Accreditation

The professional performance of our work is subject to continuous review by the Deutsche Akkreditierungsstelle GmbH (DAkkS).s

Our material testing laboratory has been accredited since 1993 in accordance with DIN EN ISO/IEC 17025, which includes the following areas:

- Mechanical and technological tests

- Metallography

- Analytical spectrometry

- Non-destructive tests

- Hardness tests

Your partner in materials testing

Our materials testing services at a glance

Destructive tests

- Tensile tests

- Pressure tests

- Notched bar impact tests

- Hardness tests

- Bending tests

- Drift-expanding tests

- Ring flattening tests

- Ring tensile tests

- Ring deformation tes

Non-destructive tests

- Visual inspection

- Magnetic particle tests

- Penetrant tests

- Spectral analysis

- Measurement technology

Analysis support for damage incidents

- Metallography

- Scanning electron microscope

- Damage examinations

Your materials in expert hands

From sample to test report

Detailed insights into material integrity

We analyze your materials with precision – from microstructure to durability. Our inspections uncover hidden risks and ensure long-term reliability. With our welding expertise and qualification testing, you benefit from proven quality and safety.

On-site examinations and standards compliance

Possible on-site examinations include surface analysis (microscopy and replicas), hardness testing, and roughness measurements. Additional examinations for welder tests and welding procedure tests in ac-cordance with DIN EN ISO and the Pressure Equipment Directive are also possible.

Personal support from start to finish

The contact to our customers is very important to us, which is why every single test request is personal-ly handed by one of our employees. Everything — from the first test to the final test report — remains the responsibility of a single person. Moreover, you can reach us by telephone at any time on work days. Our services include in-house sample production, initial sample testing, and on-site assessments.

Fast results when it matters

We understand completely that you want to know the results of materials tests as soon as possible, so we provide a meaningful test result after three to four days for subsequent tests. Test results can even be delivered within 24 hours in urgent cases.

Your materials, our precision

Our full range of materials testing services

Precision measurement ensures that components meet exact production specifications. Length, shape, position tolerances, and surface roughness are measured to verify dimensional accuracy.

- Dimensional inspection (length, shape, position)

- Surface roughness testing

These tests detect surface and internal material defects without damaging the component. Certified inspectors perform visual, penetrant, and magnetic particle tests as part of quality assurance.

- Visual inspection

- Penetrant testing

- Magnetic particle testing

This type of analysis investigates material damage and its causes, supporting recommendations for failure prevention. It combines metallography and corrosion analysis to evaluate structural weaknesses.

- Corrosion image evaluation (rust examination)

- Metallographic analysis of pores, cracks, and defects

- Fracture assessment

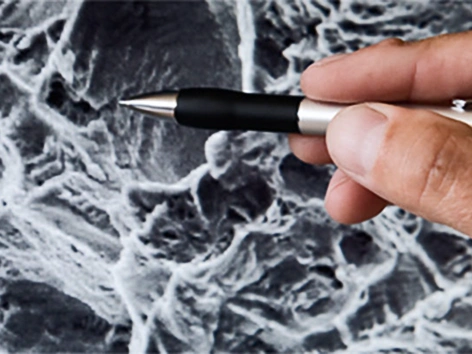

SEM provides high-resolution images of rough and fractured surfaces to clarify failure causes. Combined with EDX analysis, it enables detailed microanalysis of coatings, residues, and material structure.

- Fractography and surface examination

- Energy-dispersive X-ray (EDX) analysis

- Microanalysis of trace elements

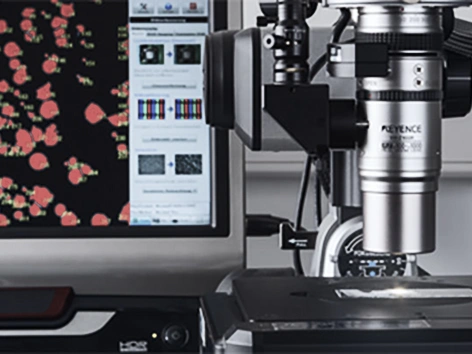

Metallography uncovers the internal microstructure of materials to detect production-related defects. It supports material evaluations through microscopic analysis of grain size, purity, and structure.

- Microsection preparation

- Stereo and reflected light microscopy

- Microstructure evaluation

- Degree of purity and grain size determination

- Replica evaluation

Analytical spectrometry is used to precisely determine the chemical composition of metal materials such as iron, aluminum, nickel, and copper. Using Optical Emission Spectrometry (OES), up to 30 elements can be analyzed simultaneously for accurate verification.

- Optical Emission Spectrometry (OES)

- Melt analysis for Fe-, Al-, Ni-, and Cu-based materials

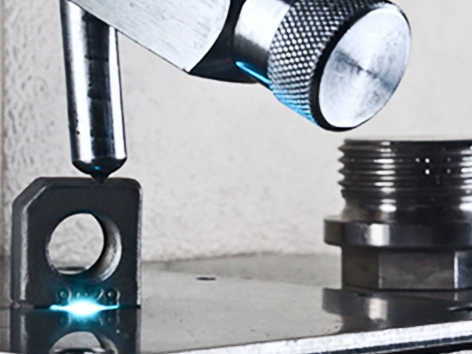

Hardness testing evaluates its durability under pressure from harder materials, therefore assess a material’s resistance to penetration. This is particularly useful in examining weld seams and heat-affected zones, revealing critical process insights.

- Brinell hardness test

- Rockwell hardness test

- Vickers hardness test

Destructive tests evaluate the mechanical properties of materials under load, revealing their strength, elasticity, and toughness. These methods are essential for understanding failure behavior and structural limits.

- Tensile test

- Bending test

- Compressive strength test

- Notched bar impact test

- Hardness test

“From the test to the test report, everything supervised by a single person.”

Nikolai Gross, Laboratory manager

Downloads

Continue reading

Contact our Everllence support team

Get the answers that move you forwards