Production site Oberhausen

The Everllence downstream (process industry) division is based in Oberhausen. The turbomachinery site is also our leading production and service location for compressors, turbines, and expanders in the industrial sector.

Approx. 1800 employees develop, test and manufacture compressors, expanders and turbines in Oberhausen for the entire world. Whether for the production of plastics, steel, industrial gases or chemical and petrochemical products, our efficient turbomachinery trains help manufacturers to decarbonize their processes and goods.

Oberhausen: Where the future is made

The company can trace its roots in the cradle of German industry, the Ruhr region:

Everllences anchestors were founded in Oberhausen-Sterkrade over 266 years ago. Oberhausen is where the future is being made: The key to various energy storage technologies lies in the site's unique compressor expertise, which is essential for a successful energy transition. Energy storage solutions contributed by Oberhausen maschinery include LAES (Liquified Air Energy Storage), CAES (Compressed Air Energy Storage), and CO2 storage solutions. In addition, Oberhausen develops and builds industrial heat pumps, solutions for “green chemicals”/ammonia, and turbomachinery for hydrogen applications.

Furthermore, the integrally geared compressors assembled at site are leading in applications for CO2 separation, storage and utilization. Everllence is not only breaking new ground in the course of decarbonization. The unique engineering approach of the Oberhausen site is also leading more and more to digital products and solutions such as remote services, virtual commissioning, dynamic simulations with AI integration and even autonomous operation.

Technology innovations

CCUS

Industrial Heat Pumps

Technology solutions from Oberhausen

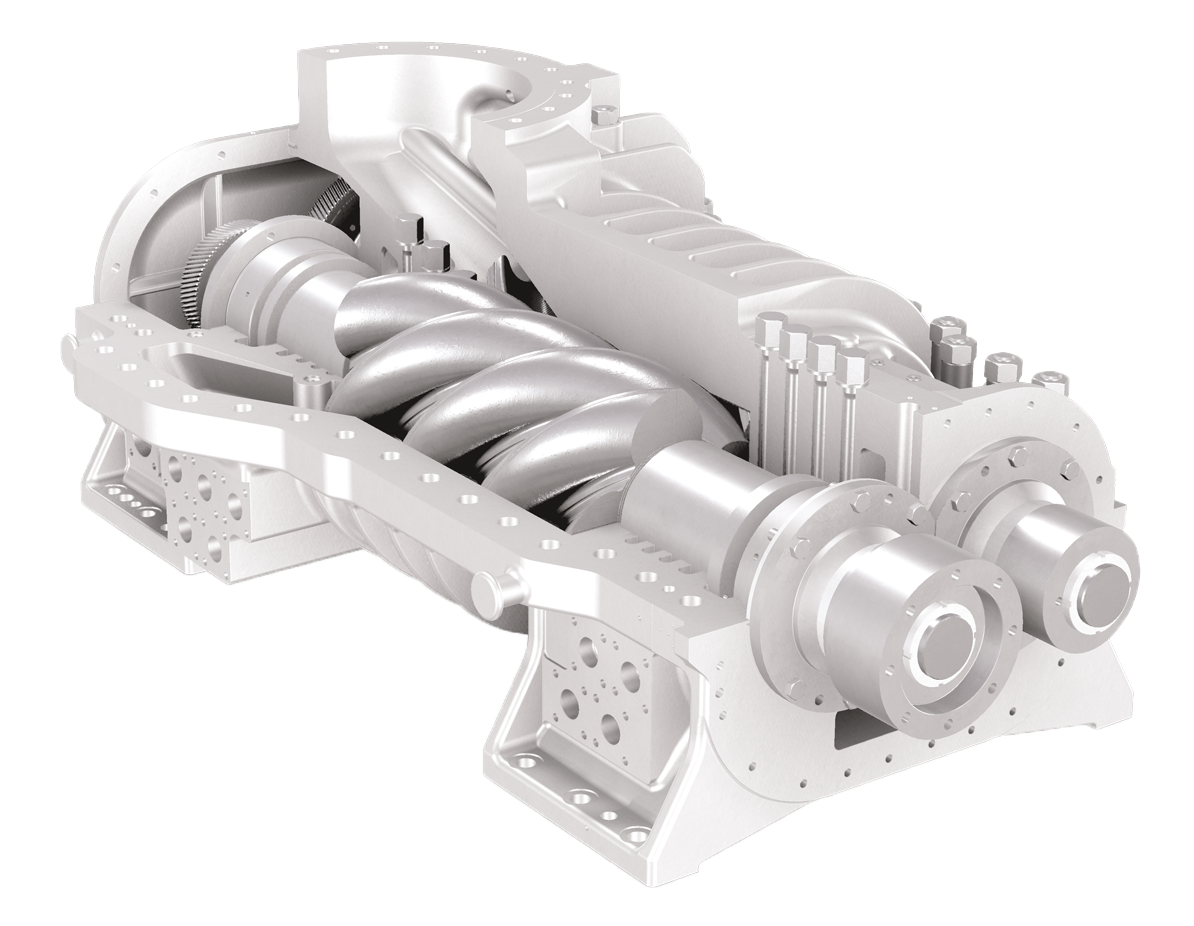

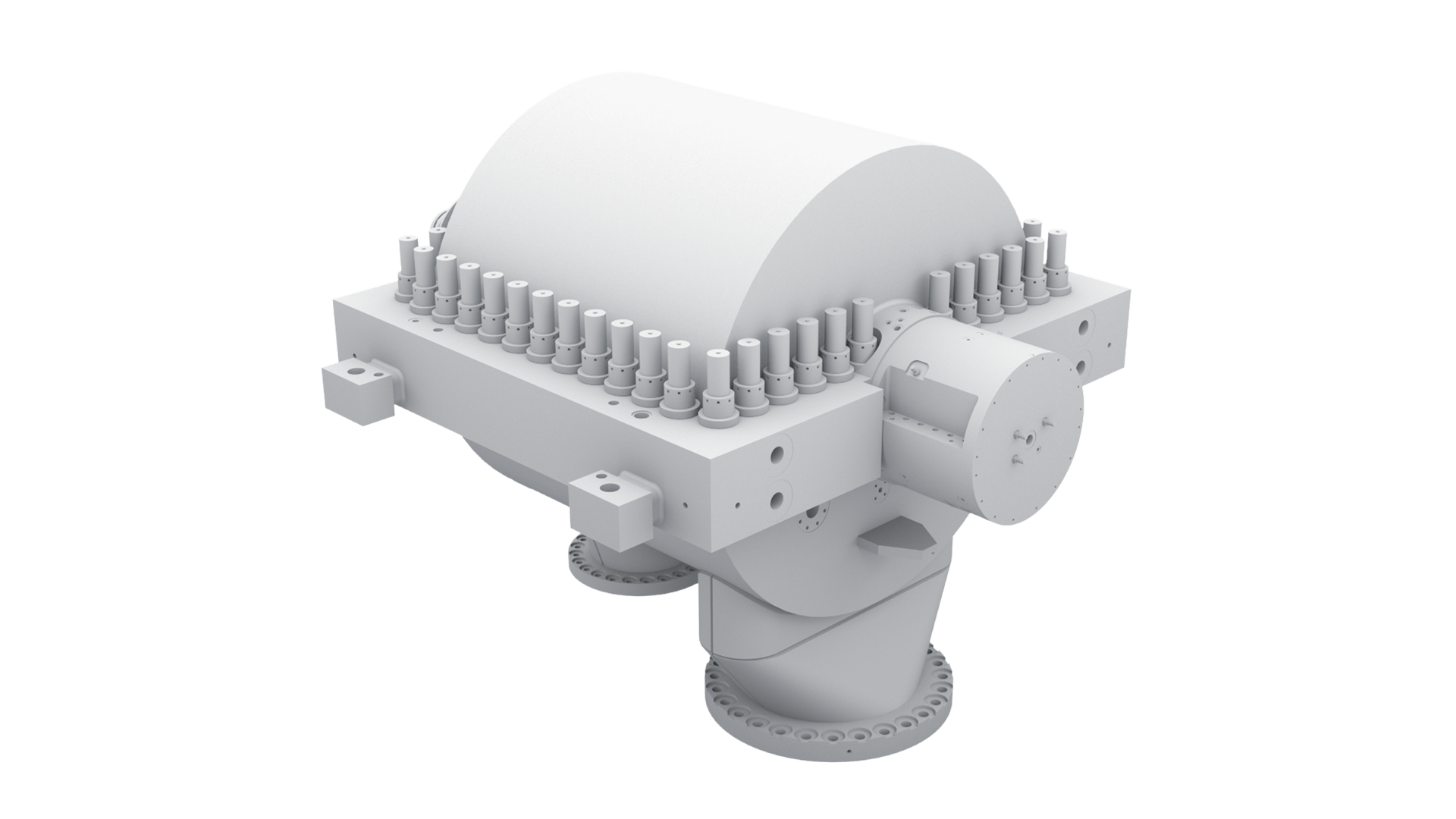

The robust process gas screw compressors of Everllence are designed to handle highly contaminated gases and other gas mixtures under heavy-duty conditions that would curtail the availability and life expectancy of other compressor types.

Our versatile process gas screw compressors are used in the after-treatment of gases such as flare gases and on FPSO ships, for example.

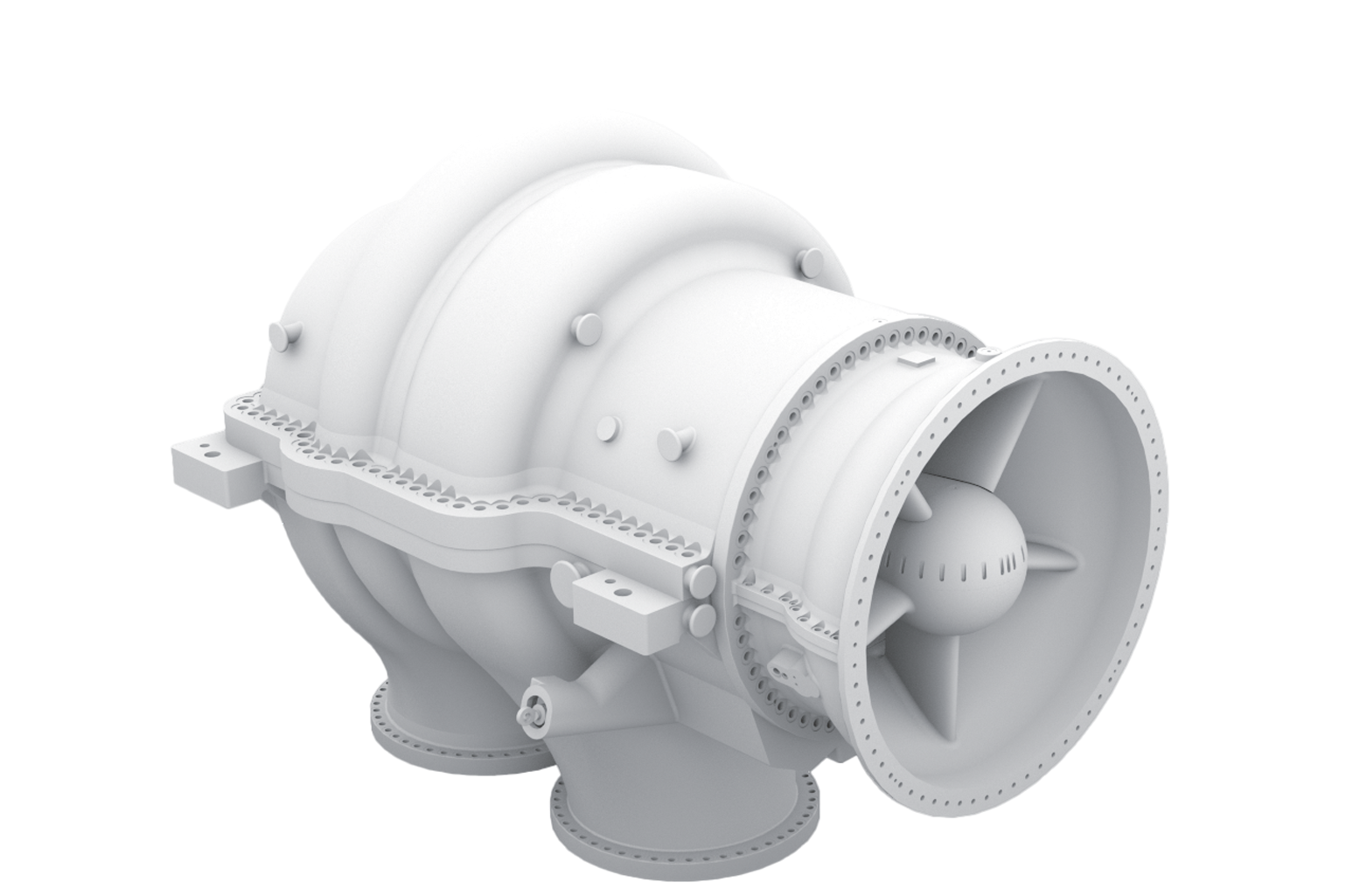

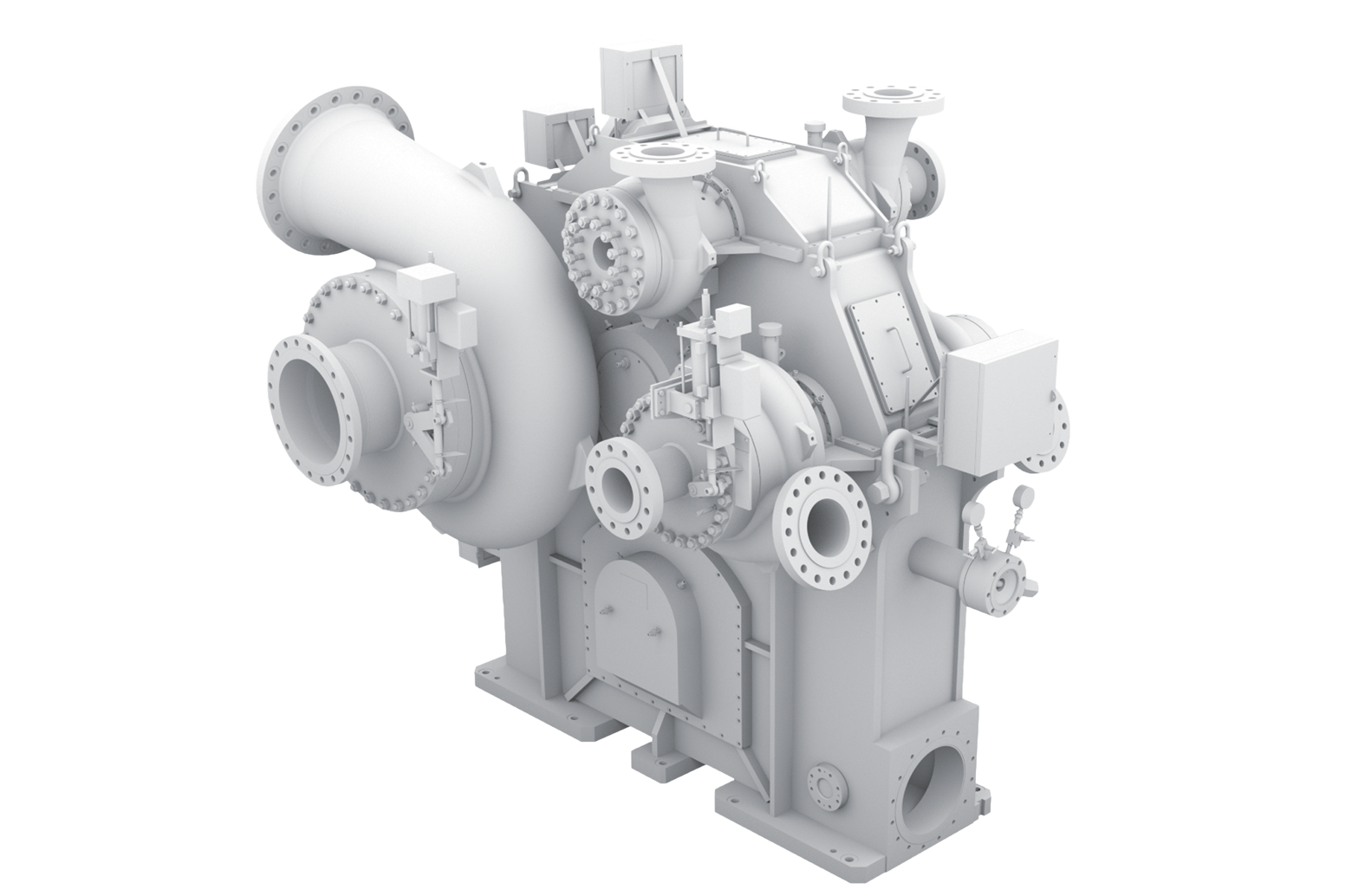

These compressors sit at the center of several high-volume flow industrial applications such as in blast furnace blowers, propane dehydrogenation, wind tunnels and others.

- Superior surge robustness

- Outstanding efficiency

- Also applied in fluid catalytic cracking (FCC)

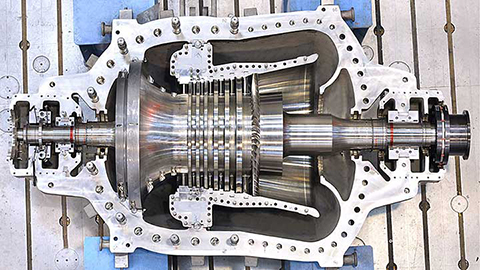

Available in horizontally split (RH) or barrel type (RB) design, these compressors are well-proven and serve in many industries, from chemicals to exploration and production, industrial gases and others.

- Highest efficiency and proven impeller design

- Pre-designed sealing systems for easy assembly

- Service-friendly design and easy maintenance

Fully adaptable to your needs, our integrally geared compressors typically stand for high efficiency and a speedy return on investment in a wide range of applications. This multi-shaft centrifugal compressor allows for up to five pinions, depending on your individual requirements.

- Individually selectable impeller speed for optimal flow and costs

- Up to three combined applications within one casing

- Sealing and intercooling opportunities

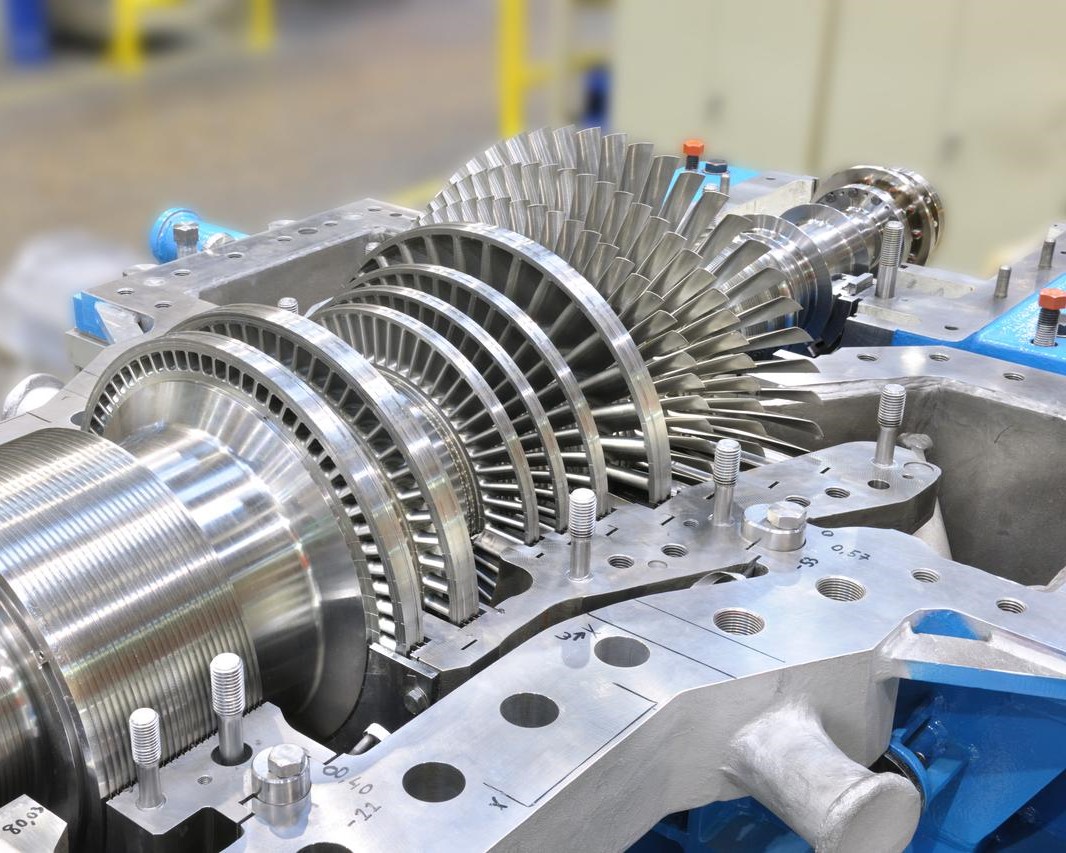

Everllence delivers industrial steam turbines for mechanical drive applications. Built on decades of turbomachinery expertise, our turbines ensure reliable performance, energy efficiency, and lasting value for diverse industrial operations.

For industrial processes like the production of Nitric acid or Purified Terephtalic Acid (PTA), expanders by Everllence ensure recovery of energy potentials, meaning enhanced efficiency and ecology.

Expanders serve in particular to improve efficiency and the energy balance by recovering energy from gases in certain chemical and petrochemical processes.

Career and training offers

Address

Everllence SE Oberhausen

Steinbrinkstraße 1

46145 Oberhausen

t +49 208 692 01

f +49 208 669 021

Site Manager

Florian Schiller

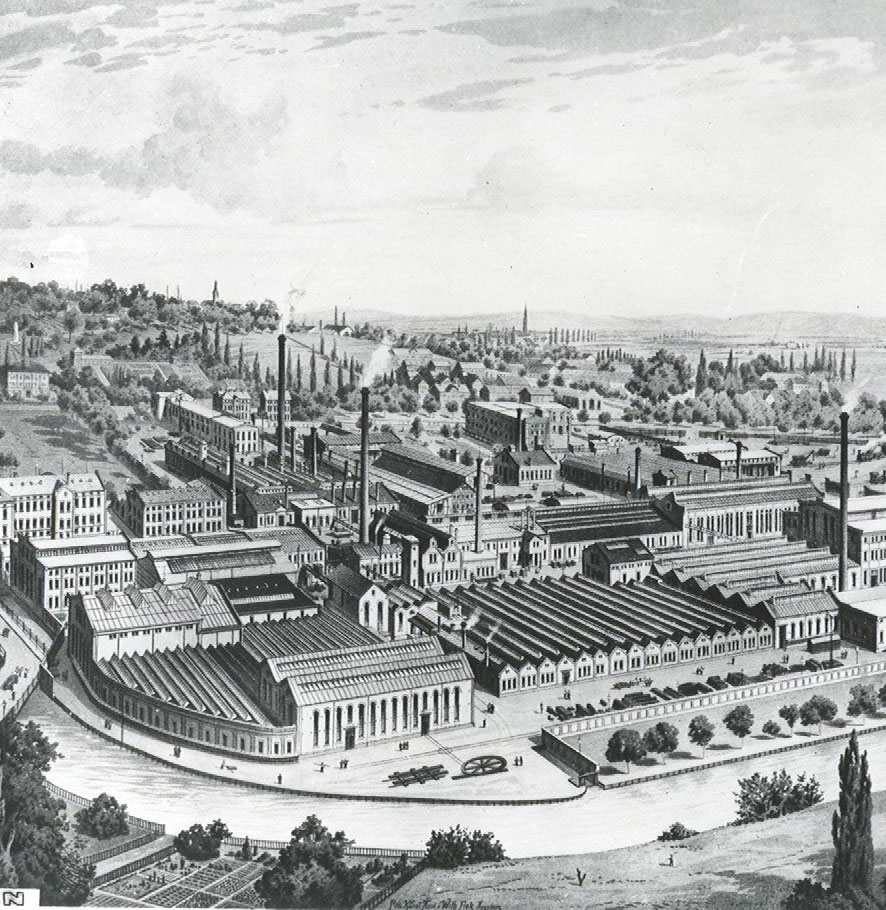

History of Oberhausen site

1758 – Founding of the St. Antony iron works

1782 – Establishment „Gute Hoffnungshütte”(GHH) steel in Sterkrade

1904 – First GHH steam turbine

1950 – First GHH axial compressor

1996 – Establishment of GHH BORSIG Turbomaschinen GmbH

1999 – Launch of Intelligent Remote Diagnostic System IRDS™

2001 – Takeover of the Sulzer AG turbomachinery activities by MAN Turbomaschinen AG GHH BORSIG

2004 – Change of name in MAN TURBO AG

2010 – Merger to form MAN Diesel & Turbo SE

2013 – New test bench MUENSTER in Oberhausen

2013 – Development of the world largest air compressor MAX1

2014 – Opening of the MAN PrimeServ Academy in Oberhausen

2014 – Entry of a new gas turbine into market

2015 – Acquisition of MaxWatt Turbines Pvt. Ltd. and integration of impulse steam turbine technology

2019 – Launch PrimeServ Assist

2020 – First remote commissioning by MAN Energy Solutions

2021 – First LAES system with grid stability service in cooperation with Highview Power

2021 – MAX1 for propane dehydrogenation (PDH)

2021 – MAN Energy Solutions as founding member of HydrOB – Campus for Hydrogen Technologies Oberhausen

2021 – First AI based automation product