Innovation built on industrial scale and proven performance

of global steel production relies on Everllence blowers

of global PTA production uses Everllence compressor trains

nitric acid output achieved

Key solutions for chemical industry

New power for the chemical industry

Powering efficient and sustainable chemical production. Everllence delivers proven technologies that improve energy efficiency, reliability, and profitability across a wide range of chemical processes.

- Compression: Oil-free screw, centrifugal, and heavy-duty axial compressors for reliable operation in demanding chemical applications.

- Expanders: Energy recovery solutions that convert process gases into valuable power.

- Steam turbines: Multi-stage mechanical drive turbines tailored to specific process requirements.

- DWE reactors: Advanced reactor technologies for the production of key chemical intermediates.

Key solutions for iron and steel industry

Highest efficiency for iron and steel production

The iron and steel industry is one of the most energy-intensive sectors. Everllence’s compressors and expanders are engineered to improve energy efficiency and reduce CO₂ emissions in steel production.

- MAX1 axial compressors: High-performance blowers designed for blast furnaces, delivering substantial airflows while minimizing energy consumption and emissions.

- Process gas screw compressors: Reliable compressors capable of handling gases containing dust or particles, ensuring high availability even under challenging conditions.

- Expanders: Expansion turbines that recover and utilize energy from blast furnace top gases, contributing to a more sustainable steel production process.

Key machinery train components

Elevating PTA plant performance

Purified terephthalic acid (PTA) is a key component in producing polyester fibers for modern textiles. Everllence provides fully optimized compressor trains to increase PTA production efficiency.

- Integrally geared compressors: Multi-shaft centrifugal compressors that offer durability and low operating costs, enabling PTA plants to achieve higher outputs without significant increases in equipment size.

- Expanders: Tailor-made expanders integrated into PTA machinery trains, designed to boost efficiency and reliability.

- Steam turbine drives: Dedicated steam turbines for saturated steam conditions, suitable for mechanical drive applications, customizable to meet specific process requirements and enhance overall plant efficiency.

Key offerings for fertilizer industry

Giving fertilizer manufacturers the edge

As the world population continues to grow, efficient fertilizer production is essential to maintaining sustainable agricultural and food supplies. Everllence supports the fertilizer industry with the robust compressor trains and drives needed for producing ammonia, urea, and nitric acid.

- Compressors for ammonia and urea plants: A comprehensive range of compressors, including natural gas, syngas, air, ammonia, and CO₂ compressors, tailored for safe and reliable fertilizer production.

- NAMAX train for nitric acid processes: A modular compressor train that enhances efficiency in nitric acid production by increasing power density and eliminating the need for intermediate gearboxes.

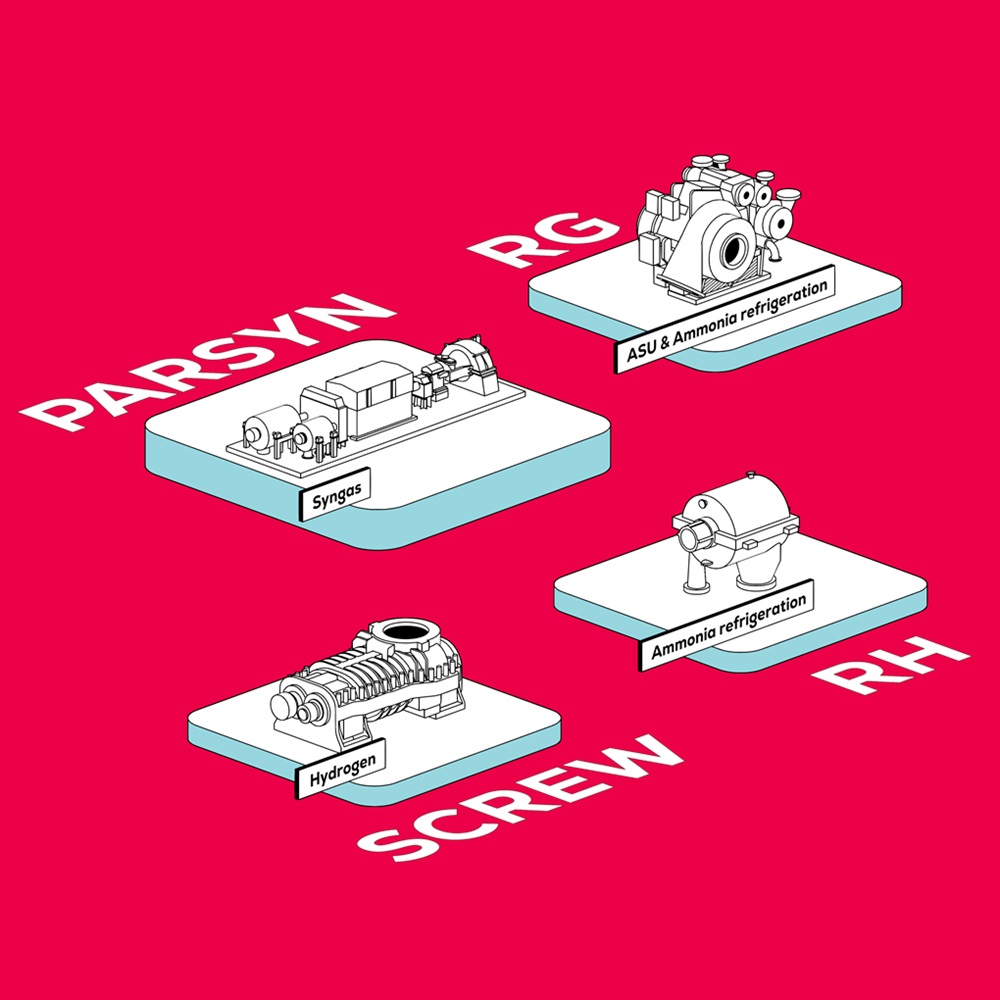

Ammonia as hydrogen carrier

Expanding the use of ammonia

Ammonia is a key component in fertilizer production and is gaining importance as a potential hydrogen carrier for the energy transition. Everllence provides high-efficiency solutions for ammonia production based on patented PARSYN(TM) concept.

- Syngas compression: Advanced compressors for synthesis gas, ensuring the efficient operation of ammonia plants.

- Ammonia refrigeration compressors: Specialized refrigeration compressors for the transport and storage of ammonia.

- Steam turbines for ammonia plants: Patented PARSYN(TM) steam turbine add-on concept as well as conventional multi-stage steam turbines for mechanical drives in ammonia plants, designed for maximum energy efficiency.

- Power-to-Ammonia (PtA) solutions: Technologies enabling sustainable ammonia production using renewable energy sources.

Key components for urea synthesis

Pioneering solutions for urea synthesis

Everllence provides advanced technologies for efficient and reliable urea production. Urea is primarily used as a nitrogen-based fertilizer and requires robust compression and process solutions.

- CO₂ compressors: Designed to compress CO₂ recovered from ammonia plants for use in urea synthesis.

- Tail gas compressors: Engineered to handle process gases efficiently and improve overall urea plant performance.

- High-efficiency heat integration concepts: Designed to optimize the integration of available heat sources and reduce energy consumption in urea processes.

- Integrated drive systems: Steam turbines and electric motors enabling precise and efficient control of urea production processes.

Contact our Everllence industry support

Are you looking to enhance your production processes?

Our decades of experience means Everllence has the products and expertise to prepare your business for a competitive future. If you want to increase output without utilizing additional resources or increasing emissions, talk to us. Find out what we can do for you.

Protect your assets and keep your turbomachinery running

With customized service agreements and global 24/7 response, Everllence PrimeServ offers an optimal support solution. Our service engineers conduct regular preventive maintenance to ensure that your trains and machinery operate at peak efficiency, in addition to providing troubleshooting assistance whenever and wherever it is needed.

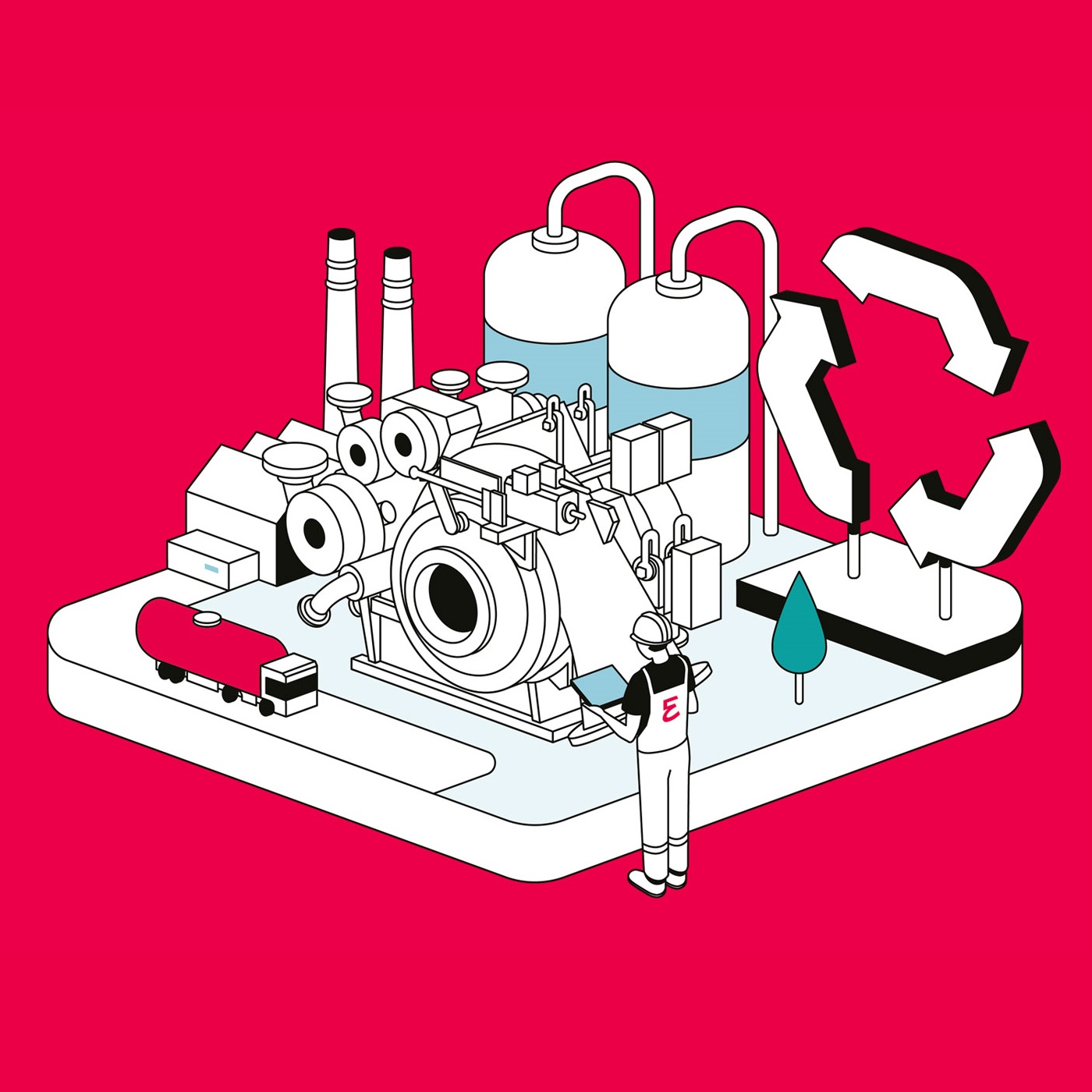

Industrial solutions for a new era

Everllence delivers integrated solutions for the process industries, combining compressors, turbines, expanders, and advanced technologies into optimized systems. Tailored to specific applications, these solutions improve plant efficiency, operational reliability, and long-term sustainability.

Empowering industries with proven technology

Everllence offers a comprehensive portfolio of compressors, steam turbines, expanders, reactors, and integrated drive systems. Designed for demanding process industries, these solutions enhance efficiency, reliability, and sustainability across the entire plant lifecycle.