Less cat fine-related engine damage for reliability

Cat fines are small, very hard particles found in marine fuel. In case of insufficient cleaning onboard, cat fines can enter the engine with the fuel and wear the engine down very fast, compromising reliability in the combustion chamber. Therefore, the fuel must be cleaned on board the ship before it reaches the engine. The 10 μm automatic backflush filter from Boll & Kirch that we integrate into our Everllence (former MAN Energy Solutions) engines significantly lowers the risk of damage to cylinder liners, piston rings, fuel pumps, FIVA valves, and fuel injection nozzles.

Combating abrasive particles

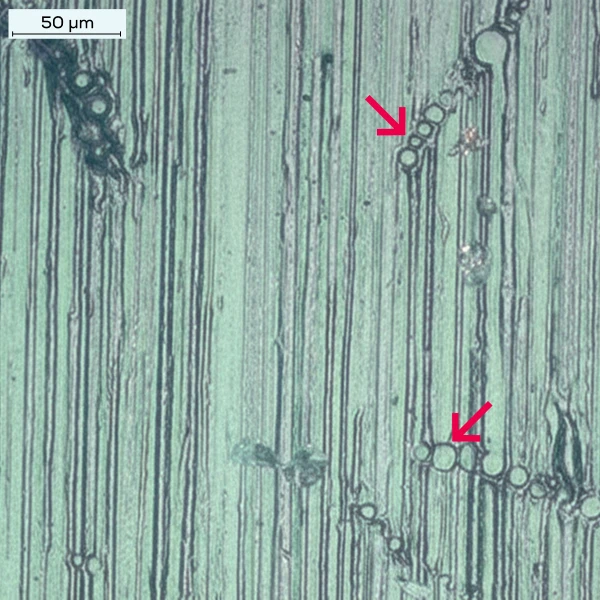

Abrasive particles, such as cat fines, cause wear when they enter the combustion chamber of two-stroke and four-stroke engines. They may get trapped between sliding surfaces, such as the piston ring and cylinder liner, or the piston ring and ring groove. An example of particle trapping can be seen in Figure 1, where cat fines are embedded in the soft graphite lamellas in the cylinder liner surface. Cat fines enter the fuel during the refining process. They are found both in heavy fuel oil (HFO) and in some of the new types of fuel with less than 0.1% sulphur (ULSFO).

Everllence’s recommendations on cat fine limits

The latest marine fuel standard specifies a maximum of up to 60 ppm Al + Si in the fuel (ISO 8217), but this causes extremely high wear in the combustion chamber. Everllence’s recommendation is to keep this level under 15 ppm. Read more in our service letter.

Product variants

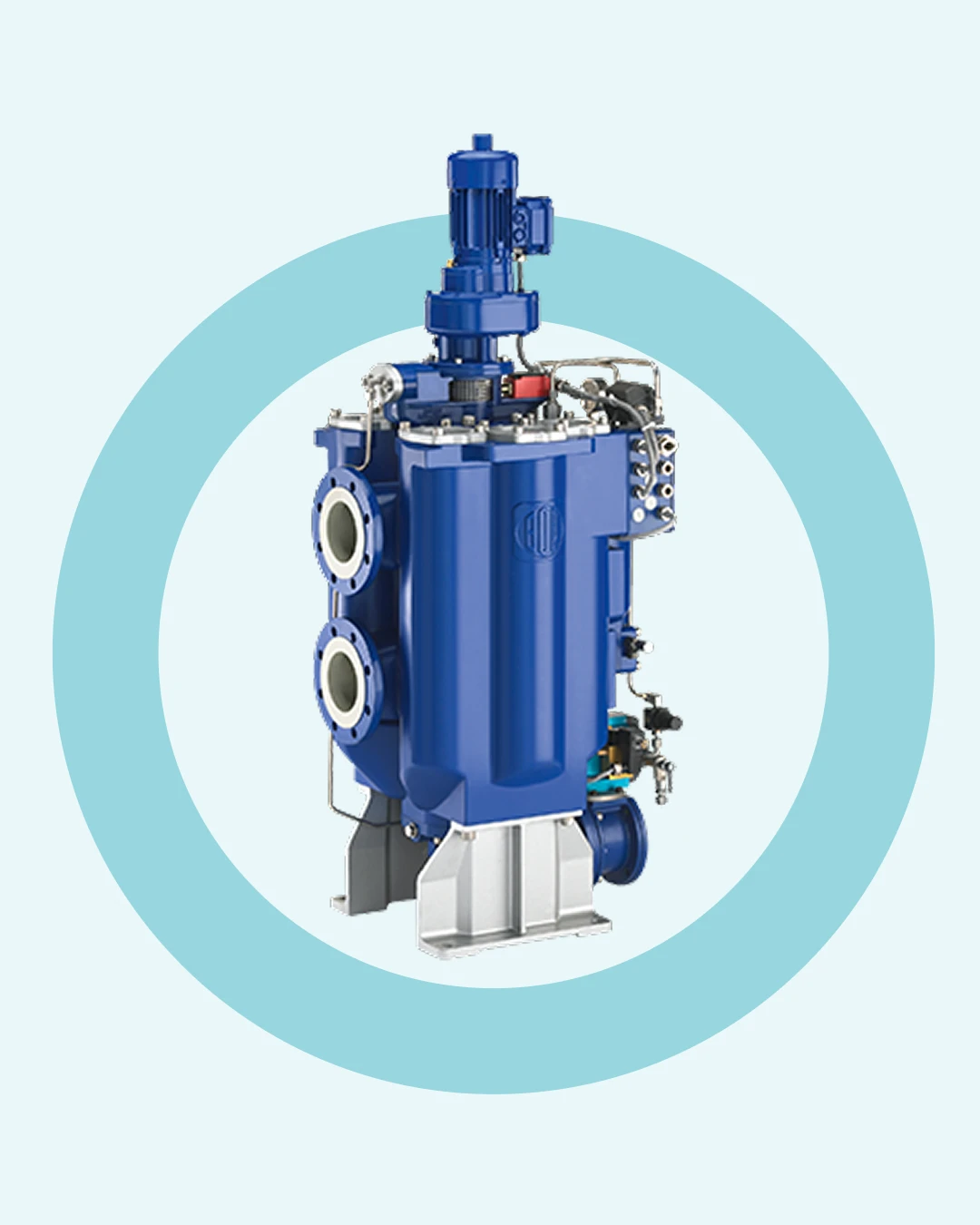

BOLLFILTER Automatic Type 6.7

- Range of application: Heavy fuel oil, diesel oil, lubricating oil

- Max. operating pressure: 16 bar

- Max. operating temperature: 160 °C

- Housing material: EN-GJS-400-15

- Nominal width of connection flanges: DN 40, DN 65, or DN 80

- Filter candle type/mesh type: Cylindrical screw-in candles or star candles with woven mesh

- Grade of filtration: 3 µm to 150 µm

- Cleaning: Sequential reverse-flow backflushing, assisted by compressed air

- Backflushing control: Differential pressure-dependent or time-dependent

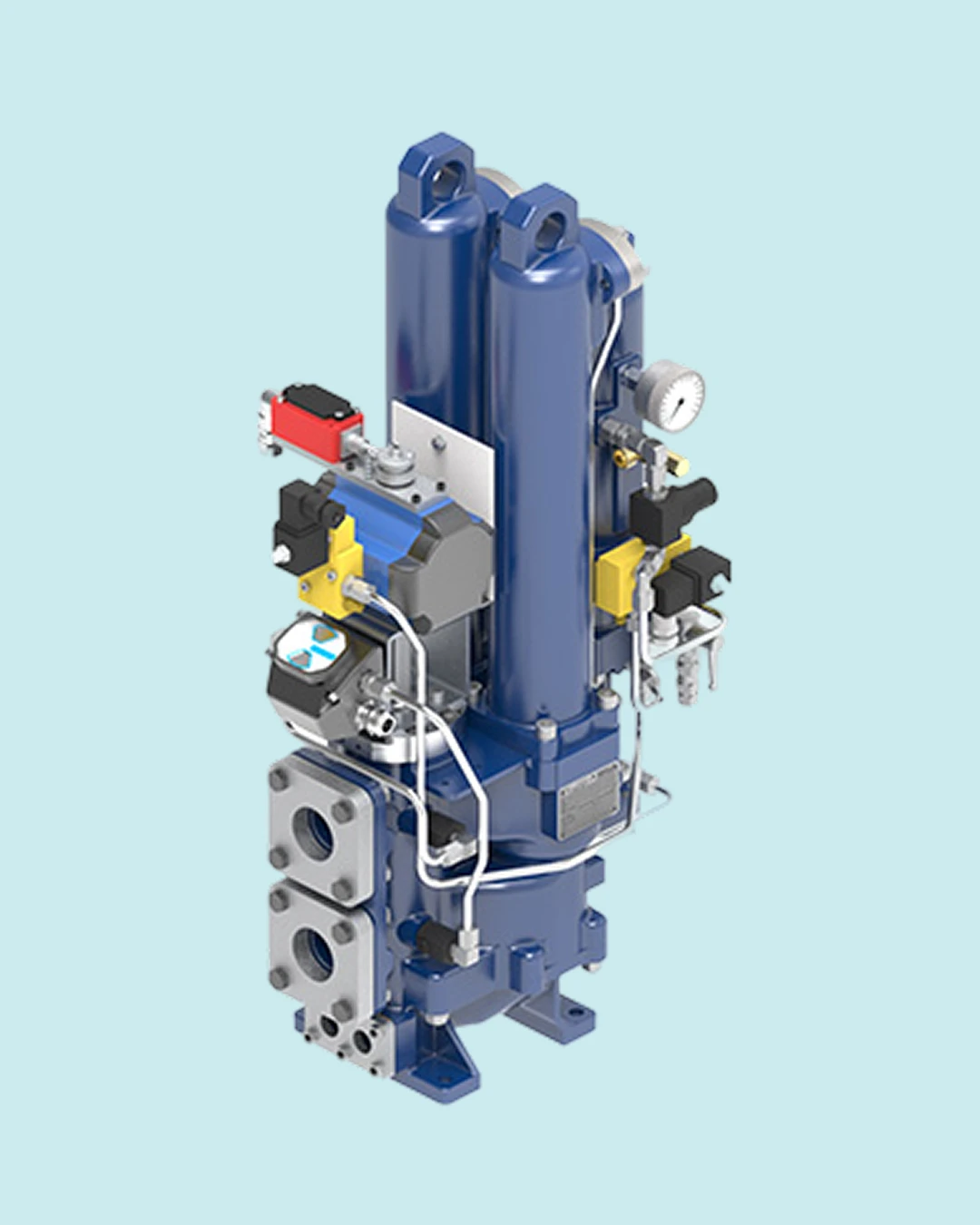

BOLLFILTER Automatic Type 6.64

Our service engineers provide preventive maintenance, assist your troubleshooting, and get your facilities up and running in no time – wherever and whenever you need them.

- Range of application: Lubricating oil, diesel oil, heavy fuel oil, coolants, emulsions, industrial wash liquids

- Differential pressure resistance: Up to operating pressure

- Operating temperature: Up to 150 °C

- Housing material: Nodular cast iron/Nickel lining on request

- Grade of filtration: Up to 10 µm abs.

- Filter candle type/mesh type: Cylindrical screw-in candles or star pleated candles with woven mesh or fiber felt

- Cleaning method: Sequential reverse-flow backflushing, assisted by compressed air

- Backflushing control: Differential pressure-dependent or time-dependent

3 reasons to choose Boll & Kirch backflush filters

Locate the nearest service location for 360° support

PrimeServ offers comprehensive support for all engine room components, no matter the manufacturer. Find your nearest service location and learn more about our Omnicare portfolio today.

Talk to our experts

Contact our Everllence PrimeServ experts

Everllence is the right partner to innovate your business and move forward to a successful future with Everllence PrimeServ. Get in touch now and learn how to optimize your operation.