Multiple monitoring functions — all in one place

Every four-stroke engine is different. That´s why we developed a modular sensor and monitoring solution that lets you decide which parameters matter most to your predictive maintenance needs.

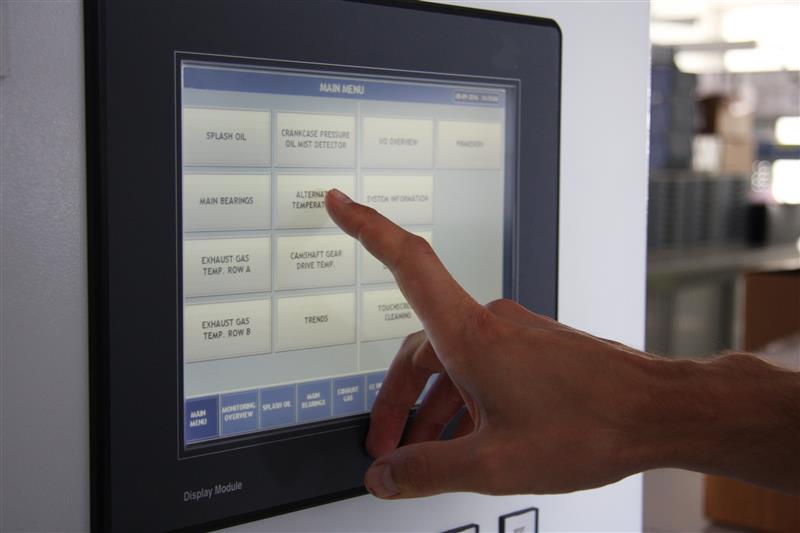

Whether you choose one or all nine modules, your team will get the data-driven insights they need for early anomaly detection and corrective action. All in one user-friendly display panel. All in their choice of six languages.

Everllence MMS

Facts about our Multifunction monitoring system

Real-time insights that matter

MMS for safety

Splash oil temperature monitoring, operational alarms, and automated shutdown

Monitors and displays temperature of oil splashed from crankpins and connecting rods to engine crankcase doors. Configurable alarms and automated shutdown based on deviations from always-calculated mean values and maximum values.

Main and thrust bearing temperature monitoring, operational alarms, and automated shutdown

Monitors and displays temperatures of all main engine bearings. Configurable alarms and automated shutdown based on maximum values. Can also be used to monitor thrust bearing temperatures on Pielstick PC-type engines.

Crankcase pressure monitoring, operational alarms, and automated shutdown

Monitors and displays pressure inside the engine crankcase. Configurable first alarm if first pressure threshold and time delay are exceeded. Configurable second alarm and automated shutdown if second pressure threshold and time delay are exceeded.

Real-time insights that matter

MMS for monitoring

Monitors and displays engine speed. Configurable overspeed alarm.

Monitors and displays the speed of one or two turbochargers. Configurable overspeed alarms.

Monitors and displays exhaust gas temperature from engine and turbocharger gas inlets. Configurable deviation from norm alarms.

Monitors and displays engine power/load.

Monitors and displays temperatures of lube oil, turbocharger oil, HT water, LT water, charge air, compressed air, and fuel oil. Monitors fuel oil temperature at engine inlet; lube oil temperature at engine inlet or TC outlet; HT water temperature at engine outlet, LT water temperature at engine inlet.

Monitors and displays pressures of lube oil, turbocharger oil, HT water, LT water, charge air, compressed air, and fuel oil. Monitors fuel oil pressure at engine inlet; lube oil pressure at engine inlet or TC outlet; HT water pressure at engine outlet, LT water temperature at engine inlet; charging air pressure after cooler rows A & B, charging air differential pressure after cooler rows A & B, starting air pressure, and control air pressure.

Discover the simplicity of real-time, data-driven insight

Give your team the data they need to detect and analyze engine anomalies — and turn information into insight and action.

Multiple modules, one interface

- Intuitive graphic display of key parameters

- Simple touchscreen navigation

- English, Chinese, French, German, Spanish, Portuguese

- Based on SaCoS technology

- CAN interface, online connectivity

- Compliant with Llyod´s, RINA, ABS, RMRS, CCS, KR, DNV & GL

Proven technology that works out of the box

Everllence´s Multifunctional Monitoring System has logged thousands of engine hours worldwide. The hardware and software are fully developed, tested, and certified — and ready to implement on any four-stroke engine. And the convenient display gives your team real-time insights when and where they need them, in a language they understand.

.png?sfvrsn=3ca0346f_1)

Engine fleet supervision

It is now possible to build a local supervision system that enables real-time monitoring of the parameters of all your engines, whatever their generation from a single centralized location.

This solution is compatible with engines from different manufacturers, ensuring seamless integration across your installation: whether you operate MAN, Pielstick, Wärtsilä, CAT, Sulzer, Stork or other engine brands, our system provides a unified and efficient way to manage your entire fleet.

Predictive maintenance

Contact us

Get in touch with our experts

Learn more about how our Multifunction Monitoring System can help you fix problems before they become big ones. We help you find the right set-up for your business.

.png?sfvrsn=6c020c25_1)