Development, production Zurich

World-class technology comes to life in the heart of Zurich. At Everllence Switzerland, 900 employees from around 40 nationalities are responsible for the development, design, production, sales and service of high-tech compression systems. These are used to enable critical processes in industry sectors such as energy and chemicals. The company strives to transform energy into sustainable progress and prosperity for a climate-neutral future. For this purpose, Everllence provides digitalized technology innovations, which set new standards within the industry.

Technology innovations

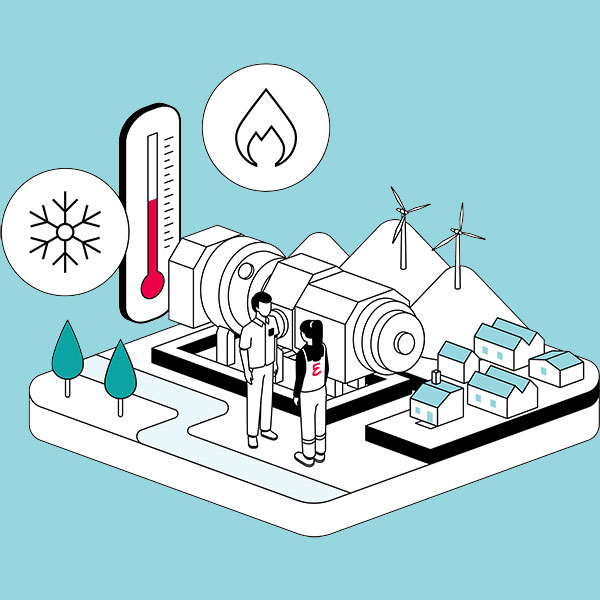

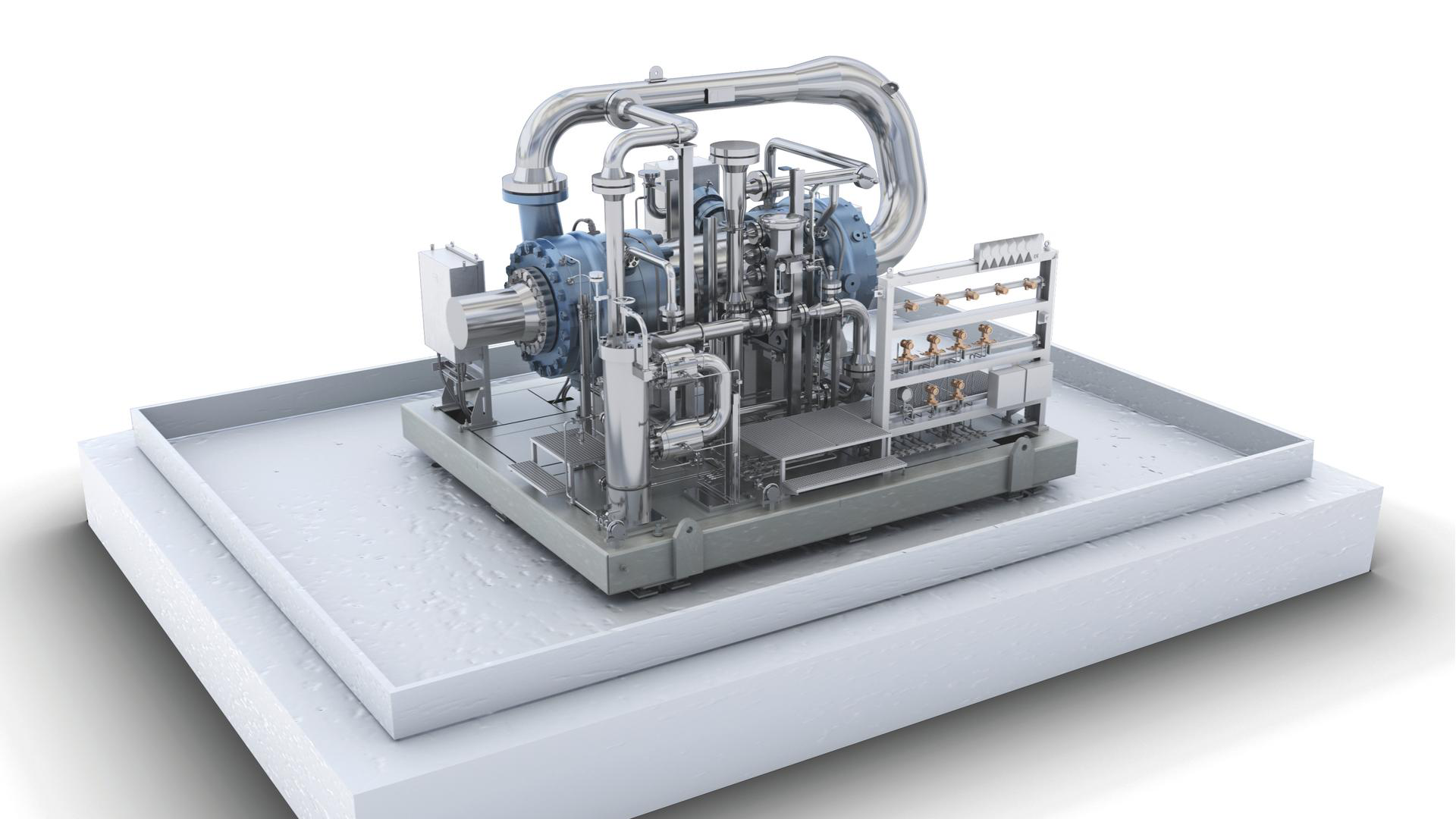

Everllence Heat Pumps

Everllence develops mega heat pumps that decarbonize entire cities by using environmental heat from water, air, or industrial processes. Integrated water tank stores enable the flexible use of surplus heat, making the system both a heat supplier and an energy reservoir. This contributes to grid stability and overall efficiency. In Esbjerg (DK), two Everllence heat pumps replace a coal plant, providing 25,000 households with district heating and saving 120,000 tonnes of CO₂ annually. Developed and manufactured in Zurich, the innovation builds on 220 years of Swiss engineering expertise.

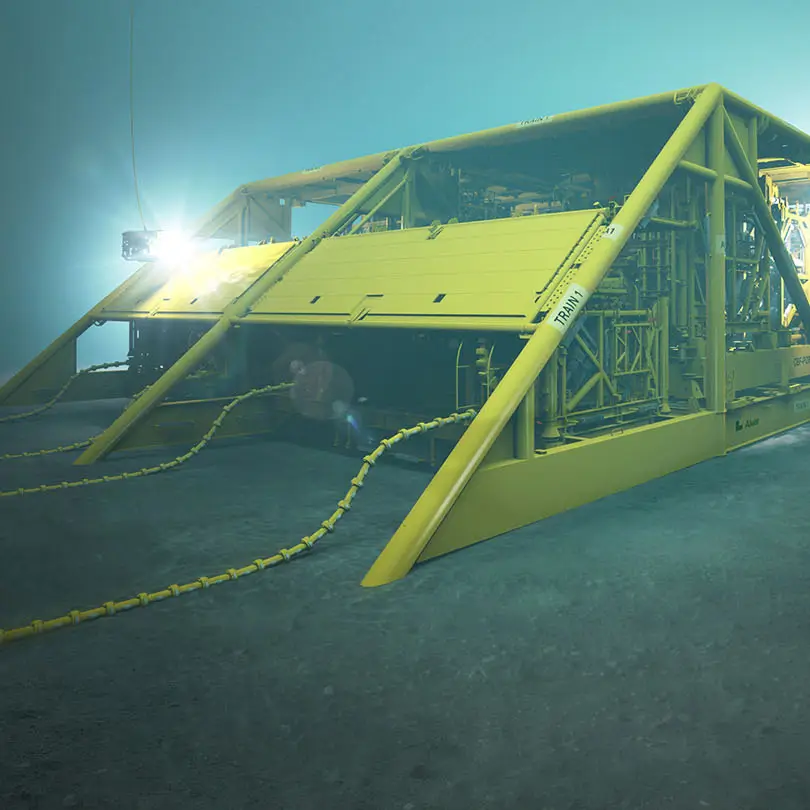

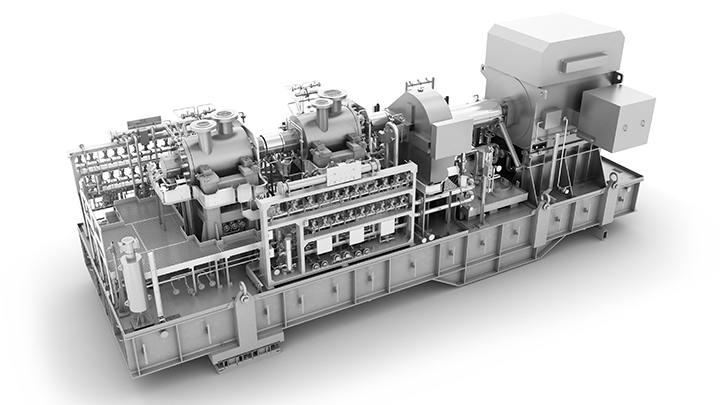

Everllence Subsea

Everllence’s subsea compression solution makes offshore gas-recovery more sustainable and efficient. The HOFIM® motor-compressor units from Zurich have proven their reliability for Equinor’s Åsgard gas field in Norway with practically no stops or interruptions since production-start in September 2015.

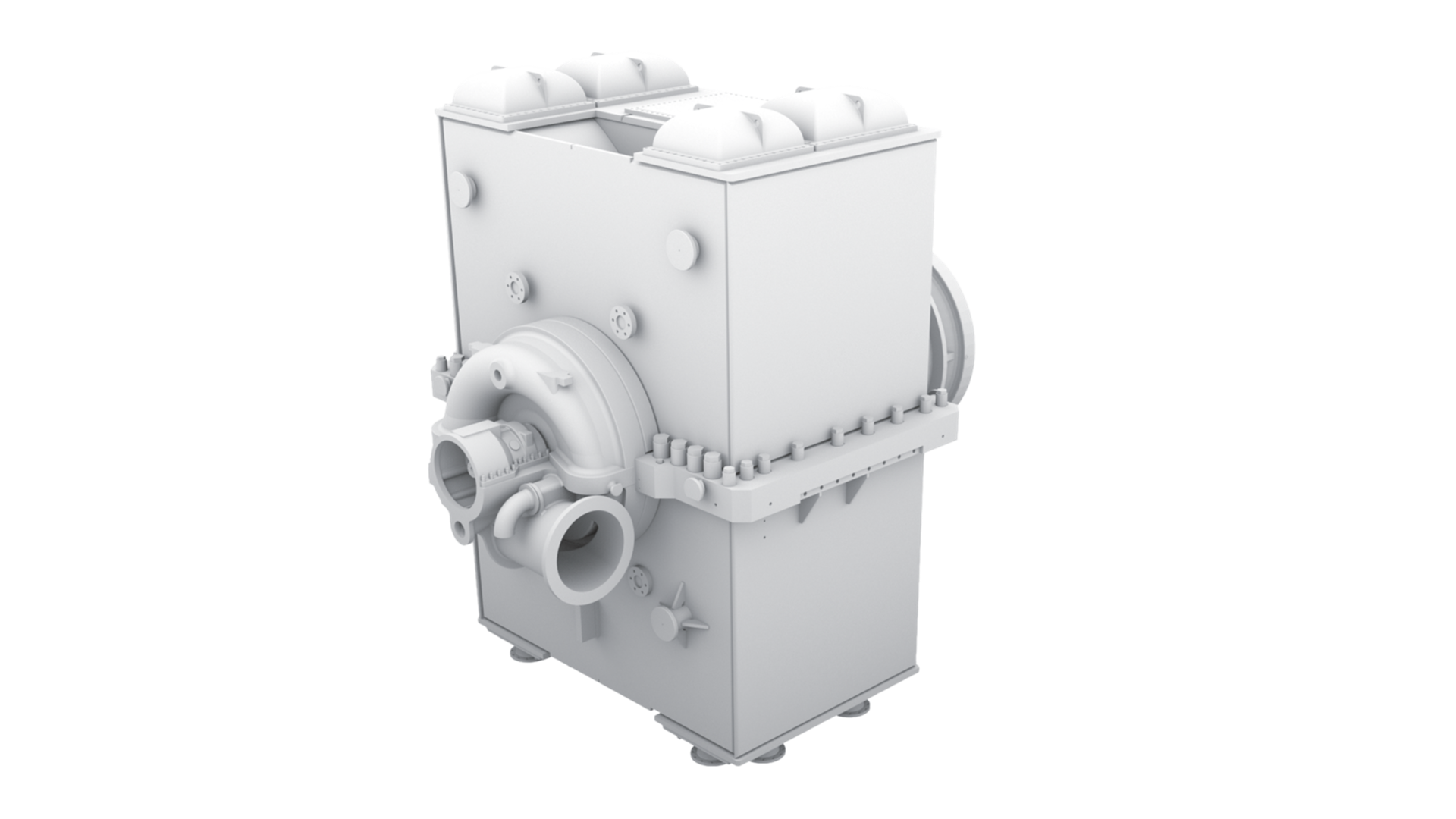

Technology solutions from Zurich

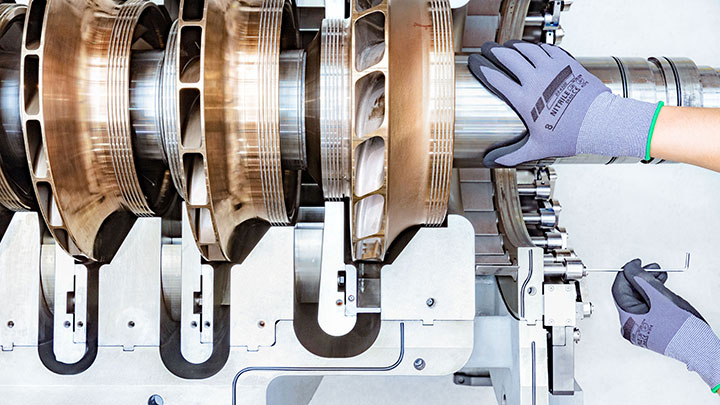

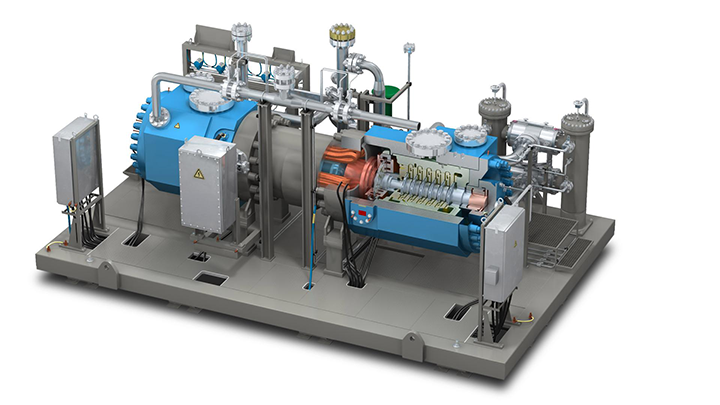

The fully sealed, oil-free HOFIM® is suitable for use in a wide range of process compression applications. It is used in pipelines, gas storage, gas export and in subsea applications. The HOFIM® compressor package features a high-speed induction motor coupled with the barrel-type compressor and active magnetic bearings (MECOS).

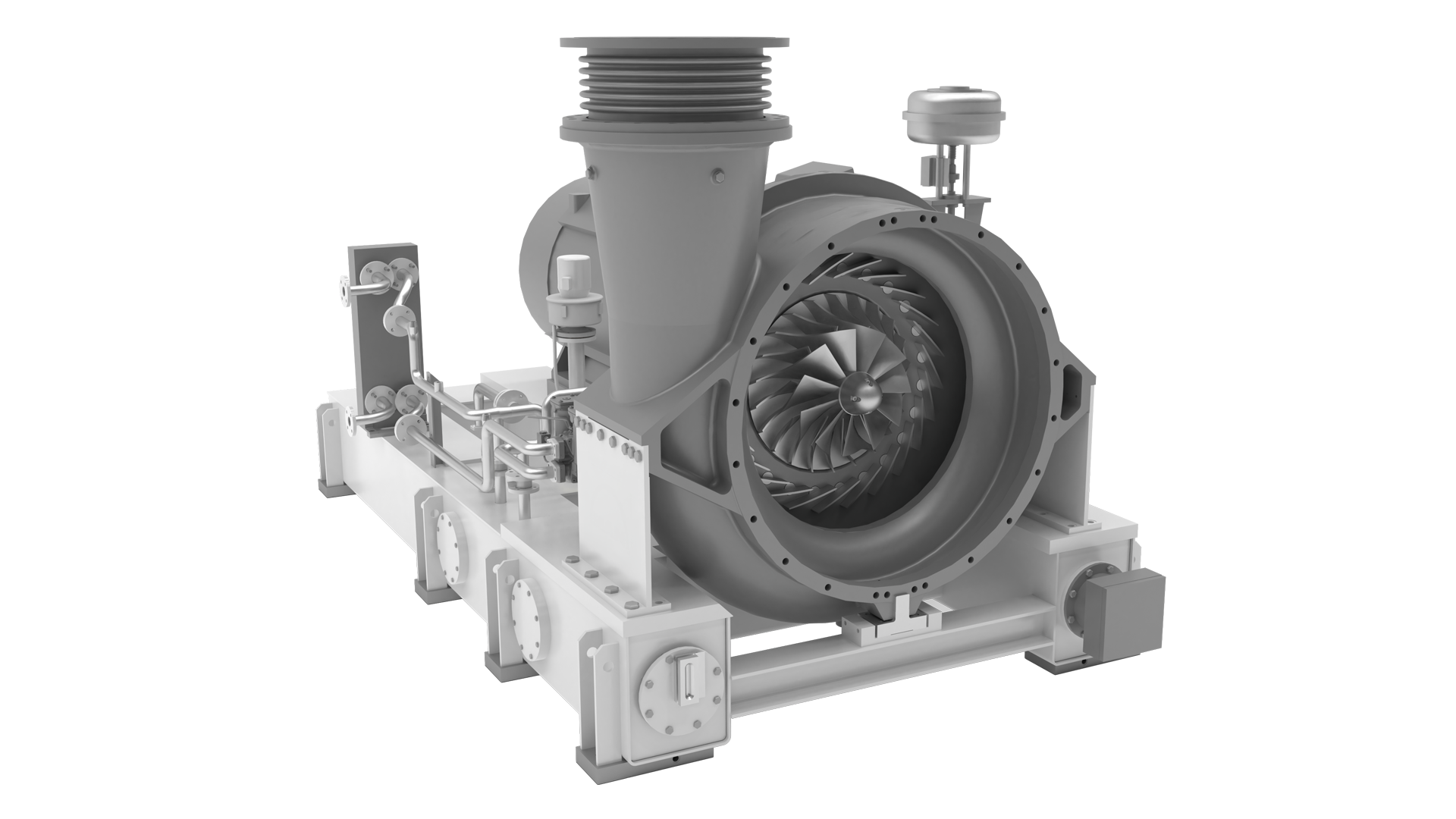

The MOPICO® is an integrated, hermetically-sealed system comprising the motor-compressor unit, a variable-frequency drive, and the unit control system.

It is primarily designed for gas pipeline applications, but is equally suited for a wide range of gas compression applications requiring high volume flows.

We developed these compressors for the pulp and paper industry in particular. TURBAIR® is available as a single blower with vacuum level up to 65 Kpa, or as a multi-stage blower with a maximum of four different vacuum levels up to 75 Kpa.

The barrel type (RB) compressors are well-proven and serve in many applications, from energy recovery to transportation.

- Highest efficiency and proven impeller design

- Pre-designed sealing systems for easy assembly

- Service-friendly design and easy maintenance

These unique integrated coolers allow for extremely high efficiency and operational robustness. Their core application is in air separation plants.

Work with us at Everllence Switzerland

At Everllence Switzerland, our most valuable assets are our employees. We support our employees in their professional development and personal growth. Everyone gets the opportunity to make a real difference for future generations by helping our customers in crucial industry sectors to achieve the target of “net zero”. It’s what we call Moving Big Things To Zero. Want to join us on this exciting journey towards a climate-neutral energy future? We look forward to meeting you!

Career and training offers

Address & local contacts

Everllence Switzerland Ltd.

Hardstrasse 319

8005 Zurich

t +41 44 278 2211

Hardstrasse 319

8005 Zürich

Everllence Switzerland Ltd.

Hardstrasse 319

8005 Zürich

Everllence Switzerland Ltd.

Hardstrasse 319

8005 Zürich

Everllence Switzerland Ltd.

Hardstrasse 319

8005 Zürich

Everllence Switzerland Ltd.

Hardstrasse 319

8005 Zürich

Everllence Switzerland Ltd.

Hardstrasse 319

8005 Zürich

Everllence Switzerland Ltd.

Hardstrasse 319

8005 Zürich

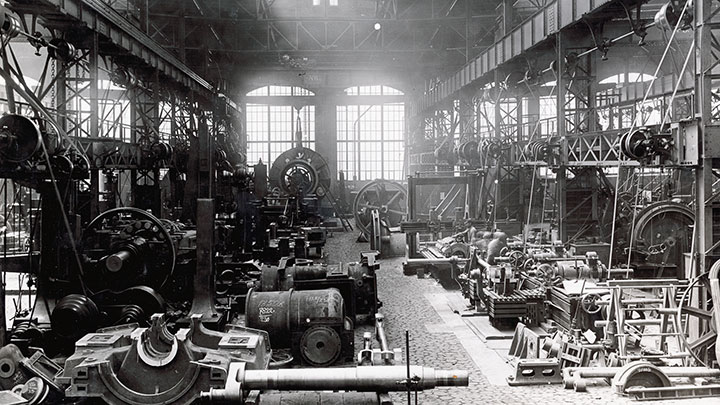

History of the Zurich site

The Zurich production site has existed for over 200 years: the company Escher Wyss & Cie. was founded in 1805 at the Neumühlequai. In 1894, the company moved to the Escher-Wyss-Platz, where Everllence (former MAN Energy Solutions) is located until this day.

Escher Wyss & Cie. and Sulzer, which was founded in 1834, merged in 1983 to Sulzer Escher Wyss AG. In 2001, Sulzer Turbo was integrated into the MAN Group as MAN Turbo and later merged with MAN Diesel to MAN Diesel & Turbo.

The current company brand Everllence was established in 2025. The new company name embodies the company's strategic and technological departure into a climate-neutral future.