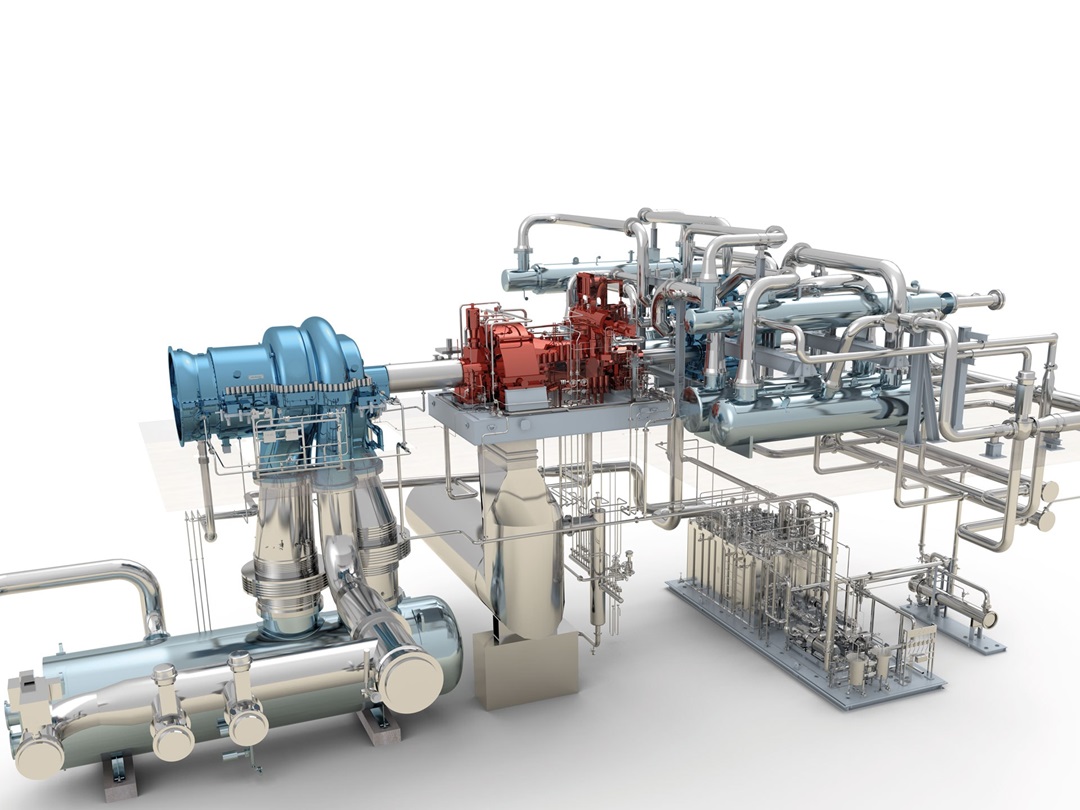

NAMAX machinery train for nitric acid production

NAMAX is Everllence’s modular machinery train for nitric acid production, designed for plant capacities from 400 to over 3,000 mtpd. Developed for modern dual-pressure processes, the NAMAX concept increases power density and enables higher rotational speeds – directly improving overall process efficiency. By integrating the AR-MAX1 air compressor into the train, all core components operate at a common speed, eliminating the need for an intermediate gearbox. Combined with robust fixed-casing compressor designs, a reduced footprint, and flexible base frame configurations, NAMAX delivers low CAPEX and OPEX as well as simplified transport, installation, and commissioning. With hundreds of references worldwide, NAMAX is a proven, future-ready solution for nitric acid plants.

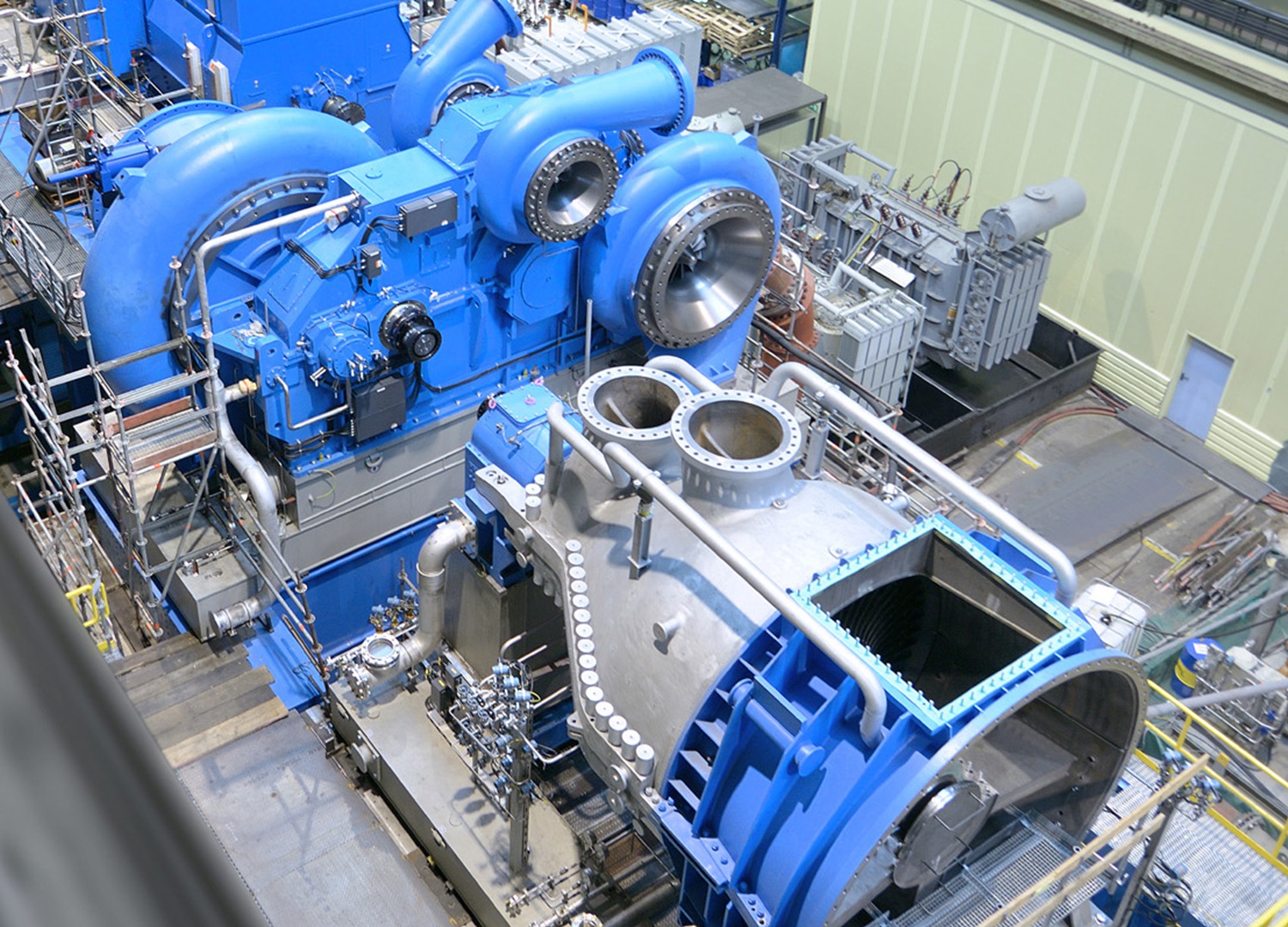

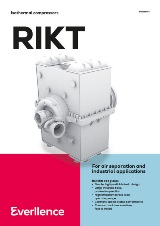

RIKT for air separation solutions in action

To reduce downtime and on-site workload, Everllence implemented a single-lift installation concept for an air separation application using a RIKT train. The electrically driven solution featured an RG-type centrifugal compressor and was fully pre-assembled and tested before delivery. This approach significantly minimized installation time and on-site activities, enabling faster commissioning while reducing manpower requirements and project risk for the customer.

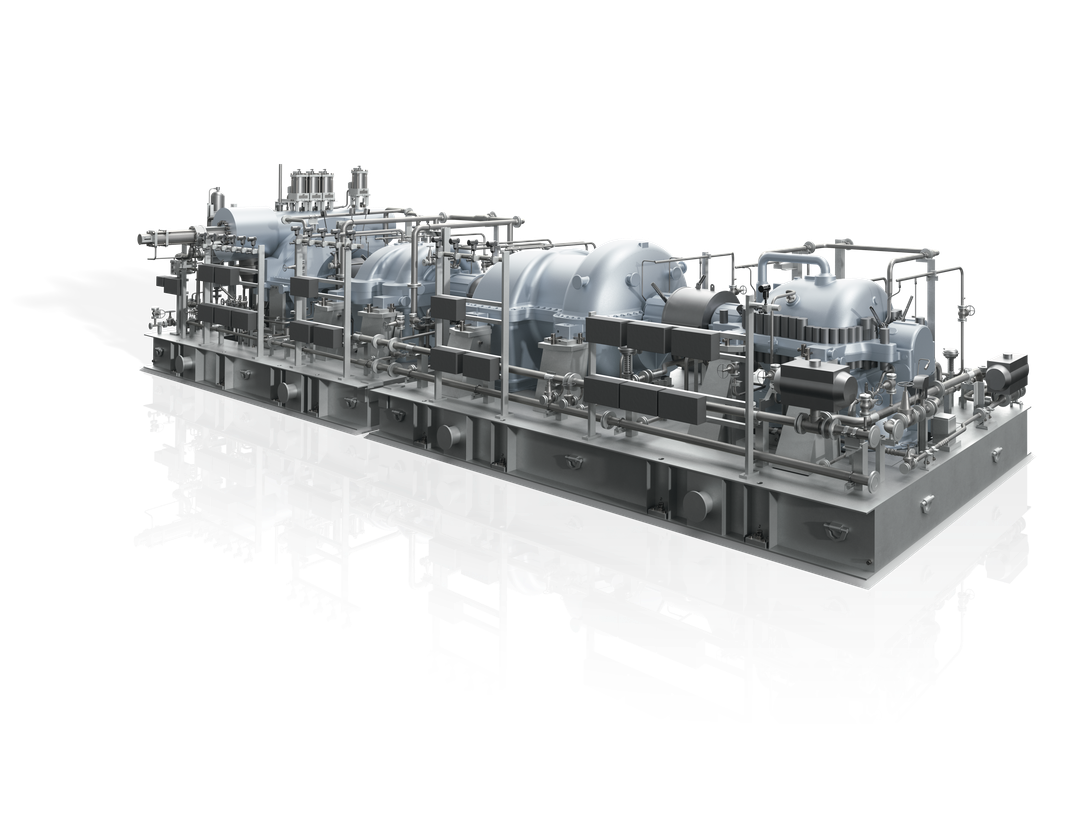

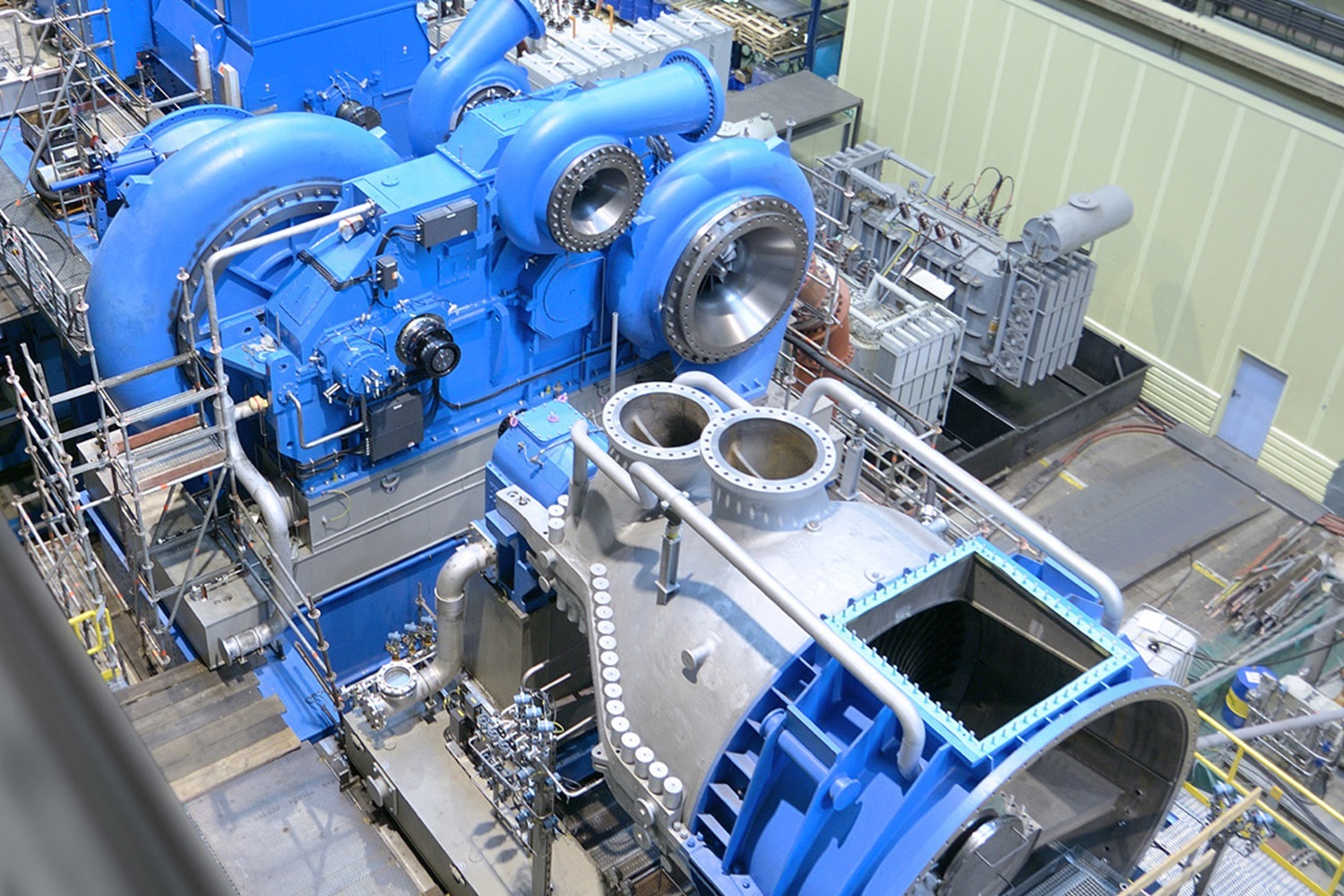

AIRMAX train for high-capacity air compression

The AIRMAX train is built around AR-MAX1, Everllence’s standardized axial/radial main air compressor, delivering volume flows of up to 1.5 million cubic meters per hour and pressures up to 25 bar. Designed for robustness and high operational reliability, AIRMAX trains offer an attractive balance of performance, CAPEX efficiency, and transportability. Thanks to the high speed and power density of the main air compressor and steam turbine, AIRMAX solutions are particularly competitive for large air separation applications.

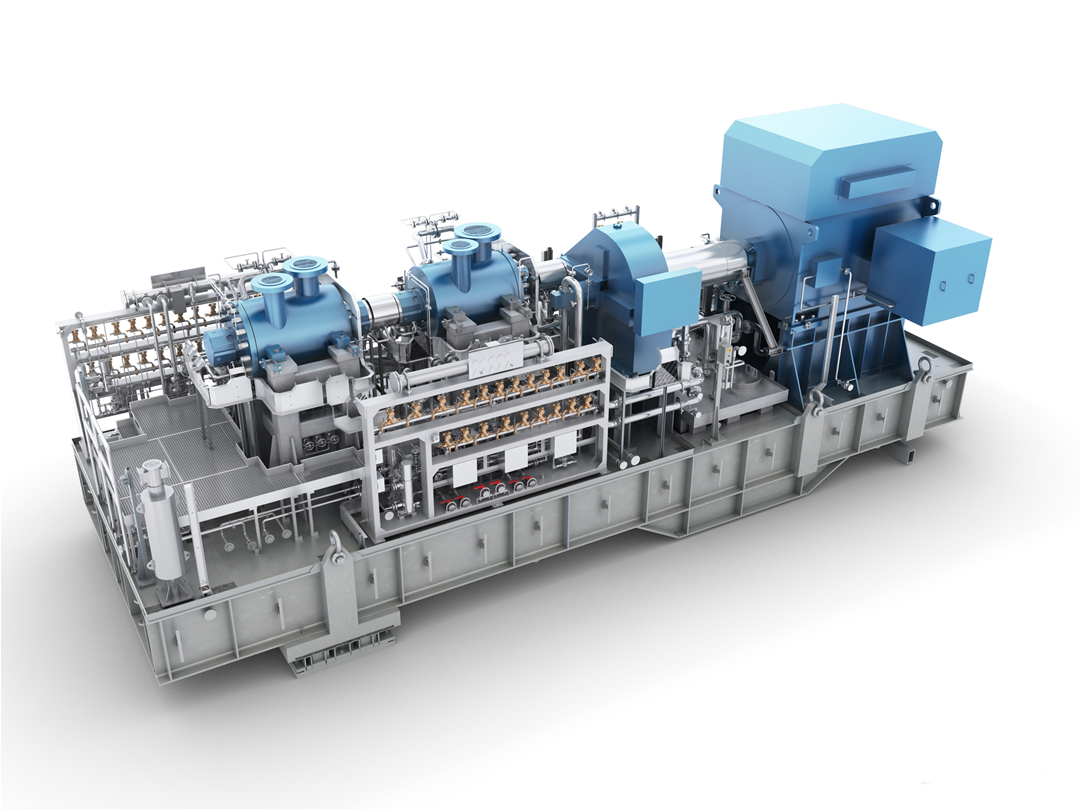

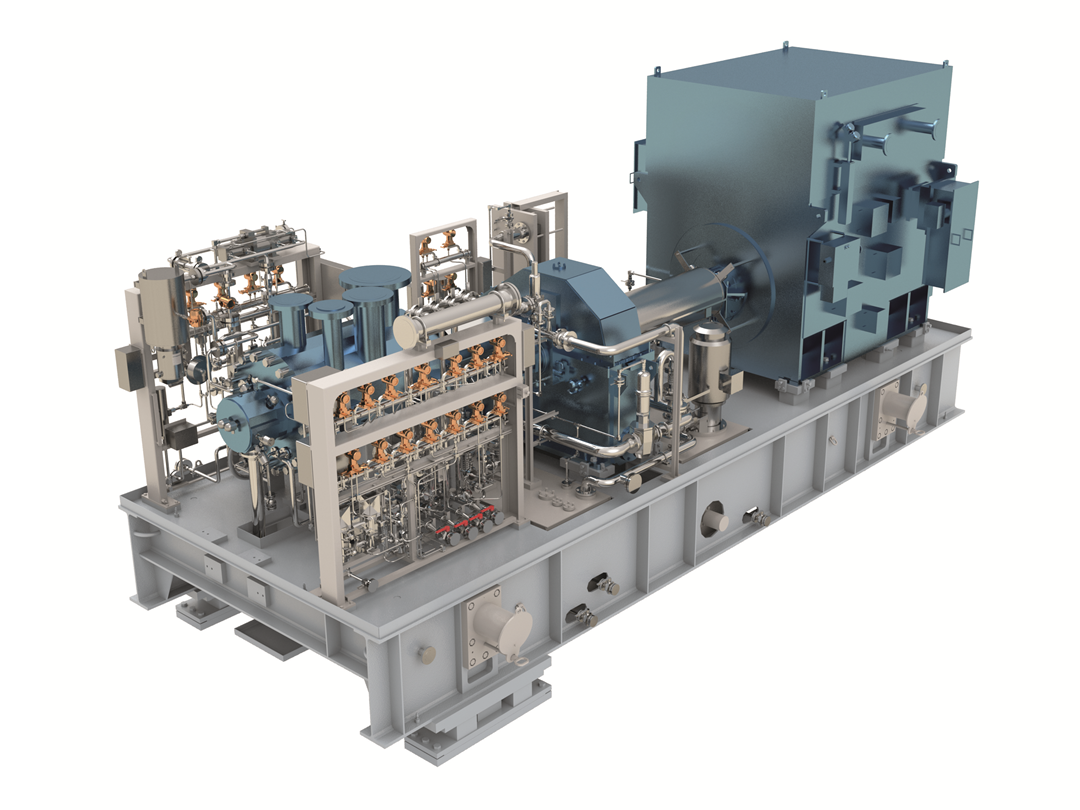

RB compressor packages

For a wide range of applications, Everllence offers RB-type centrifugal compressors in pre-engineered package solutions. These packages significantly reduce on-site installation effort and project risk for this single-shaft compressor design. Each package includes the RB compressor as the core unit, driver, gearbox (if required), lube oil system, seal gas system, on-skid process piping, and auxiliaries. While many customers benefit from our standardized, time- and cost-efficient packages, Everllence also designs fully customized solutions based on proven RB technology whenever unique process requirements demand it.

AIRTRAIN for proven air separation performance

AIRTRAIN solutions are a proven choice for air separation units (ASU) across industries ranging from iron and steel to food and medical gases. With more than 80 AIRTRAINs and hundreds of motor-driven compressors supplied worldwide, Everllence brings decades of experience to air separation applications. AIRTRAIN configurations include steam-turbine-driven main air compressors (MAC) with booster air compressors (BAC) or fully motor-driven MAC and BAC arrangements. Designed to meet oxygen demands for units between 500 tpd and 4,200 tpd, these solutions can be tailored precisely to customer-specific requirements.

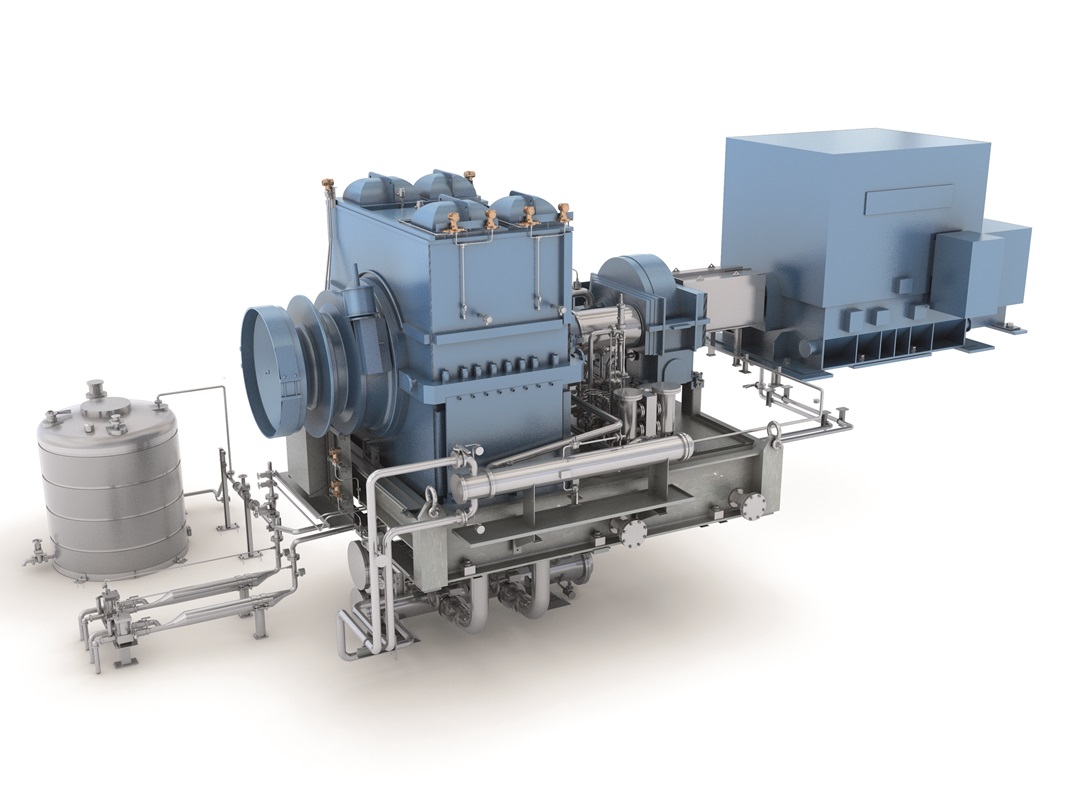

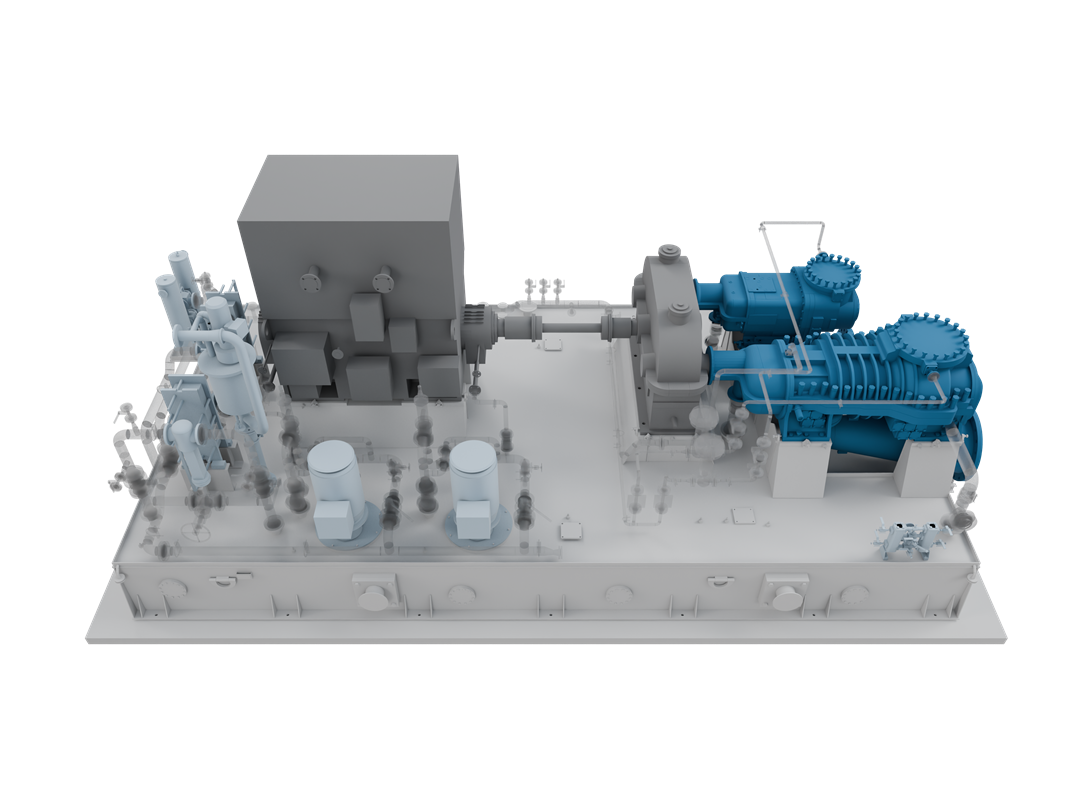

Hydrogen compression train

Our hydrogen compression train is designed to meet the demanding requirements of modern hydrogen production, particularly in large-scale electrolyzer plants. Based on proven screw compressor technology, these modular, single-lift packages combine high hydrogen volume flows with exceptional reliability and a remarkably small footprint. Their oil-free design ensures maximum hydrogen purity, while low maintenance requirements and high availability enable long-term, uninterrupted operation. Optimized for continuous duty and flexible operation, our hydrogen compressor trains provide a reliable link between green hydrogen production and downstream infrastructure such as pipelines, chemical plants, or storage systems.

Upstream package (UPac®)

The UPac® modular machinery trains are primarily designed for floating production, storage and offloading units (FPSOs), where compact design and fast availability are critical. To enable delivery times of less than 12 months, Everllence has defined standardized base frame sizes that integrate motor, gear unit, centrifugal barrel-type compressors, and all required auxiliaries. Covering typical power ranges from 1 MW to 16 MW, UPac® trains provide a highly efficient and space-saving solution. Originally developed for offshore use, these robust and flexible packages are increasingly deployed in onshore applications as well.

Key solutions for real-world applications

Our turbomachinery trains at work

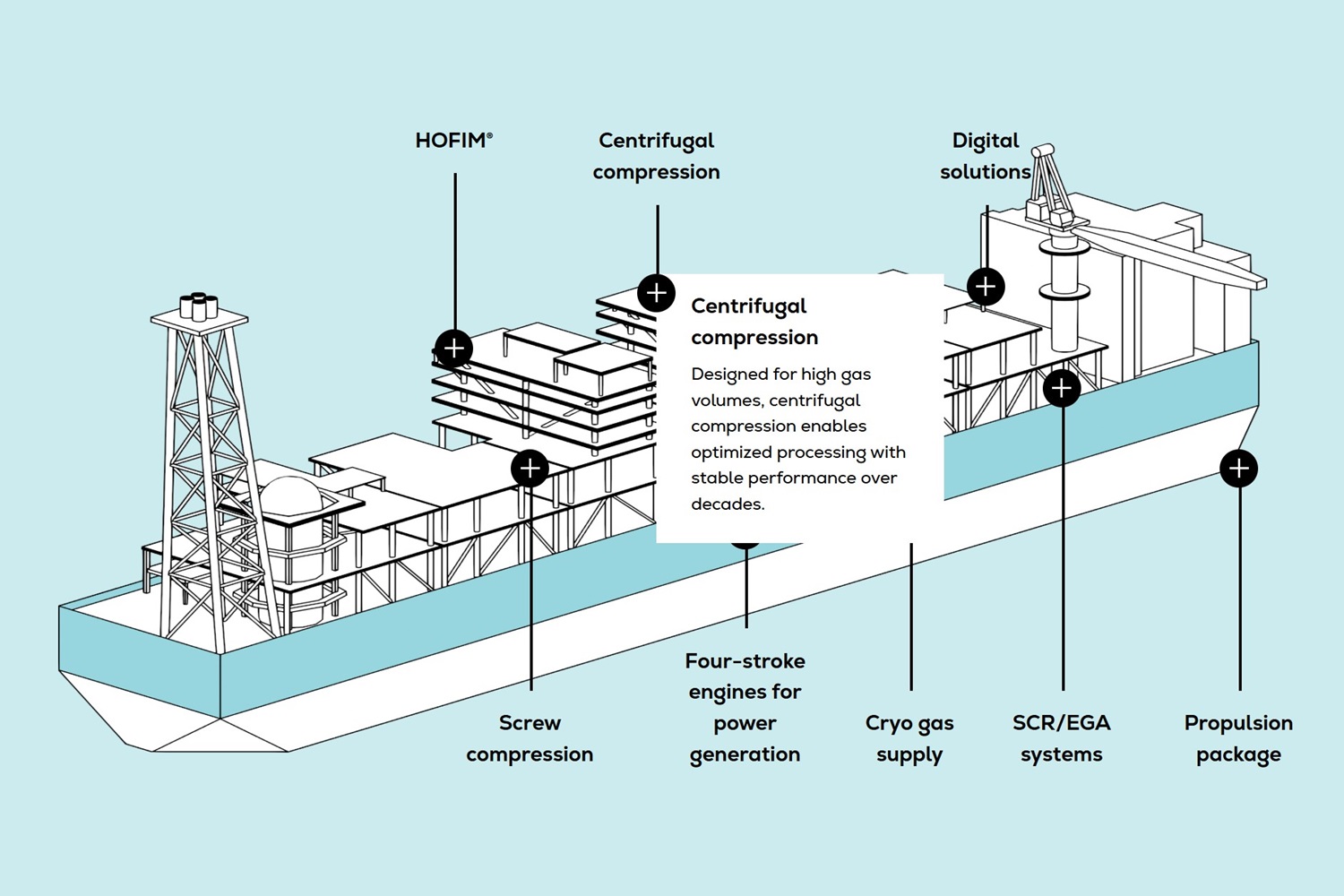

Everllence will supply high-performance compressor technology for a new floating production, storage and offloading (FPSO) unit offshore Brazil. The compression systems are designed for continuous operation under harsh offshore conditions and support efficient gas handling and processing on board. Leveraging extensive offshore and FPSO experience, Everllence delivers reliable, space-optimized solutions tailored to demanding lifecycle and availability requirements.

Customer case

FPSO compressor systems, Brazil.

Everllence will provide multiple centrifugal compressor packages for gas compression duties on a newly built FPSO unit. The scope includes engineering, manufacturing, and delivery of compressor technology designed for compact installation, high efficiency, and reliable long-term offshore operation. The equipment will play a key role in ensuring safe and efficient production throughout the FPSO’s service life.

Everllence compressors and steam turbines are used in fertilizer plants around the world to generate ammonia, urea, or nitric acid. We provide our customers with full turbomachinery train solutions or single components designed to meet the unique compression needs of fertilizer plants. Built to the same exacting standards, they guarantee efficient and reliable operation with maximum up time.

Customer case

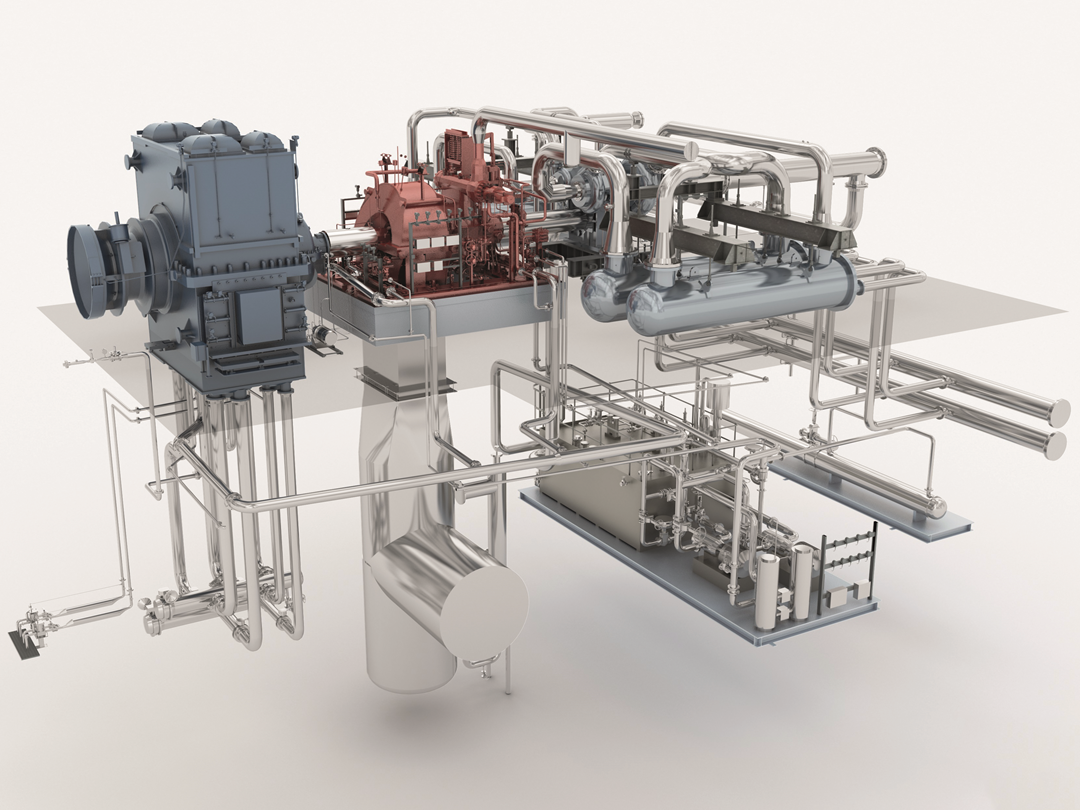

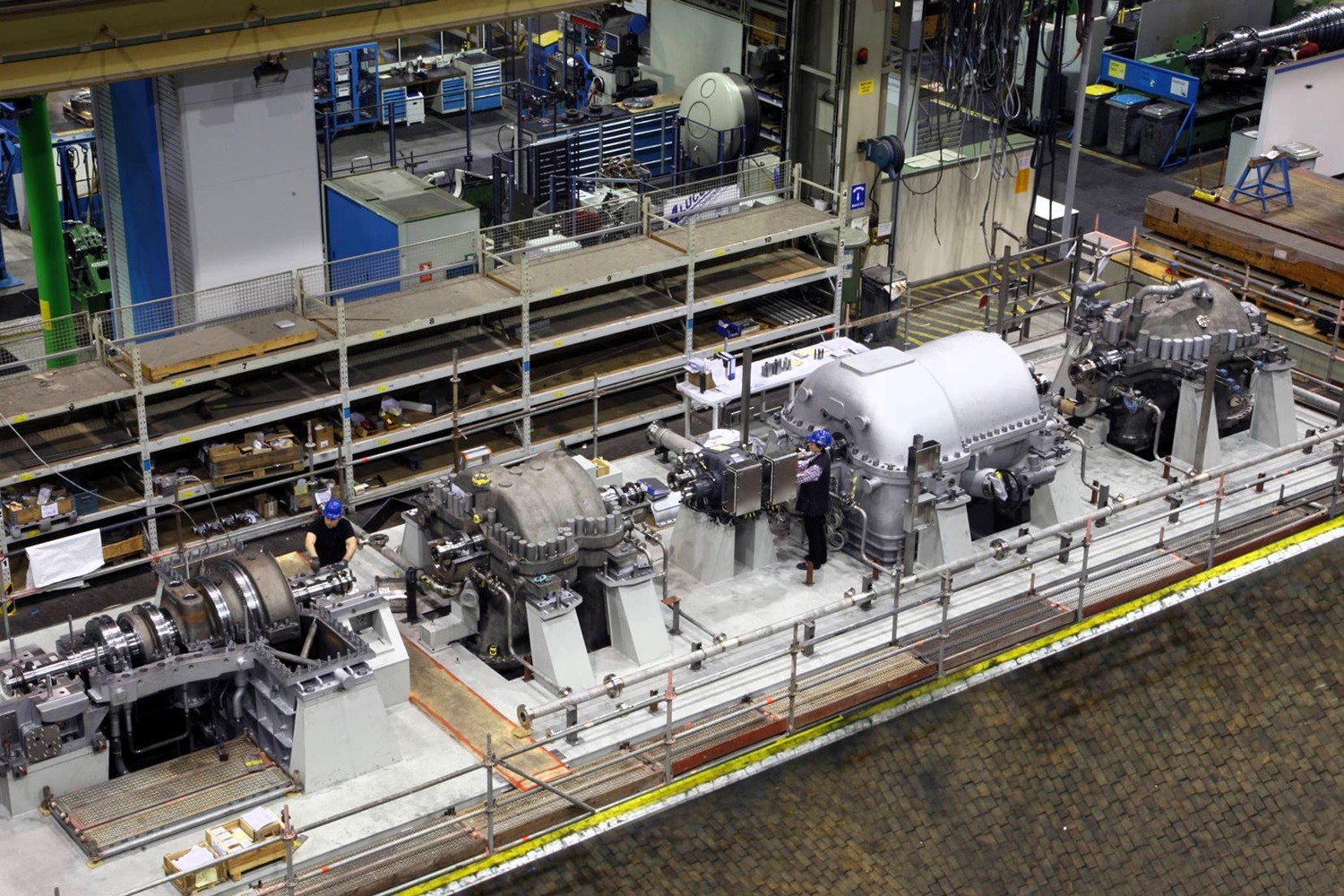

Nitric acid compressor train, Spain and Australia.

This complete five-casing nitric acid train was designed to sit on a steel base frame for an extra-short on-site assembly time. It comprises an air and NOx compressor as well as a process gas expander and steam turbine. A generator, coupled to the train, ensures optimized energy recovery.

PTA is principally used as the precursor to the production of polyethylene terephthalate (PET) for plastic bottles as well as synthetic fibers. Everllence is a major supplier of compressor trains for PTA plants worldwide. The large 30 MW – 60 MW trains are the result of more than 30 years of development and experience. Based on our extensive experience with large turbomachinery trains, Everllence serves the market for plants operating at up to 1.5 million tons/year.

Customer case

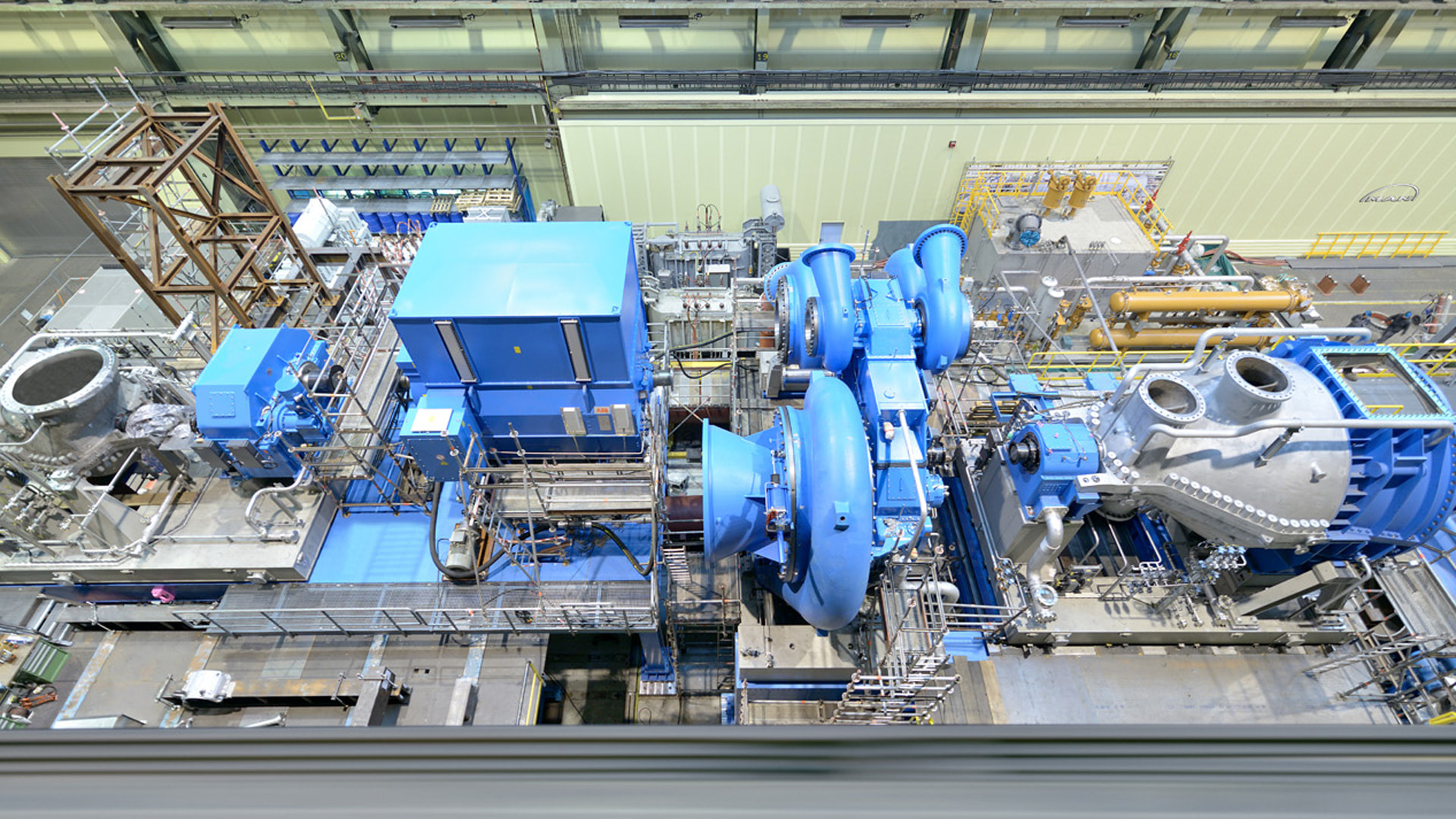

PTA compressor trains, China.

All train components were precisely matched to enable optimized energy recovery. The solution comprised four identical PTA compressor trains, each integrating a steam turbine, air compressor, motor/generator, and process gas expander. An integrated compound gear design eliminated the need for an additional gearbox, resulting in a compact and efficient layout. Close collaboration between Everllence and the petrochemical customer enabled record-time project execution, with Everllence acting as a single-source supplier for all major casings.

With our high-efficiency air compressors, we have ushered in the industrial gas production of the future. Extremely surge-resilient and capable of volumes of 7000 t/d of oxygen or more, machinery trains such as AIRMAX and the AIR TRAIN for the industrial gas industry are generating large efficiency savings for our clients. All components of your turbomachinery train are made to measure and designed to fit your business perfectly.

Contact our Everllence support team

Let’s build your business together

Having the right turbomachinery train at the heart of your operations can make all the difference. Find out more about how our bespoke turbo trains can help you cut costs, improve environmental standards, and increase competitiveness. Contact us today and together, we can take production to the next level.

Downloads

Industrial process machinery

Protect your assets and keep your turbomachinery running

With customized service agreements and global 24/7 response, Everllence PrimeServ offers an optimal support solution. Our service engineers conduct regular preventive maintenance to ensure that your trains and machinery operate at peak efficiency, in addition to providing troubleshooting assistance whenever and wherever it is needed.

Transforming basic materials for a cleaner future