Survey on hydrogen screw compressors

Your experience matters

Hydrogen screw compressors face growing expectations as hydrogen applications scale. Performance, reliability, efficiency and safety are discussed widely – but how do they perform in reality?

Removing the limits on hydrogen production

Electrolyzers turn renewable energy into green H2. The challenge is to compress the H2 so it can be fed it into a pipeline for safe distribution and utilization – wet H2 is difficult to compress because of its low molecular weight and high moisture: Everllence screw compressors are the right choice.

Everllence screw compressors are designed for continuous operation and large volume flows, providing reliable compression of H2. From atmospheric pressure the single stage solution achieves up to 6 bar and the two stage solution up to 16 bar. That makes them ideal for pipeline distribution from electrolyzer plants larger than 50 MW. The oil-free technology keeps your H2 clean and downtime low.

By loading the video you agree to YouTube's privacy policy.

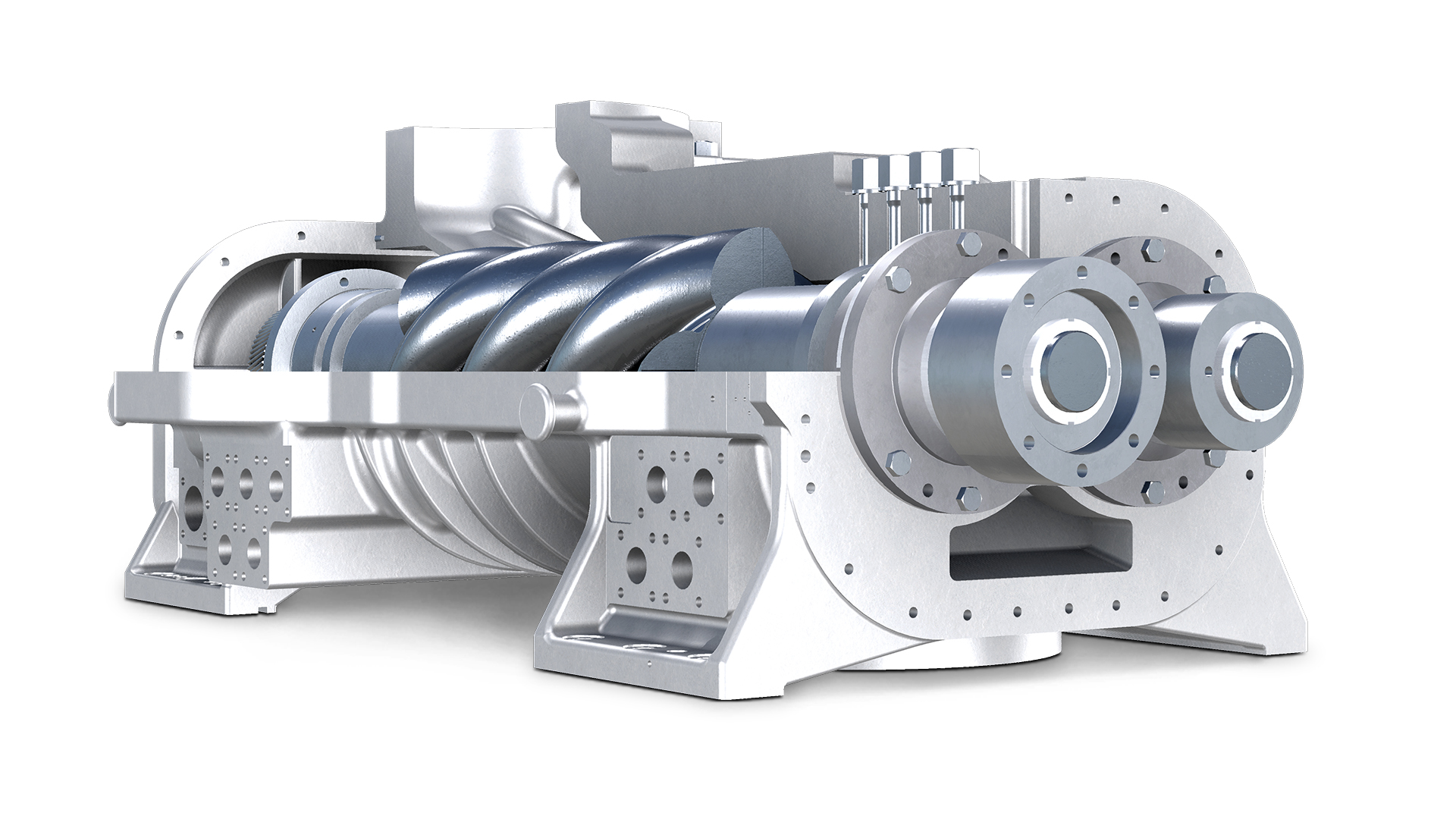

The SKUEL series: boost the volume

Perfect in hydrogen applications, SKUEL compressors deal comfortably with huge volume flows – from 4,000 – 100,000 m3/h (2,400 – 59,000 cfm) and discharge pressures up to 16 bar / 230 psia. The horizontally split casing allows easy maintenance of even the largest compressor sizes.

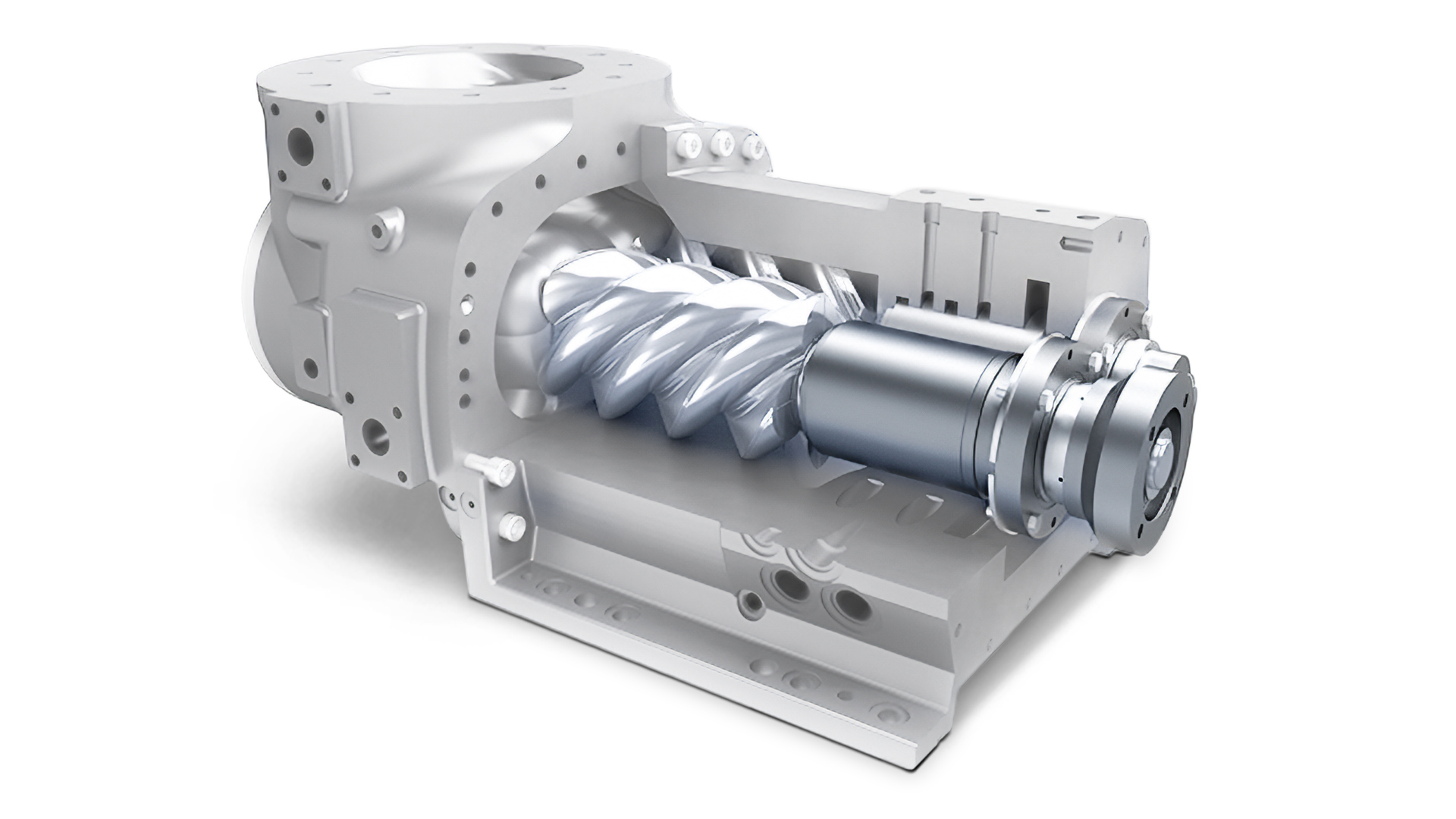

The CP series: increase the pressure

The vertical split casting of the CP compressor makes it the ideal product for high pressure operations. They comfortably handle discharge pressures of up to 52 bar / 750 psia, while allowing for volume flows between 200 and 20,000 m3/h (120 – 12,000 cfm).

References

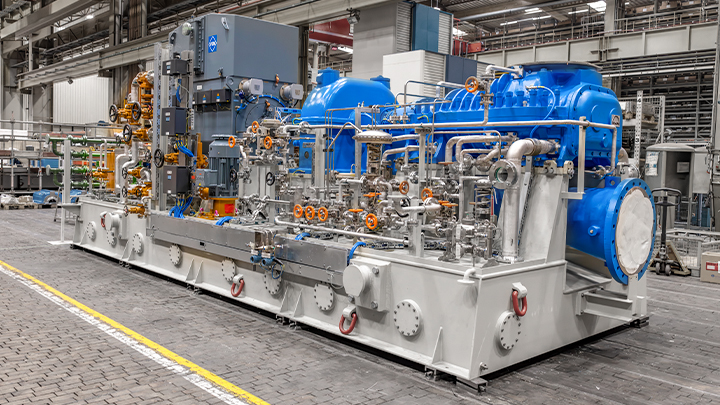

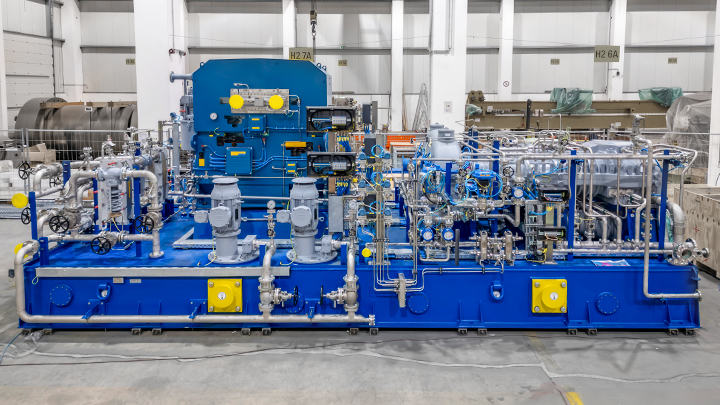

In action for green hydrogen

| Electrolyzer plant size | 50 MW |

| Compressors | SKUEL 408 screw compressors |

| Duty | H2 compression for chemical plant |

| Driver | Electric motor |

| Key feature | Variable speed drive |

| Year of delivery | 2024 |

| Electrolyzer plant size | 200 MW |

| Compressors | 4 SKUEL 408 screw compressors 4 CP 200 screw compressors |

| Duty | H2 compression for electrolyzer pipeline feeder |

| Driver | Electric motor |

| Key feature | Special sealing technology |

| Year of delivery | 2025 |

| Electrolyzer plant size | 200 MW |

| Compressors | 3 SKUEL 408 screw compressors 3 CP 200 screw compressors |

| Duty | H2 compression for electrolyzer pipeline feeder |

| Driver | Electric motor |

| Key feature | Special sealing technology |

| Year of delivery | 2026 |

.png?sfvrsn=6e623324_3)

Downloads

Continue reading

ExpertTalk

Continue viewing

Feeding the green H₂ economy

Take part in our exclusive session focusing on the latest hydrogen compression solutions with proven screw compressor technology.

Contact our experts

Get ready to distribute your hydrogen

The energy transition requires the production of significantly more green H2. If you can make it, we’ll help you move it. Our compressor experts can advise you through every phase of your project, from initial concept planning to successful plant operation.

.jpg?sfvrsn=2bd11168_1)