By loading the video you agree to YouTube's privacy policy.

“We’re at an exciting point,” says Ole Pyndt Hansen, a marine engineer by profession who joined as the new Head of Two-Stroke Research and Development at Everllence in Copenhagen. “We started full-scale testing on our latest development, the two-stroke ammonia dual-fuel engine, in November 2024. And now we’re running this research engine on ammonia at full load every day.”

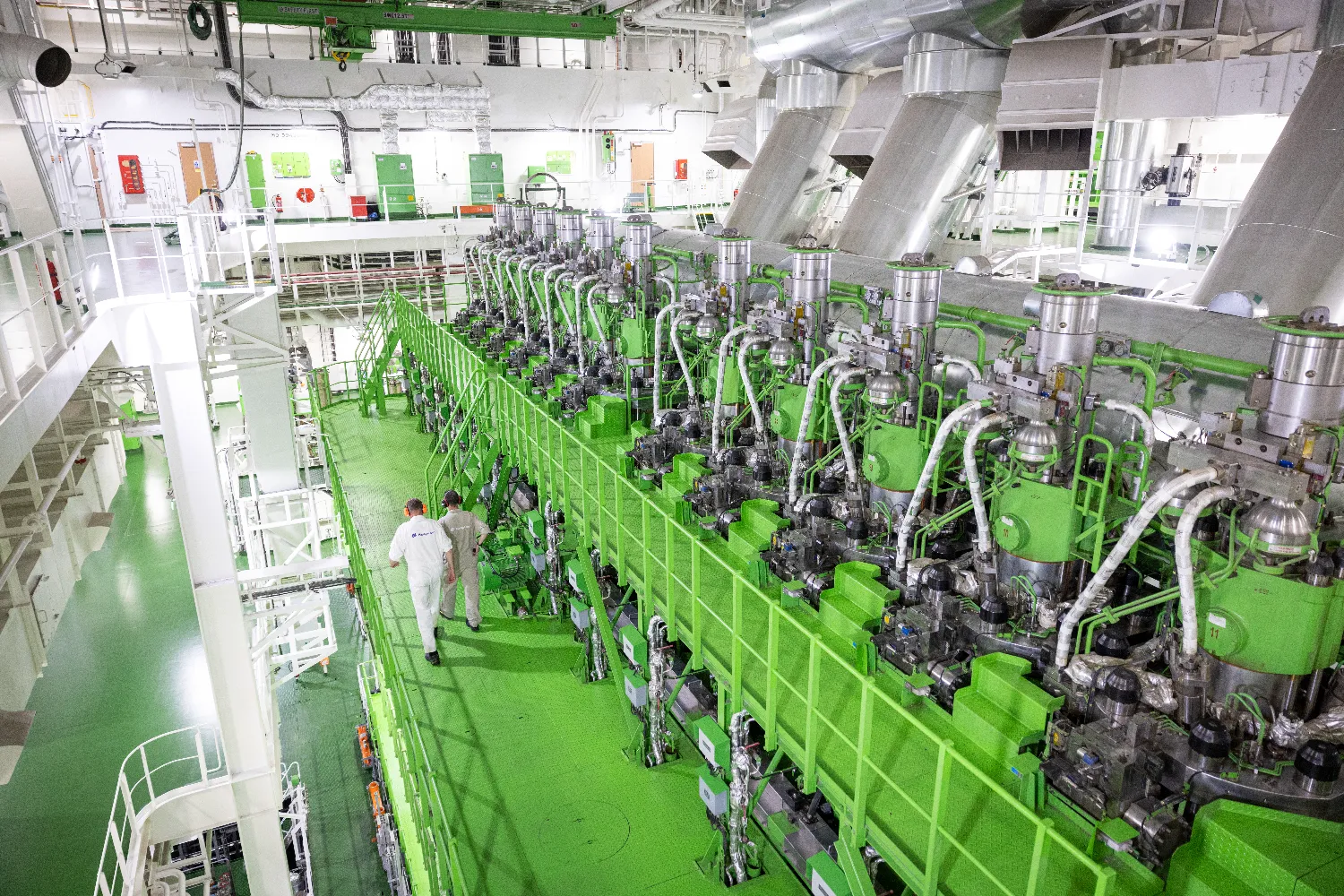

We’re inside Everllence Research Centre Copenhagen (RCC) in Denmark where for years engineers have been shaping the future of two-stroke shipping around efficiency and fuel flexibility with dual-fuel engines. These are engines that allow vessels to run on both traditional marine fuels and cleaner alternatives – a huge advantage in a market with fluctuating fuel prices and new emissions regulations.

“We see a multifuel future.”

Christian Ludwig, Head of Global Sales and Promotion, Two-Stroke Business, Everllence, Copenhagen

The company’s dual-fuel technology is already paving the way for shipping’s future, more sustainable fuels. Fuels such as green methanol and ammonia as well as synthetic natural gas, will have a tremendous impact on the shipping industry in the coming years, says Christian Ludwig, Head of Global Sales and Promotion for Two-Stroke Business at Everllence in Copenhagen. “We see a multifuel future for shipping.”

In particular, green methanol and ammonia will be the key drivers in the maritime energy transition, especially for two-stroke engines. Both of these fuels are based on green hydrogen – a vital carbon-free alternative fuel in other industries such as electricity generation, but too challenging to store and handle on merchant vessels. “Analysts predict a market share of 20 percent for methanol and 30 percent for ammonia by 2050,” says Ludwig.

Two-stroke dual-fuel capability: LNG, SNG and methanol

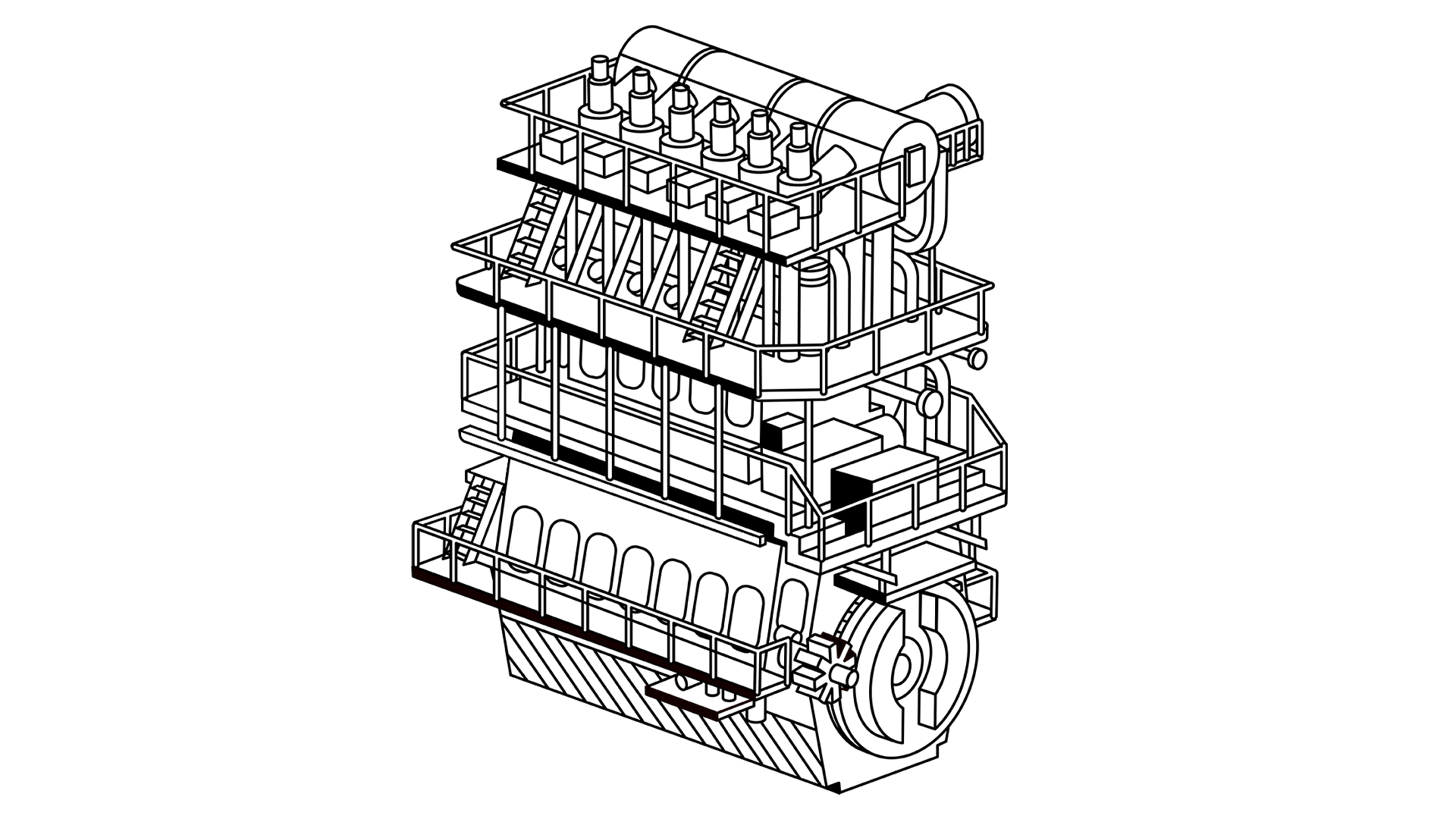

In 2011, the RCC made its first groundbreaking milestone in dual-fuel technology with its Everllence B&W ME‑GI engine, the most efficient engine for methane as a fuel. The engine runs on fuel oil or liquefied natural gas (LNG), as well as biomethane and SNG, both of which are produced from renewable energy sources.

Hapag-Lloyd recently commissioned the largest containership to sail under a German flag, a newbuild fitted with an ME-GI engine. Running on LNG, the vessel cuts up to a quarter of its carbon dioxide (CO2) emisisons. When running on SNG made from green hydrogen and captured CO2, the ME-GI can reduce emissions by up to 95 percent. No surprise then, that since it entered the market in 2014 more than 1,000 orders have been made. “These engines form the backbone of our dual-fuel engine portfolio”, says Ludwig.

The Everllence B&W ME-LGIM two-stroke dual-fuel engine is also already well established. Launched in 2016 for methanol carriers, it has since made its breakthrough on Very Large Container Vessels (VLCVs).

“It was a gamechanger and a catalyst for the market,” says Ludwig, an engineer by training who has worked in both aftersales and new sales throughout his career. “Today we have more than 230 orders for dual-fuel methanol newbuilds and an increasing focus on retrofits for methanol.” In 2024, Everllence completed the world’s first methanol retrofit of a Very Large Container Vessel and has plans for a dual-fuel ammonia retrofit as well. “Retrofits offer a cost-effective way to quickly decarbonize,” says Ludwig.

“Our two-stroke ammonia engine is at full performance, we’re running on all cylinders.”

Ole Pyndt Hansen, Head of Two-Stroke R&D, Everllence, Copenhagen

Dual-fuel two-stroke ammonia engine at 100-percent load

In the RCC’s engine room, the ten-meter-high ammonia two-stroke test engine stands like a collosal monument in the effort to power the world’s merchant ships with carbon-free and carbon-neutral fuels. Upwards of 2,000 two-stroke newbuilds are launched each year, according to the classification society DNV, and another 55,000 ships with two-stroke engines are currently in operation. Ammonia-fueled engines can decarbonize these ships down to net zero with entirely carbon-free combustion. “Our two-stroke ammonia engine is at full performance,” says Pyndt Hansen, “We’re running on all cylinders.”

Everllence’s dual-fuel ammonia engine reached a breakthrough in 2023 right here at the RCC with its first successful combustion. In December of 2024 the engine was running on one cylinder. After extensive single-cylinder testing to validate performance and safety, development advanced to four-cylinder operation with ammonia at full load in January 2025.

The engineers at the RCC are thrilled by the progress: Nitrogen oxide and nitrous oxide emissions are low, and the engine’s thermal efficiency is the same running on ammonia as on diesel. “Our latest injector technology has allowed us to reduce the ammonia slip (where ammonia that has not been combusted escapes into the atmosphere) close towards zero, while reducing the amount of marine gas oil or diesel pilot fuel to save emissions”, says Ole Pyndt Hansen. “Presently, we’ve achieved pilot fuel consumption of approximately five percent of the total energy, but we will strive to optimize it further in the future. Of course, when biofuel is used as pilot fuel, the combustion of ammonia is completely carbon-free.”

Testing the world’s first commercial two-stroke ammonia engine

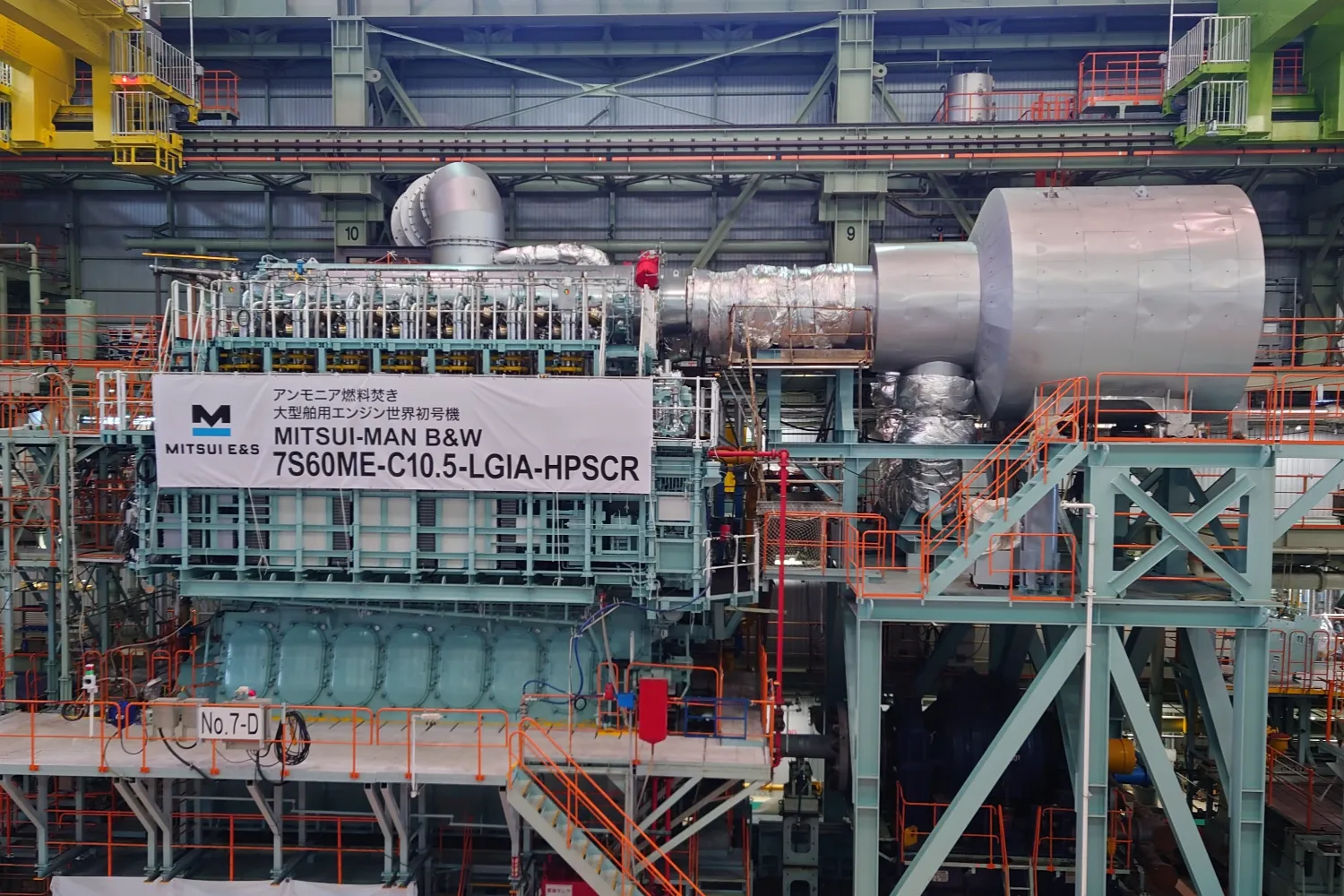

Parallel to the testing in Copenhagen, Everllence’s licensee Mitsui E&S in Japan is testing the world’s first commercial large-bore liquid gas injection ammonia engine, a 60-bore ME-LGIA engine based on the design and developments from the research engine at the RCC. In Japan, consumption and emission figures are being verified and fine-tuning will be done before the engine is installed on a bulk carrier. The test phase also includes verification of the safety and performance of the shipbuilder’s independently-developed ammonia fuel-supply system, as well as other, peripheral systems.

“Mitsui E&S’s test builds on the results of the comprehensive single-cylinder ammonia-fuel tests conducted at the RCC,” says Ole Pyndt Hansen, “and it’s exciting to see this project draw closer to commercial fruition.“

First orders of two-stroke dual-fuel ammonia carriers

Everllence has now initiated some commercial projects with select partners, rolling out a controlled market release. This will ensure that the company has the right learnings with customers and seafarers before the full sales release. Expectations are high: One partner, Eastern Pacific Shipping (EPS), has already placed an order for a new fleet of ammonia carriers with ME-LGIA engines, while Höegh Autoliners has ordered the first-ever ammonia engines for their Pure Car and Truck Carriers.

The trajectory for the new engine seems set to be similar to the two-stroke dual-fuel ME-LGIM engine. However, for both methanol and ammonia a number of conditions will first need to be met to reach the International Maritime Organizations (IMO) target of near net-zero greenhouse gas emissions by 2050. In particular, the production and supply of green fuels will have to increase rapidly to meet the rising demand.

About the author

Niels Anner is an independent journalist based in Copenhagen, who writes on business, science, technology and society in Northern Europe.