Production site Changzhou

In Changzhou, Everllence manufactures, assembles and tests turbomachinery.

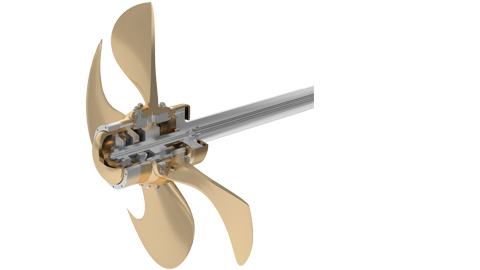

As one of the turbomachinery manufacturers in China, the Company has introduced Everllence' state-of-the-art technology in Changzhou plant and offers products and services covering a wide range of compressors, steam turbines, turbochargers, controllable pitch propellers and slide bearings. To better serve customers, our specialists provide round-the-clock after-sales service for Turbomachinery and Engines.

Innovative and competitive products

The Company has the professional team integrating specialists in Engineering, Procurement, Planning, Production and Quality Management, who are working closely with our Competence Centers in Europe, continuously striving to optimize the design and manufacturing of our tailor-made products. We practice a well-established localization concept, which integrates our Changzhou workshop with all our technological capabilities in European product centers, and we are thus able to offer innovative and competitive products to our customers.

foundation of production site Changzhou

Technology solutions from Changzhou

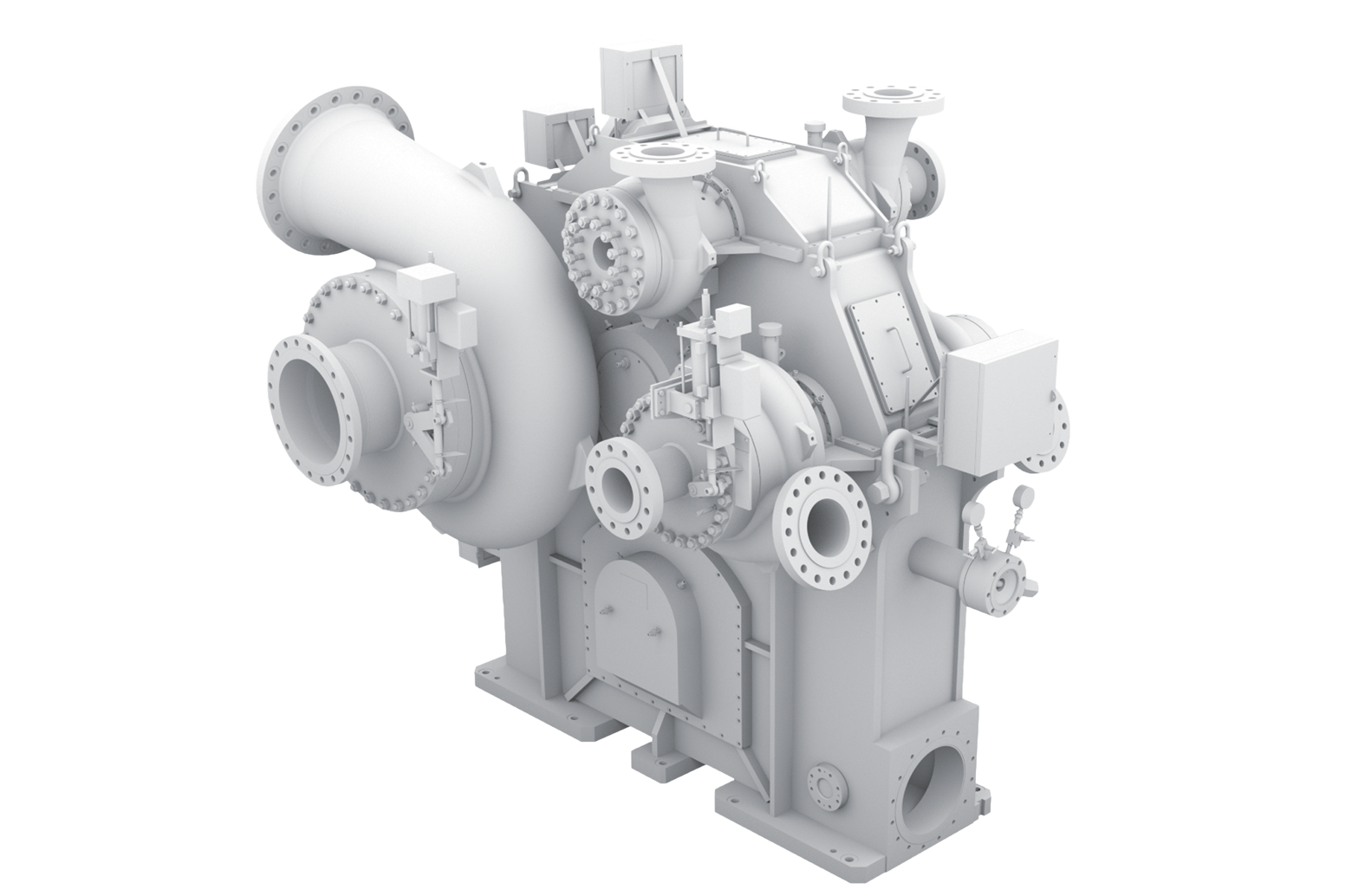

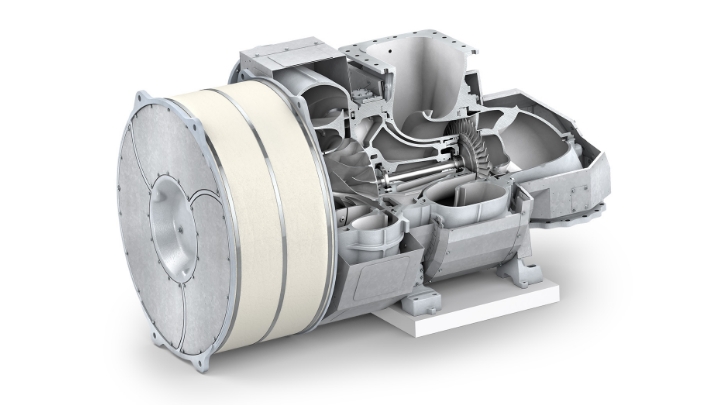

Fully adaptable to your needs, our integrally geared compressors typically stand for high efficiency and a speedy return on investment in a wide range of applications. This multi-shaft centrifugal compressor allows for up to five pinions, depending on your individual requirements.

- Individually selectable impeller speed for optimal flow and costs

- Up to three combined applications within one casing

- Sealing and intercooling opportunities

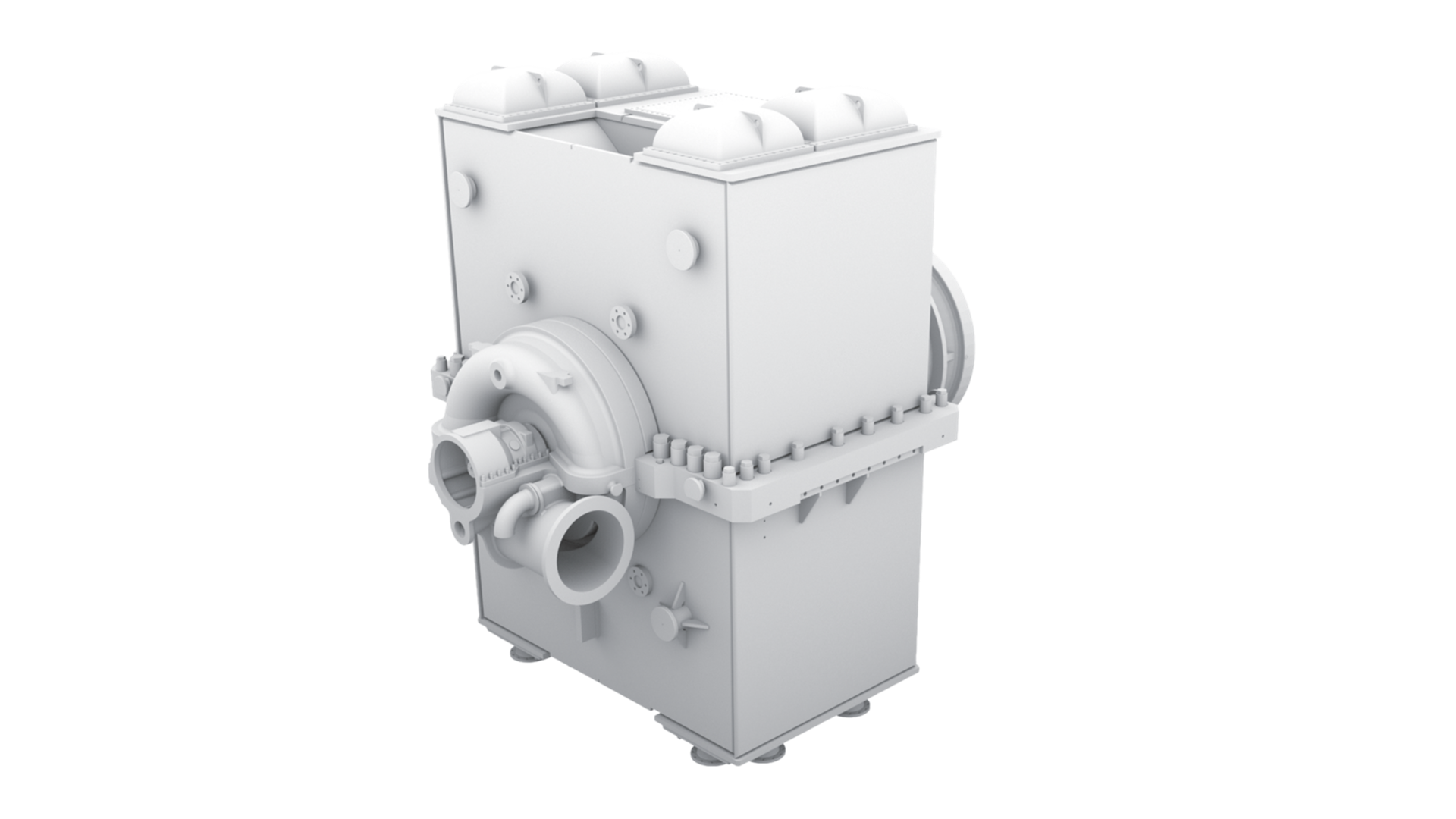

These unique integrated coolers allow for extremely high efficiency and operational robustness. Their core application is in air separation plants.

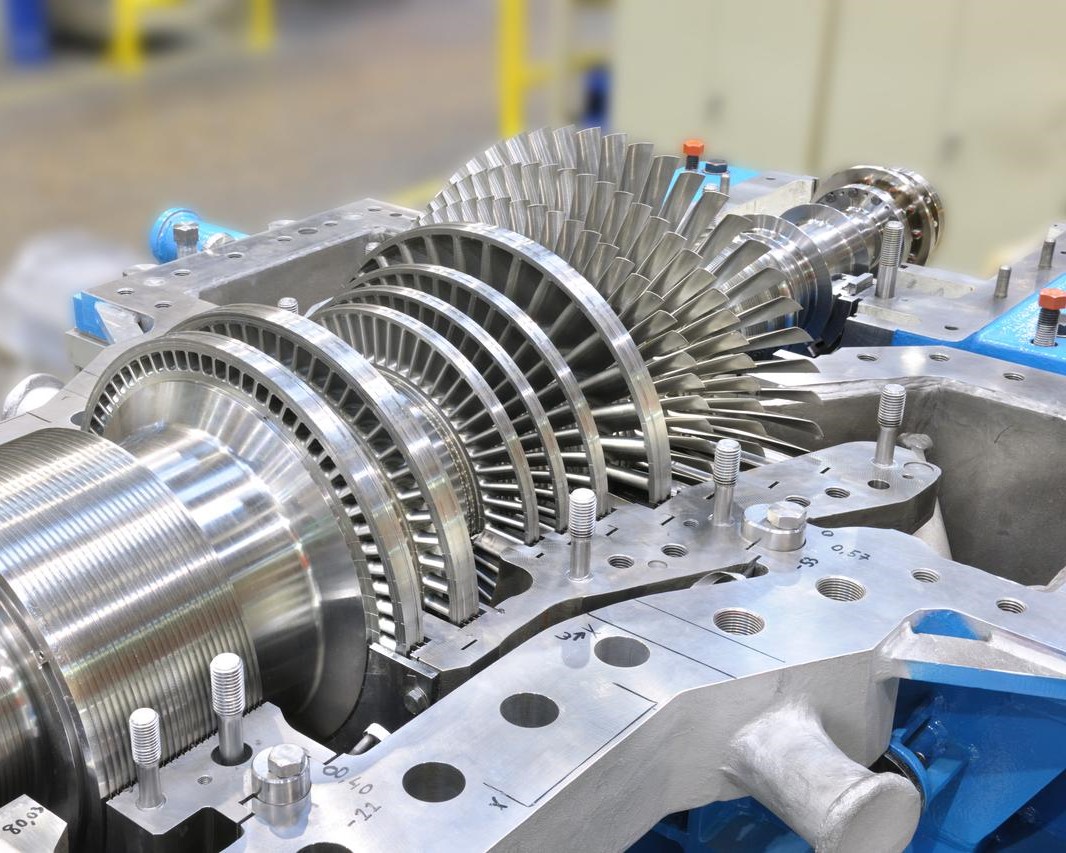

Everllence delivers industrial steam turbines for mechanical drive applications. Built on decades of turbomachinery expertise, our turbines ensure reliable performance, energy efficiency, and lasting value for diverse industrial operations.

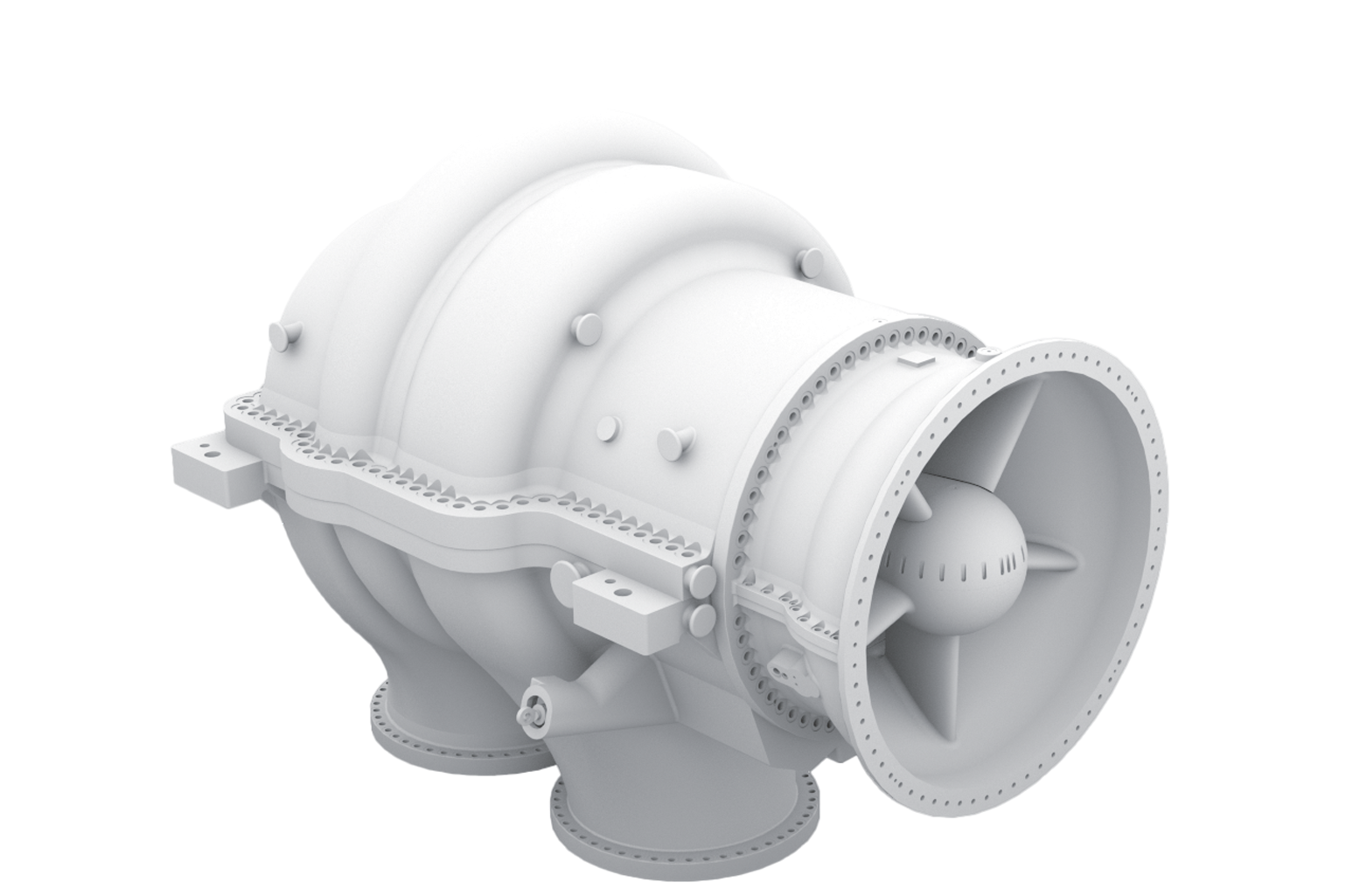

These compressors sit at the center of several high-volume flow industrial applications such as in blast furnace blowers, propane dehydrogenation, wind tunnels and others.

- Superior surge robustness

- Outstanding efficiency

- Also applied in fluid catalytic cracking (FCC)

Compressors with vertical split line are the first choice in oil & gas. Proven and extraordinary robust design lead to record high reliability. The design principle can be applied for low to very large volume flows, and highest process gas pressures. The design is ready for electric motor, steam turbine or gas turbine driver.

- In case of process changes, very short downtime for replacing the bundle

- Optimized design to perform routine maintenance interventions

- Adaptability to process changes (modification of aerodynamic gas path)

Address and local contacts

Fengming Road 9,

Jiangsu Wujin High-Tech Industrial Zone,

213164, Changzhou, P.R. China

T +86 519 86227888

Email: patrick.kettschau@everllence.com

t +86 21 5221237

Email: li.bolan@everlllence.com

t +86 1381001663

Email: markus.meier@everllence.com

t +86 519 8622 7008

Head of Sales Upstream, PTA, LNG, and Heat Pump China - Bin Sun

Email: bin.sun@everllence.com

t +86 18961193163

Head of Sales, Paper Industry China - Zhongliang Zhu

Email: zhongliang.zhu@everllence.com

t +86 13501957512

Head of Sales for Mid- Downstream & BF, CCS China - Liming Zuo

Email: liming.zuo@everllence.com

t +86 139 11468744

History of Changzhou site

The plant was established on Jan. 24, 2007 from a green field.

On Nov. 18, 2008 a grand opening ceremony took place in occasion with MAN 250 Anniversary.

The production and service workshop phase II was opened on May 18, 2011, integrating 6 business areas into Changzhou.

2007 - Groundbreaking

2008 - Phase 1 completed

2010 - First RIKT delivery

2011 - First exported compressor; phase 2 completed; First PGSK; Renk bearings production; Turbocharger production

2012 - RIKT & ST Testbed completion; first ST delivery

2014 - First RG delivery

2017 - First AV delivery; first GT packing

2018 - RG testbed completed

2019 - 100th RIKT delivery

2020 - CPP assembly; first RB

2021 - First MAX1 AG

2021 - New TCT Turbocharger

2025 - Renamed to Everllence Changzhou Production Co., Ltd