Hydrogen: powering tomorrow’s industry

Scaling up for a net-zero future

and growing: Industrial demand for H2 by 2050

energy content of hydrogen per kilogram – nearly three times more than gasoline

of H2 is produced by a 1 MW PEM electrolyzer per day

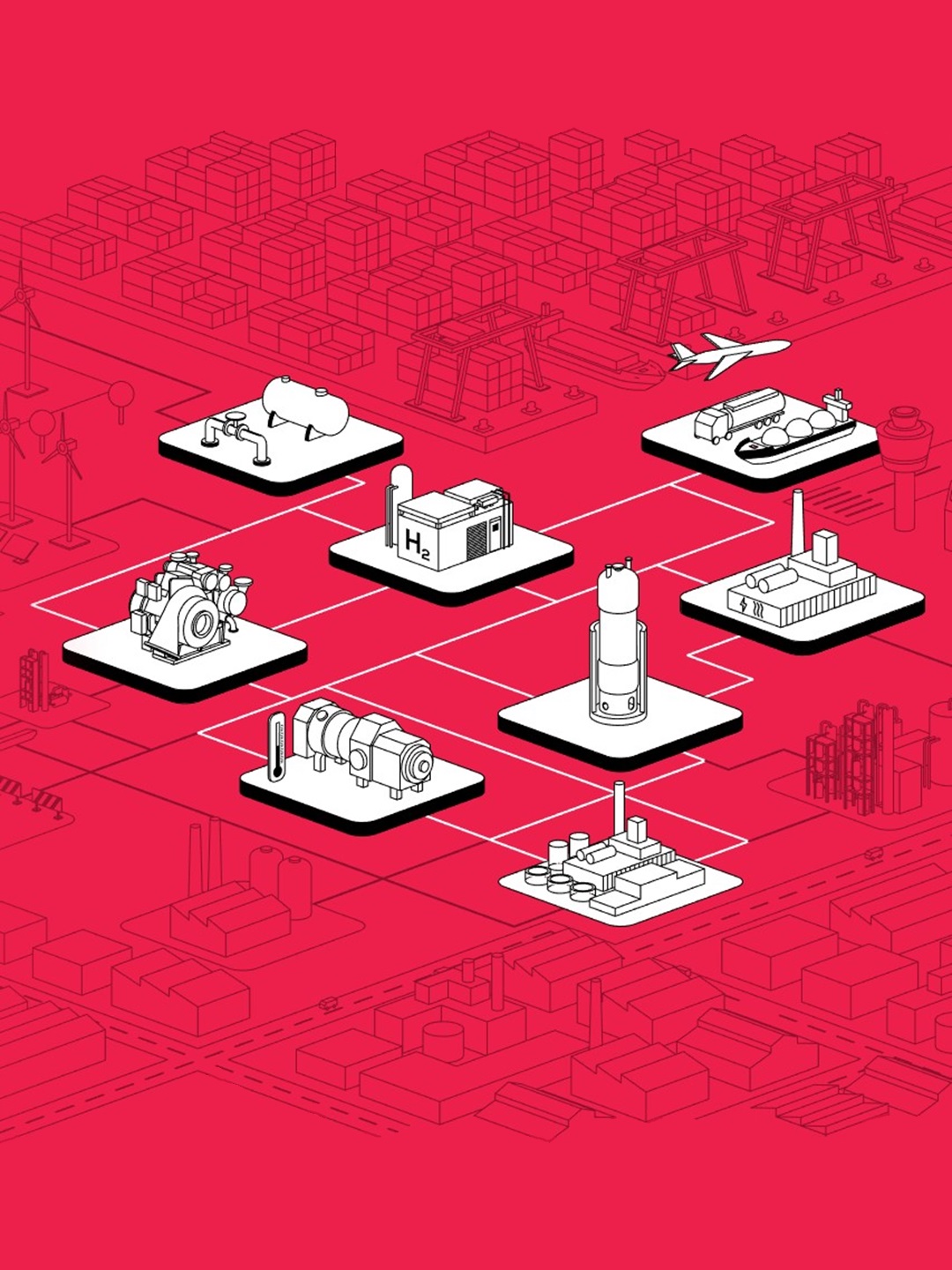

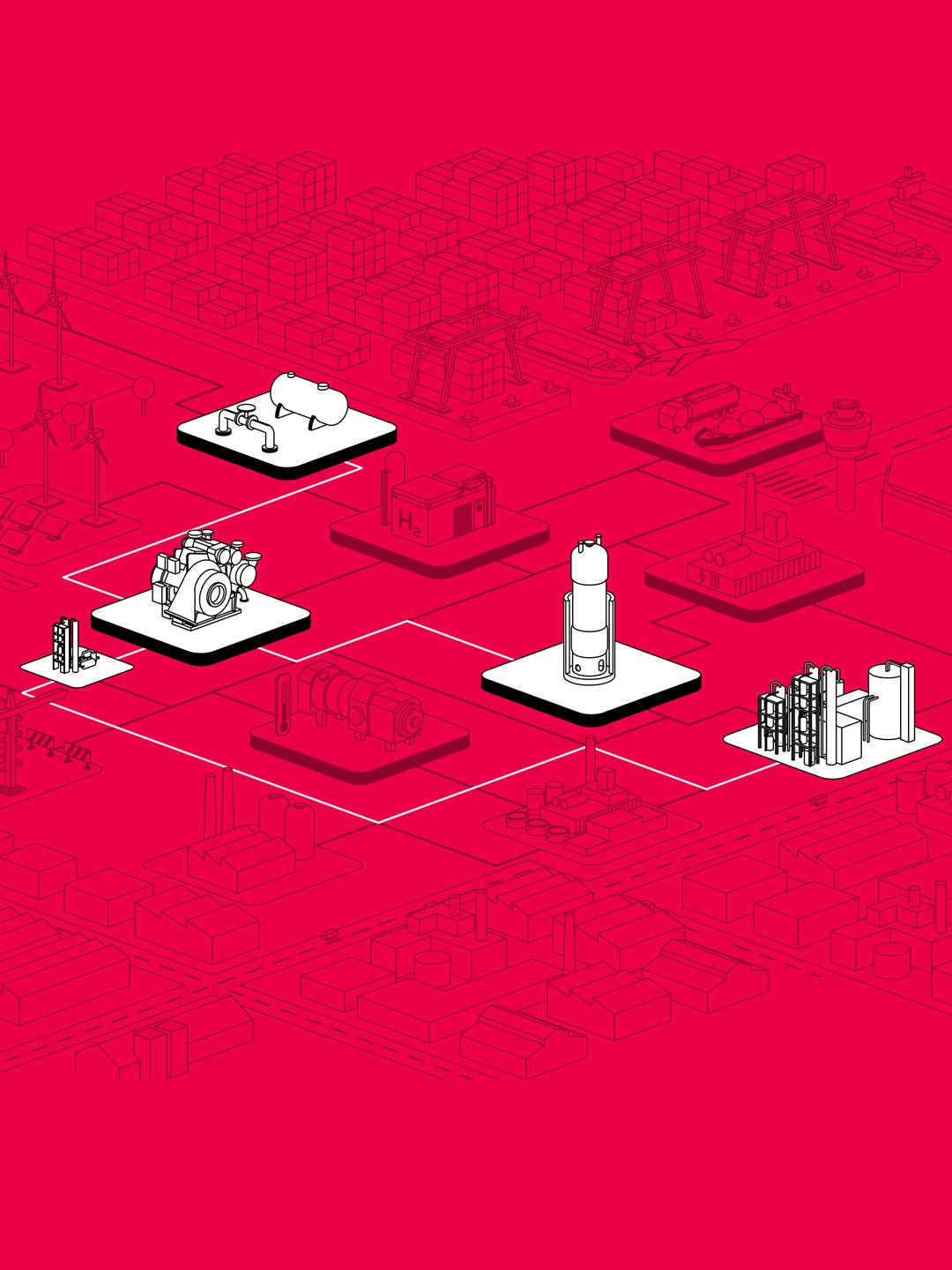

Hydrogen applications

From production and processes to transport and storage

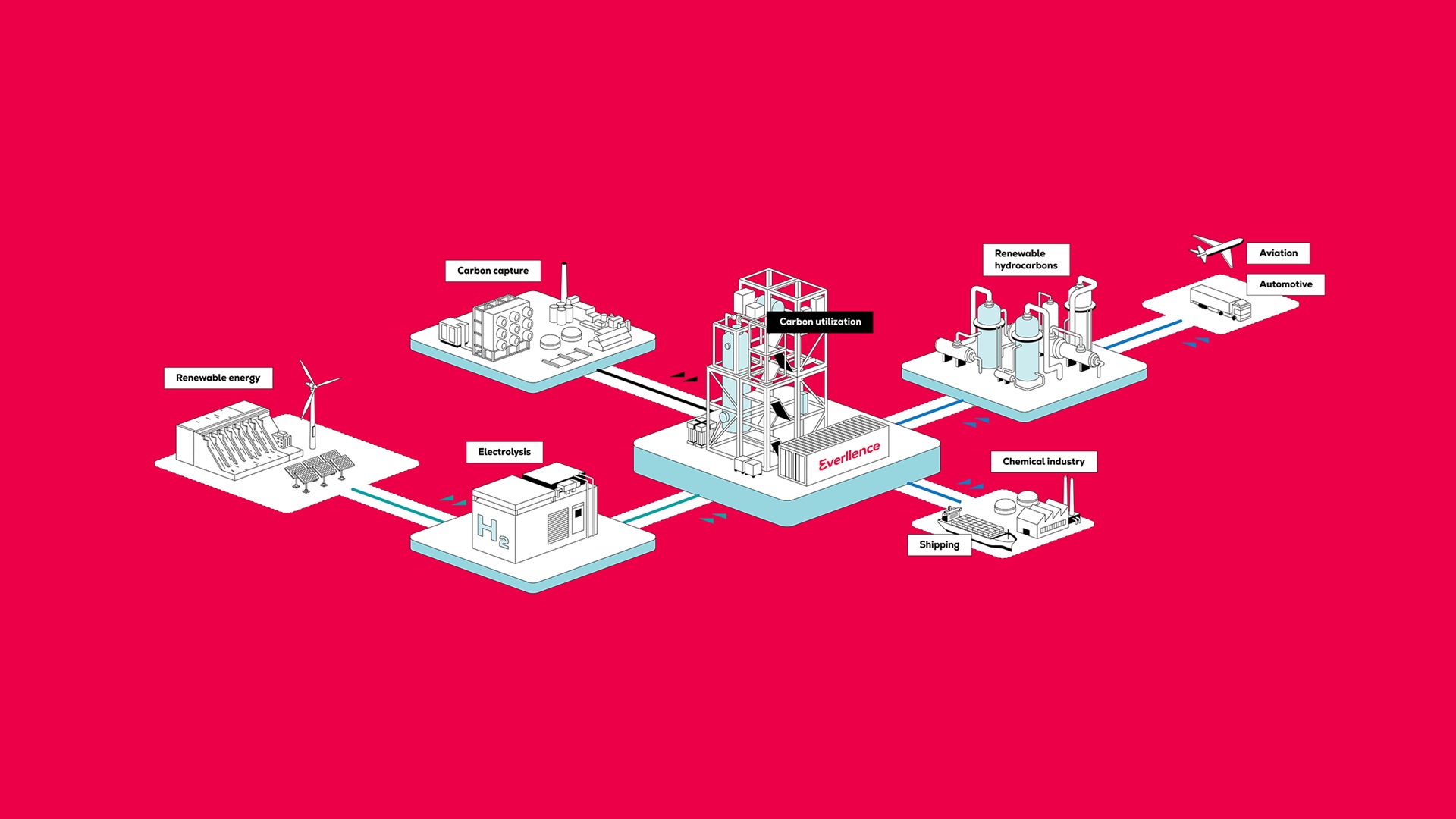

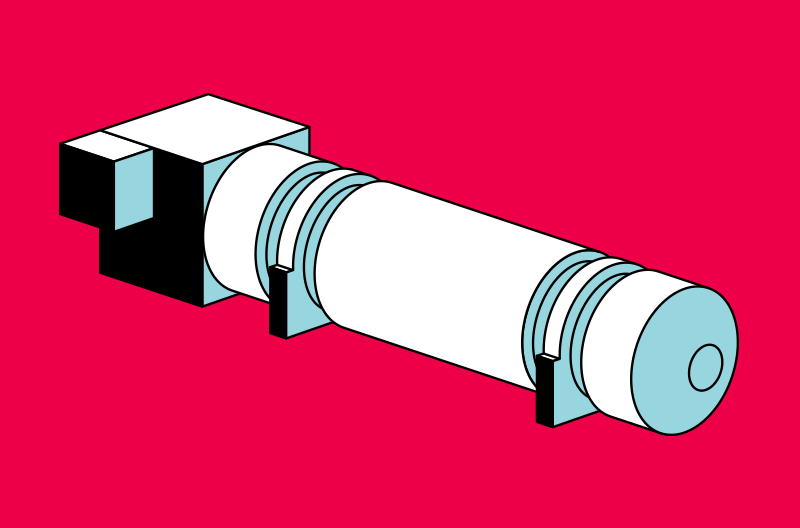

For green hydrogen to be used as feedstock in various applications and industries, it must be boosted to higher pressures after production. Only then can hydrogen be transported via pipelines and stored in salt caverns to be available in sufficient quantities 24/7. Everllence offers various compressor types to meet the requirements of your specific hydrogen transportation application, such as actual volume flow and required compression ratio.

In the future, green hydrogen will be used in the mobility and transportation sector for liquefaction or to replace natural gas in steel production. It can also be a feedstock for green ammonia plants. Green ammonia is used as a hydrogen carrier, fuel for ocean vessels, fertilizer industry feedstock, and gas turbine fuel for power generation and district heating.

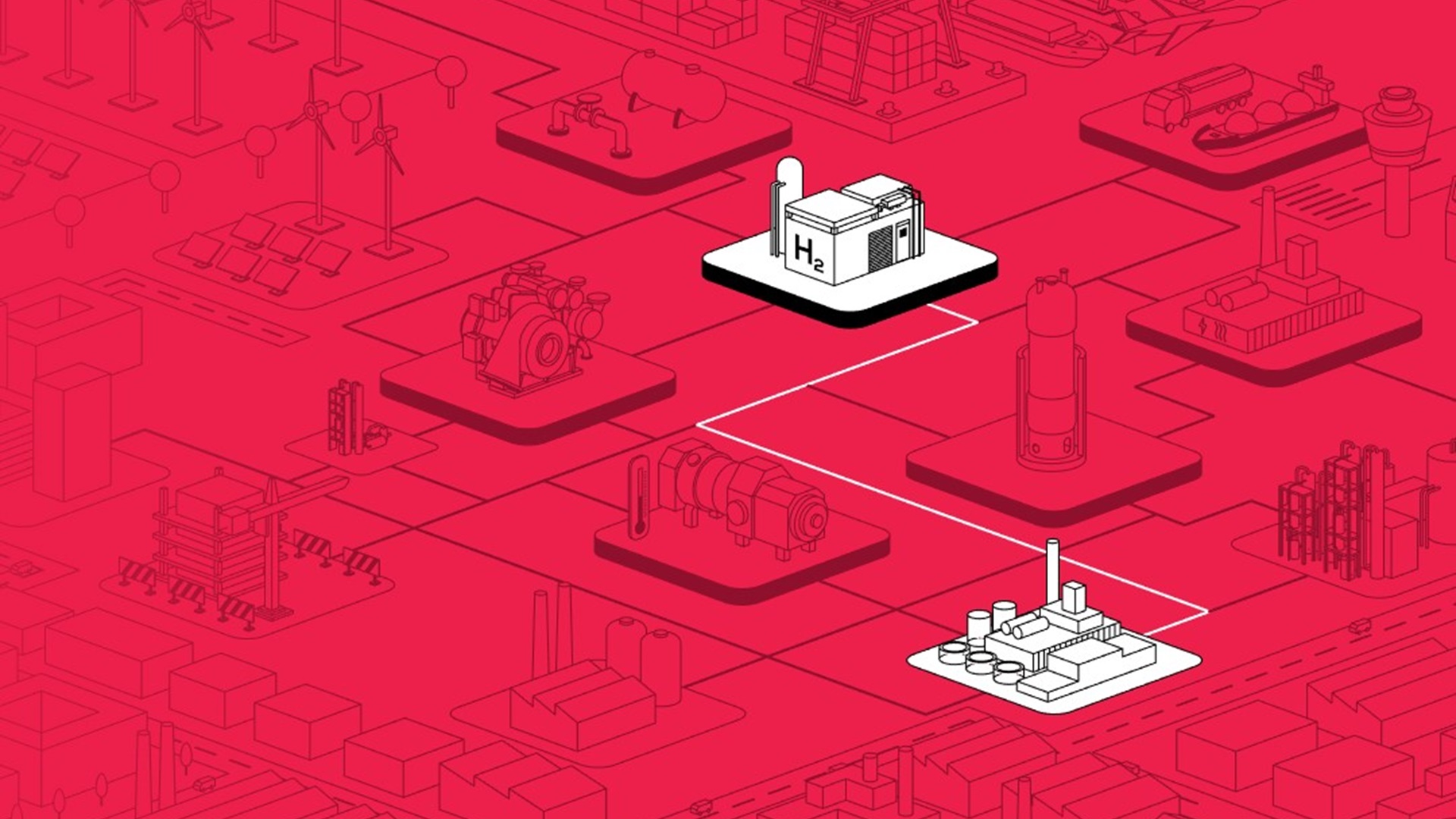

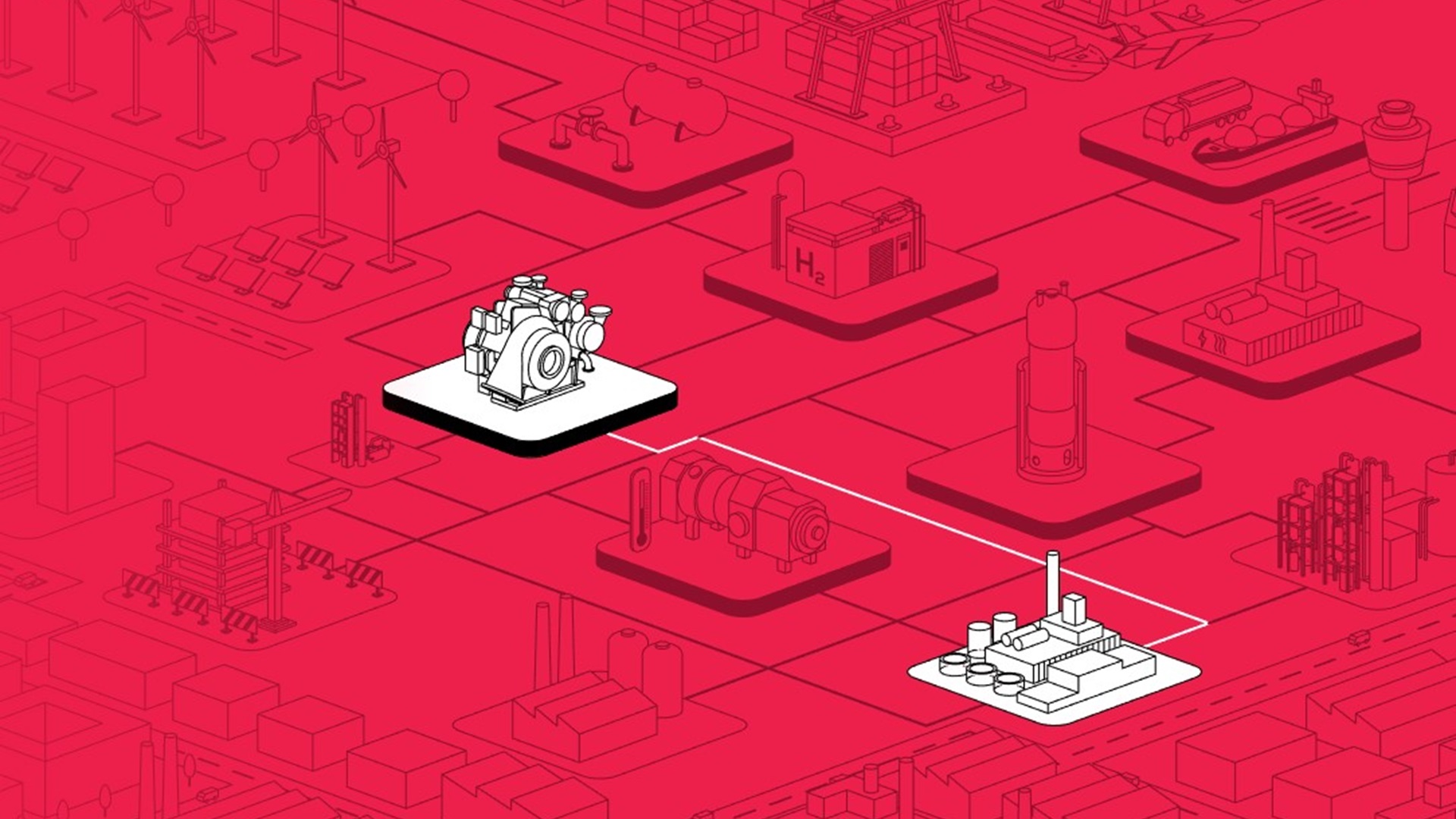

Compressor solutions

Modular designs that fit your process

Together with CO2 from carbon capture, utilization, and storage (CCUS), hydrogen could produce syngas as a feedstock for methanol plants. Methanol is used to produce synthetic fuels (synthetic kerosene, diesel, and gasoline) or synplastic in the chemical industry. CO2 and hydrogen are also key materials in the Fischer-Tropsch process for producing carbon-neutral liquid hydrocarbon fuels.

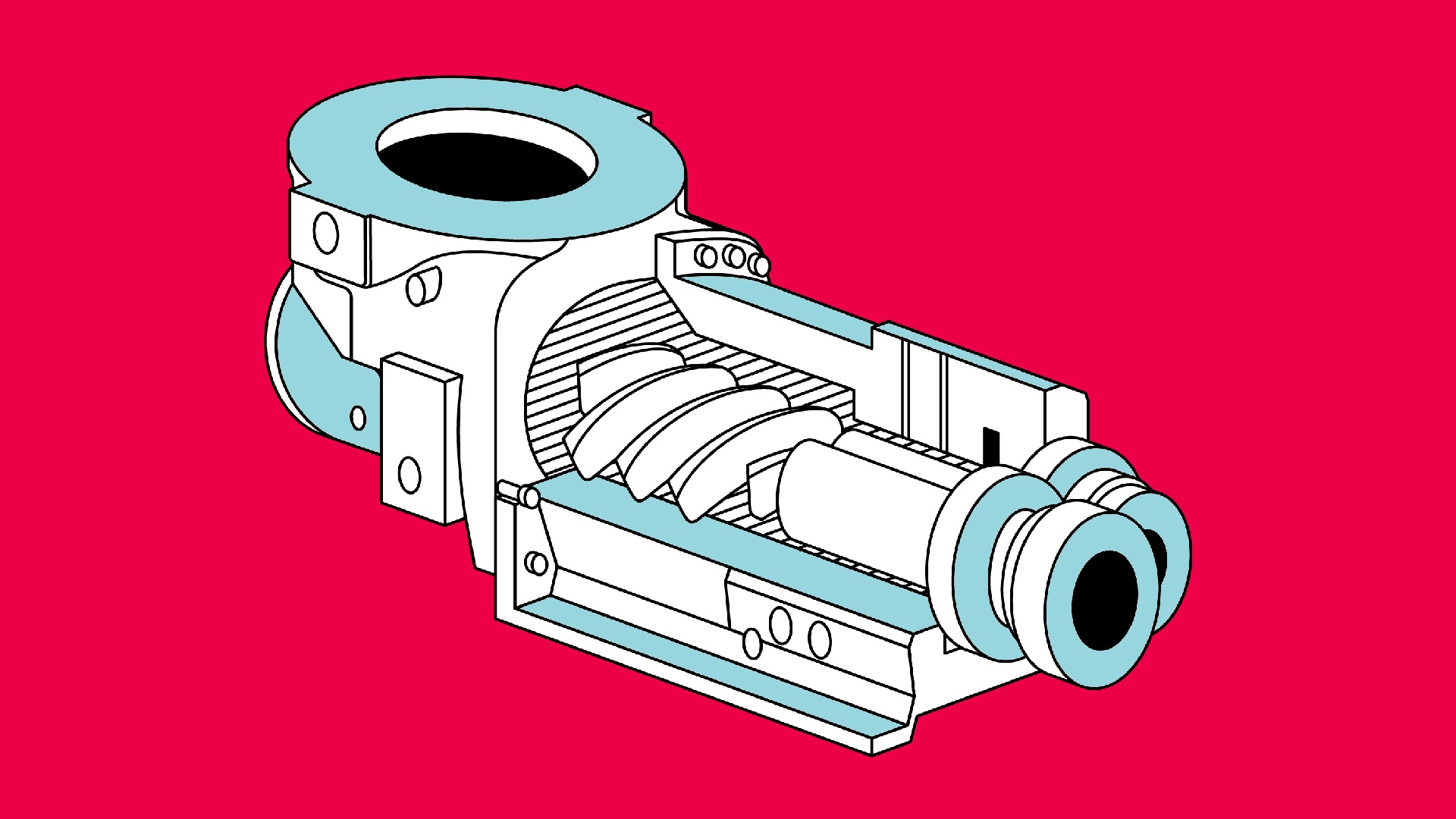

We tailor each compressor solution to your specific process and compression requirements. A modular design approach assures communality in components and adds overall reliability. Our expertise includes building industrial systems for large industrial plants that produce hydrogen, ammonia, and methanol and for carbon capture.

Scaling up for a decarbonized world

Hydrogen demand projections 2030-2070

Global hydrogen demand is projected to rise sharply between 2030 and 2070, driven by decarbonization targets and the shift to cleaner energy sources. As industries transition away from fossil fuels, hydrogen will play a central role in powering synthetic fuel production, enabling green steel, and supporting large-scale energy storage. Everllence delivers the compressor solutions that make this transformation possible – scalable, reliable, and ready for the future.Powering the hydrogen value chain

Production, compression, and synthetic fuels at industrial scale

Our products working in the hydrogen field

Innovative products for hydrogen applications

Contact our experts on compressor technology

Find the optimal solution for your hydrogen transport and storage applications.

Our experts will evaluate your project’s specific requirements including – pressure ratio, hydrogen molecular weight (dry, wet, or hydrogen-rich gas), and volume flow – to recommend the best-fit solution.

Everllence compressors deliver high reliability with minimal maintenance, low wear, and low vibration across your entire system. Their low weight and compact design help reduce CAPEX and simplify plant integration.

Protect your assets and keep your turbomachinery running

With customized service agreements and global 24/7 response, Everllence PrimeServ offers an optimal support solution. Our service engineers conduct regular preventive maintenance to ensure that your trains and machinery operate at peak efficiency, in addition to providing troubleshooting assistance whenever and wherever it is needed.

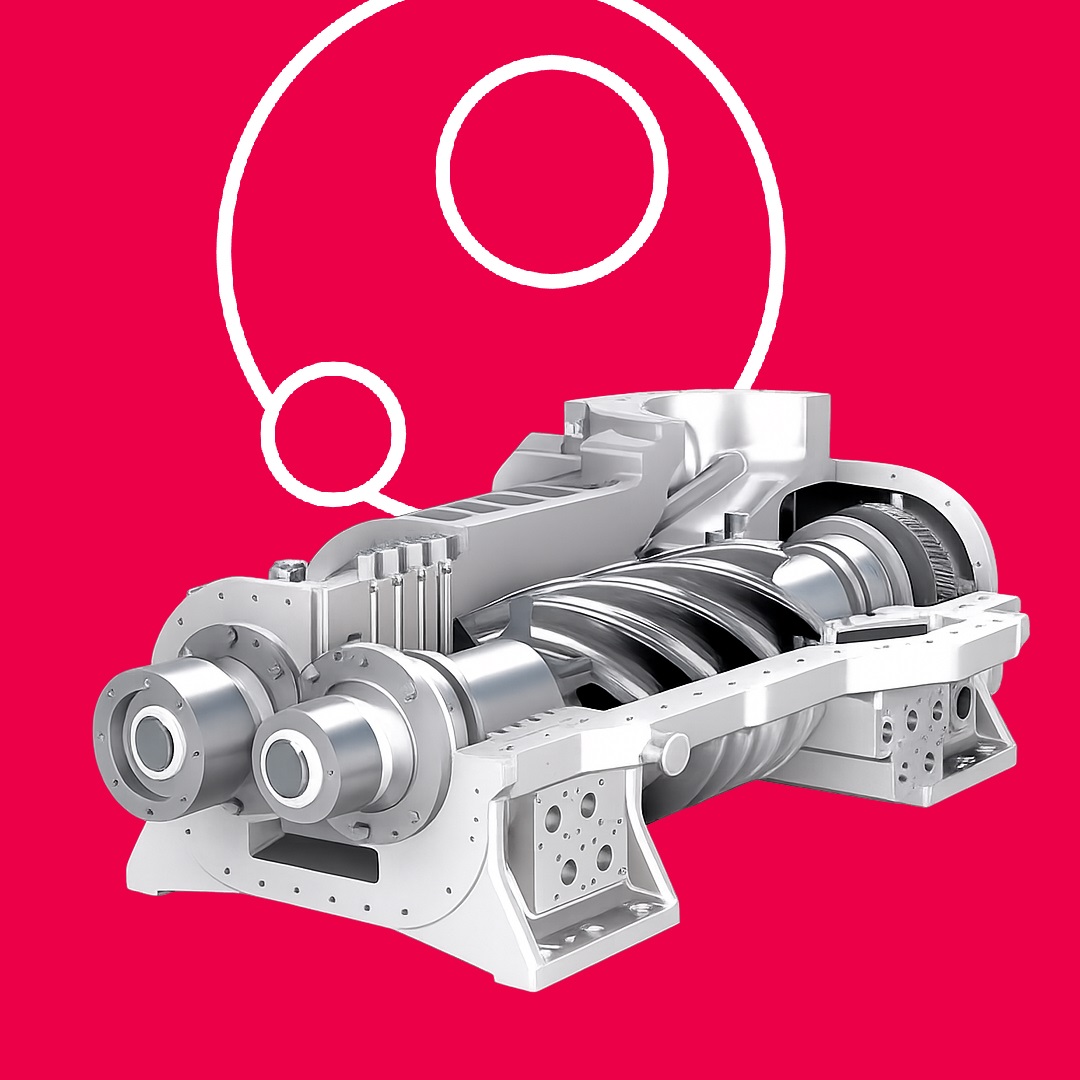

Screw compressors engineered for hydrogen

Hydrogen demands robust, efficient compression – Everllence’s screw compressors deliver. Designed for continuous operation and high gas purity, these compressors ensure safe, reliable hydrogen handling across production, storage, and transport. With oil-free technology and proven durability, Everllence makes hydrogen compression efficient, scalable, and ready for tomorrow’s energy needs.

CO₂ reduction through smart compression and heat recovery

Capturing CO₂ is only half the battle – doing it efficiently is key. Everllence combines carbon capture with waste heat recovery to cut emissions while maximizing energy utilization. Our integrated solutions make decarbonization more viable than ever.

Driving hydrogen innovation for a decarbonized tomorrow

Hydrogen is a key pillar of the energy transition. Everllence is pioneering advanced technologies across the entire hydrogen value chain – from production to compression and transport – supporting a cleaner, more sustainable energy future.