Facts

Good to know

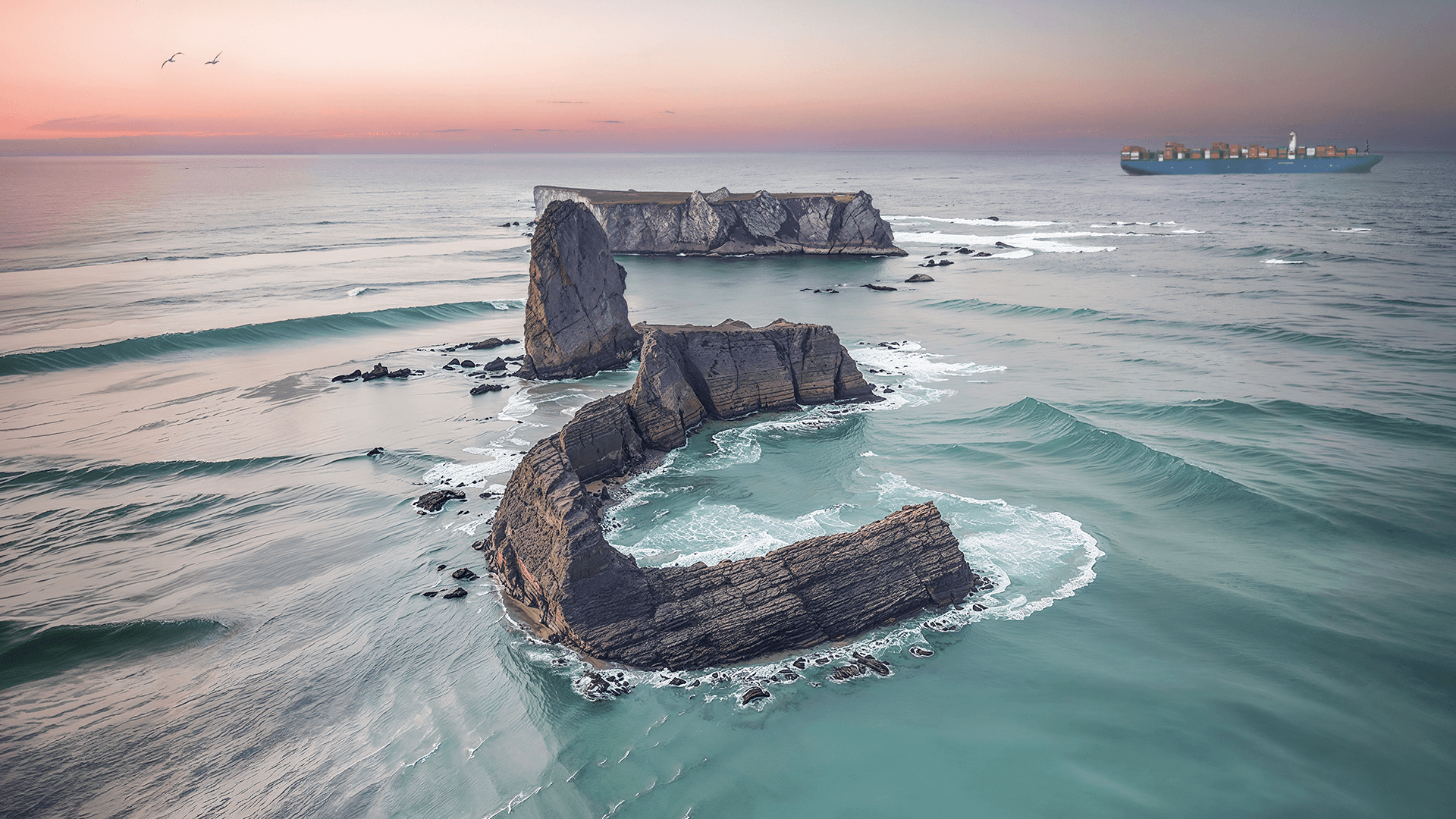

Engineered certainty for green ammonia

Everllence focuses on the economic levers: front-end planning tailored to your site and power profile, and single-source delivery that aligns equipment and process requirements. The result is lower specific energy consumption and clearer paths to levelized cost of ammonia (LCOA) targets as you scale up production.

Green ammonia white paper

Smart design, proven results

This white paper explores how turbomachinery configurations – from hydrogen to refrigeration compression – can enhance efficiency, reduce complexity, and lower emissions across the entire ammonia process chain.

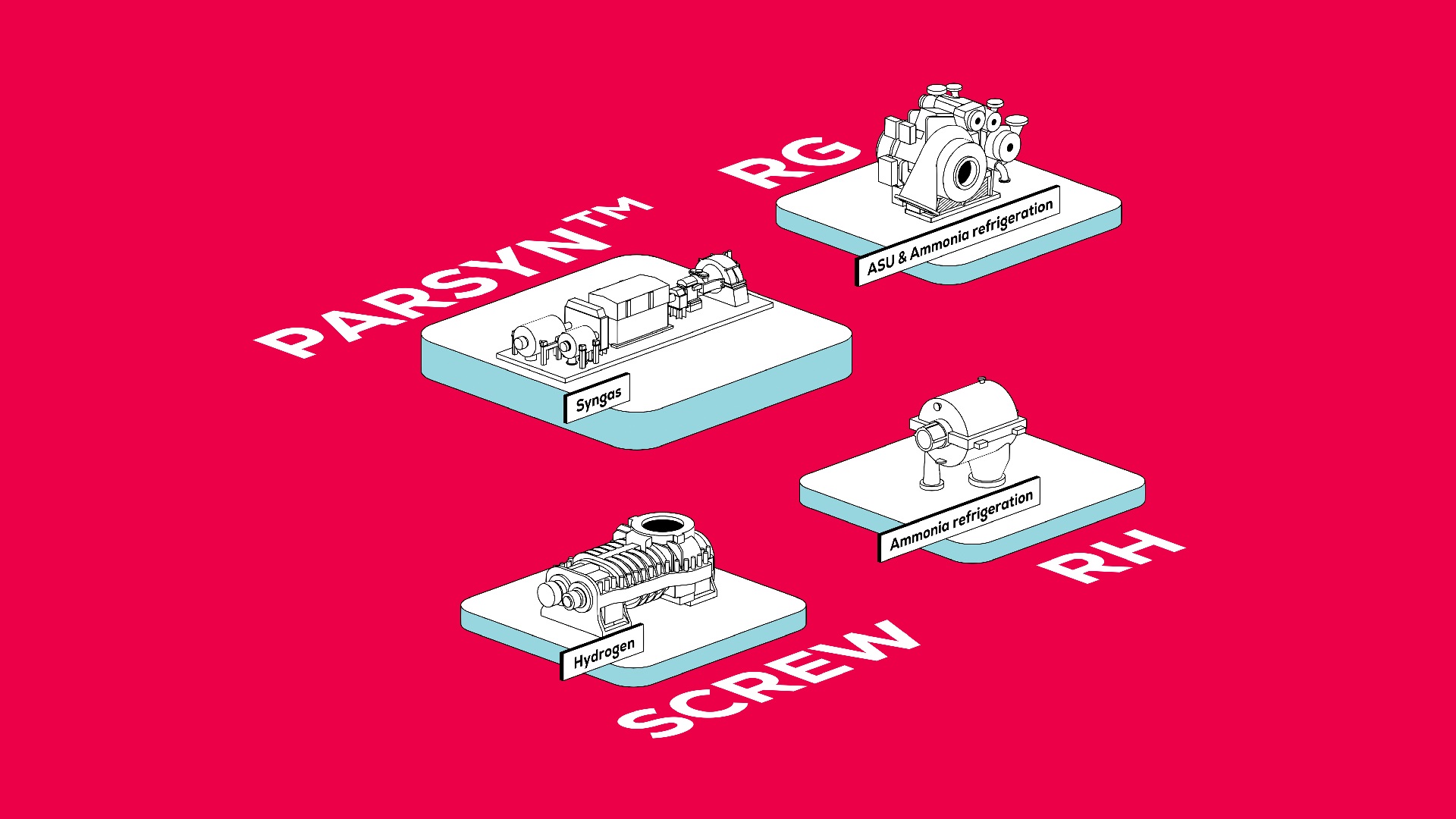

Products for your needs

Match performance and footprint to your plant

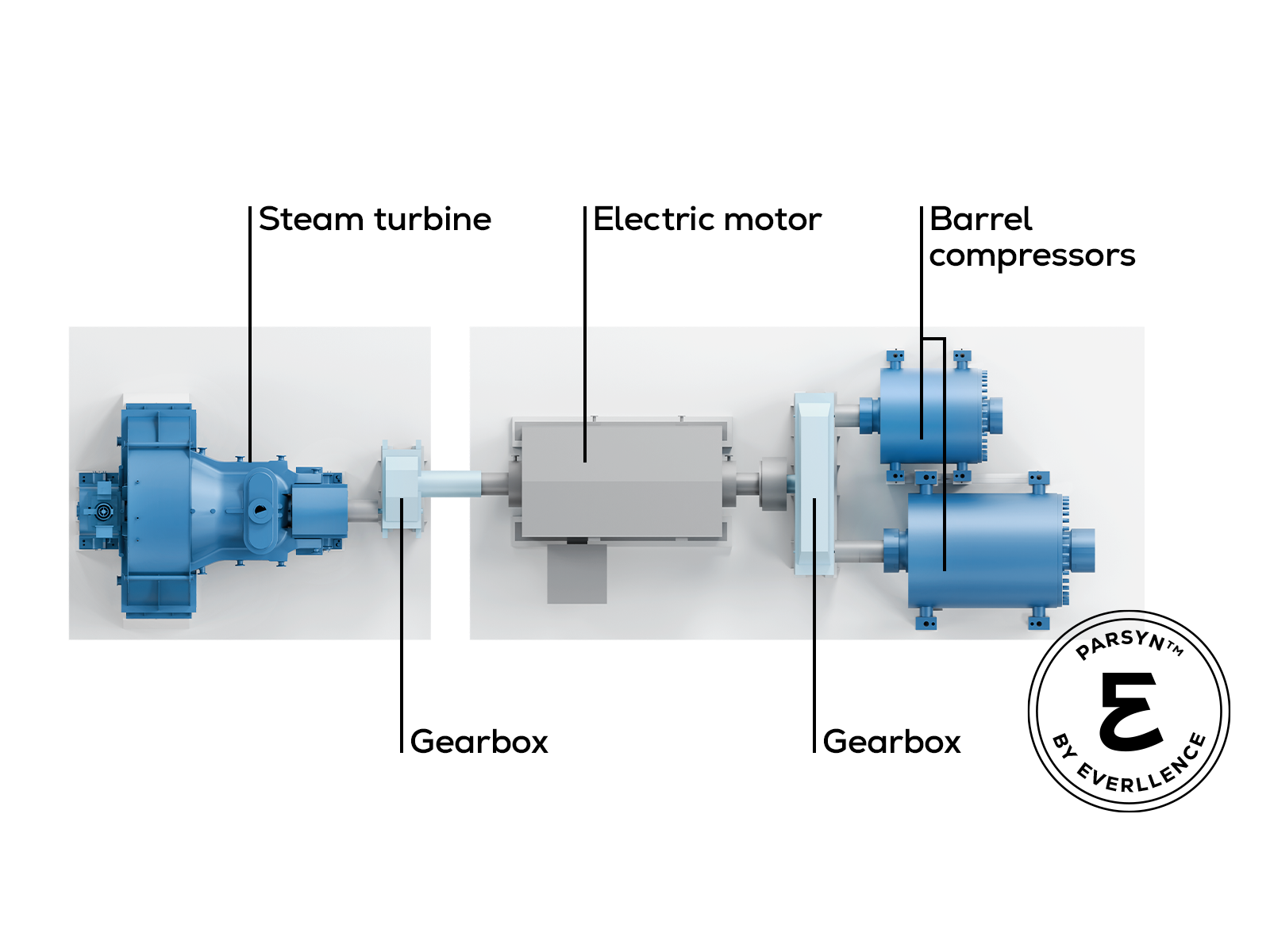

PARSYNTM

PARSYNTM is our parallel syngas compressor engineered to balance multi-train ammonia loops. It stabilizes loop pressure, extends turndown, and improves ramp rates while maintaining a safe surge margin under variable power. Integrated controls coordinate with the synthesis loop and refrigeration to cut recycle work, lower specific energy, and protect availability – ideal for electricity-based plants that must start, stop, and scale up with confidence.

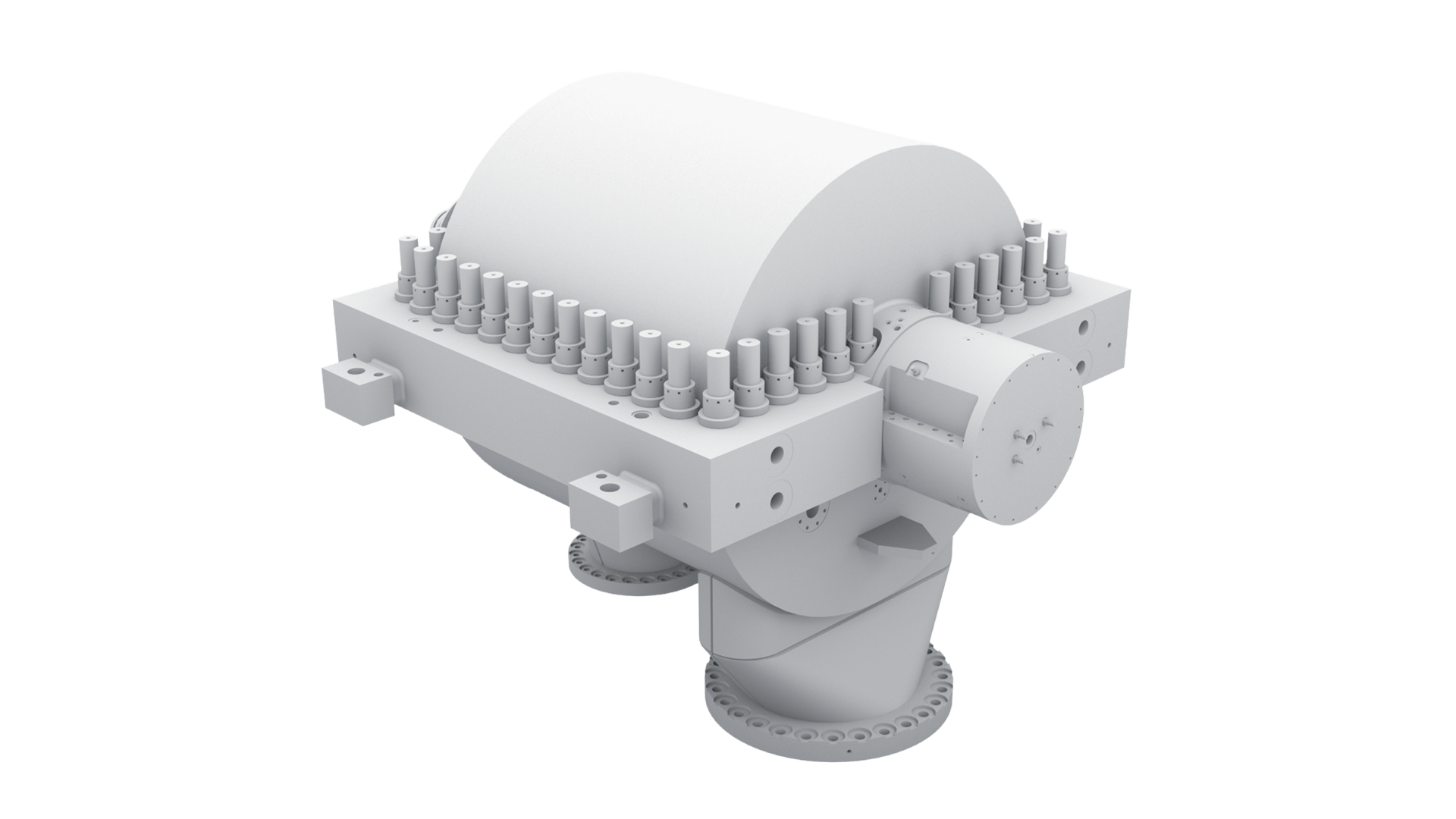

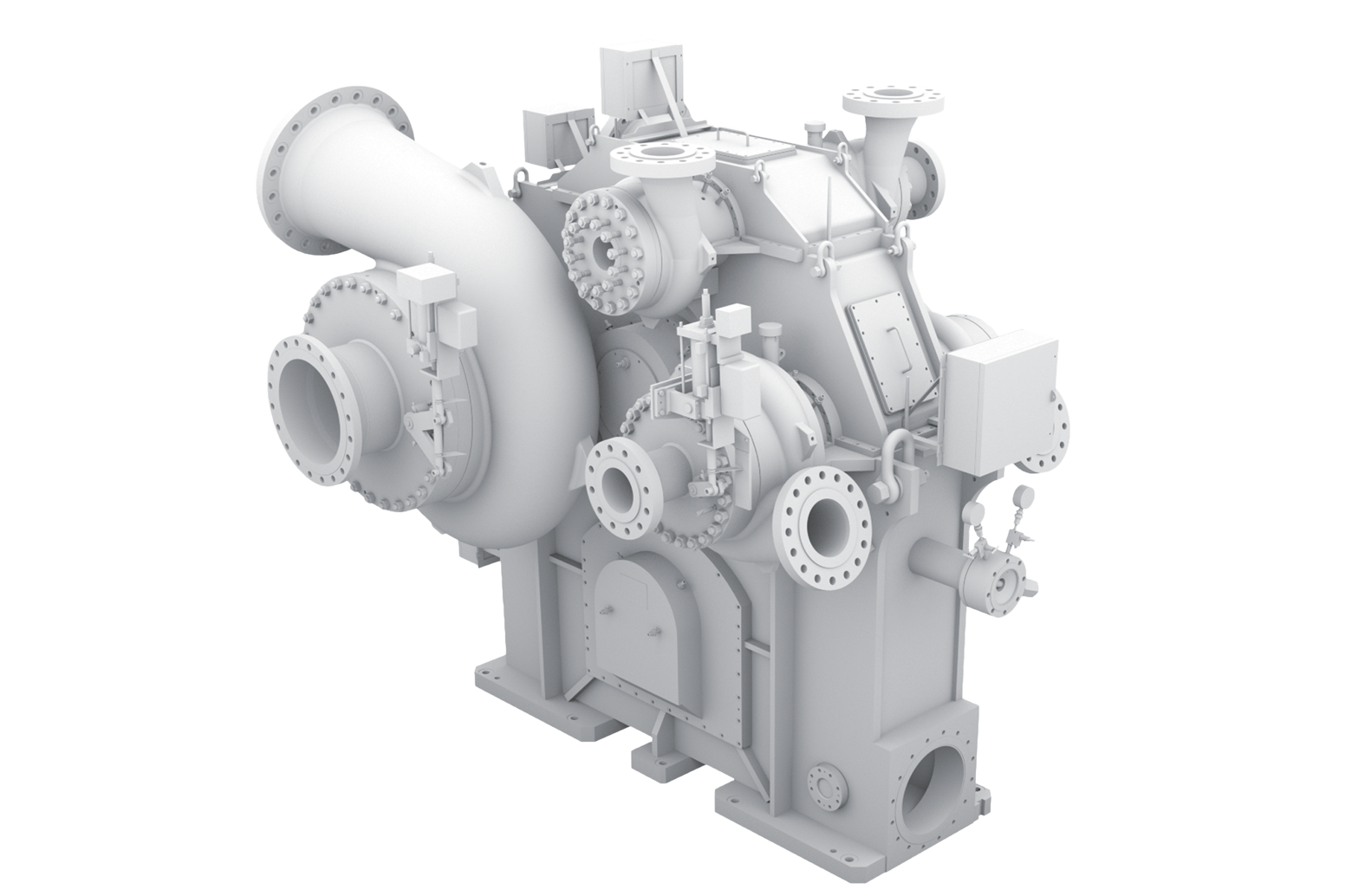

Available in horizontally split (RH) or barrel-type (RB) designs, these compressors are well-proven and are used in many industries, from chemicals to exploration and production, industrial gases and others.

These multi-shaft centrifugal compressors allow for up to five pinions, depending on your individual requirements. These compressors are popular due to their high efficiency and low investment outlay.

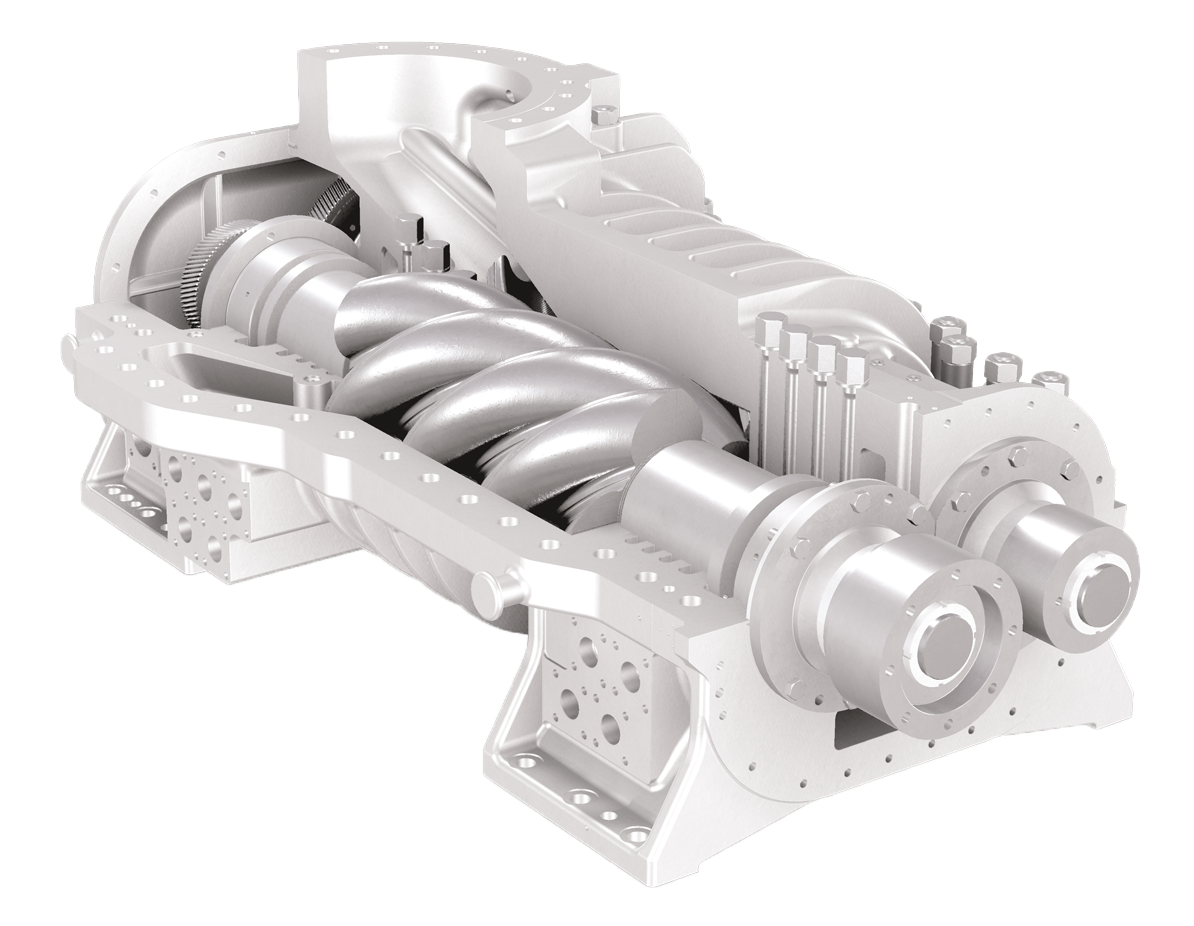

These oil-free compressors feature in a wide range of processes in exploration and production, LNG, fuel gas, industrial gases – including hydrogen, and other industries. They are suitable for onshore and offshore conditions and capable of compressing all gases except pure oxygen.

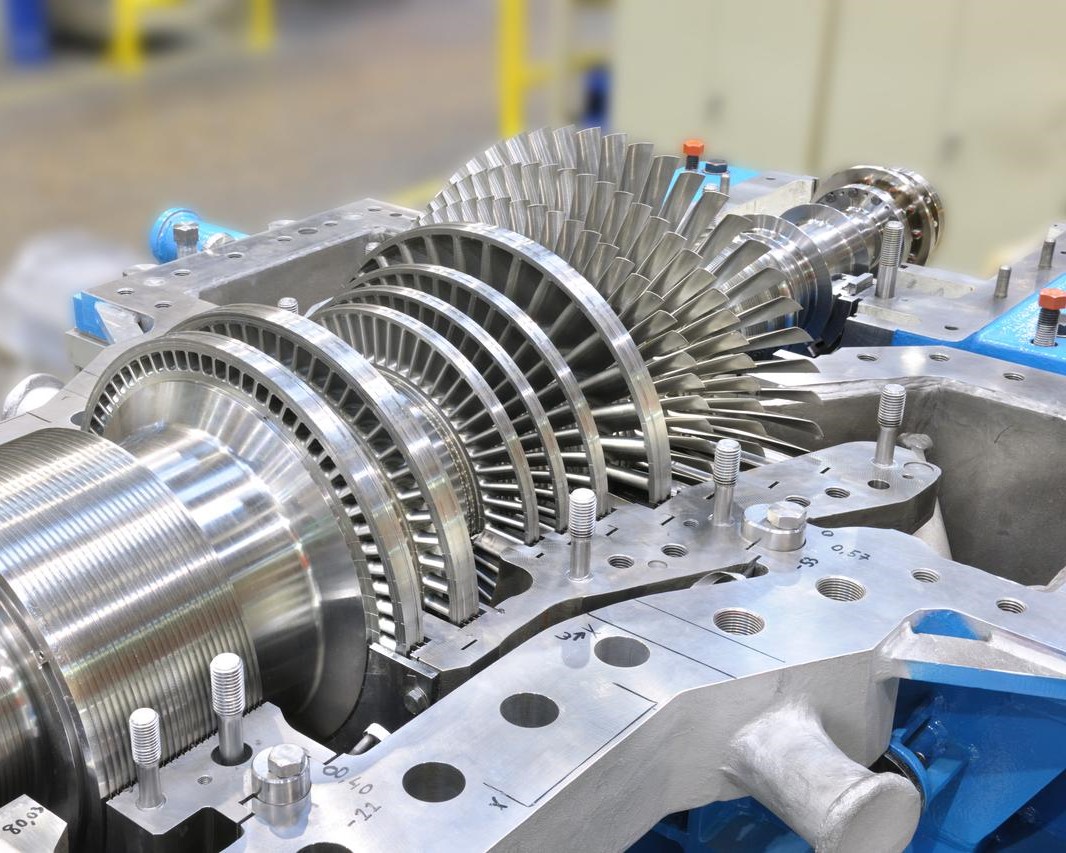

Everllence delivers industrial steam turbines for mechanical drive applications. Built on decades of turbomachinery expertise, our turbines ensure reliable performance, energy efficiency, and lasting value for diverse industrial operations.

Your roadmap to green ammonia

Watch the recording of our ExpertTalk

Scale up low-carbon ammonia production with high-efficiency turbomachinery. Our experts unpack compressor selection, system integration, and compressor control to cut energy and investment costs. Watch the video and download the presentation.

Build your ammonia capacity

What your plant needs, delivered

Equip your project with specialized turbomachinery optimized for green ammonia. Collaborate with us in planning the whole compression chain, from the raw material intake to the final product discharge, seamlessly managing every link in the process.

_1920x1080.png?sfvrsn=e1673b9a_1)