castings per year

metric tons castings are offered

A passion for casting

This video gives you some insights into how we produce high-quality castings for our customers

By loading the video you agree to YouTube's privacy policy.

Our Offer

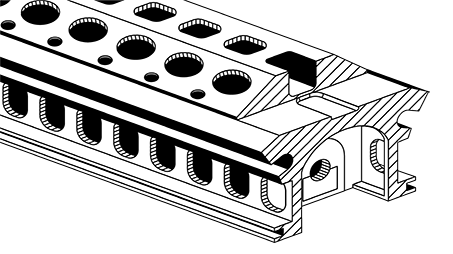

We offer castings from 300 kg up to 100 metric tons. For this we use different processes in the molding shop.

For small sizes, we have a semi-automated molding line and a sand mixer. The flask sizes are up to 1600 mm x 1600 mm with a capacity of 80 flasks a day up to 2.5 metric tons per piece.

For medium-sized products, we have 4 manual molding stations, each with its own mixer. In this area we can produce components of up to 40 metric tons and up to 8 m in length.

For large castings, up to 100 metric tons raw casting weight, we can provide 13 large molding pits. The maximum dimensions are 14 m x 4.5 m x 3 m.

- EN 1561: Gray cast iron – GJL

- EN1563: Spheroidal graphite cast iron – GJS (ductile iron

- EN 16124: Low-alloyed ferritic spheroidal graphite cast iron for elevated temperature applications – SiMo ductile iron

“Everllence’s foundry is your reliable partner for complex metal castings up to 100 metric tons.”

Marco Nagler, Head of Foundry Business

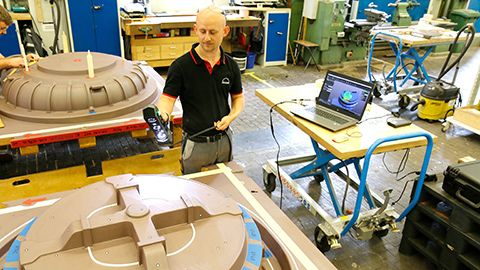

Complete Foundry Process In-House

As a full-service provider, we can offer the complete foundry process in-house, from patternmaking to metal melting and iron casting.

Patternmaking is the first and most essential part of the casting process.

Our services include:

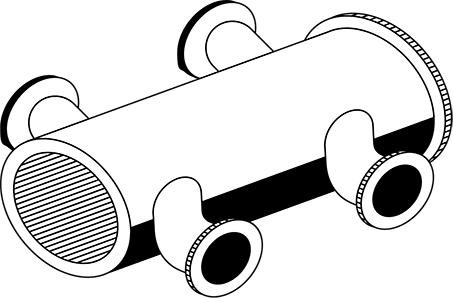

- CNC milling machines with five axes

- All quality classes in accordance with EN 12890

- Measuring with portable 3D scanner

- Routine pattern maintenance and repair

- Pattern updates due to design revisions

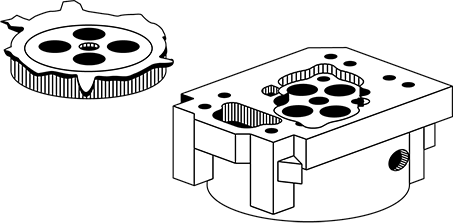

High-quality cores are essential to the iron casting process – from blasting to the conventional cold resin process.

- In the foundry workshop, we produce 75,000 cores per year – core weight from approximately 100 g up to 10 metric tons

- Water- and alcohol-based coatings are used

- Five core blasting machines for volumes from 10 to 300 liters: 10/15 liter, 20/40 liter, 30/50 liter, 300 liter

- These machines are used for producing complex core structures or series core

In our molding shop, we provide a hand mold and semi-automated molding line from 300 kg up to 100 metric tons with a component size up to 14 m in length.

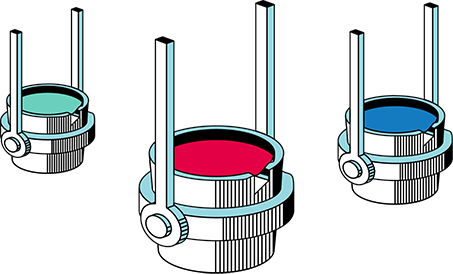

Our melting shop in Augsburg has a capacity of 40,000 metric tons per year.

We can offer the following services:

- 14 MW connected load

- Cast iron materials: gray iron, ductile iron and SiMo ductile iron

- 2 x 6-ton medium-frequency (MF) and 2 x 23-ton normal-frequency (NF) induction furnaces

- Emission spectrometer, thermal analysis, carbon combustion method

- Very well-established process

- Excellent connection to subcontractors for core printing

- Fully automated fettling station

- Three shot blasting machines

- Annealing furnace up to 900°C

- Quality control

- Engineering

- CNC machining shop up to 100-ton parts

- Paint shop

- Iron cast welding

- Service parts and proven project management

What defines us makes you move forward

Your Benefits at a Glance

Highest standards in quality, servers, and technology—for projects that deliver long-term results

Experience

Experience. Long history with extensive experience, casting know-how and state-of-the-art casting technology

Precision

High quality standards and proven long-term customer satisfaction

Full-service

Full system provider with additional services and unique selling points including engineering, prototyping, quick service parts, single lots and excellent project management

Industrial strength

Part of the VW group

Ready for the next step?

Let’s get your project into shape together.

Whether you need a one-off piece or a series, we support you with technical expertise, precision, and a strong network. Contact us to set your project on the right track – efficiently and reliably.